Professional Documents

Culture Documents

7740 8330 KG-33 Corning Schott Kimble Kavalier Pyrex Duran Kimax Simax

Uploaded by

Primaria PuhaceniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7740 8330 KG-33 Corning Schott Kimble Kavalier Pyrex Duran Kimax Simax

Uploaded by

Primaria PuhaceniCopyright:

Available Formats

FRIEDRICH & DIMMOCK, INC.

• SIMAX GLASS PROPERTIES

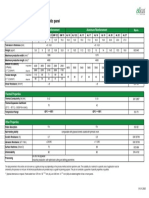

COMPARATIVE VALUES OF BOROSILICATE GLASSES

Glass Code 7740 8330 KG-33

Source Corning Schott Kimble Kavalier

Trade Name Pyrex Duran Kimax Simax

Expansion 10 -7/ °C 32.5 33.0 32.0 33.0

Strain Point °C 510 525 513 510

Annealing Point °C 560 560 565 560

Softening Point °C 821 820 827 820

Working Point 0C 1252 1260 1255 1260

Density gm / cm3 2.23 2.23 2.23 2.23

Vol.Rest Log 10

At 250 °C ohm/cm 8.1 8.0 7.9

At 350 °C ohm/cm 6.6 6.5 6.4

Dielectric 1MHz At 20°C At 25°C At 25°C At 20°C

K 4.6 4.6 4.6 4.6

Loss Factor 1% 2.6 2.2

Refractive Index 1.474 1.473 1.470 1.472

Loss Factor tan d 37x10-4

Stress Optical Coef.

10-6mm2/N 3.94 4.00 3.70 3.60

Melt Availability Continuous melt (6-8 week cycles)

Composition App Wt %

SiO2 80.6 81.0 80.0 80.4

B2O3 13.0 13.0 13.0 13.0

Na2O+K2O 4.0 4.0 4.0 4.2

Al2O3 2.3 2.0 3.0 2.4

This form should be used for reference only. Data for design and product application

should be taken from the respective company’s technical glass data.

FRIEDRICH & DIMMOCK, INC.

U.S.TOLL FREE:1-800-524-1131 • (856) 825-0305 • FAX: (856) 327-4299 www.fdglass.com

FRIEDRICH & DIMMOCK, INC. • SIMAX GLASS PROPERTIES

PHYSICAL PROPERTIES

Physical properties of Simax® Glass are set down by ISO standard 3585, or DIN ISO 3585 and 3585, or DIN

ISO 3585 and _SN ISO 3585. They are exactly certified by approved international testing methods defined by the

standards ISO, DIN ISO a _SN ISO, as shown in the table below.

TESTING CONDITIONS SYMBOL VALUE DEVIATIONS UNIT

PHYSICAL PROPERTIES

METHOD

MEAN COEFFICIENT OF LINEAR ISO 7991 20°C to x10-6K-1

a 3.3 ±0.1

THERMAL EXPANSIVITY 300°C

g.cm-3

DENSITY r 2.23 ±0.02

_SN 7005 13 20°C

20°C a_ Wm-1K-1

THERMAL CONDUCTIVITY l 1.2

100°C

SPECIFIC HEAT x103

20°C a_ c

AT CONSTANT PRESSURE

p

0.98 Jkg-1K-1

100°C

WORKING ISO 7884-2 hf1=104 °C

J f1

1260 ±20

TEMPERATURE ISO 7884-5 dPa.s

VISCOSITY POINTS

SOFTENING POINT ISO 7884-2 hf2=107.5 °C

J 820 ±10

REFERENCE

(Littleton point) ISO 7884-6 dPa.s

f2

UPPER COOLING ISO 7884-7

hf3=1013.2 °C

TEMPERATURE dPa.s 560 ±10

J f3

LOWER COOLING hf4=1014.7 °C

TEMPERATURE ISO 7884-7 dPa.s J f4 510 ±10

TRANSFORMATION °C

ISO 7884-8 tg 525

TEMPERATURE ±15

MODULUS OF ELASTICITY x103MPa

E 64

POISSON CONSTANT m

TENSILE STRENGTH 35 to 100 MPa

Simax Glass has an expansion coefficient of 33 x 10-7°C. Simply put, a 1.0m long rod will expand 0.33mm when

heated an additional 100° C. Even with such a low rate of expansion care must be taken when designing long

pipeline runs.

Density is affected by chemical composition and decreases with rising temperature of the molten glass.

MECHANICAL RESISTANCE

Generally, glass is a brittle material and fractures occur as a result of tensile stress. Mechanical properties

and service life of a given product from Simax® glass are to a major part determined by surface condition.

Particularly important is surface damage caused by handling (scratching) and secondary thermal treatment (cracks

from handling with already cooled surface flaws). A failure can result even from a damage of 5 to 10 µm in depth.

Scratch hardness of Simax® Glass is close to grade 6 (feldspar) according to the Mohs scale. Consequently, a

material of the same or higher hardness can cause mechanical damage to the surface. Therefore, the glass must be

handled with care!

Maximum permitted stress is 3.5 MPa, 7.0 MPa and 100 MPa in tension, bending and compression,

respectively. Module of elasticity in shear G is 26,500 MPa.

FRIEDRICH & DIMMOCK, INC.

U.S.TOLL FREE:1-800-524-1131 • (856) 825-0305 • FAX: (856) 327-4299 www.fdglass.com

FRIEDRICH & DIMMOCK, INC. • SIMAX GLASS PROPERTIES

TECHNICAL PROPERTIES OF SIMAX GLASS

Simax Glass® , because of its chemical composition and properties, belongs to the group of clear “hard”

borosilicate glasses “3.3” characterized by high thermal and chemical stability, as defined by the international

standard ISO 3585: Borosilicate glass 3.3 - Properties (or by identical Czech version of the standard _N ISO

3585: Borosilicate glass - Properties, or German DIN ISO 3585). The glass fully meets the requirements set down

by these standards. Pyrex 7740 and Duran 8330 belong to this same class.

Simax® Glass is used in applications where the highest demands are put on products regarding their thermal and

chemical stability. Its neutral formulation will not interfere with substances or preparations coming into contact with

them, i.e. in chemistry, petrochemistry, food industry, cooling technologies, power engineering, metallurgy, health

service, microbiology, pharmacy, engineering, laboratories, home preparation of foods.

The drawn tubing and rod products are manufactured using the latest technology that yields pristine surfaces that

are smooth and pore-free, perfectly transparent, and corrosion-resistant. The quality is not only on the surface and

in the glass but is also in the production methods and philosophy of Kavalier Glassworks. This process and

dedication produces consistent and clearly superior results.

CHEMICAL COMPOSITION

The glass formulation is SiO2-Al2O3-B2O3-Na2O-K2O.

The relative chemical composition of Simax® Glass is expressed Testing method Content [% by weight]

in glass-forming oxides that are given in the table to the right.

SiO2 80.4

B2O3 13.0

Al2O3 2.4

CHEMICAL PROPERTIES

Na2O + K2O 4.2

Products from Simax Glass are chemically stable, and

relatively inert. They exhibit excellent resistance against the effects of water, steam, acids, and salt solutions. Their

resistance to alkalis is also excellent.

The chemical resistance of Simax® Glass is determined by the ISO standard

3585 or DIN ISO 3585 and 3585 or DIN ISO 3585 and _SN ISO 3585. It is diligently certified by approved

international testing methods as defined by the ISO standards DIN ISO a _SN ISO, as shown in the following table:

Chemical resistance against Testing method Class of resistance Loss of Maximum permitted

value

water at 98 °C ISO 719 HGB 1 Na2O [mg/g] 31

water at 121 °C ISO 720 HGA 1 Na2O [mg/g] 62

Acids ISO 1776 1 weight [mg/dm2] 100

Effect of boiling water

solution of mixed alkalis ISO 695 A2 weight [mg/dm2] 175

FRIEDRICH & DIMMOCK, INC.

U.S.TOLL FREE:1-800-524-1131 • (856) 825-0305 • FAX: (856) 327-4299 www.fdglass.com

FRIEDRICH & DIMMOCK, INC. • SIMAX GLASS PROPERTIES

mechanical damage to the surface. Therefore, the glass must be handled with care!

Maximum permitted stress is 3.5 MPa, 7.0 MPa and 100 MPa in tension, bending and compression,

respectively. Module of elasticity in shear G is 26,500 MPa.

THERMAL PROPERTIES

The high thermal shock resistance of Simax® Glass is afforded by its low coefficient of expansion. The excellent

thermal conductivity of the material also prevents high temperature gradients from forming within the walls of the

product.On cooling and heating, undesirable internal stresses can develop in the glass. Fracture of the glass by

temperature change results from tensile stress on the product surface caused by linear thermal expansion of the glass

during rapid cooling of the product surface. Therefore, thermal resistance of the glass object is always higher on

rapid heating than on rapid cooling. Quick cooling is far more dangerous as tensile stress is generated on the

surface and, with synergetic effect of mechanical damage of the product surface, fracture can take place.

Mechanical damage of the product surface dramatically reduces thermal resistance! During use, the products should

not be exposed to temperatures exceeding 450°C or else they should be annealed afterwards.

ANNEALING

Annealing is a thermal process whereby the strain induced in the glass from forming the glass into products is

removed.

The annealing cycle is a theoretically calculated time-controlled procedure of heating and slowly cooling the glass

in an annealing oven. The thermal cycling consists of three stages:

Temperature increase of the ware at a controlled rate. This ramp up will vary depending on thickness of

glassware and the total mass of material in the oven.

Dwell at temperature of the product for a certain time period at the proper annealing temperature. The purpose

is to allow all strain previously induced in the glass to dissipate. The “soaking period” will also vary according to

product thickness and oven load.

Cool Down of the product at the cooling rate from lower annealing temperature to final temperature or to the

surrounding temperature (this is important for subsequent practical handling of products).

A typical cooling cycle is given in the following table:

Temperature range 20 - 550 560 560 - 490 490 - 440 440 - 40

[°C]

MAXIMUM THICKNESS TEMPERATURE DWELL AT

TEMPERATURE

COOLING OF WALL INCREASE TEMPERATURE

DROP [°C.min-1]

CYCLE [mm] [°C.min-1] [min]

3 140 5 14 28 140

6 30 10 3 6 30

9 15 18 1.5 3 15

12 8 30 0.6 1.6 8

FRIEDRICH & DIMMOCK, INC.

U.S.TOLL FREE:1-800-524-1131 • (856) 825-0305 • FAX: (856) 327-4299 www.fdglass.com

FRIEDRICH & DIMMOCK, INC. • SIMAX GLASS PROPERTIES

OPTICAL PROPERTIES Wavelength [nm] Refractive index Value

404.66 nh 1.48419

486.13 nf 1.47724

546.07 ne 1.47403

589.30 nd 1.47231

656.27 nc 1.47011

Simax® Glass is clear and colourless, it does not show any marked absorption in the visible spectrum.

Transmittance of ultraviolet rays is higher than that of common sheet glass which makes it possible to use glass

products for photochemical reactions.

The Refractive index of Simax® Glass is close to that of pure quartz and is lower than that of common alkaline

lime-silicate glasses. The values of refractive index for main spectral lines are shown in the following table.

Photoelastic constant is 3.6.10-6 MPa-1.

Irradiation of the glass Simax® with UV light and hard radiation causes solarization (browning) which fades away

by heating up to 400°C to 450C.

ELECTRIC PROPERTIES

Under normal temperatures Simax® Glass is non-conductive - it acts as an insulator. Specific electric resistance of

the glass Simax® at room temperature (20°C) and in a humidity-free environment is higher than 1013 to 1015 Ω.cm

(specific resistance of insulants should be higher than 1010 to 1012 Ω.cm).

Due to atmospheric humidity at temperatures up to 100°C, glasses are generally covered with an adsorbed thin

layer of water, a very weak surface conductivity occurs, surface resistance is reduced with rising relative humidity of

the atmosphere and, up to 100°C, also with rising surface temperature of the insulant.

Surface resistance in a humidity-free environment is 1015 per square, at the relative humidity of 50% it is 1010 to

10 Ω per square which fully meets the conditions put on insulants.

13

Electric strength is given by two aspects: Either dielectric breakdown takes place when actual electric strength of

the material is reached and an electric impulse wave is generated, or thermal breakdown occurs when the insulant

is locally heated up and, at the same time, electric resistance is reduced which results in a spontaneous passage of

electric current.

Electric strength is approximately 1000 kVcm-1 in air and 10 kVcm-1 in oil. The limit value of 10 000 kVcm-1 is

seldom reached because of rupture of the insulant after localized heating caused by dielectric losses at higher

frequencies. .

Generally, dielectric losses are expressed by a loss factor as the product of permittivity ε (ratio of capacitance of

the capacitor with the glass dielectric to the ideal one) and loss angle tg δ (δ is angle vector of total current with

respect to charging ideal capacitor). The losses increase steeply with rising temperature and change with frequency.

in such a way that their minimum is at about 106 Hz. More detailed data are given in the following table:

Dependence Frequency [Hz] (20°C) Temperature [C] (1MHz)

Value 103 106 3.109 20 100 200 300

x 4.7 4.6 4.5 4.6 4.7 5.1 5.7

3

tg * .10 8.6 4.9 6.4 4.9 9.0 30.0 150.0

Neither Simax® Glass nor other glasses of the group “3.3” are glasses of low losses (max. loss factor is 50x10-4, for

Simax® Glass at 1MHz and 20°C is 184x10-4). Nevertheless, low values of permittivity render this glass ideally suited

as an insulator.

FRIEDRICH & DIMMOCK, INC.

U.S.TOLL FREE:1-800-524-1131 • (856) 825-0305 • FAX: (856) 327-4299 www.fdglass.com

You might also like

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Specifications & Properties for Motiva Base OilsDocument1 pageSpecifications & Properties for Motiva Base OilsMassimiliano VolaNo ratings yet

- NIC Components NPIM - C SeriesDocument6 pagesNIC Components NPIM - C SeriesNICCompNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- PolyCast TDS V5.2-20230912Document6 pagesPolyCast TDS V5.2-20230912GoNo ratings yet

- Datasheet-Kanthal-A-1-En-V2018-07-06 12 - 16 Version 1Document3 pagesDatasheet-Kanthal-A-1-En-V2018-07-06 12 - 16 Version 1putrastevanofyNo ratings yet

- Kanthal-A-1-En-V2021-02-04 13 - 30 Version 1Document3 pagesKanthal-A-1-En-V2021-02-04 13 - 30 Version 1BerchtoldNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Kanthal-D-En-V2021-02-04 13 - 31 Version 1Document3 pagesKanthal-D-En-V2021-02-04 13 - 31 Version 1Eduardo Campos RoblesNo ratings yet

- Motiva Group II Base OilDocument1 pageMotiva Group II Base Oiliescobar0702No ratings yet

- Product Specification Ovax 800: General InformationDocument4 pagesProduct Specification Ovax 800: General InformationAntonioNo ratings yet

- PolyTerra-PLA TDS V5.3-20231113Document6 pagesPolyTerra-PLA TDS V5.3-20231113nerze0777No ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- Co. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultDocument1 pageCo. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultNaveen SinghNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Apc-2 Peek 031912-01Document6 pagesApc-2 Peek 031912-01Angel LagrañaNo ratings yet

- TDS Enus 1Document2 pagesTDS Enus 1Director ResearchNo ratings yet

- Toray Btcy-1: Description FeaturesDocument6 pagesToray Btcy-1: Description FeaturesAkhil HebbarNo ratings yet

- Nitronic® 40 Stainless Steel: Chemical CompositionDocument2 pagesNitronic® 40 Stainless Steel: Chemical CompositionBagus WicaksanaNo ratings yet

- Calcium Silicate Board Insulation: 4641 Mcree Avenue 314-773-7500 St. Louis, Mo 63110 Fax 314-773-8371Document1 pageCalcium Silicate Board Insulation: 4641 Mcree Avenue 314-773-7500 St. Louis, Mo 63110 Fax 314-773-8371abdulmenem arafaNo ratings yet

- RO3000 Series BondplyData Sheet Processing GuidelinesDocument4 pagesRO3000 Series BondplyData Sheet Processing GuidelinesEricson NavasNo ratings yet

- Lss-A286 Astm A453 PDFDocument2 pagesLss-A286 Astm A453 PDFmazolasboNo ratings yet

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 pageGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Stellite Grade 12-DatasheetDocument2 pagesStellite Grade 12-DatasheetNinad PawarNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- 8552Document6 pages8552staedtlerpNo ratings yet

- Corning 1737 AMLCD Glass Substrates: Material InformationDocument3 pagesCorning 1737 AMLCD Glass Substrates: Material InformationAfzal ImamNo ratings yet

- spec sheetDocument6 pagesspec sheettristanNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet

- ConstantDocument8 pagesConstantDhayane RedoquerioNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Kanthal-Am100-En-V2021-02-04 13 - 49 Version 1Document3 pagesKanthal-Am100-En-V2021-02-04 13 - 49 Version 1Venkatesh PandianNo ratings yet

- Standard and reinforced PA grades overviewDocument2 pagesStandard and reinforced PA grades overviewabhishek_negi_41No ratings yet

- Crofer 22 HDocument27 pagesCrofer 22 HSarveshNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- Cofran Mecanep 220 enDocument2 pagesCofran Mecanep 220 enMATHEW JOSENo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument2 pagesTechnical Card Gruppo Lucefin Revision 2013 All Rights Reservednovkovic1984No ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Asphalt Binder Basics Specifications, History and FutureDocument40 pagesAsphalt Binder Basics Specifications, History and FutureEdmundo Jaita CuellarNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Seriola 1510Document2 pagesSeriola 1510nicolasNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- 230 DS Nickel Rolled Alloys Data SheetDocument2 pages230 DS Nickel Rolled Alloys Data Sheetbhavesh nakumNo ratings yet

- 3496445985Document2 pages3496445985yosep gomezNo ratings yet

- Victrex TDS 650GDocument2 pagesVictrex TDS 650GKumaar RanjanNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Bambu Lab A1 3DDocument6 pagesBambu Lab A1 3DAngel Jacobo Figueroa ArriolaNo ratings yet

- Arkema PEKK kKepstan 8001 TDSDocument3 pagesArkema PEKK kKepstan 8001 TDSstartionlilNo ratings yet

- Mumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Document1 pageMumbai - Maharashtra Email: Sandeep@vivant - in - Mobile: 72195 61918Abhinav VarmaNo ratings yet

- Thermo Scientific Heraeus Labofuge 400 and 400 R CentrifugesDocument6 pagesThermo Scientific Heraeus Labofuge 400 and 400 R CentrifugesPrimaria PuhaceniNo ratings yet

- Centrifuges HA 1000-6 - ProspectDocument1 pageCentrifuges HA 1000-6 - ProspectPrimaria PuhaceniNo ratings yet

- Thermo Scientific Heraeus Labofuge® 400 and 400 R, Rotor GuideDocument12 pagesThermo Scientific Heraeus Labofuge® 400 and 400 R, Rotor GuidePrimaria PuhaceniNo ratings yet

- Thermo Scientific Heraeus Labofuge® 400 and 400 RDocument6 pagesThermo Scientific Heraeus Labofuge® 400 and 400 RPrimaria PuhaceniNo ratings yet

- Katalog Labo 2008Document168 pagesKatalog Labo 2008Primaria PuhaceniNo ratings yet

- Catalogo SimaxDocument168 pagesCatalogo SimaxHugh SteeleNo ratings yet

- Maths SolutionDocument10 pagesMaths SolutionAbhay KumarNo ratings yet

- Ringkasan LaguDocument4 pagesRingkasan LaguJoe PyNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- Ahu, Chiller, Fcu Technical Bid TabulationDocument15 pagesAhu, Chiller, Fcu Technical Bid TabulationJohn Henry AsuncionNo ratings yet

- 1491559890CL 0417 PDFDocument48 pages1491559890CL 0417 PDFCoolerAdsNo ratings yet

- HHG4M - Lifespan Development Textbook Lesson 2Document95 pagesHHG4M - Lifespan Development Textbook Lesson 2Lubomira SucheckiNo ratings yet

- KingmakerDocument5 pagesKingmakerIan P RiuttaNo ratings yet

- Business StrategiesDocument2 pagesBusiness Strategiesthristanlexter694No ratings yet

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- Angelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannDocument374 pagesAngelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannEusebius325100% (2)

- GRP Product CatalogueDocument57 pagesGRP Product CatalogueMulyana alcNo ratings yet

- Software Client Linux 21 01Document81 pagesSoftware Client Linux 21 01BronskyNo ratings yet

- Galambos 1986Document18 pagesGalambos 1986gcoNo ratings yet

- Proposed Panel Antenna: Globe Telecom ProprietaryDocument2 pagesProposed Panel Antenna: Globe Telecom ProprietaryJason QuibanNo ratings yet

- SHORT STORY Manhood by John Wain - Lindsay RossouwDocument17 pagesSHORT STORY Manhood by John Wain - Lindsay RossouwPrincess67% (3)

- General Biology 2-Week 2-Module 4-Evidence of EvolutionDocument16 pagesGeneral Biology 2-Week 2-Module 4-Evidence of EvolutionFEMALE Dawal LaizaNo ratings yet

- ElectricalDocument30 pagesElectricalketerNo ratings yet

- Geometric Sculpture From 72 PencilsDocument5 pagesGeometric Sculpture From 72 PencilsHugo Iván Gonzalez CruzNo ratings yet

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- WEEK 8. - Gen Math-PortfolioDocument12 pagesWEEK 8. - Gen Math-PortfolioOreo ProductionsNo ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet

- Final Annotated BibiliographyDocument4 pagesFinal Annotated Bibiliographyapi-491166748No ratings yet

- Chapter 2 RM - Research ProcessDocument46 pagesChapter 2 RM - Research ProcesseyasuNo ratings yet

- Solutions: Spheres, Cones and CylindersDocument13 pagesSolutions: Spheres, Cones and CylindersKeri-ann MillarNo ratings yet

- 41 PDFsam Redis CookbookDocument5 pages41 PDFsam Redis CookbookHữu Hưởng NguyễnNo ratings yet

- Jotrun TDSDocument4 pagesJotrun TDSBiju_PottayilNo ratings yet

- Inspection and Acceptance Report: Stock No. Unit Description QuantityDocument6 pagesInspection and Acceptance Report: Stock No. Unit Description QuantityAnj LeeNo ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- Athenaze 1 Chapter 7a Jun 18th 2145Document3 pagesAthenaze 1 Chapter 7a Jun 18th 2145maverickpussNo ratings yet

- 8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityDocument3 pages8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityNickesh ShahNo ratings yet