0% found this document useful (0 votes)

422 views21 pagesBasic Working Drawing: Why Are Working Drawings Used?

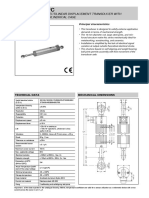

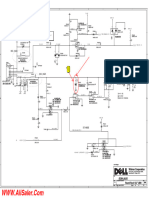

The document discusses the key components of basic working drawings, including shape description using multi-view, pictorial, and sectional drawings, size description through proper dimensioning, specifications to describe design and materials, and detail drawings to show small or intricate parts. Working drawings are important for communicating technical information between designers and manufacturers to construct a project accurately.

Uploaded by

Brett AmbilCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

422 views21 pagesBasic Working Drawing: Why Are Working Drawings Used?

The document discusses the key components of basic working drawings, including shape description using multi-view, pictorial, and sectional drawings, size description through proper dimensioning, specifications to describe design and materials, and detail drawings to show small or intricate parts. Working drawings are important for communicating technical information between designers and manufacturers to construct a project accurately.

Uploaded by

Brett AmbilCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd