Professional Documents

Culture Documents

DCC045 Atlox Metasperse 550S

Uploaded by

David RuizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCC045 Atlox Metasperse 550S

Uploaded by

David RuizCopyright:

Available Formats

Atlox Metasperse™ 550S

Polymeric Dispersant

Atlox Metasperse 550S is designed as a polymeric dispersant for use in a variety of solid or liquid formulations

(SC, SE, EW, and WG) and demonstrates excellent performance and physical stability at low to moderate use

levels.

Benefits:

Higher performance (suspension number, and stability) than competing dispersant types

Performance is consistently high at the same level of dispersant use in WG and WP formulations

Performance is consistent across a range of active ingredients

The dispersant technology can enable the rapid commercialisation of higher assay and/or higher

performing granules

For higher concentration granules, there is higher revenue/greater volume from the same assets

maximising productivity. There are also processing cost savings as a direct result of having to process

fewer total volumes of product to deliver the same mass of active ingredient

Lower total cost in use due to performance of these products at reduced concentrations in extruded

granules

Recommended formulation development approaches ensure success in formulating high activity granules

Atlox Metasperse shows its most obvious benefits when used as the dispersant in a WG formulation for hard

water conditions where it brings about a degree of suspension stability not seen with other dispersants. Water

dispersible granules allow for the production of highly concentrated formulations which are wettable and easily

disintegrate in contact with water. As a result Atlox Metasperse is particularly useful for formulas that demand a

high loading of active ingredient because the space left for inerts is limited.

Atlox Metasperse 550S is a sodium-neutralized styrene/acrylic acid copolymer provided as a spray dried

powder (min. 95% active). It is readily blended and milled with dry components prior to addition of water in

paste extrusion.

Atlox Metasperse 550S is typically used at low rates (2% to 5% of formulation by weight, dry basis) and offers a

high performing alternative or additive to naphthalene sulfonate formaldehyde condensates and lignin

sulfonates. Unlike lignin based formulas that darken over time, Atlox Metasperse 550S-based granules remain

an attractive light colour.

For example, a formulation containing Atlox Metasperse 550S shows much higher robustness to hard water

conditions when compared to formulations containing naphthalene sulfonate formaldehyde condensates or

sulfonated lignin as the dispersant.

Croda Europe Ltd Cowick Hall Snaith Goole East Yorkshire DN14 9AA England 05/13 DCC045

Tel +44 (0)1405 860551 Fax +44 (0)1405 861767 E-mail cropcare@croda.com www.croda.com/cropcare Page 1 of 5

Innovation you can build on™

Formula % (w/w)

Carbaryl 75WG 75.00

Kaolin Clay 10.00

Dispersant/Wetter/Kaolin Clay 15.00

As a result, Atlox Metasperse 550S is required at a much lower percentage of the formula than alternatives due

to demonstrating a better performance level across a range of concentrations (Figure 1).

Carbaryl 75 WG

(Metasperse 550S in 1000 ppm Hardness)

Suspension Number

Percent Dispersant

Naphthalene Sulfonate Condensate Sulfonated Lignin

Figure 1: Suspension number at increasing dispersant content. Measurements collected in 1000 ppm

hardness water

This ability to perform to a high standard in hard water conditions is further highlighted when the suspension

number (for method see Appendix) is assessed at decreasing dispersant percentage content in the 15%

dispersant, wetter and kaolin clay mix (Figure 2).

Ratio No. Dispersant Kaolin Clay Wetter

13 9% 3% 3%

21 7.50% 0% 7.50%

33 5% 5% 5%

40 3% 9% 3%

44 3% 3% 9%

Croda Europe Ltd Cowick Hall Snaith Goole East Yorkshire DN14 9AA England 05/13 DCC045

Tel +44 (0)1405 860551 Fax +44 (0)1405 861767 E-mail cropcare@croda.com www.croda.com/cropcare Page 2 of 5

Innovation you can build on™

Dispersant Performance with Carbaryl 75WG in 1000 ppm Hardness

100

90

80

70

Suspension Number

60

50

40

30

20

10

0

Ratio 13 Ratio 21 Ratio 33 Ratio 40 Ratio 44

Metasperse 550S Napthalene Sulfonate Condensate Sulfonated Lignin

Figure 2: Suspension number at different formulation recipes in 1000 ppm hardness water.

The Atlox Metasperse-containing formulation has a consistently higher suspension number

displaying an improved stability especially at low concentrations. The Atlox Metasperse-containing

formulation also shows a consistent performance level which gives formulators much greater

freedom when designing a robust, finished product. What this data also demonstrates is that in

many cases, actual total excipient cost can be lower using Atlox Metasperse 550S dispersant due to

significantly lower dispersant use rates in the finished formulation when compared to alternative,

lower ‘per kg’ costing, dispersant materials.

Furthermore, Atlox Metasperse formulations demonstrate greater long term stability than other

industry standards. This is displayed in figure 3 where results were collected after the formulations

had been kept for three months at 50ºC.

Croda Europe Ltd Cowick Hall Snaith Goole East Yorkshire DN14 9AA England 05/13 DCC045

Tel +44 (0)1405 860551 Fax +44 (0)1405 861767 E-mail cropcare@croda.com www.croda.com/cropcare Page 3 of 5

Innovation you can build on™

Dispersant Performance with Carbaryl 75WG in 1000 ppm Hardness

Dispersion stability after 3 months storage

100

90

80

70

Suspension Number

60

50

40

30

20

10

0

Ratio 13 Ratio 21 Ratio 33 Ratio 40 Ratio 44

Metasperse 550S Napthalene Sulfonate Condensate Sulfonated Lignin

Figure 3: Suspension number at different formulation recipes in 1000 ppm hardness water after storage

for three months at 50ºC.

The Atlox Metasperse formulation remains stable with no drop in suspension number over a period of time. The

performance differential over naphthalene sulfonate condensate WG and sulfonated lignin WG is maintained

with Atlox Metasperse 550S continuing to show a better performance level.

A WG formulation containing Atlox Metasperse 550S as the dispersant continues to show a better performance

level than other industry standards when used with a variety of different actives. Similar performance levels are

seen with: Atrazine 75WG & 90WG, Chlorothalonil 75WG, Diuron 75WG, Iprodione 75WG, Metalachlor 25WG,

Permethrin 25WG and Simazine 75WG.

75%W/W Extruded Granule Physical Suspension Number In 342ppm Hardness Water:

Point Number Diuron Carbaryl Chlorothalonil Simazine Atrazine Iprodione

13 92 94 64 86 97 86

21 93 95 73 90 97 87

33 93 93 65 85 95 81

40 94 91 64 59 90 84

44 94 91 52 No Test No Test 87

The following formulas, for each of the above active ingredients, can therefore be recommended as

cost/performance effective formulations:

Croda Europe Ltd Cowick Hall Snaith Goole East Yorkshire DN14 9AA England 05/13 DCC045

Tel +44 (0)1405 860551 Fax +44 (0)1405 861767 E-mail cropcare@croda.com www.croda.com/cropcare Page 4 of 5

Innovation you can build on™

%W/W %W/W %W/W

Diuron 75.00 Carbaryl 75.00 Chlorothalonil 75.00

Metasperse 550S 3.00 Metasperse 550S 3.00 Metasperse 550S 3.00

1

Morwet™ EFW 3.00 Morwet™ EFW 3.00 Morwet™ EFW 3.00

Kaolin Clay 19.00 Kaolin Clay 19.00 Kaolin Clay 19.00

%W/W %W/W %W/W

Simazine 75.00 Atrazine 75.00 Iprodione 75.00

Metasperse 550S 5.00 Metasperse 550S 3.00 Metasperse 550S 3.00

Morwet™ EFW 5.00 Morwet™ EFW 3.00 Morwet™ EFW 9.00

Kaolin Clay 15.00 Kaolin Clay 19.00 Kaolin Clay 13.00

In all the examples evaluated to date, the use of Atlox Metasperse 550S as the primary dispersant for a

finished WG product delivered storage stability and suspension performance equal to or better than competitive

products when used at significantly lower rates in extruded granules.

As a direct added benefit, the low dispersant requirement for Atlox Metasperse 550S in the extruded granule

formulation can allow for the development of higher active ingredient concentration WG formulations. This is

primarily due to lower dispersant requirement and the higher performance of the dispersant itself. Granule

assay may be successfully driven higher when using Atlox Metasperse dispersants for extruded granules.

The higher performance of Atlox Metasperse 550S can offer the option to formulate granules with the same

dispersant concentration as the corresponding wettable powders (2-4% w/w) without loss of performance. This

may not be the case with naphthalene sulfonate condensates or lignin sulfonates, which may require a 200-

300% increase in dispersant concentration when used in extruded granules.

This flexibility can provide a ready step-up opportunity with reduced development and registration effort for new

or existing wettable powder formulations where regulatory pressure could require conversion to a granular

delivery system.

Appendix

Suspensibility was measured by a modified method in which 1g of the granular formulation was dispersed into

100ml of 1000ppm hardness water in a test cylinder, the cylinder was inverted 10 times and allowed to stand

for 5 minutes, then again inverted 10 times and allowed to stand for 30 minutes. The upper 90% was drawn off

with a suction tube, taking care not to disturb the sediment. The remaining material was filtered through a pre-

weighed filter paper, dried and re-weighed to determine the weight of material unsuspended. The suspensibility

(%) is the concentration of the powder in the upper 90% of the water.

Non-warranty

The information in this publication is believed to be accurate and is given in good faith, but no representation or warranty as to its completeness or accuracy is

made. Suggestions for uses or applications are only opinions. Users are responsible for determining the suitability of these products for their own particular

purpose. No representation or warranty, expressed or implied, is made with respect to information or products including, without limitation, warranties of

merchantability, fitness for a particular purpose, non-infringement of any third party patent or other intellectual property rights including, without limit, copyright,

trademark and designs. Any trademarks identified herein are trademarks of the Croda group of companies.

©2013 Croda Europe Ltd

1 Morwet™ EFW is a trademarked product from Akzo Nobel

Croda Europe Ltd Cowick Hall Snaith Goole East Yorkshire DN14 9AA England 05/13 DCC045

Tel +44 (0)1405 860551 Fax +44 (0)1405 861767 E-mail cropcare@croda.com www.croda.com/cropcare Page 5 of 5

Innovation you can build on™

You might also like

- MSCC010 Atlox Metasperse RangeDocument2 pagesMSCC010 Atlox Metasperse RangePetr CiglerNo ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- Atlox™ 4913 Graft Comb' Copolymer: Dispersant For Aqueous Suspension ConcentratesDocument2 pagesAtlox™ 4913 Graft Comb' Copolymer: Dispersant For Aqueous Suspension Concentratesherry prasetyo100% (1)

- Carbendazim 50 SC Using Atlox 4913 & 4894Document2 pagesCarbendazim 50 SC Using Atlox 4913 & 4894Pongthip PesachpinankulNo ratings yet

- C 2Document24 pagesC 2Eugene MakNo ratings yet

- Guide To EWDocument2 pagesGuide To EWlb_BotsNo ratings yet

- Specialty Phosphate Esters Selector Guide: ME FormulationsDocument1 pageSpecialty Phosphate Esters Selector Guide: ME FormulationszoilaNo ratings yet

- Guide To ODDocument2 pagesGuide To ODlb_BotsNo ratings yet

- Ametech - ProductsDocument3 pagesAmetech - Productsalbus898No ratings yet

- Formulator's Toolbox - Croda - Artigo BaseDocument69 pagesFormulator's Toolbox - Croda - Artigo BaseDeivid Metzker100% (1)

- Synperonic EthoxylatesDocument2 pagesSynperonic Ethoxylatesjacky ye100% (1)

- Industrial Chemicals Overview Product Brochure 01-16Document14 pagesIndustrial Chemicals Overview Product Brochure 01-16Daryl Chian100% (1)

- BrochureDocument20 pagesBrochureMoatz HamedNo ratings yet

- SASOL SURFACTANTS Product RangeDocument40 pagesSASOL SURFACTANTS Product RangeAlex100% (1)

- 0901 B 8038091 CFC 5Document6 pages0901 B 8038091 CFC 5ForeverNo ratings yet

- WP & EC ReceipesDocument4 pagesWP & EC ReceipesNadeem Mirza100% (3)

- Crop Solutions BrochureDocument30 pagesCrop Solutions BrochureThe PopeNo ratings yet

- Brochure Miracare SLBDocument12 pagesBrochure Miracare SLBvalkira1100% (1)

- Pluronic PE TypesDocument16 pagesPluronic PE TypesMehul KhimaniNo ratings yet

- US - Surfactants Nonionic - Specialty Ethoxylates Based On Short Chain AlcoholsDocument20 pagesUS - Surfactants Nonionic - Specialty Ethoxylates Based On Short Chain AlcoholsARTHA -LESTARINo ratings yet

- 2008 CropProtection Newsroom Brochures CropProtectionProductRangeDocument19 pages2008 CropProtection Newsroom Brochures CropProtectionProductRangeRomán M Martín del C0% (1)

- Evonik - Tomadol Product Guide PDFDocument34 pagesEvonik - Tomadol Product Guide PDFJacek MisztalNo ratings yet

- 1Document16 pages1mercuriusNo ratings yet

- Brand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide EnglishDocument15 pagesBrand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide Englishgemm88No ratings yet

- Brochure Cleaning Emeia Product CatalogDocument40 pagesBrochure Cleaning Emeia Product Catalogpkh29No ratings yet

- Lankem E-Brochure 2022Document16 pagesLankem E-Brochure 2022MOGES ABERANo ratings yet

- Basf Home Care and I&i 2020 Guide To Sustainable IngredientsDocument20 pagesBasf Home Care and I&i 2020 Guide To Sustainable IngredientsLaban KantorNo ratings yet

- General Purpose Degreasing Formulation HC/HS/09Document1 pageGeneral Purpose Degreasing Formulation HC/HS/09Shingi MameNo ratings yet

- Huntsman Agro Brochure - Final101306Document24 pagesHuntsman Agro Brochure - Final101306eduardoaffre67% (6)

- Co-Formulants in Authorised Plant Protection Products (1 November 2020)Document18 pagesCo-Formulants in Authorised Plant Protection Products (1 November 2020)David SilverNo ratings yet

- Eo Po Block Co PolymersDocument29 pagesEo Po Block Co PolymersUtpalNo ratings yet

- Clariant Brochure Emulsion Polymerization Portfolio 2017 EN PDFDocument4 pagesClariant Brochure Emulsion Polymerization Portfolio 2017 EN PDF幸福100% (1)

- Agro SurfactantsDocument4 pagesAgro SurfactantsJanakiram Yarlagadda100% (1)

- Brochure Additives For Pesticide FormulationslDocument24 pagesBrochure Additives For Pesticide FormulationslMostafa FawzyNo ratings yet

- Rheology Modifiers Product Recommendations For EuropeDocument2 pagesRheology Modifiers Product Recommendations For EuropeHamood AbdoNo ratings yet

- CognisDocument56 pagesCognisivate100% (7)

- Li Edaplan Metolat Dispersing TechnologyDocument15 pagesLi Edaplan Metolat Dispersing TechnologyPulbere NeagraNo ratings yet

- AkzoNobel Narrow Range Ethoxylates - 2015Document4 pagesAkzoNobel Narrow Range Ethoxylates - 2015Vilas DhakappaNo ratings yet

- Cognis EP Surfactants 2011junDocument80 pagesCognis EP Surfactants 2011junVilas DhakappaNo ratings yet

- Technical Data Sheet: Latex Emulsion PaintsDocument2 pagesTechnical Data Sheet: Latex Emulsion PaintsAaron Chris Gonzales100% (1)

- Additive Coatings and Inks Ver 2.1 2021Document8 pagesAdditive Coatings and Inks Ver 2.1 2021nano100% (1)

- AkzoNobel Paint Eng Tcm54-18194Document20 pagesAkzoNobel Paint Eng Tcm54-18194a2009sNo ratings yet

- 2017 - Formulation & Adjuvant TechnologyDocument36 pages2017 - Formulation & Adjuvant TechnologyCatherine TangNo ratings yet

- Kao Optimized Coacervation FormationDocument5 pagesKao Optimized Coacervation FormationQuỳnh-Mai Nguyễn100% (1)

- 2009 Industrial Lubricants Newsroom Brochures Surf Act Ants BrochureDocument27 pages2009 Industrial Lubricants Newsroom Brochures Surf Act Ants BrochureCüneyt Gökhan TosunNo ratings yet

- Cognis Surfactants PDFDocument27 pagesCognis Surfactants PDFEdin Krdžalić Edo100% (2)

- FoamStar ST 2412 August 2018 R3 ED2Document2 pagesFoamStar ST 2412 August 2018 R3 ED2APEX SONNo ratings yet

- Catalogue Surfactants PDFDocument16 pagesCatalogue Surfactants PDFMukesh KumarNo ratings yet

- Clariant Surfactant BrochureDocument21 pagesClariant Surfactant BrochureMohamed Halem100% (2)

- Silwet BroschuereDocument20 pagesSilwet BroschuereDinh Van TinhNo ratings yet

- Lamberti Product List Agro Surf Act Ants & Adjuvants Aug 1 2008Document19 pagesLamberti Product List Agro Surf Act Ants & Adjuvants Aug 1 2008Don Leming100% (3)

- Jo GradeDocument40 pagesJo GradeEvonne TanNo ratings yet

- LEVACO - Agrochemicals ProductsDocument6 pagesLEVACO - Agrochemicals Productsmercurius100% (1)

- Alcohol Ethoxylate GuideDocument24 pagesAlcohol Ethoxylate GuideFadhli KusumaNo ratings yet

- Curran® Granules: Your Biobased Solution For Improved Water Based CoatingsDocument2 pagesCurran® Granules: Your Biobased Solution For Improved Water Based CoatingsWendell SanchezNo ratings yet

- MAN0015751 2162579 89877-8 89882-3 89889-94 89807-8 Zeba Desalting UGDocument3 pagesMAN0015751 2162579 89877-8 89882-3 89889-94 89807-8 Zeba Desalting UGyhquisNo ratings yet

- (Spring - 2013 - CVEN350) Environmental Engineering: Experiment #6 Coagulation and FlocculationDocument6 pages(Spring - 2013 - CVEN350) Environmental Engineering: Experiment #6 Coagulation and FlocculationConstantinTudoseNo ratings yet

- Silica Gel Sorbsil Chameleon Granules With Moisture IndicatorDocument2 pagesSilica Gel Sorbsil Chameleon Granules With Moisture IndicatorIssam AssomNo ratings yet

- MAN0011691 Zeba Spin DesaltCol Plate 40K MWCO UGDocument3 pagesMAN0011691 Zeba Spin DesaltCol Plate 40K MWCO UGyhquisNo ratings yet

- Metodo Cipac PropinebDocument3 pagesMetodo Cipac PropinebDavid RuizNo ratings yet

- Metodo Cipac MetamidofosDocument6 pagesMetodo Cipac MetamidofosDavid RuizNo ratings yet

- Metodo Cipac PropamocarbDocument3 pagesMetodo Cipac PropamocarbDavid RuizNo ratings yet

- Technical Information 1279 - Successful Use of AEROSIL® Fumed Silica in Liquid SystemsDocument12 pagesTechnical Information 1279 - Successful Use of AEROSIL® Fumed Silica in Liquid SystemsDavid RuizNo ratings yet

- Biosensors: Advances in The Detection of Dithiocarbamate Fungicides: Opportunities For BiosensorsDocument26 pagesBiosensors: Advances in The Detection of Dithiocarbamate Fungicides: Opportunities For BiosensorsDavid RuizNo ratings yet

- Cosmetics: Rosmarinus o Plant With Uses in Personal Healthcare and CosmeticsDocument17 pagesCosmetics: Rosmarinus o Plant With Uses in Personal Healthcare and CosmeticsDavid RuizNo ratings yet

- What S New in Ezchrom Elite 3 3 2 Sp2Document13 pagesWhat S New in Ezchrom Elite 3 3 2 Sp2David RuizNo ratings yet

- Auerbach M.S., Carrado K.a., Dutta P.K. Handbook of Layered Materials (CRC, 2004) (ISBN 0824753496) (659s)Document659 pagesAuerbach M.S., Carrado K.a., Dutta P.K. Handbook of Layered Materials (CRC, 2004) (ISBN 0824753496) (659s)Young Jun ChoNo ratings yet

- Prepaación para La Sequía en BrasilDocument12 pagesPrepaación para La Sequía en BrasilDavid RuizNo ratings yet

- 9.admin Rosal Vs ComelecDocument4 pages9.admin Rosal Vs Comelecmichelle zatarainNo ratings yet

- Mpi Model QuestionsDocument4 pagesMpi Model QuestionshemanthnagNo ratings yet

- Safety Data Sheet: Fumaric AcidDocument9 pagesSafety Data Sheet: Fumaric AcidStephen StantonNo ratings yet

- 1980WB58Document167 pages1980WB58AKSNo ratings yet

- The Role of OrganisationDocument9 pagesThe Role of OrganisationMadhury MosharrofNo ratings yet

- Preventing OOS DeficienciesDocument65 pagesPreventing OOS Deficienciesnsk79in@gmail.comNo ratings yet

- Quality in CRDocument10 pagesQuality in CRkaushikcrNo ratings yet

- Gmo EssayDocument4 pagesGmo Essayapi-270707439No ratings yet

- Principles of SOADocument36 pagesPrinciples of SOANgoc LeNo ratings yet

- Lexington School District Two Return To School GuideDocument20 pagesLexington School District Two Return To School GuideWLTXNo ratings yet

- Millionaire Next Door QuestionsDocument7 pagesMillionaire Next Door Questionsapi-360370073No ratings yet

- Brochure 2017Document44 pagesBrochure 2017bibiana8593No ratings yet

- Writing Task The Strategy of Regional Economic DevelopementDocument4 pagesWriting Task The Strategy of Regional Economic DevelopementyosiNo ratings yet

- Project Management: Chapter-2Document26 pagesProject Management: Chapter-2Juned BhavayaNo ratings yet

- Unit 5 Andhra Pradesh.Document18 pagesUnit 5 Andhra Pradesh.Charu ModiNo ratings yet

- Service Manual: Model: R410, RB410, RV410, RD410 SeriesDocument116 pagesService Manual: Model: R410, RB410, RV410, RD410 SeriesJorge Eustaquio da SilvaNo ratings yet

- Icom IC F5021 F6021 ManualDocument24 pagesIcom IC F5021 F6021 ManualAyam ZebossNo ratings yet

- Starkville Dispatch Eedition 12-9-18Document28 pagesStarkville Dispatch Eedition 12-9-18The DispatchNo ratings yet

- Vodafone M2M Integrated M2M Terminals Overview BrochureDocument4 pagesVodafone M2M Integrated M2M Terminals Overview BrochureJamie JordanNo ratings yet

- Fracture and FatigueDocument15 pagesFracture and FatigueZou JiaweiNo ratings yet

- Elliot WaveDocument11 pagesElliot WavevikramNo ratings yet

- GATE General Aptitude GA Syllabus Common To AllDocument2 pagesGATE General Aptitude GA Syllabus Common To AllAbiramiAbiNo ratings yet

- 0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMEDocument4 pages0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMESreedharanPN100% (4)

- CSA Report Fahim Final-1Document10 pagesCSA Report Fahim Final-1Engr Fahimuddin QureshiNo ratings yet

- Document 3Document3 pagesDocument 3AdeleNo ratings yet

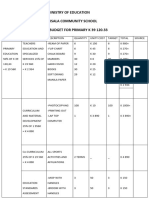

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- Preventive Maintenance - HematologyDocument5 pagesPreventive Maintenance - HematologyBem GarciaNo ratings yet

- Relevant Cost For Decision: Kelompok 2Document78 pagesRelevant Cost For Decision: Kelompok 2prames tiNo ratings yet

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocument3 pages88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNo ratings yet