Professional Documents

Culture Documents

155CMD SBR - Equipemnt

Uploaded by

Hemant KaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

155CMD SBR - Equipemnt

Uploaded by

Hemant KaleCopyright:

Available Formats

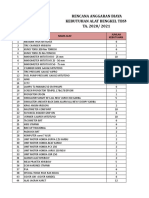

BOQ-EQUIPMENTS

SN Item 155 Nos Total Rate Cost Remarks

Capacity Unit Duty Stadndby

1 Coarse Screen,20 mm 16 m3/hr 0 0 0

2 Fine Bar Screen , 6 mm 16 m3/hr 1 0 1 Use this If before Balancing Tank

Fine Bar Screen, 6 mm 6.5 m3/hr 1 0 1 0 Use this if after Balancing Tank

3 Manual By Pass 16 m3/hr 1 0 1 Use this If before Balancing Tank

6 m3/hr 1 0 1 Use this if after Balancing Tank

4 Grit Removal 16 m3/hr 1 0 1 NOT APPLICABLE

6 m3/hr 1 0 1 Use this if after Balancing Tank

Note : The oil grease IS NOT STATED In Balancing Tank ,if reqd provde Skimmer mechanism OR AT LEAST COST FOR IT

5 Balancing Tank 0

Submersible SBR feed Pumps 6.46 m3/hr 1 1 2

Blower for Mixing 30 m3/hr 1 1 2

Diffusers, Coarse Bubble 10 m3/hr 3 3

0 0 0

6 SBR

SBR Aeration Blowers 109 m3/hr 2 1 3 0

Fine Bubble Diffusers 5 m3/hr 44 0 44 0

Decant Mechanism/Valve 19.375 m3/hr 2 0 2 0

WAS pumps 1 m3/hr 2 1 3 0

2 2 0

7 Chlorination System 2 2 0

Dosing Pumps 0.92 l/hr 1 1 2 0

Dosing Tank 28.18 litres 1 0 1 0

Mixers ? On tank 1 Hp 1 0 1 0

0

8 Pressure Sand Filter System dia 0

Pressure Sand Filter 0.90 m 1.00 0 1 0

Filter Feed Pumps, 20 mwc 7.18 m3/hr 1 1 2 0

Backwash Pumps, 20 mwc 19.08 m3/hr 1 1 2 0

Air blowers 32 m3/hr 1 1 2 0 Balancing Tank blower tobe used

9 Sludge Holding Tank

Air blower required 14 m3/hr 1 1 2 0 If combined with Balancing Tank

Coarse Bubble Diffusers 12 m3/hr 1 or SBR blowers, needs tapping

from main aeration line

TOTAL 0 0

Add 5 % for miscellaneous

Add 10 % for erection

GRAND TOTAL OF B/O 8 0.00

2SBR REACTOR -155 CMD 5 Equipments

PIPING

SN From - to Flow,m3/h V, m/s Size SIZE MOC L (mtrs) Mat. Rate Mat cost Lbr rate Lbr Cost Total cost Remarks

LIQUID- RAW SEWAGE, TSE 155

1 Gravity flow from C/S to Balance tank(BT) 16 0.75 87.2 100

2 SBR feed Pump A-Duty 6.46 1.80 36 50

SBR feed Pump B-Standby 6.46 1.80 36 50

3 Raw Sewage Inlet to SBR 1 6.46 2 36 50

Raw Sewage Inlet to SBR 2 6.46 2 36 50

4 Treated Sewage Outlet of SBR-1 19 0.65 103 150

Treated Sewage Outlet of SBR-2 19 0.65 103 150

5 Common Treated Sewage Outlet to CCT 19 0.65 103 150

6 Suction of Filter Feed Pumps 7 1.50 41 50

Dischrage of Filter Feed Pumps 7 2.00 36 50

7 Suction Backwash Pumps 19 1.80 61 80

Discharge of Backwash Pumps 19 2.00 58 80

8 WAS Pumps A- Suction 1 1.00 19 80 Not apllicbale if submersible

WAS Pumps B-scution 1 1.00 19 80

WAS Pumps A-Discharge 1 1.20 17 80

WAS Pumps B-Discharge 1 1.20 17 80

9 Sludge Pumps - Suction 2 1.00 29 80

Sludge Pumps -Discharge 2 1.20 26 80

AIR PIPING

8 Balancing Tank Blower Discharge 30 18.00 24 25

Drop pipes in Balancing tank 3 10 18.00 8 25

9 Air Inlet to SBR-1 109 18.00 46 50

Air Inlet to SBR-2 109 18.00 46 50

10 Drop pipes in SBR-1 , EACH 5 109 18.00 21 25

Drop pipes in SBR-2, EACH 5 109 18.00 21 25

11 Sludge Holding Tank air piping 14 18.00 17 25

Drop pipes in Sludge digestor 2 14 18.00 12 25

TOTAL

Add Fittings cost 20 % of the material cost

GRAND TOTAL OF PIPING

2SBR REACTOR -155 CMD 6 piping

2SBR REACTOR -155 CMD 7 piping

5

2SBR REACTOR -155 CMD 8 piping

0

2SBR REACTOR -155 CMD 9 piping

VALVES

SN Location 155 SIZE MOC Type Operation Nos Rate Cost Remarks

LIQUID- RAW SEWAGE, TSE , BFV:Butterfly valve

Gravity flow from C/S to Balance tank(BT) 100 0 GV -Gate Valve,BV-Ball Valve

KGV-Knife Edge Gate Valve

2 Common Suction of SBR pumps 50 SS-Disc KGV 1 Not applicable if submersible

Isolation valves in individual suctions 50 SS-Disc KGV 2 Not applicable if submersible

SBR feed Pump -suction 50 SS-Disc GV 2 Not applicable if submersible

SBR feed Pump - Delivery 50 SS-Disc GV 2

NRV for Above 50 SS -Disc FLAP 2

3 Raw Sewage Inlet to SBR 1 and 2 50 SS-Disc GV Motorized 2

4 Treated Sewage Outlet of SBR-1 and 2 150 SS-Disc BFV Motorized 2 for Decanters

6 Common Suction of Filter Feed Pumps 50 SS -Disc BFV 1 Not applicable if submersible

Isolation valves in individual suctions 50 SS -Disc BFV 2 Not applicable if submersible

Dischrage of Filter Feed Pumps 50 SS - Disc BFV 2

NRV for Above 50 SS - Disc FLAP 2

7 Backwash Pumps-Common Suction 80 CI BFV 1 Not applicable if submersible

Backwash Pump -Isolation valves 80 CI BFV 2 Not applicable if submersible

Backwash Pumps-Discharge of 80 CI BFV 2

NRV for Above 0 80 CI FLAP 2

8 WAS Pumps isolation valves 80 CI KGV 3

WAS Pumps - Suction 80 CI BFV 3 Not applicable if submersible

WAS Discharge 80 CI BFV 3

NRV for above 80 FLAP 3

PRV valves for above 50 3 if Progressive cavity pump used

9 Service Inlet - Pressure Sand Filter 50 SS -Disc BFV Motorized 1

Service Outlet- Pressure Sand Filter 50 SS -Disc BFV Motorized 1

Backwash Inlet - Pressure Sand Filter 80 SS -Disc BFV Motorized 1

Backwash outlet - Pressure Sand Filter 80 SS -Disc BFV Motorized 1

10 Common isloation VALVE 80 SS - Disc 8 1 if Digestor is used

Sludge Pumps - Suction 80 SS - Disc KGV 2 if Digestor is used

Sludge Pumps -Discharge 80 SS-Disc KGV 2 if Digestor is used

NRV for above 80 FLAP 2

PRV valves for above 50 2 if Progressive cavity pump used

AIR PIPING

SBR Blower Discharge , 1 2,3 50 BV 3

SBR Blower Discharge , 1 2,3 50 NRV 3

SBR AIR INLET 50 BFV 2

SBR DROP PIPES 25 BV 10

Sludge Blower Discharge ,1,2 25 BFV 2

Sludge Blower Discharge ,1,2 25 NRV 2

sludge holding tank Drop pipes 25 BV 2

Balancing Tank Blower Discharge 25 CI BFV 2 2 nos. I duty + standby blower

2SBR REACTOR -155 CMD 10 valves

You might also like

- 1.03 MLD Sbr-EquipmentDocument3 pages1.03 MLD Sbr-EquipmentHemant KaleNo ratings yet

- Equipment Boq Rev1Document5 pagesEquipment Boq Rev1Hemant KaleNo ratings yet

- Wakra Equipment Boq Rev-1Document5 pagesWakra Equipment Boq Rev-1Hemant KaleNo ratings yet

- Barwa Equipment BoqDocument1 pageBarwa Equipment BoqHemant KaleNo ratings yet

- Water Demand CalculationsDocument2 pagesWater Demand Calculationssorryfrom66No ratings yet

- PLUMBING Booster Pump (AS PER IPC) - 13Document55 pagesPLUMBING Booster Pump (AS PER IPC) - 13Mohsin ShaikhNo ratings yet

- Private: Total Demand Calculation: Al Muna Gardens For Each Villa Fixtures TypeDocument3 pagesPrivate: Total Demand Calculation: Al Muna Gardens For Each Villa Fixtures TypeEMAAD0% (1)

- Municipal Plant Case Studies ZeomediaDocument13 pagesMunicipal Plant Case Studies ZeomediaAlfonso GarcíaNo ratings yet

- Cold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentDocument2 pagesCold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentMaxmore KarumamupiyoNo ratings yet

- Slickline Tally BookDocument32 pagesSlickline Tally BookloucifNo ratings yet

- Mechanical Part - Lesotho ProjectDocument2 pagesMechanical Part - Lesotho ProjectYogesh SonawaneNo ratings yet

- Farasan Hospital Query Sheet-R1Document3 pagesFarasan Hospital Query Sheet-R1Dilshad AhemadNo ratings yet

- Mud Report Geotermal 11.04.2024Document1 pageMud Report Geotermal 11.04.2024cristianjugaruNo ratings yet

- Basic Design of Bna PlantDocument11 pagesBasic Design of Bna Plantmasprie2010100% (1)

- Mechanical ItemDocument4 pagesMechanical ItemMohammed A. HelalNo ratings yet

- Adobe Scan 27 Mei 2023Document1 pageAdobe Scan 27 Mei 2023Panji WijanarkoNo ratings yet

- Design Standard Pump Key DataDocument1 pageDesign Standard Pump Key DataHardikNo ratings yet

- Rexroth Flush ValveDocument2 pagesRexroth Flush ValveanandsubbiahNo ratings yet

- 200kld STP Proposal FOR Bhumi AssociatesDocument6 pages200kld STP Proposal FOR Bhumi AssociatesTech MongerNo ratings yet

- Techno Commercial Offer For 120 KLD MBBR Based STP - Option 2 Civil Tank - 02.09.2023-2Document18 pagesTechno Commercial Offer For 120 KLD MBBR Based STP - Option 2 Civil Tank - 02.09.2023-2Saiful SaifNo ratings yet

- Tank Capacity, Pump Capacity and Water DemandDocument1 pageTank Capacity, Pump Capacity and Water DemandDesigner ForeverNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- W Heater CalcDocument2 pagesW Heater CalcMohammedRiyadNo ratings yet

- Tri Con Presentation2013Document29 pagesTri Con Presentation2013Jim TsikasNo ratings yet

- 2FRMDocument3 pages2FRMdivortiareNo ratings yet

- Booster PumpDocument1 pageBooster PumpAdarshNo ratings yet

- SWT Juli 20Document24 pagesSWT Juli 20kusumaNo ratings yet

- Water DemandDocument1 pageWater DemandNghiaNo ratings yet

- MTC 1000 SpecDocument2 pagesMTC 1000 SpecJuan José Tovar PérezNo ratings yet

- Slickline TallybookDocument29 pagesSlickline Tallybookpitia100% (3)

- 25M2 Trash Screen Mass SplitupsDocument7 pages25M2 Trash Screen Mass Splitupshari prasadNo ratings yet

- Liquid Ring Compressor: KLH 47005, KLH 47105Document8 pagesLiquid Ring Compressor: KLH 47005, KLH 47105Jhon Jairo Arango MarquezNo ratings yet

- Cement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated TempsDocument3 pagesCement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated Tempsislam atifNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- Bom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capDocument12 pagesBom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capRajdeepsinhNo ratings yet

- BUDGETDocument20 pagesBUDGETKhairil HafizinNo ratings yet

- Daily InventoryDocument3 pagesDaily InventoryGrace SevillaNo ratings yet

- Chapter 6 Vacuum Pumps: April 2008Document28 pagesChapter 6 Vacuum Pumps: April 2008GopalVarthyaNo ratings yet

- SRB & LHD Machine Inventory As On - January 2010Document4 pagesSRB & LHD Machine Inventory As On - January 2010arif_abdinNo ratings yet

- AWWA M22 SpreadsheetDocument2 pagesAWWA M22 SpreadsheetmassodiqNo ratings yet

- Product Consumable and Accessory Guide 2016 WEBDocument32 pagesProduct Consumable and Accessory Guide 2016 WEBAlexander ContrerasNo ratings yet

- Softener FRP With BlendingDocument5 pagesSoftener FRP With BlendingAnkita BiswasNo ratings yet

- مرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقDocument20 pagesمرفق رقم 8 - مواصفات وحدة معالجة الصرف الصناعي - مجزر الزقازيقHesham ElshazelyNo ratings yet

- Electric Load Details-NagaDocument3 pagesElectric Load Details-NagabalveersyanNo ratings yet

- Weco - Oily Water SeparatorDocument1 pageWeco - Oily Water SeparatorCelestia ValestiNo ratings yet

- Maret April Febuary: Plan Schedule WTP BTR ProjectDocument1 pageMaret April Febuary: Plan Schedule WTP BTR ProjectTri NoviyantoNo ratings yet

- Evaluation - Chemical Pit - 0Document8 pagesEvaluation - Chemical Pit - 0Aiman AmirullahNo ratings yet

- CBEX Elite 100-800 HP: EmissionsDocument4 pagesCBEX Elite 100-800 HP: EmissionssebaversaNo ratings yet

- MBR Design SheetDocument9 pagesMBR Design SheetVenkatesh SivaramanNo ratings yet

- Hydraulic Proppant Fracturing PDFDocument41 pagesHydraulic Proppant Fracturing PDFJLLMexNo ratings yet

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistNo ratings yet

- LubrilineDocument20 pagesLubrilinekaniappan sakthivelNo ratings yet

- Sop WTP CombinedDocument17 pagesSop WTP CombinedsiccppNo ratings yet

- Hyva Catalogue Pump PtoDocument24 pagesHyva Catalogue Pump PtoDeny Adi Irawan100% (1)

- 931.021-PDC For Ballast - SystemDocument3 pages931.021-PDC For Ballast - SystemAli MohamedNo ratings yet

- Vacuum Filter Description in Sugar Industry - Optimization of Sugar LossDocument19 pagesVacuum Filter Description in Sugar Industry - Optimization of Sugar Lossवैभव धुरीNo ratings yet

- CH 6 EsfDocument19 pagesCH 6 EsfGaurav GuptaNo ratings yet

- By Pass Tanks SpecsDocument3 pagesBy Pass Tanks SpecsHemant KaleNo ratings yet

- Primary Clarifiers Followed by Secondary TreatmentDocument2 pagesPrimary Clarifiers Followed by Secondary TreatmentHemant KaleNo ratings yet

- Appendix A6 3Document6 pagesAppendix A6 3Hemant KaleNo ratings yet

- Chapter 1 - 0Document19 pagesChapter 1 - 0Nagesh ChitariNo ratings yet

- Appendix A6 1Document2 pagesAppendix A6 1Hemant KaleNo ratings yet

- Appendix A7 1Document1 pageAppendix A7 1Hemant KaleNo ratings yet

- Al Ain Sludge Dewatering ReportDocument15 pagesAl Ain Sludge Dewatering ReportHemant KaleNo ratings yet

- Pumping Detail in Phase 1: Current Time: 0.000 HoursDocument1 pagePumping Detail in Phase 1: Current Time: 0.000 HoursHemant KaleNo ratings yet

- Design Basis For M-35 Sludge Handling SystemDocument2 pagesDesign Basis For M-35 Sludge Handling SystemHemant KaleNo ratings yet

- Lab Analysis 2005Document1 pageLab Analysis 2005Hemant KaleNo ratings yet

- Mansheyet Elhorreya STP Mass Balance-03jun2019Document16 pagesMansheyet Elhorreya STP Mass Balance-03jun2019Hemant KaleNo ratings yet

- Pressures at Air ValvesDocument1 pagePressures at Air ValvesHRK65No ratings yet

- Al Ain Sludge-Status For BwiDocument3 pagesAl Ain Sludge-Status For BwiHemant KaleNo ratings yet

- 8 Sutari Aeration Mixing SystemsDocument43 pages8 Sutari Aeration Mixing SystemsTech ManagerNo ratings yet

- 2SBR REACTOR - 550CMD-MAHA POLICE - XLSXDocument5 pages2SBR REACTOR - 550CMD-MAHA POLICE - XLSXHemant KaleNo ratings yet

- 1.03 MLD Sbr-Process DesignDocument4 pages1.03 MLD Sbr-Process DesignHemant KaleNo ratings yet

- Wakra Equipment BoqDocument1 pageWakra Equipment BoqHemant KaleNo ratings yet

- Design Inputs QTY Unit: CalculationDocument7 pagesDesign Inputs QTY Unit: CalculationHemant Kale100% (1)

- Ten States Standards For Wastewater (2004)Document158 pagesTen States Standards For Wastewater (2004)HRK65No ratings yet

- Design Stanadards For Waste Water Treatment Plants PDFDocument48 pagesDesign Stanadards For Waste Water Treatment Plants PDFGAMalik0% (1)

- Ocu Specs Sydnew Wtaer PDFDocument43 pagesOcu Specs Sydnew Wtaer PDFHRK65No ratings yet

- RWB Regs2010Document62 pagesRWB Regs2010kevinning51No ratings yet

- Caihe ch1Document30 pagesCaihe ch1dwaraganathan100% (1)

- HAZOP Saudi Aramco HAZOP GuidelinesDocument92 pagesHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- Sludge Digestion-1Document17 pagesSludge Digestion-1Hemant KaleNo ratings yet

- ME8492 Kinematics of Machinery Notes 1 by WWW - Studymaterialz.inDocument123 pagesME8492 Kinematics of Machinery Notes 1 by WWW - Studymaterialz.inyuvaraj gopalNo ratings yet

- 1 - Cavidade Válvulas - 18318-00Document56 pages1 - Cavidade Válvulas - 18318-00gabriel guedesNo ratings yet

- Non MovingDocument254 pagesNon MovingmsdrajNo ratings yet

- Group 3 Tests and Adjustments: 1. Clutch Cut-Off Pressure Switch TestDocument3 pagesGroup 3 Tests and Adjustments: 1. Clutch Cut-Off Pressure Switch TestHenry Valeriano MaqueraNo ratings yet

- Dolly Invention FieldDocument21 pagesDolly Invention FieldAhmedNo ratings yet

- Parts Book TG 190-A - G9381013 - G9381016Document342 pagesParts Book TG 190-A - G9381013 - G9381016Raisa Kostina60% (5)

- Positive Displacement PumpsDocument10 pagesPositive Displacement PumpsJie Lee Chuin CheeNo ratings yet

- Main Valve Block, DescriptionDocument13 pagesMain Valve Block, DescriptionWesley MonsaNo ratings yet

- 416E, 422E and 428E Backhoe Loader Hydraulic SystemDocument2 pages416E, 422E and 428E Backhoe Loader Hydraulic SystemFerney LaraNo ratings yet

- 2017 GST - Sant Retail Price List Dated 27.07.17 PDFDocument60 pages2017 GST - Sant Retail Price List Dated 27.07.17 PDFkoto group100% (1)

- How Caterpillar Backhoe Loaders WorkDocument4 pagesHow Caterpillar Backhoe Loaders WorkJosephNo ratings yet

- Rab Bengkel TBSM Astra HondaDocument4 pagesRab Bengkel TBSM Astra HondaRetma Fahreyza Mahretta0% (1)

- Problem Symptoms Table: U140F Automatic Transaxle - Automatic Transaxle SystemDocument3 pagesProblem Symptoms Table: U140F Automatic Transaxle - Automatic Transaxle SystemWawan SatiawanNo ratings yet

- Steering FundamentalDocument25 pagesSteering FundamentalLUCIFERBREONo ratings yet

- MPL TrainingDocument10 pagesMPL TrainingOsiel BarretoNo ratings yet

- Rexroth: Spare Parts ListDocument35 pagesRexroth: Spare Parts ListadelmomouraNo ratings yet

- Chapter 13 - Camshaft DriveDocument10 pagesChapter 13 - Camshaft Drivenikolasthermosolutions100% (1)

- Chapter 4 Automation SummaryDocument2 pagesChapter 4 Automation SummaryAnonymous 1VhXp1No ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (1)

- Eurofluid Hydraulic Gb-DeDocument144 pagesEurofluid Hydraulic Gb-DeRhdh kldmkNo ratings yet

- Chapter 32Document61 pagesChapter 32KautukBabarNo ratings yet

- Mechanical Power Transmission Fundamentals-R1Document33 pagesMechanical Power Transmission Fundamentals-R1V SquareNo ratings yet

- Starting Means (Diesel Engine) - Ms5001Document6 pagesStarting Means (Diesel Engine) - Ms5001Kuladip BaroNo ratings yet

- 700R4 Manual PDFDocument96 pages700R4 Manual PDFK B100% (3)

- Module 2Document21 pagesModule 2MansoorNo ratings yet

- AW60-41SN Vac Test LocationsDocument5 pagesAW60-41SN Vac Test Locations2791957No ratings yet

- SKF HydraulicsDocument117 pagesSKF HydraulicsJose luis Consuegra100% (1)

- Hydr Aulic: Syst emDocument13 pagesHydr Aulic: Syst emAzriel Varrand KhaleviNo ratings yet

- Chapter 6 GearDocument13 pagesChapter 6 GearMEWAEL MIZANNo ratings yet

- P&id 05Document1 pageP&id 05PETNo ratings yet