Professional Documents

Culture Documents

Speed Sensor

Uploaded by

Вячеслав ГлушакCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed Sensor

Uploaded by

Вячеслав ГлушакCopyright:

Available Formats

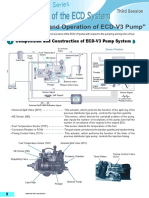

This session describes the construction and operation of products (sensors) associated with the input

signal of the ECD system.

1 Speed Sensor

This is an electromagnetic sensor for detecting the cam angle of the injection

pump. There is a magnet and a coil inside the sensor, and as the pulsar rotates,

the magnetic flux that passes through the coil increases, generating an

alternating current. The pulsar is constructed of 56 teeth, with 4 toothless

sections each the size of 2 teeth. The pulsar rotates once for every 2 rotations

of the engine, generating a cam angle pulse at the electromagnetic sensor.

From the number of these pulses and the interval between them, the engine

ECU calculates the cam angle and the engine speed.

The speed sensor, along with the throttle position sensor and the accelerator

sensor, is one of the main sensors used for calculating the basic injection Speed Sensor Connector

volume.

Coil Pulsar

Magnet Speed Sensor

Toothless Section

Pulsar

Roller Ring

Speed Sensor

+

Output

Voltage 0

- Sensor Output Signal Time

2 Throttle Position Sensor

This sensor is installed on the venturi (intake) and moves in unison with the main valve in order to detect the throttle

position. The sensor is constructed with a variable resistor to detect the throttle position and a contact point to detect

the idle position. Along with the speed sensor, it is one of the main sensors used for calculating the basic injection

volume.

Throttle Position

Sensor

9 SERVICE TECH Vol.467 03-8

2-1 Throttle Position Detection

The sensor is constructed with a resistor and a moving contact point in order to convert the position of the main

valve into a voltage value. The engine ECU supplies 5V to the VC terminal. Because the sensor moves in unison

with the main valve, when the moving contact point moves, a voltage proportionate to the throttle position is output

from the VA terminal.

2-2 Idle Position Detection

The idle condition is detected by whether the contact

point is on or off. The contact point closes when the main

valve is fully closed (idling), which generates continuity

between the IDL terminal and E2. When not idle, the

contact point is open. The engine ECU judges whether

or not the engine is idling, and corrects the idle speed

control and the acceleration rate.

3 Accelerator Sensor

In some systems, the venturi (throttle valve) does not work in unison with the accelerator pedal. These systems use

an accelerator sensor that is installed on the accelerator pedal and directly detects the accelerator position. This

sensor uses a hall element that reacts to magnetic force to generate electromotive force. It is a non-contact type using

a dual system with two internal electric circuits, increasing durability and reliability. Along with the speed sensor, it is

one of the main sensors used for calculating the basic injection volume.

SERVICE TECH Vol.467 03-8

10

4 Intake Air Pressure Sensor

This sensor detects the air pressure inside the intake manifold and sends a voltage signal to the engine ECU. It is a

semi conductor pressure sensor, with internal crystals (silicone chips) that change their electrical resistance when

pressure is increased. The intake air pressure (absolute pressure) is converted into an electrical signal and amplified.

It is sent to the engine ECU, where the intake air volume is calculated. The output voltage increases during the

charging boost of the turbo charger, in order to increase the injection volume.

5 Coolant Temperature Sensor and Intake Air Temperature Sensor

The coolant temperature sensor is installed on the engine cylinder block to detect the temperature of the engine

coolant. The sensor uses a thermistor, the resistance of which varies according to the temperature. The temperature

variation is converted into a resistance variation, which is detected. As the temperature increases, the resistance of

the thermistor decreases. When the coolant temperature is low, the injection volume is increased and the injection

timing is advanced.

The intake air temperature sensor is installed inside the air cleaner to detect the temperature of the intake air. The

sensor uses the same type of thermistor as the coolant temperature sensor. The density of the air varies with

temperature, so the injection volume is corrected.

6 Fuel Temperature Sensor

The fuel temperature sensor is installed on the injection pump. It detects the temperature of the fuel and sends the

information to the engine ECU. It uses the same type of thermistor as the coolant temperature sensor. The viscosity

of the fuel varies with temperature, so the injection volume is corrected.

11 SERVICE TECH Vol.467 03-8

7 Correction Resistor and Correction ROM

A resistor molded from plastic or a ROM is installed on the side of the injection pump. The engine ECU reads the

data from the resistor or ROM to calculate the fuel injection volume. There are 31 types of resistors with different

resistance values, so the most appropriate one is used.

The ROM type can store over 10 data points dealing with the engine speed and the accelerator position. This enables

high accuracy fuel injection control whatever the engine conditions, which lowers exhaust gas emissions. The ROM

can be modified when adjusting the pump, so that during normal driving a fixed value is input to the engine ECU.

SERVICE TECH Vol.467 03-8

12

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Service Manual R721 TYPE GOVERNORDocument48 pagesService Manual R721 TYPE GOVERNORВячеслав ГлушакNo ratings yet

- Passenger Presence SensorDocument1 pagePassenger Presence SensorВячеслав ГлушакNo ratings yet

- Ultrasonic SensorDocument1 pageUltrasonic SensorВячеслав ГлушакNo ratings yet

- Read - Me - 17 10 2019Document65 pagesRead - Me - 17 10 2019Вячеслав ГлушакNo ratings yet

- Service Manual RSV GovernorDocument33 pagesService Manual RSV GovernorВячеслав Глушак100% (1)

- CRS (ECD-U2P) For Land CruiserDocument45 pagesCRS (ECD-U2P) For Land CruiserВячеслав ГлушакNo ratings yet

- Composition and Construction of ECD-V3 Pump SystemDocument4 pagesComposition and Construction of ECD-V3 Pump SystemВячеслав ГлушакNo ratings yet

- Large-Scale Multiplex CommunicationDocument4 pagesLarge-Scale Multiplex CommunicationВячеслав ГлушакNo ratings yet

- Rail Outline: SERVICE TECH Vol.479 05-8Document4 pagesRail Outline: SERVICE TECH Vol.479 05-8Вячеслав ГлушакNo ratings yet

- Types of Systems in ECD-V SeriesDocument4 pagesTypes of Systems in ECD-V SeriesВячеслав ГлушакNo ratings yet

- Freon Free SystemDocument5 pagesFreon Free SystemВячеслав ГлушакNo ratings yet

- Intake Restriction ControlDocument4 pagesIntake Restriction ControlВячеслав ГлушакNo ratings yet

- 8th Session Injector Construction and OperationDocument4 pages8th Session Injector Construction and OperationВячеслав ГлушакNo ratings yet

- CAN Features and Access MethodsDocument4 pagesCAN Features and Access MethodsВячеслав ГлушакNo ratings yet

- Vehicle Mounted Multiplex Communication and Controller Area NetworkDocument4 pagesVehicle Mounted Multiplex Communication and Controller Area NetworkВячеслав ГлушакNo ratings yet

- HTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500432EDocument68 pagesHTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500432EВячеслав ГлушакNo ratings yet

- HTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500196EDocument58 pagesHTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500196EВячеслав Глушак100% (1)

- Communication Protocol and FramesDocument4 pagesCommunication Protocol and FramesВячеслав ГлушакNo ratings yet

- HTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500195EDocument68 pagesHTTP Contents2.ss - Denso.co - JP Sics Tsics5 Secu Edemo - Asp Docpic Doc5 PDF 0 00500195EВячеслав ГлушакNo ratings yet

- Product Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Document4 pagesProduct Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Вячеслав ГлушакNo ratings yet

- Starter ManualDocument161 pagesStarter ManualВячеслав ГлушакNo ratings yet

- Hot-Gas Power HeaterDocument4 pagesHot-Gas Power HeaterВячеслав ГлушакNo ratings yet

- Important: Read This Entire Agreement Carefully. This Is A Legal Document Under Which You Have Certain Legal Rights and ObligationsDocument3 pagesImportant: Read This Entire Agreement Carefully. This Is A Legal Document Under Which You Have Certain Legal Rights and ObligationsВячеслав ГлушакNo ratings yet

- Microsoft Software License Terms Microsoft Visual Studio Professional 2012 and Trial EditionDocument12 pagesMicrosoft Software License Terms Microsoft Visual Studio Professional 2012 and Trial EditionВячеслав ГлушакNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Science 10 FINAL Review 2014Document49 pagesScience 10 FINAL Review 2014Zara Zalaal [Student]No ratings yet

- Productstock 2021-01-18 (Produk Laku & Belum KinwatchDocument32 pagesProductstock 2021-01-18 (Produk Laku & Belum KinwatchKin WatchNo ratings yet

- Particle FilterDocument16 pagesParticle Filterlevin696No ratings yet

- NTCC Project - Fake News and Its Impact On Indian Social Media UsersDocument41 pagesNTCC Project - Fake News and Its Impact On Indian Social Media UsersManan TrivediNo ratings yet

- BVP651 Led530-4s 830 Psu DX10 Alu SRG10 PDFDocument3 pagesBVP651 Led530-4s 830 Psu DX10 Alu SRG10 PDFRiska Putri AmirNo ratings yet

- Imamsha Maharaj Na Parcha NewDocument16 pagesImamsha Maharaj Na Parcha NewNARESH R.PATELNo ratings yet

- Richard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Document87 pagesRichard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Maverick MinitriesNo ratings yet

- Ism Practical File NothingDocument84 pagesIsm Practical File NothingADITYA GUPTANo ratings yet

- Resume Of: Name: Kingshuk Saha Address: Mobile: E-MailDocument2 pagesResume Of: Name: Kingshuk Saha Address: Mobile: E-MailKingshuk Saha PalasNo ratings yet

- NPN Silicon: Semiconductor Technical DataDocument8 pagesNPN Silicon: Semiconductor Technical DataMinh Hà QuangNo ratings yet

- LGDocument36 pagesLGNanchavisNo ratings yet

- Small Molecule Modulators of PCSK9 A Litera 2018 Bioorganic Medicinal CHDocument6 pagesSmall Molecule Modulators of PCSK9 A Litera 2018 Bioorganic Medicinal CHMikeNo ratings yet

- PapernathazDocument26 pagesPapernathazAbelardo LapathaNo ratings yet

- Student Ought To Possess To Produce Clean-Up and In-Between DrawingsDocument2 pagesStudent Ought To Possess To Produce Clean-Up and In-Between Drawingscristian friasNo ratings yet

- Irregular Verbs Lesson PlanDocument13 pagesIrregular Verbs Lesson Planapi-311868026No ratings yet

- FTP Booster Training Plan OverviewDocument1 pageFTP Booster Training Plan Overviewwiligton oswaldo uribe rodriguezNo ratings yet

- Nonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical PlaneDocument10 pagesNonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical Planesamsaptak ghoshNo ratings yet

- Character AnalysisDocument3 pagesCharacter AnalysisjefncomoraNo ratings yet

- Growth Performance of Papaya Plants As Influenced by Organic MulchesDocument9 pagesGrowth Performance of Papaya Plants As Influenced by Organic MulchesMa. Christine Lyn AustriaNo ratings yet

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Document81 pagesChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanNo ratings yet

- BronchiolitisDocument5 pagesBronchiolitisreshianeNo ratings yet

- Brochure Mastertile TilingDocument48 pagesBrochure Mastertile TilingMaha Mufleh100% (1)

- Punctuation WorksheetsDocument10 pagesPunctuation WorksheetsRehan Sadiq100% (2)

- 10 TazmahalDocument12 pages10 TazmahalSifat E Noor SahibaNo ratings yet

- 1349122940100212diggerDocument24 pages1349122940100212diggerCoolerAdsNo ratings yet

- BagbagtoDocument3 pagesBagbagtoJayson Valentin EscobarNo ratings yet

- 4148-Article Text-14752-1-10-20211029Document7 pages4148-Article Text-14752-1-10-20211029Daffa AzkaNo ratings yet

- Installation ManualDocument16 pagesInstallation ManualJosé Manuel García MartínNo ratings yet

- Subordination, Non - Disturbance and Attornment AgreementDocument7 pagesSubordination, Non - Disturbance and Attornment AgreementDavid CromwellNo ratings yet

- The Impact of Teaching PracticeDocument14 pagesThe Impact of Teaching PracticemubarakNo ratings yet