Professional Documents

Culture Documents

Method Statement & Risk Assessment For Pressure Testing

Uploaded by

chandanprakash30Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement & Risk Assessment For Pressure Testing

Uploaded by

chandanprakash30Copyright:

Available Formats

)

ST

EA

LE

D

ID

(M

RS

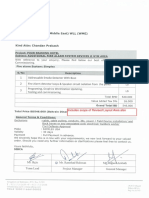

METHOD STATEMENT & RISK ASSESSMENT FOR

IO

PRESSURE TESTING WORKS

R

TE

IN

R

LO

O

RC

TE

A

W

Private & Confidential Document of WME 1 5/14

Method Statement for Pressure Testing

Purpose

The purpose of this method statement is to make sure that Hydro-static pressure testing of chilled water

piping system is done safely as per client requirements and applicable standards.

Scope of Work

This method statement covers the Hydro-static testing of mild steel pipework at the project and to be

followed for all piping works at site.

Prior to the start of the hydro-static pressure testing all other works on the system shall have been

snagged by construction team and de-snagged and signed off by the quality department.

)

ST

Pressure Testing Method of Statement

EA

Permit to work for pressure test to be obtained from safety department.

LE

All open flanged, valved or screwed ends will be blanked off.

D

The fill point will be installed at the lowest point of the system, and a valved vent at the highest

ID

point of the system to be tested. The vent will be piped to a drain point.

(M

Pressure gauges with valid calibration certificates/stickers will be fitted adjacent to the pressure

RS

pump.

Pipework will be filled with water sufficiently in advance of the test to allow it to come to room

IO

temperature so that any sweating can evaporate. When the systems sufficiently filled the vent

R

valve will be opened and allowed to run freely for a period of 5 minutes to ensure all the air is

TE

out of the system, at that point the valve will be closed.

IN

When the system is full and vented the test rig will be linked to the system and the pressure

R

increased to the required system test pressure, as required by the specification 1.5 the operating

LO

pressure. When the test pressure is reached the valve at the fill point will be closed for a period

of 15 minutes to stabilize the system, the gauges will be checked to see if any pressure loss has

O

occurred due to the stabilization, if so the test rig will be applied to bring the system test pressure

RC

back up to the specification requirements. Upon re-pressurization the test rig shall than be

TE

dismantled from the system.

A

Care will be taken at this point to record the ambient room temperature of the start and finish

W

time of the test. The duration of the test will be 24 hours and temperatures should be recorded

frequently.

A visual inspection of joints will take place during the test period to check for leaks, if any

leakage found the test will be aborted. After the leakage is rectified, the above procedure will be

repeated for a re-test to take place.

On satisfactory completion of the test, witnessed by the client, the pressure will be released

through the vent pipe. The system then shall be drained. Pressure testing report shall be witnessed

by the client, the pressure will be released through the vent pipe. The system then shall be

drained. Pressure testing report shall be prepared and signed by the client or any other concerned

party.

Private & Confidential Document of WME 2 5/14

Health & Safety Requirements

In ordered to ensure that all hydrostatic testing of chilled water works to takes place in a safe manner the

following shall be considered

Spot safety meeting will be done by competent engineer to the working group.

Fitting, thread and connections will be checking up for broken or unthreaded parts.

To make sure everyone in testing area knows that the pressure test will be done and proper tags to

be displayed.

Ensure that all pipes are fastened properly.

Warning signs will display in both English and the local language

Valves operations to be understood by operator before pressure test starts

Restrict the access for common people to testing area, use communication system for

announcements etc.

Only authorized persons are allowed to check the pipes during the pressure in progress

)

ST

After test is complete the pressure should be released slowly and open all valves once the pressure

EA

is zero, to ensure that there is no pressure trapped anywhere in the system.

LE

D

ID

(M

RS

RIO

TE

IN

R

LO

O

RC

TE

A

W

Private & Confidential Document of WME 3 5/14

RISK ASSESSMENT FORM FOR PRESSURE TESTING

RISK BEFORE RESIDUAL RISK AFTER

SL NO HAZARDS CONTROL MEASURE CONTROL MEASURES NEEDED TO REDUCE RISK IMPLEMENTING

IN PLACE CONTROL MEASURES

1. Pipe Fitter Shall Be Trained And Competent.

2. Plumber Shall Be Trained And Competent.

3. Work Crews Will Use Appropriate PPE. (Hand Gloves, Safety Goggles).

4. STARRT Talks For Crews by supervisor Involve In Pressure Test.

)

5. Ensure Appropriate Barricades (Tape) & Sign Boards Placed Around The Area During

ST

Hydro Test, Gravity Water

1 High Pressure Testing. Low

Test, High Pressure Leak

EA

6. Proper Communication during Pressure Testing.

7. Training for Proper Use of Hydro Test Manual and Hydro Test Booster Pump.

LE

8. Tools Will Be Used Only For Their Intended Purposes & Inspect Prior To Start Of Work.

9. First Aid Kit Will Be Available.

D

10. Pressure relive valve to be installed.

ID

1. All operatives will be trained in the correct and safe manual handling techniques.

(M

Manual Handling

2. Weights will be kept to safe levels as far as reasonably practicable. Heavy loads will be

Potential injuries associated

RS

2 Medium broken down if possible. Low

with manual handling tasks

3. Operatives know via their training only lift what is within their own capabilities and to ask for

and incorrect lifting

O

assistance if required

RI

Use of tools and equipment 1. All tools are visually inspected before use

TE

Potential injury associated 2. Operatives are responsible to keep tools in good condition and report any defects. Faulty

3 Medium Low

with use of hand tools – tools will be replaced.

IN

knocks and abrasions 3. Specific equipment/tools are only used by competent users.

R

Minimal hot works take place

LO

1. Hot works is only allowed under a permit to work system (PTW) – Welders will adhere to

Hot Works PTW controlled by Engineer In-charge at site

O

4 Potential injuries associated High 2. Full welding face shields provided for welders. Low

RC

with hot works 3. Only skilled welders will be allowed for welding.

4. Client/Customer fire procedure will be adhered to.

TE

5. Hot Work guidance available.

A

Slips and Trips 1. Operatives will clear up any rubbish as they go.

W

5 Potential injuries associated Medium 2. All spillages will be cleared up immediately and spill kits will be kept handy. Low

with slips and trips 3. Equipment and product will be stored safely while working on site.

Private & Confidential Document of WME 4 5/14

You might also like

- Task Sheet - Replace and Pressure Test Pipework - Kensington OlympiaDocument4 pagesTask Sheet - Replace and Pressure Test Pipework - Kensington OlympiaLeeJB09No ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- Piping Hydrotest ProcedureDocument9 pagesPiping Hydrotest Procedurewendypost73100% (1)

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Atmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsDocument2 pagesAtmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsBen Hamed KhaterNo ratings yet

- JX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionDocument21 pagesJX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionAmyNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- M-Series 150Document20 pagesM-Series 150agus sutiawanNo ratings yet

- Electric Pneumatic Level Indicating System Instruction ManualDocument12 pagesElectric Pneumatic Level Indicating System Instruction ManualGilbert San Jose0% (1)

- Fixed Nozzle Desuperheater ManualDocument12 pagesFixed Nozzle Desuperheater ManualjabalpuramitNo ratings yet

- Ensuring LNG Liquefaction Facilities Sys PDFDocument12 pagesEnsuring LNG Liquefaction Facilities Sys PDFdhurjatibhuteshNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Method Statement For Hydrostatic Pressure Testing of Chilled Water PipeworkDocument3 pagesMethod Statement For Hydrostatic Pressure Testing of Chilled Water Pipeworkamg007100% (3)

- Slimline Install RevBDocument14 pagesSlimline Install RevBClaudio CundariNo ratings yet

- 038CEMS TestingDocument6 pages038CEMS TestingYudha Andrie Sasi ZenNo ratings yet

- Sela PassDocument11 pagesSela PassAlsayed Rabiea MiesalamNo ratings yet

- Petrochen - 4-10Document2 pagesPetrochen - 4-10pppppp5No ratings yet

- Pressure Testing & QC Test PackDocument10 pagesPressure Testing & QC Test Packravi00098No ratings yet

- SATR-A-2007Document2 pagesSATR-A-2007razzak.me.enggNo ratings yet

- Hydrotesting of ShellDocument4 pagesHydrotesting of Shellmsaqibraza93No ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Calibration and leak testing of Saudi Aramco instrumentation systemsDocument10 pagesCalibration and leak testing of Saudi Aramco instrumentation systemsNAVANEETHNo ratings yet

- Stackflow 200: SP IPDocument2 pagesStackflow 200: SP IPHuidulescu AndreiNo ratings yet

- TIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureDocument16 pagesTIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureMechanical Static WRKNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007Shahzad HussainNo ratings yet

- PRDS PRS DSH Systems Operation and Installation ManualDocument125 pagesPRDS PRS DSH Systems Operation and Installation Manual윤병택No ratings yet

- FE900 - Field Testing of FansDocument6 pagesFE900 - Field Testing of FansAhmad NilNo ratings yet

- Safety Valve Test 2.0: The Innov AtionDocument8 pagesSafety Valve Test 2.0: The Innov AtionKauffman LOKONo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- Relay Testing ProcedureDocument50 pagesRelay Testing Procedureunnikrish05No ratings yet

- 02 ESP Operation and MaintenanceDocument38 pages02 ESP Operation and MaintenancerandyNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Laptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesDocument3 pagesLaptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesMuhammad RezaNo ratings yet

- FE 900 Field Testing of FansDocument6 pagesFE 900 Field Testing of FansAvery OppegardNo ratings yet

- Sprinkler Test 2Document5 pagesSprinkler Test 2nag_2004No ratings yet

- Visual and Technical Checking of I&C SystemsDocument13 pagesVisual and Technical Checking of I&C SystemszhangyiliNo ratings yet

- RPM1600 Series Room Pressure Monitors: Installation InstructionsDocument19 pagesRPM1600 Series Room Pressure Monitors: Installation Instructionsarman71No ratings yet

- PP802-TN Leak TestDocument5 pagesPP802-TN Leak TestGerardo SepulvedaNo ratings yet

- BENCH TEST PROCEDURE FOR THE PERFORMANCE OF POWER STEERING PUMPDocument13 pagesBENCH TEST PROCEDURE FOR THE PERFORMANCE OF POWER STEERING PUMPm.srinivasanNo ratings yet

- Piping For Process Plants Part 6 PDFDocument7 pagesPiping For Process Plants Part 6 PDFSandra MArrugoNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- Oden At: Primary Current Injection Test SystemDocument7 pagesOden At: Primary Current Injection Test Systemidris_pmNo ratings yet

- Saudi Aramco Pre-Pressure ChecklistDocument2 pagesSaudi Aramco Pre-Pressure ChecklistnadeemNo ratings yet

- Firefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFDocument5 pagesFirefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFjajakaNo ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Sistema de Prueba de Corrosión - PCMSRMDocument2 pagesSistema de Prueba de Corrosión - PCMSRMjhoger2012No ratings yet

- Testing and Commissioning Method Statement Procedure For Argonite SystemDocument2 pagesTesting and Commissioning Method Statement Procedure For Argonite SystemHumaid ShaikhNo ratings yet

- Hydro test processDocument7 pagesHydro test processjeswinNo ratings yet

- Prefunctional ChecklistsDocument37 pagesPrefunctional Checklistsrenjithv_4100% (1)

- ChecklistDocument1 pageChecklistnaveentsipvtNo ratings yet

- Tutorial 1a:: CHG 501: Process Dynamics and ControlDocument14 pagesTutorial 1a:: CHG 501: Process Dynamics and ControlAanu OlumuyiwaNo ratings yet

- Portable Pneumatic Calibrator SERIES 65-120: Technical InformationDocument4 pagesPortable Pneumatic Calibrator SERIES 65-120: Technical InformationNyoman RakaNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- 2.0 Pressure TestingDocument11 pages2.0 Pressure TestingHATEMNo ratings yet

- PCSU Chapter 6Document16 pagesPCSU Chapter 6rawanisephiaNo ratings yet

- Method Statement & Risk Assessment For Hot Works WeldingDocument4 pagesMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- Ladders: Generic Risk Assessment FormDocument3 pagesLadders: Generic Risk Assessment Formvasanth pugazhendhiNo ratings yet

- Method Statement For Roller ShutterDocument2 pagesMethod Statement For Roller Shutterchandanprakash30100% (1)

- Method Statement & Risk Assessment For Roller ShutterDocument3 pagesMethod Statement & Risk Assessment For Roller Shutterchandanprakash30100% (1)

- Risk Assesment Form For Pressure TestingDocument1 pageRisk Assesment Form For Pressure Testingchandanprakash30No ratings yet

- Flooring Method Statement and Risk AssessmentDocument5 pagesFlooring Method Statement and Risk Assessmentchandanprakash300% (1)

- Risk Assesment Form For False Ceiling WorksDocument1 pageRisk Assesment Form For False Ceiling Workschandanprakash30No ratings yet

- Flooring Method Statement and Risk AssessmentDocument5 pagesFlooring Method Statement and Risk Assessmentchandanprakash300% (1)

- Method Statement For Pressure TestDocument3 pagesMethod Statement For Pressure Testchandanprakash30No ratings yet

- Risk Assesment Form For Flooring WorksDocument1 pageRisk Assesment Form For Flooring Workschandanprakash30No ratings yet

- Method Statement& Risk Assesment For Demolition WorksDocument5 pagesMethod Statement& Risk Assesment For Demolition Workschandanprakash30No ratings yet

- Method Statement & Risk Assesment For Flooring WorksDocument6 pagesMethod Statement & Risk Assesment For Flooring Workschandanprakash3033% (3)

- Demolition of Wainwright Primary School Method StatementDocument172 pagesDemolition of Wainwright Primary School Method StatementhrithikvNo ratings yet

- Method Statement& Risk Assesment For Demolition WorksDocument5 pagesMethod Statement& Risk Assesment For Demolition Workschandanprakash30No ratings yet

- Method Statement & Risk Assesment For Flooring WorksDocument6 pagesMethod Statement & Risk Assesment For Flooring Workschandanprakash3033% (3)

- Method Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksDocument17 pagesMethod Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksSiti Noor Rahimah IbarahimNo ratings yet

- Risk Assesment Form For Welding WorksDocument1 pageRisk Assesment Form For Welding Workschandanprakash30No ratings yet

- Risk Assesment Form For Demolition WorksDocument1 pageRisk Assesment Form For Demolition Workschandanprakash30No ratings yet

- WORK AT HEIGHT RISK ASSESSMENT FORMDocument1 pageWORK AT HEIGHT RISK ASSESSMENT FORMchandanprakash30No ratings yet

- Includes Scope of Revised Layout Area AlsoDocument1 pageIncludes Scope of Revised Layout Area Alsochandanprakash30No ratings yet

- Demolition of Wainwright Primary School Method StatementDocument172 pagesDemolition of Wainwright Primary School Method StatementhrithikvNo ratings yet

- Risk Assesment Form For ScaffoldingDocument1 pageRisk Assesment Form For Scaffoldingchandanprakash30No ratings yet

- Bill of Quantities for Ceiling, Sections, and Shop Front MaterialsDocument2 pagesBill of Quantities for Ceiling, Sections, and Shop Front Materialschandanprakash30No ratings yet

- WORK AT HEIGHT RISK ASSESSMENT FORMDocument1 pageWORK AT HEIGHT RISK ASSESSMENT FORMchandanprakash30No ratings yet

- BBS FormatDocument112 pagesBBS Formatchandanprakash30No ratings yet

- Method Statement For Roller ShutterDocument1 pageMethod Statement For Roller Shutterchandanprakash30100% (5)

- Draft Invoice - Zuba CafeDocument1 pageDraft Invoice - Zuba Cafechandanprakash30No ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- Cost Forecasting FormatDocument102 pagesCost Forecasting Formatchandanprakash30No ratings yet

- BBC Product AdvantagesDocument6 pagesBBC Product Advantagesfomed_twNo ratings yet

- 9781315173078Document187 pages9781315173078John Leandro ReyesNo ratings yet

- Tudor h705 Final Specification Plush Collection - 3 09.08.2023Document2 pagesTudor h705 Final Specification Plush Collection - 3 09.08.2023Sastivel SNo ratings yet

- Modern CV Template StyleDocument2 pagesModern CV Template StyleRedi Joel Córdova ArbietoNo ratings yet

- Knowledge Management of Glendy, Aziel, Thor, KumalDocument7 pagesKnowledge Management of Glendy, Aziel, Thor, KumalrekcuftnucNo ratings yet

- Comparison of Rigid Pavement Thickness Design SystemsDocument168 pagesComparison of Rigid Pavement Thickness Design Systemskamalnath100% (1)

- GLA University - Student's No Dues DetailsDocument2 pagesGLA University - Student's No Dues DetailsRishi JakarNo ratings yet

- Mse 104 HW#4Document2 pagesMse 104 HW#4Dendi ZezimaNo ratings yet

- Revit 2020 StructureDocument36 pagesRevit 2020 StructurejonrasNo ratings yet

- Quick Start GuideDocument3 pagesQuick Start Guideswornavidhya.mahadevanNo ratings yet

- Consulting IndustryDocument34 pagesConsulting Industryaayushpahuja2824No ratings yet

- Stockhausen Cuatro Criterios de La Música ElectrónicaDocument44 pagesStockhausen Cuatro Criterios de La Música ElectrónicaFa SolisNo ratings yet

- Time Management - Anthony RobbinsDocument55 pagesTime Management - Anthony RobbinsWind100% (24)

- SAV Achieving Low Return Temperatures From RadiatorsDocument7 pagesSAV Achieving Low Return Temperatures From RadiatorsNikolay GeorgievNo ratings yet

- G+1 Residential Building Bill of Quantity YITAYALDocument31 pagesG+1 Residential Building Bill of Quantity YITAYALYemane TsadikNo ratings yet

- Mann KendallDocument4 pagesMann KendallOm Prakash SahuNo ratings yet

- Exit StrategyDocument2 pagesExit StrategyMuhammad KashifNo ratings yet

- Fac1601 - Fasset Classes - Part 4Document2 pagesFac1601 - Fasset Classes - Part 4Abdullah SalieNo ratings yet

- Brochure For CTPT AnalyzerDocument6 pagesBrochure For CTPT AnalyzerBogdan IlieNo ratings yet

- Foundation Design Philosophy For Rotating EquipmentDocument7 pagesFoundation Design Philosophy For Rotating EquipmentKyaw Kyaw AungNo ratings yet

- Notes 2 PDFDocument5 pagesNotes 2 PDFJoel DsouzaNo ratings yet

- Webquest PozdniakovaDocument6 pagesWebquest PozdniakovaAlina PozdnyakovaNo ratings yet

- Muet Paper 3 (Reading) Trial 2019Document13 pagesMuet Paper 3 (Reading) Trial 2019PRAKASH100% (1)

- Gate 2 K 13 PosterDocument1 pageGate 2 K 13 Poster7killers4uNo ratings yet

- Coordinates Activity SheetDocument2 pagesCoordinates Activity SheetBernadette L. Macadangdang100% (2)

- Universal Summit Nozzles Data SheetDocument2 pagesUniversal Summit Nozzles Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- Heat EnginesDocument4 pagesHeat EnginesZaib RehmanNo ratings yet

- Lesson Plan Semester 2Document3 pagesLesson Plan Semester 2api-643035312No ratings yet

- Re-Test SUBJECT-English Core Class - Xi Time: 2 Hrs. M.M: 50 General InstructionsDocument8 pagesRe-Test SUBJECT-English Core Class - Xi Time: 2 Hrs. M.M: 50 General InstructionsSunilDwivediNo ratings yet

- R55 R-Series 60 HZ FinalDocument2 pagesR55 R-Series 60 HZ FinalCelso Fernandes BentoNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)