Professional Documents

Culture Documents

MONGEMO Article Keeping Machines Up and Running OMICRON Magazine 2016 ENU

Uploaded by

Amanda MeloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MONGEMO Article Keeping Machines Up and Running OMICRON Magazine 2016 ENU

Uploaded by

Amanda MeloCopyright:

Available Formats

News 11

News

Keeping Machines Up and Running

New MONGEMO PD monitoring system for motors and generators

With the increasing age of motors and generators, on-line partial discharge (PD) monitoring has

become an essential asset management tool. Compared with routine off-line diagnostic tests,

on-line PD monitoring provides you with a continuous insulation condition status while rotating

machines are in operation. It indicates whenever operational stress and aging could be damaging

electrical insulation and putting machines at risk.

Meet MONGEMO for rotating machines

Our new MONGEMO on-line PD moni-

toring system continuously assesses the

dielectric condition of stator winding

insulation in rotating machines under load,

such as turbo generators, hydro generators

and electrical motors. The permanently-

installed system collects and analyzes PD

data over time and identifies insulation

defects that could lead to dielectric failure

and machine outages.

“Based on continuous, on-line PD measure-

ments, operators of motors and generators

can assess the risk of failure and take timely

condition-based maintenance actions to

minimize the risk of machine outages,”

says Felix Nadolni, Product Manager at

OMICRON. “The actionable data not only

enables maintenance strategies to be

optimized, it also helps to ensure reliable

operation.”

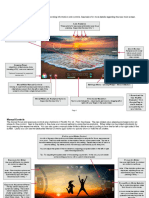

Automatic Cluster Separation – Single PD sources

are shown in the corresponding PRPDs that

enable even non PD experts to perform an initial

assessment of PD activity and potential risk.

Magazine | Volume 7 Issue 1 2016

12 News

1

1

MONGEMO can be customized to match the exact requirements

of various rotating machines. It consists of coupling capacitors

MONGEMO for PD detection, a 4-channel PD acquisition unit, and a central

>> Customized system approach for matching computer with monitoring and PD analysis software. “With the

specific monitoring requirements convenient web interface, operators can configure the monitoring

>> Synchronous, four-channel PD data acquisition system remotely, view data, and analyze historical data that has

for complete assessment been collected,” Felix adds.

>> Advanced noise suppression and fully

automated PD cluster separation for Modular, expandable design

convenient evaluation MONGEMO can be implemented at any point in time during the

>> Records raw PD data at selected intervals for service life of rotating machines. Its modular design allows the

in-depth post analysis system to be easily customized and expanded to match specific

>> Seamless integration with third-party monitoring requirements for single or multiple machines.

monitoring devices and SCADA systems

Actionable data for assessing failure risk

www.omicronenergy.com/mongemo The MONGEMO monitoring software automatically displays

real-time data as well as historical trend diagrams of PD parameters

for each monitored machine, such as PD magnitude and PD pulse

frequency. The high measurement s ensitivity of MONGEMO is based

on our advanced PD m

easurement technology for noise suppres-

sion and source separation.

“The insulation materials typically used in rotating machines

are resistant to a certain level of PD,” Felix explains. “However,

an increase in PD activity over time can indicate insulation

Magazine | Volume 7 Issue 1 2016

News 13

MONGEMO – One system for complete on-line PD monitoring:

1 Coupling capacitors

2 Protective enclosure

3 PD data acquisition unit

4 Fiber optic connectivity

5 Central computer with monitoring and analysis software

defects that could lead to serious damage and failure in rotating “Multiple PD sources are distinguished from external noise

machines,” he warns. To indicate increased PD activity, the through synchronous multi-channel measurements combined

monitoring software also provides operators with an event log with advanced methods like 3PARD (3-Phase Amplitude Relation

that displays warnings and alarms when PD activity reaches or Diagram) and automatic cluster separation for convenient visual

exceeds pre-defined threshold values. evaluation,” Felix clarifies.

Unique technology for convenient data evaluation Seamless integration with third-party systems

Advanced features in the MONGEMO monitoring software MONGEMO supports multiple industrial communications

enable operators to record raw PD data for in-depth post analysis. standards. “This enables PD monitoring data from MONGEMO to

The software’s unique automated cluster separation allows be exported to SCADA systems easily,” says Felix. “The system also

effective noise elimination to help classify the source of PD more displays monitoring data from other third-party devices, such as

conveniently than ever before. temperature sensors.”

«An increase in PD activity over time can indicate insulation

defects that could lead to serious damage and failure in rotating

m

achines.»

Felix Nadolni

Product Manager, OMICRON

Magazine | Volume 7 Issue 1 2016

You might also like

- Certification of Safety-Critical Software Under DO-178C and DO-278ADocument13 pagesCertification of Safety-Critical Software Under DO-178C and DO-278AAlp Bulent Burc SurmeliNo ratings yet

- Pro Safe PLCDocument44 pagesPro Safe PLClimresNo ratings yet

- Abending Evaluation and ResolutionDocument20 pagesAbending Evaluation and Resolutionrams7869No ratings yet

- Free Gift Card Guide Jan 2024Document2 pagesFree Gift Card Guide Jan 20241904celtNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- WAF Imperva - Deployment Monitoring - 26122017Document33 pagesWAF Imperva - Deployment Monitoring - 26122017Zanuar Dwi RockavankaNo ratings yet

- 4 Online Monitoring of GasDocument24 pages4 Online Monitoring of GasM Ahmad Tauqeer0% (1)

- 1 Online Monitoring of PPDocument13 pages1 Online Monitoring of PPbhawnaNo ratings yet

- Online Grading System With Examination For Philiipine Institute of Quezon City CAPSTONE PROJECTDocument49 pagesOnline Grading System With Examination For Philiipine Institute of Quezon City CAPSTONE PROJECTCelo Sioson Batiduan IIINo ratings yet

- Mongemo Brochure EnuDocument16 pagesMongemo Brochure EnuAhmad JunaidiNo ratings yet

- MONGEMO Brochure ENUDocument12 pagesMONGEMO Brochure ENUHANIF AKBARNo ratings yet

- OMICRON Magazine Article 01 2019 MONTESTO 200 ENUDocument4 pagesOMICRON Magazine Article 01 2019 MONTESTO 200 ENUMarcioNo ratings yet

- Datasheet OPCom Particle Monitor 10051 EN USDocument4 pagesDatasheet OPCom Particle Monitor 10051 EN USmetinNo ratings yet

- Vehicle Fault Detection SystemDocument19 pagesVehicle Fault Detection SystemHrudhay LuckyNo ratings yet

- Moncablo Press Release EnuDocument3 pagesMoncablo Press Release EnusedianpoNo ratings yet

- Observing Partial Discharge Over TimeDocument2 pagesObserving Partial Discharge Over TimesalemNo ratings yet

- Prakul Garg: Career ObjectiveDocument5 pagesPrakul Garg: Career ObjectiveAmit JainNo ratings yet

- Guardian Angel Brochure BDocument9 pagesGuardian Angel Brochure BronfrendNo ratings yet

- Fag Smartcheck: High Process Security by Means of Decentralised Machinery MonitoringDocument26 pagesFag Smartcheck: High Process Security by Means of Decentralised Machinery Monitoringl_aguilar_mNo ratings yet

- Exfo Spec-Sheet IolmDocument11 pagesExfo Spec-Sheet IolmAmos Mbuva MusembiNo ratings yet

- Otdr-Exfo Spec-Sheet Ftb-730 v12 enDocument5 pagesOtdr-Exfo Spec-Sheet Ftb-730 v12 enمحمد ابو حمزةNo ratings yet

- Tecnomotor Socio X6 Integrated Vehicle Diagnostics ENDocument4 pagesTecnomotor Socio X6 Integrated Vehicle Diagnostics ENMAK OBDNo ratings yet

- Smart Factory SolutionDocument2 pagesSmart Factory SolutionsamNo ratings yet

- Blue Eyes TechnologyDocument23 pagesBlue Eyes TechnologyFaheem SalmanNo ratings yet

- Seminar On Blue Eyes: Submitted To: Submitted byDocument23 pagesSeminar On Blue Eyes: Submitted To: Submitted byMõhâñNo ratings yet

- Particle LS13320XR BrochureDocument6 pagesParticle LS13320XR BrochureNatrawin MaskasunNo ratings yet

- Jumping Into Industry 4.0 With Predictive Maintenance SolutionsDocument26 pagesJumping Into Industry 4.0 With Predictive Maintenance SolutionsNantha Kumara PeriasamyNo ratings yet

- Predicon Predicon: Supplying Afdable Complete SolutionsDocument8 pagesPredicon Predicon: Supplying Afdable Complete SolutionsronfrendNo ratings yet

- Optimum Process Control:: The SIMOCODE Pro Libraries For PCS 7Document10 pagesOptimum Process Control:: The SIMOCODE Pro Libraries For PCS 7señorbmxNo ratings yet

- Pd-Scan BR en PDFDocument12 pagesPd-Scan BR en PDFSharin Bin Ab GhaniNo ratings yet

- Agilent N3900A - 3910AL DatasheetDocument28 pagesAgilent N3900A - 3910AL DatasheetAmir GoodarziNo ratings yet

- Batch 18 3 ReviewDocument18 pagesBatch 18 3 ReviewARUNKUMAR ANo ratings yet

- 3612 Ijdps 04Document19 pages3612 Ijdps 04atheeq ahmedNo ratings yet

- Latest - Industrial - Symphony Industrial Ai Data Sheets Watchman 360 - Brochure - 20220620Document3 pagesLatest - Industrial - Symphony Industrial Ai Data Sheets Watchman 360 - Brochure - 20220620MILTON CÉSAR AGUILAR DE AZAMBUJANo ratings yet

- Tier-2 Optical Time Domain Reflectometer For Multimode and Single-Mode Fibre CablingDocument6 pagesTier-2 Optical Time Domain Reflectometer For Multimode and Single-Mode Fibre Cablingsorangel_123No ratings yet

- Index: Blue Eyes TechnologyDocument27 pagesIndex: Blue Eyes TechnologyAmreen KhanNo ratings yet

- High Performance Partial Discharge Diagnostic System: AQUILA - Portable PD AnalyzerDocument2 pagesHigh Performance Partial Discharge Diagnostic System: AQUILA - Portable PD AnalyzerShahnawaz AhmadNo ratings yet

- Manual Simocode Pro V PN Fdi En-UsDocument172 pagesManual Simocode Pro V PN Fdi En-UsFrederico OliveiraNo ratings yet

- Drowsiness Detection Via Car SeatDocument16 pagesDrowsiness Detection Via Car Seatmanugj12mNo ratings yet

- Second Generation Multi Purpose Camera (MPC2) : Chassis Systems ControlDocument4 pagesSecond Generation Multi Purpose Camera (MPC2) : Chassis Systems ControlKevin TanNo ratings yet

- Ifm Octavis Brochure 2013 ZaDocument12 pagesIfm Octavis Brochure 2013 ZasandeshshivaNo ratings yet

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Plagiarism Checker X Originality Report: Similarity Found: 18%Document12 pagesPlagiarism Checker X Originality Report: Similarity Found: 18%Saket Sukhwant SinghNo ratings yet

- TDS3201 January 2016 B - NEST Technical Datasheet ENDocument11 pagesTDS3201 January 2016 B - NEST Technical Datasheet ENjayesh gohilNo ratings yet

- Ronds Wireless CMS CatalogueDocument6 pagesRonds Wireless CMS Cataloguemortazavi.technicalNo ratings yet

- A Smart Industrial Pollution Monitoring System UsingDocument5 pagesA Smart Industrial Pollution Monitoring System Usingt24042567No ratings yet

- Driver Drowsiness D FormatDocument20 pagesDriver Drowsiness D FormatVedantNo ratings yet

- MONTESTO 200 Brochure ENUDocument16 pagesMONTESTO 200 Brochure ENUKhoilnNo ratings yet

- Vehicle Detection SystemDocument4 pagesVehicle Detection SystemHrudhay LuckyNo ratings yet

- Success Story Paper Master enDocument3 pagesSuccess Story Paper Master enPhu, Le HuuNo ratings yet

- OMS 605 Brochure ENUDocument12 pagesOMS 605 Brochure ENUConstantNo ratings yet

- Eagle Brochure AcoemDocument6 pagesEagle Brochure AcoemBURIN SITTIMONGKONNo ratings yet

- Ijarcet Vol 3 Issue 3 860 865 PDFDocument6 pagesIjarcet Vol 3 Issue 3 860 865 PDFKunal AhiwaleNo ratings yet

- Smart Motors - Point Machine MonitoringDocument10 pagesSmart Motors - Point Machine MonitoringMartha MiralpeixNo ratings yet

- 319 204B2Document130 pages319 204B2sprt82No ratings yet

- s71500 Communication Function Manual en-US en-USDocument445 pagess71500 Communication Function Manual en-US en-USVichu DummyNo ratings yet

- Predictive Machining Learning To Stop Failures in Their Tracks 2020Document6 pagesPredictive Machining Learning To Stop Failures in Their Tracks 2020rohit reddyNo ratings yet

- Blue Eyes TechnologyDocument24 pagesBlue Eyes TechnologySumanthkalyanNo ratings yet

- s71500 Communication Function Manual en-US en-USDocument424 pagess71500 Communication Function Manual en-US en-USbocaNo ratings yet

- High Performance Partial Discharge Diagnostic System: AQUILA - Portable PD Test InstrumentDocument2 pagesHigh Performance Partial Discharge Diagnostic System: AQUILA - Portable PD Test Instrumentmohamed anasNo ratings yet

- Terminationguard: PD Monitoring SystemDocument4 pagesTerminationguard: PD Monitoring SystemNazirAhmadBashiriNo ratings yet

- Design On Security Alarming System of Vehicle Terminal EquipmentDocument4 pagesDesign On Security Alarming System of Vehicle Terminal EquipmentLets TalkNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- rx2540m6 Umm enDocument716 pagesrx2540m6 Umm enrZL CXZNo ratings yet

- 2018 Firmware Update Instructions For Ver 8.53 PEH448H.AVH - PDFDocument7 pages2018 Firmware Update Instructions For Ver 8.53 PEH448H.AVH - PDFjavier_khanNo ratings yet

- EricssonDocument5 pagesEricssoneferrazbastos100% (1)

- Filmicpro V6 Android: Quick Start GuideDocument5 pagesFilmicpro V6 Android: Quick Start Guideozziesk8No ratings yet

- MAD - PRACTICAL EXAM Slips - 23 - 24Document9 pagesMAD - PRACTICAL EXAM Slips - 23 - 24unreleasedtrack43No ratings yet

- M .Ai A: A I 101 F W - C O AI A Vip Ai 101 C SDocument22 pagesM .Ai A: A I 101 F W - C O AI A Vip Ai 101 C Smehmet nedimNo ratings yet

- Data Storage HierarchyDocument14 pagesData Storage HierarchyLogeswari GovindarajuNo ratings yet

- ANSYS, Inc. Licensing Guide PDFDocument136 pagesANSYS, Inc. Licensing Guide PDFEDIZON100% (1)

- Programming in CDocument7 pagesProgramming in CAditya BhattacharayaNo ratings yet

- 505 WorkShop ManualDocument704 pages505 WorkShop ManualTim GreverNo ratings yet

- Final Thesis RevisedDocument85 pagesFinal Thesis RevisedChester Allan F. BautistaNo ratings yet

- Solutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriDocument5 pagesSolutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriMarkib Singh AdawitahkNo ratings yet

- What To Expect From Today's Training Session?: Log-In Instructions How To Access The Adse 2023 Exercise StoryDocument9 pagesWhat To Expect From Today's Training Session?: Log-In Instructions How To Access The Adse 2023 Exercise Storyhaofeng xDNo ratings yet

- Seminar Web Application SecurityDocument30 pagesSeminar Web Application SecurityGauraviNo ratings yet

- School of Computing and Informatics Computer Science ProgramDocument2 pagesSchool of Computing and Informatics Computer Science ProgramSARA ALABAHRAANo ratings yet

- Pro Material Series: Free Placement Video Tutorial With Mock Test VisitDocument10 pagesPro Material Series: Free Placement Video Tutorial With Mock Test VisitPuneethNo ratings yet

- 廖雪峰 2018官方Python3教程(二)Document156 pages廖雪峰 2018官方Python3教程(二)Xavier edwardsNo ratings yet

- Capacitor WhitepaperDocument17 pagesCapacitor WhitepaperRambabu UppalaNo ratings yet

- LC 2Document6 pagesLC 2Williamson B EnocNo ratings yet

- Assignment 1: ERD and SQL: CRICOS Provider No. 00103D ITECH2004 Assignment1 ER-SQL 2020Document5 pagesAssignment 1: ERD and SQL: CRICOS Provider No. 00103D ITECH2004 Assignment1 ER-SQL 2020Pratap SinghNo ratings yet

- ControlLogix 1757-SRM Redundancy Quick StartDocument6 pagesControlLogix 1757-SRM Redundancy Quick StartLucianoNo ratings yet

- 9 Months - System Development Tracks OverviewDocument8 pages9 Months - System Development Tracks OverviewSami MahmoudNo ratings yet

- SEBI Grade A IT 2024 Complete Guide PDFDocument16 pagesSEBI Grade A IT 2024 Complete Guide PDFsamwelch1819No ratings yet

- Lecture 1Document25 pagesLecture 1Bandar AlmaslukhNo ratings yet