0% found this document useful (0 votes)

235 views43 pages4-1-Lesson Plan

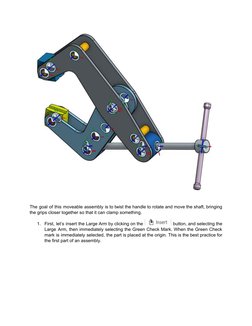

This document provides an overview of assemblies in Onshape. It discusses how assemblies allow multiple parts to be assembled together and define motion between parts using mates and relations. Key points covered include degrees of freedom, mate connectors, different types of mates, fixing the first part of an assembly, and using a revolute mate to allow rotational motion between arms in a cantilever clamp assembly example. The document aims to explain Onshape's approach to assemblies using high-level mates compared to traditional multiple constraint methods.

Uploaded by

Zero TwoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

235 views43 pages4-1-Lesson Plan

This document provides an overview of assemblies in Onshape. It discusses how assemblies allow multiple parts to be assembled together and define motion between parts using mates and relations. Key points covered include degrees of freedom, mate connectors, different types of mates, fixing the first part of an assembly, and using a revolute mate to allow rotational motion between arms in a cantilever clamp assembly example. The document aims to explain Onshape's approach to assemblies using high-level mates compared to traditional multiple constraint methods.

Uploaded by

Zero TwoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd