Professional Documents

Culture Documents

Coatings & Substrates Chart: Tin Altin Altin Nano CBN

Uploaded by

Kiên Trung NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coatings & Substrates Chart: Tin Altin Altin Nano CBN

Uploaded by

Kiên Trung NguyễnCopyright:

Available Formats

TECHNICAL INFORMATION

COATINGS & SUBSTRATES CHART

TiN AlTiN AlTiN Nano CBN

Coating/

Substrate: Titanium Aluminum Aluminum Titanium Cubic Boron

Nitride Titanium Nitride Nitride Nano Nitride

-C1 -C3 -C6

• General purpose coating • High performance coating • Premium coating in • Solid CBN tipped endmills

for machining ferrous in ferrous materials. ferrous materials. designed for finishing

materials. hardened steels 52Rc to

• Excellent high • Latest generation AlTiN

68Rc.

temperature resistance coating mixed with silicon

and hardness. to produce a unique • Use only in applications

nanocomposite coating. with light, consistent

• Maintains high surface

This structure improves depth of cut.

hardness at elevated

hardness, heat resistance,

temperatures improving • Run at high RPM and feed

and toughness over

tool life and allowing rates.

traditional AlTiN coatings.

faster feed rates.

• CBN can withstand high

• Superior results,

• Produces aluminum oxide temperatures and its

extended tool life and

layer at high temperature hardness is second only to

reduced cycle times over

which reduces thermal diamond.

traditional AlTiN coatings

conductivity, transferring

in demanding applications

heat into the chip.

where setup minimizes

Application/ runout and vibration.

• Excellent in dry

Benefits: machining, machining

• Not recommended for

titanium alloys, inconel,

use in aluminum and

stainless alloys and cast

aluminum alloys.

iron.

• Not recommended for

use in aluminum and

aluminum alloys.

Materials: Ferrous Materials & Exotic Metals

General Purpose Ferrous Alloy steels, stainless Hardened steels, hardened Finishing hardened steels

Materials steels, tool steels, titanium, stainless, nickel based 52Rc to 68Rc

inconel, nickel and other alloys, tool steels, titanium

aerospace materials alloys, inconel and other

aerospace materials

Color: Gold Dark Gray / Black Blue / Black Black

Nano Composite

Structure: Mono-layer Multi-layer

Multi-layer

Solid Cubic Boron Nitride

Hardness

21.7 35.5 45.0 65.0

(GPa):

Coefficient

0.5 0.6 0.5 0.2

of Friction:

Coating

Thickness 2-5 2-5 1-4 Solid CBN Tip

(microns):

Max.

Working 1000° F 1400° F 2100° F 2500° F

Temp:

PLEASE NOTE: Information and test results were compiled from multiple sources and testing methods. Data presented is intended to be a

general application guideline for comparing various coatings / substrates.

308 CALL: 800-645-5609 • FAX: 978-948-8558

TECHNICAL INFORMATION

COATINGS & SUBSTRATES CHART

Amorphous CVD PCD

ZrN TiB2

Diamond Diamond Diamond

Zirconium Titanium Diamond-Like Crystalline CVD Polycrystalline

Nitride Diboride Coating Diamond Diamond

-C7 -C8 -C4

• High hardness, • Primary benefit over • A PVD amorphous • True Crystalline CVD • PCD diamond is

lubricity and abrasion other non-ferrous diamond coating which diamond is grown manufactured as a

resistance. coatings is extremely improves lubricity and directly into a carbide carbide backed flat

low affinity to wear resistance in non- end mill. wafer. The wafer is

• Improves performance

aluminum. ferrous materials. brazed to a carbide

over uncoated carbide • Dramatically improves

body to form an end

in a wide variety of • Prevents build-up on • Coating is thin relative hardness.

mill.

non-ferrous materials. cutting edge, chip to CVD diamond,

• Hardness improves

packing and extends preventing edge • PCD has excellent

• Less expensive abrasion resistance

tool life. rounding. hardness and abrasion

alternative to diamond. and extends tool life

resistance, and is the

• Recommended in • Sharp edges improve up to 50x and allows

thickest diamond layer

Aluminum Alloys and results (performance higher feed rates than

we offer.

Magnesium Alloys. and finish) over CVD uncoated carbide.

in certain abrasive, • Sharply ground cutting

• Not ideally suited for • Ideal for machining

non-ferrous materials edges and thick

abrasive varieties of Graphite, Composites,

(copper, brass, high diamond layer combine

these alloys. Green Carbide, and

silicon aluminum). the sharp edge benefits

Green Ceramics.

of Amorphous Diamond

• Low temperature

• Diamond layer approx with the abrasion

threshold makes

5 times thicker than resistance of CVD

diamond unsuitable for

Amorphous Diamond, Diamond.

ferrous applications.

improving wear

• Low temperature

resistance.

threshold makes

• Low temperature diamond unsuitable for

threshold makes ferrous applications.

diamond unsuitable for

ferrous applications.

Thin coating maintains Thicker diamond layer Thickest diamond layer

sharper edge. for increased wear ground to sharp edge.

resistance.

Non-Ferrous & Non-Metallic Materials

Abrasive non-ferrous Aluminum Alloys, Abrasive Plastics, Graphite, Composites, Abrasive Plastics,

alloys such as Brass, Magnesium Alloys Graphite, Carbon Fiber Green Carbide, Green Graphite, Carbon Fiber

Bronze, Copper and Materials, Composites, Ceramics Materials,Composites,

Abrasive Aluminum Alloys Aluminum, Copper, Brass, Aluminum, Copper, Brass,

Bronze, Carbon, Gold, Bronze, Carbon, Gold,

Silver, Magnesium, Zinc Silver, Magnesium, Zinc,

Green Carbide, Green

Ceramics

Light Gold / Champagne Light Gray / Silver Charcoal / Gray Gray Gray / Black

True Crystalline CVD Polycrystalline Diamond

Mono-layer Mono-layer Mono-layer

Multi-Layer (Carbide Backed)

24.6 27.5 78 - 88 88 - 98 88 - 98

0.5 0.45 0.1 .05 - .3 .05 - .2

.010" - .030"

2-5 1-3 .5 - 2.5 8 - 10

Solid PCD Layer

1100° F 900° F 750° F 1100° F 1100° F

PLEASE NOTE: Information and test results were compiled from multiple sources and testing methods. Data presented is intended to be a

general application guideline for comparing various coatings / substrates.

EMAIL: sales@harveytool.com • VISIT: www.harveytool.com 309

You might also like

- Inserts Chart CoatingsDocument2 pagesInserts Chart CoatingsRelu ChiruNo ratings yet

- New Beyond Indexable Milling Grades: KCK15, KCSM30, KCPM40Document4 pagesNew Beyond Indexable Milling Grades: KCK15, KCSM30, KCPM40Mehdy HosseiniNo ratings yet

- Advanced Materials in Japan: Source Book 1992From EverandAdvanced Materials in Japan: Source Book 1992No ratings yet

- Cutting Tool MaterialsDocument26 pagesCutting Tool MaterialsMaheshwar DwivedyNo ratings yet

- Brochure HEFDocument12 pagesBrochure HEFsreedhar srinivasanNo ratings yet

- Cera Board 100Document2 pagesCera Board 100Javier TrujillanoNo ratings yet

- Cutting oil drilling tapping technical sheetDocument1 pageCutting oil drilling tapping technical sheetgopalakrishna100% (1)

- Belt Caster Feed NozzlesDocument1 pageBelt Caster Feed NozzlesManoj ChitreNo ratings yet

- Ceramic Fiber HeatersDocument22 pagesCeramic Fiber HeatersElias100% (1)

- Non-iron materials seminar presentationDocument13 pagesNon-iron materials seminar presentationqasim ijazNo ratings yet

- Catalogo Afã Motores CaterpillarDocument166 pagesCatalogo Afã Motores CaterpillarAlexis SanchezNo ratings yet

- Physics Based MachiningDocument22 pagesPhysics Based MachiningGirija MNo ratings yet

- Amirul Afiq Bin Ab Hisham 2017220378 J4Em1102GDocument3 pagesAmirul Afiq Bin Ab Hisham 2017220378 J4Em1102GFarah RashidNo ratings yet

- Class27 Cutting Tool MaterialsDocument25 pagesClass27 Cutting Tool MaterialsMohamed Farag MostafaNo ratings yet

- Metal CuttingDocument24 pagesMetal CuttingFRANCIS THOMASNo ratings yet

- Cutting Tool Materials History and TypesDocument58 pagesCutting Tool Materials History and TypesBikram Panthee100% (1)

- TeroMatec OA 2020Document2 pagesTeroMatec OA 2020EdwinNo ratings yet

- Ewac 1001 EBDocument1 pageEwac 1001 EBHari Mohan GuptaNo ratings yet

- Neutral Refractories 2021Document36 pagesNeutral Refractories 2021Daniel AppuingNo ratings yet

- Viking: Tool Steel For Heavy Duty Blanking and FormingDocument9 pagesViking: Tool Steel For Heavy Duty Blanking and Formingkbwoniu123No ratings yet

- Class 6 - 19th AugustDocument50 pagesClass 6 - 19th AugustAADESH GUPTANo ratings yet

- G2 Nonferrous AlloysDocument67 pagesG2 Nonferrous AlloysArt Lemuel LotereñaNo ratings yet

- Characteristics of Cutting Steels and Saw Tooth FormsDocument8 pagesCharacteristics of Cutting Steels and Saw Tooth FormsAlvaro RochaNo ratings yet

- Advanced Tool MaterialsDocument8 pagesAdvanced Tool MaterialsSry Putri AbdullahNo ratings yet

- High-Hardness Nickel Alloy Powder for Wear Resistance ApplicationsDocument1 pageHigh-Hardness Nickel Alloy Powder for Wear Resistance ApplicationsGanesh Badgire ReddyNo ratings yet

- Teromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionDocument2 pagesTeromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionJuan Carlos EspinozaNo ratings yet

- What Are Are Refractory Materials?Document15 pagesWhat Are Are Refractory Materials?priyanshu dhawanNo ratings yet

- Unit-2 Part-5Document9 pagesUnit-2 Part-5Tisha MishraNo ratings yet

- Thick Film HeatersDocument8 pagesThick Film HeatersEliasNo ratings yet

- StainTrode DDocument2 pagesStainTrode DGyanaranjan2011No ratings yet

- Genaral Broucher (BOHLER)Document20 pagesGenaral Broucher (BOHLER)SEIHU ALINo ratings yet

- CNC Tooling Materials and ApplicationsDocument58 pagesCNC Tooling Materials and ApplicationsDEVARAJU VNo ratings yet

- TC350 Laminates Data SheetDocument2 pagesTC350 Laminates Data Sheetnzeyap sechieNo ratings yet

- TMC - Metal 3D Printing HubDocument11 pagesTMC - Metal 3D Printing HubTHE METAL COMPANYNo ratings yet

- Rex Cut 2020 - Product - CatalogDocument44 pagesRex Cut 2020 - Product - CatalogJosé Del Orbe GarcíaNo ratings yet

- Machining Magnesium: Speeds, Feeds and Depths of CutDocument13 pagesMachining Magnesium: Speeds, Feeds and Depths of CutRudra DasNo ratings yet

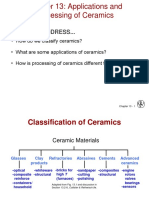

- Chapter 13 - Applications and Processing of CeramicsDocument26 pagesChapter 13 - Applications and Processing of CeramicsAngelino PimentelNo ratings yet

- Manufactured Substances in Industry: Name: Irdina BT Azhar CLASS: 401 Teacher'S Name: Pn. NorlizaDocument10 pagesManufactured Substances in Industry: Name: Irdina BT Azhar CLASS: 401 Teacher'S Name: Pn. NorlizaKHAYRA AZHARNo ratings yet

- Continuous Wire, Strip and Tube Annealing FurnacesDocument2 pagesContinuous Wire, Strip and Tube Annealing FurnacesEr Vijay MishraNo ratings yet

- 2 Drilling PDFDocument28 pages2 Drilling PDFgkhnNo ratings yet

- Machining MagnesiumDocument15 pagesMachining Magnesiumgaurav chauhanNo ratings yet

- Section 2Document62 pagesSection 2oscar perez perez nietoNo ratings yet

- Answers To The Review QuestionsDocument16 pagesAnswers To The Review QuestionsMohamed AbdoNo ratings yet

- TEFC Vertical Pump Motors up to 1000hpDocument2 pagesTEFC Vertical Pump Motors up to 1000hpDinalpinNo ratings yet

- CeramTec SemiCon Data SheetDocument6 pagesCeramTec SemiCon Data SheetЧжэньаоNo ratings yet

- Durelloy: Heat Treated Hot Roll AlloyDocument7 pagesDurelloy: Heat Treated Hot Roll AlloyPeterWayNo ratings yet

- High Performance Stainless Takes The Gall: Properties & General DataDocument2 pagesHigh Performance Stainless Takes The Gall: Properties & General Datajoker63000No ratings yet

- AMECA - Insert CoilDocument20 pagesAMECA - Insert CoilHector MartinezNo ratings yet

- Refractories NitaDocument11 pagesRefractories Nitanikunj chauhanNo ratings yet

- MD Mat 2Document43 pagesMD Mat 2Rounak AgrawalNo ratings yet

- Types of CeramicsDocument1 pageTypes of CeramicsGandalfNo ratings yet

- Rex-Cut CatalogDocument36 pagesRex-Cut CatalogBepdjNo ratings yet

- Petrolume® Series: Hazardous LocationsDocument4 pagesPetrolume® Series: Hazardous LocationsAnonymous v4akjrQxKNo ratings yet

- Preheat PDFDocument4 pagesPreheat PDFKamal UddinNo ratings yet

- Ferrous and Non-Ferrous Alloy Properties and ApplicationsDocument6 pagesFerrous and Non-Ferrous Alloy Properties and ApplicationsJesús GuardadoNo ratings yet

- Material Properties ChartDocument2 pagesMaterial Properties ChartNick PieperNo ratings yet

- Cutting ToolsDocument58 pagesCutting Toolsspy_raj89No ratings yet

- Runout - Circular Vs TotalDocument1 pageRunout - Circular Vs TotalKiên Trung NguyễnNo ratings yet

- GD&T - Perpendicularity of a SurfaceDocument5 pagesGD&T - Perpendicularity of a SurfaceKiên Trung NguyễnNo ratings yet

- Chapter Five Machining Quality and A NalysisDocument41 pagesChapter Five Machining Quality and A NalysisKiên Trung NguyễnNo ratings yet

- EML2322L TolerancesDocument7 pagesEML2322L TolerancesSandeep DeshmukhNo ratings yet

- Extracted Pages From Manufacturing Engineering and Technology - BookDocument1 pageExtracted Pages From Manufacturing Engineering and Technology - BookKiên Trung NguyễnNo ratings yet

- 08 Milling Full SlidesDocument35 pages08 Milling Full SlidesAnonymous mKdAfWifNo ratings yet

- 4.7.3 Exercise 8: Contact Plate: Complex NC ProgramsDocument2 pages4.7.3 Exercise 8: Contact Plate: Complex NC ProgramsKiên Trung NguyễnNo ratings yet

- Refer PDFDocument2 pagesRefer PDFkosmitoNo ratings yet

- Chapter Four Purposes of Jigs and Fixtures and Their Design PrinciplesDocument46 pagesChapter Four Purposes of Jigs and Fixtures and Their Design PrinciplesKiên Trung NguyễnNo ratings yet

- Chapter One Introduction To Manufacturing and MachiningDocument24 pagesChapter One Introduction To Manufacturing and MachiningKiên Trung NguyễnNo ratings yet

- Chapter Five Machining Quality and A NalysisDocument41 pagesChapter Five Machining Quality and A NalysisKiên Trung NguyễnNo ratings yet

- Introducing Steels: EF 420 Lecture 5 John TaylorDocument52 pagesIntroducing Steels: EF 420 Lecture 5 John TaylorKiên Trung NguyễnNo ratings yet

- Chapter Four Purposes of Jigs and Fixtures and Their Design PrinciplesDocument46 pagesChapter Four Purposes of Jigs and Fixtures and Their Design PrinciplesKiên Trung NguyễnNo ratings yet

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- Reaming TipDocument11 pagesReaming TipKiên Trung NguyễnNo ratings yet

- Reaming TipDocument11 pagesReaming TipKiên Trung NguyễnNo ratings yet

- Graphics 1: Sketching and Drafting: Engineering Sciences 51 Fall 2005Document13 pagesGraphics 1: Sketching and Drafting: Engineering Sciences 51 Fall 2005Kiên Trung NguyễnNo ratings yet

- Graphics - 2: Dimensioning and Tolerances: Engineering Sciences 51 Fall 2005Document16 pagesGraphics - 2: Dimensioning and Tolerances: Engineering Sciences 51 Fall 2005Kiên Trung NguyễnNo ratings yet

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- ES51 Lecture 3 05 Graphics 2Document16 pagesES51 Lecture 3 05 Graphics 2Kiên Trung NguyễnNo ratings yet

- Lecture4 5 MEC223 1Document17 pagesLecture4 5 MEC223 1Kiên Trung NguyễnNo ratings yet

- Graphics - 3: Tolerances: Engineering Sciences 51 Fall 2005Document14 pagesGraphics - 3: Tolerances: Engineering Sciences 51 Fall 2005Kiên Trung NguyễnNo ratings yet

- Graphics - 4: Fits: Engineering Sciences 51 Fall 2005Document9 pagesGraphics - 4: Fits: Engineering Sciences 51 Fall 2005Kiên Trung NguyễnNo ratings yet

- Introducing Steels: EF 420 Lecture 5 John TaylorDocument52 pagesIntroducing Steels: EF 420 Lecture 5 John TaylorKiên Trung NguyễnNo ratings yet

- Fastener HandoutDocument32 pagesFastener HandoutRaifan RaizerNo ratings yet

- Reaming TipDocument11 pagesReaming TipKiên Trung NguyễnNo ratings yet

- Runout - Circular Vs Total: Home GD&TDocument1 pageRunout - Circular Vs Total: Home GD&TKiên Trung NguyễnNo ratings yet

- Lab 1 - Machine Shop Basics: Layout, Band Saw, Drill Press, TappingDocument19 pagesLab 1 - Machine Shop Basics: Layout, Band Saw, Drill Press, TappingKiên Trung NguyễnNo ratings yet

- Fundamentals of Mechanical DesignDocument102 pagesFundamentals of Mechanical Designmans2014No ratings yet

- ITN524 Midterm PDFDocument4 pagesITN524 Midterm PDF_Vezir_No ratings yet

- Applications of Schrodinger Wave Equation: V (X), A X 0Document4 pagesApplications of Schrodinger Wave Equation: V (X), A X 0jasonNo ratings yet

- Bee Book by Gulzar AhmadDocument337 pagesBee Book by Gulzar AhmadMegha Singh100% (1)

- Intensive and Extensive Properties Intensive property: Whose value is independent of the size or extent i.e. mass of the system. These are, e.g., pressure p and temperature T. Extensive property: Whose value depends on the size or extent i.e. mass of the system (upper case letters as the symbols). e.g., Volume, Mass (V, M). If mass is increased, the value of extensive property also increases. e.g., volume V, internal energy U, enthalpy H, entropy S, etc. Specific property: It is a special case of an intensive property. It is the value of an extensive property per unit mass of system. (Lower case letters as symbols) eg: specific volume, density (v, ρ).Document3 pagesIntensive and Extensive Properties Intensive property: Whose value is independent of the size or extent i.e. mass of the system. These are, e.g., pressure p and temperature T. Extensive property: Whose value depends on the size or extent i.e. mass of the system (upper case letters as the symbols). e.g., Volume, Mass (V, M). If mass is increased, the value of extensive property also increases. e.g., volume V, internal energy U, enthalpy H, entropy S, etc. Specific property: It is a special case of an intensive property. It is the value of an extensive property per unit mass of system. (Lower case letters as symbols) eg: specific volume, density (v, ρ).mohammedammeenNo ratings yet

- Feldman e SeredaDocument10 pagesFeldman e SeredaKimberley HollandNo ratings yet

- Bernt - EC3 1 5Document44 pagesBernt - EC3 1 5Rosario BlancaNo ratings yet

- Group 3: Micropumps and MicrovalvesDocument20 pagesGroup 3: Micropumps and MicrovalvesPhenias ManyashaNo ratings yet

- 1998.05.15 - Aguileragranja - PRB - Magneticmoments of Ni ClustersDocument7 pages1998.05.15 - Aguileragranja - PRB - Magneticmoments of Ni ClustersAlejandra AwimbaweNo ratings yet

- Effects of Recrystallization Temperature On CuZn30Document6 pagesEffects of Recrystallization Temperature On CuZn30Hakan KuşdemirNo ratings yet

- Design of Structure-III (RCE701) : Unit IDocument2 pagesDesign of Structure-III (RCE701) : Unit IRohit TiwariNo ratings yet

- High Early Strength ConcreteDocument29 pagesHigh Early Strength ConcreteHadeer HosnyNo ratings yet

- European Steel and Alloy Grades: About Us EN 10209Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10209farshid KarpasandNo ratings yet

- E2864 - Metal - Oxides InhalationDocument6 pagesE2864 - Metal - Oxides InhalationOfir LidorNo ratings yet

- Effect of Zinc Oxide Nanoparticle On Pro PDFDocument4 pagesEffect of Zinc Oxide Nanoparticle On Pro PDFJoseph EspinozaNo ratings yet

- ASME B30.2 Lifting LugDocument8 pagesASME B30.2 Lifting LugEliza Nightry De Large100% (1)

- BEAM BOX Built-Up SectionDocument13 pagesBEAM BOX Built-Up Sectionmoseslugtu6324No ratings yet

- Smvo 4Document10 pagesSmvo 4selrajanNo ratings yet

- StatesDocument5 pagesStatesoffenberg1No ratings yet

- Fluid Mechanics n5 - General Introduction To Fluid MechanicsDocument11 pagesFluid Mechanics n5 - General Introduction To Fluid MechanicsMOSES MADHLALANo ratings yet

- Applied Circuit Analysis 1st Edition Sadiku Solutions ManualDocument24 pagesApplied Circuit Analysis 1st Edition Sadiku Solutions Manualfrederickhoanvt2100% (26)

- Confining Pressure 10 Mpa Von Mises StressDocument2 pagesConfining Pressure 10 Mpa Von Mises StressMoj TabaNo ratings yet

- Tut 04 Intro Tut 19 Evaporating LiquidDocument42 pagesTut 04 Intro Tut 19 Evaporating LiquidSergio EscobarNo ratings yet

- Biomechanics of Pin and Post Retained Restorations-MadhurimaDocument190 pagesBiomechanics of Pin and Post Retained Restorations-Madhurimarasagna reddy100% (1)

- Chapter 6Document26 pagesChapter 6yuwarajaNo ratings yet

- Hydrothermal Synthesis of ZnO NanoparticlesDocument4 pagesHydrothermal Synthesis of ZnO NanoparticlesSubhashini VedalaNo ratings yet

- Measurement of Fabric Abrasion Resistance FOR LABDocument5 pagesMeasurement of Fabric Abrasion Resistance FOR LABSudip TalukdarNo ratings yet

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- 1-Pwq Iso Grup 1 Wi'89Document25 pages1-Pwq Iso Grup 1 Wi'89Ir FankovicNo ratings yet

- Chemistry Term PaperDocument14 pagesChemistry Term PaperAkash SinghNo ratings yet

- Astm F 1940-01 PDFDocument9 pagesAstm F 1940-01 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet