Professional Documents

Culture Documents

Thermal Production of Phosphoric Acid

Uploaded by

Duy TrầnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Production of Phosphoric Acid

Uploaded by

Duy TrầnCopyright:

Available Formats

PI 0.414 u.414 ... ... ~. ... ... ...

C

SiF.

+

0 1.199

0.072

( 0 )o.54!1

~ . .

(01 u:bir

... 0'0.14

... ...

...

U.lKU

... n:ois

~ . . 0:47,

...

...

...

n*o 0.096 ... ... ... . . ... 0:096 ... ...

v. c. .M. a.nn9 . . ~ ... . ~ . . . ... .. ... ... ... 0.00Q

cnniiow 11*or;rnr>risi ~ ~ ~~- -~~ , .~-S,.ro .*x,i.,x,r r- ___ PlOS B*L.,*cE:-~--

PeOa + 5C Pa + 5C0 1.unii x 0 423 0.423

++c3C= =zcoFe* + 8CCJ

~

x n.m

~

FclOi o.040 o.226 =

COI

creased by increase of temperature iiritil sucli iircrciise ei'leat,,. ( 3 ) The ~J~W'IIWUS may be wliected in elemental state,

a statc of physical change by brillging tile otilcr followed by a step ill wlrich the 0nid:ition and hydration are per-

P*06arid carbon into further contact. This usually r(:- fi,rmcil in r:ont,inuity.

control, since the synclironisinl: of several steps for continuous

The C a M i O I ratio may vary considerably frolri the 3 to 2, as operation demands marc careful design in the solution of

shown, but this combination is known to result in satisfathory prolAems arising than in control of tire individual step func-

operation. As above statcd, this reaction is involved in tions. However, the disconnected processes involve greater

substantially every thermal process that has tiad any degree uttendant costs and processing losses than connected or

of successful employment. Where ptiosplioric acid is the continuous processes. The conversion of a process from

desired final product, there rmrst be siibseqiierit operatioils d separated or intermittent stage operation to one of continuity

reoxidation and hydration. The oxidation fiinetion is usriallv involves ovcrcomine" manv difficulties in desinn.,

usually written etinstruction, and operation before successful outcome re-

~~

Pz 5CO + +

10 ( 0 ) = €'&a 5 0 1 + snlt,s.

Ti<-hvdrat,ion i s ,in-

_ _ i _ ....

ELWXROTEERMAI.

derstood as PRocEss

PrOa + 3Hn0 =

21I*POI

Tlie electrothermal

phosphoric acid proc-

ess inuseatAnniston,

The steps shown in Ala., was conceived

the three f o r e g o i n g upon the above prin-

r e a c t i o n s may be, ciple of greater econo-

and are in different miesfrnm process eon-

instances, conducted tinuity. Its develop

separately or in con- ment to a commcr-

tinuity: cia1 silecess required

s o l u t i o n of m a n y

(1) All threc may

be conducted &s R con- problems not foreseen

tinuous meration. i 11 t 11e disconnected

(2) Ail t h r e e may step process. There

heconducted s e p a - had heen several pre-

vious a t t e m p t s at

production of phos-

lected. then'oxidieed Dhoric acid tlrrouxh I

with separate collection reduetioil of phos-

of the P,Oa u-hieh is ON C ~ a n r . m cPLATFORM

PxrosPtxoktIc! ACIDFuux~ces,1,oo~tnoDOWN PROM

then h y d r a t e d to CRANE phorus, with imme-

H,PO,. All fuinhoes are operetins under full load. diate reoxidation and

liydration in i:o~itinuuosprocess. For various rcasoiis, largely Wl1e11 the pliosphorus and carbun iiionoxide are burned with

technical, none had been sufficiently profitablc t o justify cold air, using about 25 per cent excess, the temperature

continuance in t.lie field. of couibustion is around 1800O C. This heat must be re-

'Po explain more clearly some of the problems encountered moved from these gases sufficiently to bring the tempera-

and solved in the development of the Anniston (Swann ture down to wound 200" C. before the Pros may be hy-

C!orporation) process, a review of the cliemical and tliermal drated to H,PO*. Whether this available heat in the gases

fundamentals is of advantage. In Table I is given a is utilized by transference to the incoming cold charge or

theoretical metallurgical halancc of phosphate-smelting, based other useful purposes, or is wasted in such cooling, there is a

uunn tsnical mate- serious nroblem of

volved in the production of phosphorus by thermal means. tlirougli the walls provide3 a sufficient cooling rate to make a

Where no combustion of tlie pliosphorus and carbon monoxide protective coating from the corrosion products themselves,

occurs in contact with the charge within the furnace, the tm- proili~ceda satisfactory solution.

perature of the escaping gases from the furiiaee is, as shown,

about 200" C. However, if the gases are burned in contact FURKACE

~l~ECl~l% lC AS ~ ' H l l ~ I ~ H A l ~ E - ~ ~ ~ DVEHICLE

UcTlos

with the top surface of the charge, a portion of the heat evolved

from such combustion will raise the temperature of the in- The electric furnace its a pliospliate-reduction vehicle has its

coming and descending charge; hence, it will cause tlie gases advantages, not so much in tlie usually assumed purpose of

escaping through t.he charge t o attain 5 liiglier temperature. high-tempcrature producing capacity, as in its reserve quanti-

tative lreat capacity, wliicli is essential for the thermal reduc-

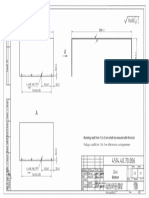

'IABLE 11. THEORETICAL

THERMAL

BALANCE

OF SMELTING

OF tion of pliosphorus from natural phosphate. To illustrate

PH~WIIATE

ROCK this essential point, note the tliermoehemistry of tiie principal

(Per pound Pros charged) reaction,

PaosenATr E30CI- Em-

FAemn

3CitO - 2SiO*

I<**VTl"r; ROCB THERYiC THEBYLC

Polrnda P. C . U." 1'. C. lJ. P. C. ti. _ _ ~ ~+~5~ + ZSiOt = f: + .5CO

(CuO)~P~*.

-

+

01'3200 392000 14.5600 832050

~

Malcoular heat requirement = 323950 P. C. U.

or, per pound of I'dh = 2280P. u. c.

The exothermic reactions of fomiation of carbom monoxide

fnmi the reducing carbon and that of the combination of

lime and silica involved in the fusion, above mentioned, to

provide the feature of tile liquid phase for complete reduc-

tion of the PIOr, occur sinmltaneously wit11 the reduction per

se; lienee, they reduce the roquireinent by tliat amount. I t

mmt, liowcvr?r, be borne in mind that tlre 2280 1'. C. U.,

wlrieh is about 54 per cent of the total heat required per

unit of PzO,involved, must be supplied a t a temperature

Pound Centigrade uuiw. of around 1300" t o 1400" C. in order t.o perform any work in

tiie required reduction. In practical furnacing operations,

The combustion of tlic plii~pliorusarid carboii m o ~ i ~ ~ x ithis

d ~ fundamental requiremerit demands a reservoir of heat

evolved in the above typicd example will develop lieat as enerLy available at temperatures above 1300" C. When

follows: such lieat energy is derived from fuel combustioil, with tbe

P, to P&: 0.414 x 58Y5 = 2440 P. C. U. (pound Centigrade difficulty of ~naintaiuingsuch a reserve supply with requisite

units) thermal liead, it is necessary to carry such reserve at the

CO t o CO,: I , 199 X 2430 = 1'. C. U. risk of lienvy condiiction and radiation losses, especially if

Tatid heat evolved 5353 P. c. I,'. convent,ional types of fiirriaces are employed. With the heat

5353 == 1,263 times energy theoreticall>-I'equirad for re- t.rsnsfer from combustion gases, the temperature of the source

Then

4229 actions within fnmnee falls rapidly wit11 effective transfer, so that, iinless the reser-

374 I N D U S T R I A L ,4N D E N G I N E E R I N G C H E M I S T R Y Vol. 21, No. 4

voir contains available energy far in excess of that required for In addition to the difficulties of finding refractories t o with-

the reactions, the temperature of the gases from which the stand such temperatures, there is one outstanding feature that

reaction demand is supplied may drop to the point a t which has defeated the greater number of efforts a t practical applica-

such reaction stops. The heat useful in raising the tempera- tion of heat transfer in this case. This lies in the avidity of

ture of the charge consumes only about 40 per cent of the total the nascent Pz06for the compounds in the charge (Ca0)3P205

required energy in phosphorus reduction. This may all be and silica, probably according to the reactions

supplied up to 1300" C. After such raise in temperature of

the charge is effected,no additional heat supply is of any value +

PtOs Si02 = SiPIO,

unless it be kept available a t above 1300" C. This probably +

2P105 4(Ca0)3P20j= 6Ca2P20,

explains the failures resulting from many efforts a t fuel-fired

methods of phosphate smelting, or the low thermal economy These compounds and analogs have lower melting points

attained in many cases. than other constituents of the charge; hence, when formed on

I n the electric furnace the reservoir of available heat a t the the surface of aggregates thereof, they produce a cohesion of

required thermal head lies in the power source, since the the mass of the charge which bodily prevents further descent

transformation from electrical energy to heat energy may be into the fusion zone and effectively stops operation. Where-

had instantly and without temperature limitation. ever the heat transfer from the combustion gases bearing

DISADVANTAGES OF ELECTRICAL METHOD PZOSis attempted by convection through contact, with the

entering charge, these reactions will defeat the object. It

With the above described specific advantage in the electrical is therefore necessary that the transfer be made without

method also lies a possible disadvantage, not discernible actual physical contact of the nascent PzO6 with the (CaO)a-

except through actual experience. This consists in the disas- P206 and silica materials of the charge, in order that the

trous practical effects resulting from excessive temperature in available benefits may be derived. Partial heat transfer has

phosphate smelting. When the temperature of a phosphate- been accomplished from this available source. There are yet

smelting charge appreciably exceeds the 1400" C. essential a number of practical problems to be solved to carry the

for reduction, a volatilization phenomenon occurs in which available heat economy to the ultimate degree. The newer

the usually nonvolatile constituents, such as lime, silica, developments in refractories provide means for approaching

alumina, magnesia, etc., are carried over with the phosphorus the problem with greater hope of success. The thermal

and carbon monoxide. When such constituents take the processes for phosphoric acid production have yet great

fume state in presence of the oxidation of the phosphorus and possibilities in economy. The concentration and purity of the

carbon monoxide in the gas phase, there results a series product offer distinct advantages in production of phosphate

of complex compounds of Pn06with the silica, lime, etc., salts demanded in the impending developments in the chemical

that renders collection and especially purification of the re- fertilizer industry.

sulting acid practically impossible, thus defeating the pur- The relative fertilizing value of plant food compounds can

pose of the operation. This difficulty asserted itself in the only be known with scientific exactness when substantially

early stages of the Anniston operations to such an extent as to pure compounds are available. Nitrogen and potassium

threaten defeat of the entire project. This was overcome compounds are being offered in the fertilizing field relatively

through the accumulative effect of a number of governing pure and free from minor elements, the influence of which is

factors being maintained under exact control. These include still subject to question. P z O ~compounds in any degree of

sizing; proportioning and proper mixing of the materials; purity are available only to a very limited degree for this

maintaining of exact depth of charge; especially avoiding field. When such are available in unlimited quantities, there

accumulation of carbon in the reducing zone beyond that will probably result some beneficial discoveries and results

necessary for reduction, as well as preventing arcing a t any in agricultural chemistry. Development of the obvious

local points; and regulating relative aggregates of the various possibilities in the thermal phosphoric acid processes carry

materials according to resistivity necessary. contributing potentialities of great importance in agricultural

The above-noted fact, that the heat of combustion of the economics.

evolved gases is around one and a quarter times that necessary

for the net smelting-energy requirement, naturally accelerates LITERATURE

CITED

efforts toward utilization of this heat through returning it t o

the charge By use of preheated combustion air, the initial (1) Jacobs e t al., IND. ENG.CHEM.,20, 1240 (1928).

(2) Jacobs et al., I b i d . , 21, 1126 (1929).

temperature of combustion of the gases bearing PZOSmay (3) Pike, I b i d . , 22, 242 (1930).

be had over 2000" C., thus giving a thermal head adequate (4) Ross et al., I b i d . , 16, 563-6 (1924).

to transfer a considerabIe portion of the energy to the charge

in the reduction range. February 3, 1932.

RECEIVED

SULFURIN THE UNITEDSTATESIN 1931. Production, ship- Duval Texas Sulphur Co. a t Palangana Dome, Benavides,

ments, and exports of sulfur in 1931 showed marked decreases Duval County; Freeport Sulfur Co. at Bryan and Hoskins

in comparison with 1930, according t o the United States Bureau Mounds, Freeport, Brazoria County; and the Texas Gulf

of Mines. Sulfur production amounted t o 2,128,930 long tons, Sulphur Co. at Long Point Dome, Long Point, Ft. Bend County,

a decrease of 17 per cent from the record output of 2,558,981 Big Hill Dome, Gulf, Matagorda County, and a t Boling Dome,

tons in 1930. Shipments declined from 1,989,917 tons, valued Xewgulf, Wharton County:

at about $35~,800,000,in 1930, t o 1,376,526 tons, valued a t The average quoted price for sulfur was unchanged at $18

$24,800,000, in 1931, or 31 per cent both in quantity and a ton €. 0 . b. mines throughout the year. Open prices were $1

in value, and were the smallest recorded since 1922. Stocks t o $3 a ton higher and prices for sulfur exported n-ere given as

of sulfur a t the mines increased steadily and amounted t o $22 a ton f . a. s. Atlantic ports.

3,250,000 tons on December 31, 1931, a net gain of 753,000 KO imports of sulfur or sulfur ore were recorded for the year

tons for the year. These stocks n-ere approximately 250,000 1931. Exports of sulfur or brimstone in 1931 totaled 407,586

tons higher than the previous record stocks on hand at the long tons, compared with 593,312 tons in 1930, a decrease of

mines at the end of 1923. 31 per cent. Exports t o all the countries that receive important

As in 1930, Texas was the only sulfur-producing state. The quantities of American sulfur, with the exception of those to

properties that contributed t o this production were those of the France, showed large decreases.

You might also like

- Microsilica StandartsDocument1 pageMicrosilica StandartsKaan TekinturhanNo ratings yet

- T.Btiteje D: Oii Globat Bas1S'Are The At.5Mcii - Io and Thecs /. A235Document1 pageT.Btiteje D: Oii Globat Bas1S'Are The At.5Mcii - Io and Thecs /. A235Kaan TekinturhanNo ratings yet

- สัตวานุกรมวิธานพร้อมตัวอย่างการศึกษาของไรDocument104 pagesสัตวานุกรมวิธานพร้อมตัวอย่างการศึกษาของไรOrmphipod WongkamhaengNo ratings yet

- Adobe Scan 11 May 2023Document1 pageAdobe Scan 11 May 2023Su SiNo ratings yet

- Book 4 Jan 2024Document17 pagesBook 4 Jan 2024krishivpatel7108No ratings yet

- G&Rgloinqry-Jted: Erojitp"Jers-Iltr Iat"RyilidisffiDocument1 pageG&Rgloinqry-Jted: Erojitp"Jers-Iltr Iat"RyilidisffiDeepak MalikNo ratings yet

- CDC - Guide To Vaccine ContraindicationsDocument34 pagesCDC - Guide To Vaccine ContraindicationsJean-Paul de MontréalNo ratings yet

- Computations - OR Sep 7, 2022Document2 pagesComputations - OR Sep 7, 2022Hera ArgeiaNo ratings yet

- CUC6300Document10 pagesCUC6300Babis ZevgarasNo ratings yet

- Adobe Scan 10 Nov 2022Document11 pagesAdobe Scan 10 Nov 2022Bhumi PatelNo ratings yet

- 1993 - Papailiou - The Structure of Water-Air Bubble Grid Turbulence in A Square DuctDocument5 pages1993 - Papailiou - The Structure of Water-Air Bubble Grid Turbulence in A Square DuctLeizaNo ratings yet

- Thames Estuary: Pollution and Recovery: CASE 7.1Document34 pagesThames Estuary: Pollution and Recovery: CASE 7.1Suriyah SivakumarNo ratings yet

- Scan 27 Jan. 2018Document5 pagesScan 27 Jan. 2018PkNo ratings yet

- 1.7 Dimensions Threads: Basie 1.7.1 NPTFDocument1 page1.7 Dimensions Threads: Basie 1.7.1 NPTFKristian Raphael BVNo ratings yet

- Ansi B1 20 3 17Document1 pageAnsi B1 20 3 17Kristian Raphael BVNo ratings yet

- Ansi B1 20 3 17Document1 pageAnsi B1 20 3 17Kristian Raphael BVNo ratings yet

- Ansi B1 20 3 17Document1 pageAnsi B1 20 3 17Kristian Raphael BVNo ratings yet

- Terirem de Petru BerechetDocument3 pagesTerirem de Petru BerechetCiprian ConstantinNo ratings yet

- 4514.40.70.006 Rev0Document1 page4514.40.70.006 Rev0noah alsadiNo ratings yet

- May 2013Document48 pagesMay 2013Dylan EllulNo ratings yet

- Screenshot 2023-05-28 at 9.06.37 AMDocument3 pagesScreenshot 2023-05-28 at 9.06.37 AMnagaraja nagaNo ratings yet

- Loewenstein, K 1979 Teoría de La Constitución 2da Ed BarcelonaDocument312 pagesLoewenstein, K 1979 Teoría de La Constitución 2da Ed BarcelonapolicarpoxitlalyhernqndezNo ratings yet

- Bruno McGinnSmith W2 1994 (GA-04)Document1 pageBruno McGinnSmith W2 1994 (GA-04)Albany Times UnionNo ratings yet

- Psychological Warfare Operational Deficiencies Noted in Korea - A Study PDFDocument125 pagesPsychological Warfare Operational Deficiencies Noted in Korea - A Study PDFJerry BuzzNo ratings yet

- Í 1 E ZPHQ - Qocdíq' L: I TtnicukljpvdaDocument1 pageÍ 1 E ZPHQ - Qocdíq' L: I TtnicukljpvdaBeto VillaNo ratings yet

- Operation Maintenance:: . : R Eitability: Includes:FacforsDocument1 pageOperation Maintenance:: . : R Eitability: Includes:FacforsMashaelNo ratings yet

- Emergency Switchboard PDFDocument162 pagesEmergency Switchboard PDFPaul Lucian Ventel100% (3)

- 24DBE92C58EA2F4BDocument4 pages24DBE92C58EA2F4BClaudia FrontedduNo ratings yet

- 24dbe92c58ea2f4b PDFDocument4 pages24dbe92c58ea2f4b PDFClaudia FrontedduNo ratings yet

- BH No. 1Document3 pagesBH No. 1debapriyoNo ratings yet

- Guidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance) Reprint - 2013Document111 pagesGuidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance) Reprint - 2013ward dhapakhelNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-56Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-56Fornvald TamasNo ratings yet

- Adobe Scan 06 Sep 2021Document6 pagesAdobe Scan 06 Sep 2021Gali Pavan Kumar ReddyNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-37Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-37Fornvald TamasNo ratings yet

- 4005 Solutions V POWDERDocument1 page4005 Solutions V POWDERSereibot YemNo ratings yet

- Ligeti, Sq2 IIIDocument4 pagesLigeti, Sq2 IIIRiccardo PeruginiNo ratings yet

- Pipe Fitters GuideDocument86 pagesPipe Fitters GuideFerdie UlangNo ratings yet

- Chapter 13Document19 pagesChapter 13Vivi FathiyaturrahmahNo ratings yet

- Pfaff 1035.Document17 pagesPfaff 1035.Mátis ViktóriaNo ratings yet

- Scan May 11 2020 3Document4 pagesScan May 11 2020 3api-511711329No ratings yet

- CH 9 Rev1Document13 pagesCH 9 Rev1Ahmed Musa AlShormanNo ratings yet

- PPS CourseworkDocument14 pagesPPS CourseworkIanNo ratings yet

- Guidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance)Document111 pagesGuidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance)anjan luitelNo ratings yet

- Merging Files MZB - Ijzh STR PDF - MergedDocument3 pagesMerging Files MZB - Ijzh STR PDF - MergedLenny Fuji HarjatiNo ratings yet

- Assignment Test 03 - Omkar - 2020164Document3 pagesAssignment Test 03 - Omkar - 2020164Omkar PatilNo ratings yet

- Re.o.d: N - 1q, - 00: V Ra.p "Document2 pagesRe.o.d: N - 1q, - 00: V Ra.p "V phonhNo ratings yet

- EN18383362 Cost ManagementDocument1 pageEN18383362 Cost ManagementSulaksha WimalasenaNo ratings yet

- Amy Hall Civil Complaint Against The Brookline Police DepartmentDocument13 pagesAmy Hall Civil Complaint Against The Brookline Police DepartmentAbby PatkinNo ratings yet

- SecDocument4 pagesSecanjalikumarigupNo ratings yet

- Ipc 33 590011 3Document500 pagesIpc 33 590011 3LeandroCamposNo ratings yet

- Fundamental Studies On The Mechanism of Ultrasonic WeldingDocument56 pagesFundamental Studies On The Mechanism of Ultrasonic WeldingStupinean LarisaNo ratings yet

- Perforated Pipe Underdrains For Rapid Sand FiltersDocument19 pagesPerforated Pipe Underdrains For Rapid Sand Filters305773253No ratings yet

- Ultimate Bearing Capacity of Foundation On Clays Meyerhof PDFDocument3 pagesUltimate Bearing Capacity of Foundation On Clays Meyerhof PDFNadherNo ratings yet

- TPG Insulator FIADocument8 pagesTPG Insulator FIAApongNo ratings yet

- Dok Laporan 2019-09-10 21.19.56Document8 pagesDok Laporan 2019-09-10 21.19.56Nur RahmaNo ratings yet

- Adobe Scan 25 Jan 2024Document2 pagesAdobe Scan 25 Jan 2024sureshgandhiNo ratings yet

- Multiple Choice Practice Test PDFDocument104 pagesMultiple Choice Practice Test PDFKristopher CharlesNo ratings yet

- Design and Construction Standards: Technical SpecificationDocument9 pagesDesign and Construction Standards: Technical SpecificationolivaresjhonNo ratings yet

- Syl Lab Us AgriculturalDocument14 pagesSyl Lab Us AgriculturalashkansoheylNo ratings yet

- N24-Atlantic Water HeatersDocument28 pagesN24-Atlantic Water HeatersPatrick MorcosNo ratings yet

- Air Cooled Heat Exchanger !Document17 pagesAir Cooled Heat Exchanger !RehinaNo ratings yet

- Physics: Googol-XiiiDocument22 pagesPhysics: Googol-Xiiiayush ayushNo ratings yet

- Cryogenic MachiningDocument16 pagesCryogenic MachiningSagar MoreNo ratings yet

- Solutions Manual - Chapter 4Document144 pagesSolutions Manual - Chapter 4Mauricio MenezesNo ratings yet

- Commercial Air Conditioners: Water Cooled Screw ChillerDocument16 pagesCommercial Air Conditioners: Water Cooled Screw ChillerYosephanderNo ratings yet

- Heat Loss CalculationDocument12 pagesHeat Loss CalculationRajaramNo ratings yet

- 2 1diurnalenergybudgetsDocument2 pages2 1diurnalenergybudgetsAraijan AbaiNo ratings yet

- Chiller Maintenance ListDocument1 pageChiller Maintenance Listadnan100% (7)

- 608 750GDocument2 pages608 750GbioarquitecturaNo ratings yet

- All 10Document11 pagesAll 10YacelinNo ratings yet

- Equipment ScheduleDocument53 pagesEquipment ScheduleRaju KsnNo ratings yet

- Datasheet ET7 16 F1 4040 TA RT W6Document3 pagesDatasheet ET7 16 F1 4040 TA RT W6Sermed IngenierosNo ratings yet

- Chapter 3 ConvectionDocument137 pagesChapter 3 ConvectionHải MâyNo ratings yet

- Unit 3 - 1-D Heat Conduction (Part 1) CDocument15 pagesUnit 3 - 1-D Heat Conduction (Part 1) CabhayNo ratings yet

- BRC2C51Document1 pageBRC2C51Lei ZhangNo ratings yet

- ZD Pichler Pkom4 enDocument4 pagesZD Pichler Pkom4 enLe nabarroNo ratings yet

- EMAG W01 RodHeatingDocument16 pagesEMAG W01 RodHeatingMiguel Ángel ArizaNo ratings yet

- 05di Dscsasc 30Document3 pages05di Dscsasc 30Erdinc KlimaNo ratings yet

- DAIKIN General Catalogue 2015 Part2Document198 pagesDAIKIN General Catalogue 2015 Part2Nemesis2103No ratings yet

- Multi Max Inverter AHRI CertificatesDocument7 pagesMulti Max Inverter AHRI CertificatesdimashrnndzNo ratings yet

- Total Air Solution Provider: LG Electronics VietnamDocument8 pagesTotal Air Solution Provider: LG Electronics VietnamCong VietNo ratings yet

- Addma D 16 00022Document27 pagesAddma D 16 00022chethanNo ratings yet

- W bwm22106420en-GB02Document16 pagesW bwm22106420en-GB02Jakaria JakaNo ratings yet

- Steam Trap TroublesDocument6 pagesSteam Trap TroublesAlexander100% (1)

- On Solar Vapour Absorption Refrigeration System: Seminar ReportDocument16 pagesOn Solar Vapour Absorption Refrigeration System: Seminar ReportlokeshjakharNo ratings yet

- Air Distribution System Specification GuideDocument29 pagesAir Distribution System Specification GuidecaroweNo ratings yet