Professional Documents

Culture Documents

My Assignment - 04

My Assignment - 04

Uploaded by

Qurat Ul AinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

My Assignment - 04

My Assignment - 04

Uploaded by

Qurat Ul AinCopyright:

Available Formats

Better Air is Our Business ®

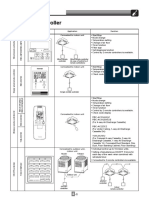

BioCel I ®

High Efficiency Extended Surface Air Filter

The BioCel I filter was designed primarily to remove airborne biological

contaminants in hospital critical areas and food and pharmaceutical

processing plants. It has also been engineered to meet the exacting

requirements of precision manufacturing operations and laboratories,

where very high efficiency filtration of fine particulate matter is

necessary.

BioCel I ® filters meet efficiency

High Efficiency - Low Resistance requirements established for LEED ®

Project Certification.

The air cleaning efficiency of the BioCel I filter is significantly higher

than that of 90-95% ASHRAE efficiency filters. BioCel I filters exceed

the maximum efficiency of 98% which can be measured by Ideal for Variable Volume Systems

ASHRAE 52.1 test method.

Due to the rigid all metal construction and water resistant media

Rated at 95% efficiency on 0.3 micrometer challenge aerosol and in a supported pleat type configuration, BioCel I filters can be

MERV 16 by ASHRAE Standard 52.2, the BioCel I filter has the used in systems with difficult operating conditions:

advantage of much lower pressure drop than a typical HEPA filter

(0.4" versus 1.0" w.g. at 250 FPM). BioCel I filters fill the gap between • Variable air volume

ASHRAE grade high efficiency filters and ultra-high efficiency HEPAs • Turbulent airflow

at half the weight and pressure drop.

• Repeated fan shutdown

This compact, lightweight filter will withstand operating temperatures

• High temperature

to 350˚F, if recommended final resistance is not exceeded.

• High humidity

To maximize filter life, use BioCel I filters with high quality AAF

prefilters. • Intermittent exposure to water such as sea coast installations

Construction

BioCel I filters consist of a pleated media pack enclosed in a

galvanized steel frame assembly. The media is made of ultra-fine BioCel ® M-Pak – A New Alternative

fiberglass formed into a series of pleats. Corrugated aluminum The BioCel M-Pak filter offers the same media area and

separators maintain uniform spacing between each pleat to allow pressure drop as the BioCel I filter in a 6" deep, high-

unrestricted airflow through the filter. Bar braces are installed on impact polystyrene cell side.

both sides of the filter for extra reinforcement of the media pack.

A flattened, expanded metal faceguard installed on both sides of The BioCel M-Pak filter offers several advantages in

the filter is available as an option. comparison to the BioCel I filter.

BioCel I filters have a single piece galvanized steel header on the air • Lighter – half the weight

entering side that is interlocked to the cell sides in a patented fashion • Requires less storage space

that prevents leakage and forms a totally rigid construction.

• Reduces disposal costs

• Easier handling

• Fully Incinerable

For more information on the

BioCel ® M-Pak filter, see brochure AFP-1-117.

BioCel I ®

Product Information

Rated Rated Gross

Nominal Size Actual Size Airflow Capacity Initial Resistance Media Filters Shipping

(Inches) (Inches) (CFM) (in. w.g.) Area Per Weight

(W x H x D) (W x H x D) 125 FPM 250 FPM 500 FPM 125 FPM 250 FPM 500 FPM (sq. ft.) Carton (lbs.)

95% Initial Efficiency (0.3µm Particles)

24 x 24 x 12 23 /8 x 23 /8 x 11 /2

3 3 1

500 1000 2000 .19 .40 .95 156 1 20.0

(a)

24 x 24 x 12 24 x 24 x 11 1/2 500 1000 2000 .19 .40 .95 165 1 21.5

24 x 20 x 12 23 3/8 x 19 3/8 x 11 1/2 413 825 1650 .19 .40 .95 127 1 17.0

(a)

20 x 24 x 12 19 /8 x 23 /8 x 11 /2

3 3 1

413 825 1650 .19 .40 .95 127 1 18.5

12 x 24 x 12 11 3/8 x 23 3/8 x 11 1/2 250 500 1000 .19 .40 .95 72 1 12.0

Recommended Final Resistance 2.0 in. w.g.

24 x 24 x 6 23 3/8 x 23 3/8 x 5 7/8 500 1000 — .30 .60 — 93 2 22.0

(a)

24 x 24 x 6 24 x 24 x 5 /8 7

500 1000 — .30 .60 — 98 2 24.0

24 x 20 x 6 23 /8 x 19 /8 x 5 /8

3 3 7

413 825 — .30 .60 — 93 2 22.0

(a)

20 x 24 x 6 19 3/8 x 23 3/8 x 5 7/8 413 825 — .30 .60 — 96 2 21.5

12 x 24 x 6 11 /8 x 23 /8 x 5 /8

3 3 7

250 500 — .30 .60 — 42 2 14.0

Recommended Final Resistance 1.5 in. w.g.

(a) Available in double header construction only.

Metric Conversion Info

1.0 in. = 2.54 cm 1 CFM = 1.7 m 3 / hr

2 2

1 ft = .09 m 1.0 in. w.g. = 249 Pa

1 FPM = .005 m/sec.

Options Performance Data

• Double header construction is Initial Efficiency vs. 100

available for installation into Particle Diameter

other manufacturers' framing At rated airflow, the BioCel I filter

80

systems. has efficiency of 95% on 0.3

Fractional Efficiency (%)

• 6" or 12" depths available. micron particles and is classified

MERV 16 in accordance with 60

• HEPA filter construction ASHRAE Standard 52.2.

available. See Bulletin

AFP-1-110. 40

Underwriters Laboratories,

Inc. Classification

BioCel I filters are classified 20

Class 1. Testing was performed

according to UL Standard 900.

0

0. 1 .2 .4 .6 .8 1 2 4 6 8 10

Particle Diameter (micrometers)

ASHRAE 52.2 Composite Minimum Efficiency Curve

BioCel I ®, BioCel ®, and AAF Green ® are registered trademarks of AAF-McQuay Inc. in the U.S.

10300 Ormsby Park Place Suite 600 AAF has a policy of continuous product research and

Louisville, Kentucky 40223-6169 improvement and reserves the right to change

design and specifications without notice.

www.aafintl.com

Customer Service 888.AAF.2003 ISO Certified Firm

Fax 888.223.6500 ©2010 AAF International

®

The USGBC Member logo and LEED are trademarks owned by

AFP-1-116T MAR '10 the U.S. Green Building Council and are used by permission.

You might also like

- Continental O-300 PartsManualDocument48 pagesContinental O-300 PartsManualswooshcmk82% (11)

- AirCobraCube AFP 1 160Document2 pagesAirCobraCube AFP 1 160Carlos GonzálezNo ratings yet

- Practice Paper 3 (Calculator) : GCSE Higher MathsDocument12 pagesPractice Paper 3 (Calculator) : GCSE Higher MathsMorena PotenzaNo ratings yet

- Precalculus LRDocument1,483 pagesPrecalculus LRe.k choi100% (1)

- Technical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Document56 pagesTechnical Manual: Package Air Conditioner Rooftop - Cooling Only (50Hz)Im Chinith100% (1)

- Activity No 2 - PHENOLDocument4 pagesActivity No 2 - PHENOLpharmaebooks100% (4)

- Varicel V: High Efficiency Supported Pleat FiltersDocument2 pagesVaricel V: High Efficiency Supported Pleat Filterselly1818No ratings yet

- VariSorb XL - Prod - Mark - SHT - GPF 1 121F NewDocument2 pagesVariSorb XL - Prod - Mark - SHT - GPF 1 121F NewFRAJCO9248No ratings yet

- MEGApleat M11 AFP 1 182Document2 pagesMEGApleat M11 AFP 1 182Pablo B.No ratings yet

- Filter Inserts Type Fa - Psfi3209-UkDocument2 pagesFilter Inserts Type Fa - Psfi3209-UkNabeel MohammedNo ratings yet

- Biomax 99 - 97 SBM - Chart Jhonson ControlDocument1 pageBiomax 99 - 97 SBM - Chart Jhonson ControlJuan Carlos Soto OrihuelaNo ratings yet

- Membrana Xfrle 400 34iDocument2 pagesMembrana Xfrle 400 34iHenry SalasNo ratings yet

- AAF Leaflet BioCel VXL AstroCel VXLDocument2 pagesAAF Leaflet BioCel VXL AstroCel VXLsoumya saswatNo ratings yet

- Hurricane B7-41/1000: Product ReferenceDocument8 pagesHurricane B7-41/1000: Product ReferenceY.EbadiNo ratings yet

- VariCel 2SCProdMarkShtAFP1242B NewDocument2 pagesVariCel 2SCProdMarkShtAFP1242B NewMarco Antonio Rivera DoteroNo ratings yet

- GT Datasheet HydroVeeDocument2 pagesGT Datasheet HydroVeeArjan BajwaNo ratings yet

- MX 75-98Document2 pagesMX 75-98Compras WConexNo ratings yet

- Rivulis F7250 English Metric 20210518 WebDocument8 pagesRivulis F7250 English Metric 20210518 WebMehdi BassouNo ratings yet

- PrePleat M11 HC Prod Mark SHT AFP 1 388Document2 pagesPrePleat M11 HC Prod Mark SHT AFP 1 388luisNo ratings yet

- Rivulis F3240 English Metric 20191223 WebDocument10 pagesRivulis F3240 English Metric 20191223 WebMehdi BassouNo ratings yet

- Element Brochure 9 3Document6 pagesElement Brochure 9 301DOGG01No ratings yet

- VariCel 2HCProdMarkShtAFP1243C NewDocument2 pagesVariCel 2HCProdMarkShtAFP1243C NewpolNo ratings yet

- CatalogueDocument6 pagesCatalogueRakesh RanjanNo ratings yet

- Donaldson LF Series PDFDocument8 pagesDonaldson LF Series PDFSebastian GanciNo ratings yet

- En Aquacarb207c12x30Document2 pagesEn Aquacarb207c12x30fenda2No ratings yet

- VP LC-CleanerRebuild 23 BDI VP1355 enDocument8 pagesVP LC-CleanerRebuild 23 BDI VP1355 enClaudinei MayerNo ratings yet

- VariCel II - Prod - Mark - SHT - AFP 1 237Document2 pagesVariCel II - Prod - Mark - SHT - AFP 1 237Võ HòaNo ratings yet

- AstroPak - Prod - Data - Sheet - AFP 1 109CDocument1 pageAstroPak - Prod - Data - Sheet - AFP 1 109CluisNo ratings yet

- Brochure BioelementsDocument8 pagesBrochure BioelementsMohamed SabryNo ratings yet

- Emd00284en Lube Oil Filter 350Document8 pagesEmd00284en Lube Oil Filter 350dionisio emilio reyes jimenezNo ratings yet

- Acidity Removal - HDU2x27 108 108 - PSST1003UKDocument2 pagesAcidity Removal - HDU2x27 108 108 - PSST1003UKAlexis BarolinNo ratings yet

- Varicel V (AFP-1-258H)Document4 pagesVaricel V (AFP-1-258H)Im ChinithNo ratings yet

- Tri Lock BG BF Bag in Bag Out Hepa Housing 2500 9Document4 pagesTri Lock BG BF Bag in Bag Out Hepa Housing 2500 9FELIX DOSSNo ratings yet

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićNo ratings yet

- Nalco Ultrasand Plus High Efficiency Filters (Hef) : FeaturesDocument6 pagesNalco Ultrasand Plus High Efficiency Filters (Hef) : FeaturesAyahKenzieNo ratings yet

- Spin-On Breathers: Adaptors and Disposable BreathersDocument4 pagesSpin-On Breathers: Adaptors and Disposable BreathersOscar NavarroNo ratings yet

- Leopold Type 360 Data SheetDocument2 pagesLeopold Type 360 Data SheetjalanidhimareNo ratings yet

- DC Tech MBR CatalogueDocument2 pagesDC Tech MBR CatalogueXuân HoàngNo ratings yet

- Der Katalog 21 enDocument244 pagesDer Katalog 21 enJocemar MartinsNo ratings yet

- 10m3 WWTP For Hotel MontanaDocument10 pages10m3 WWTP For Hotel Montanatabaki73No ratings yet

- Cleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureDocument5 pagesCleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureAnonymous a4Jwz14WNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersвлад камрNo ratings yet

- KNA Stratopanel PDS FINALDocument3 pagesKNA Stratopanel PDS FINALKevin LiNo ratings yet

- Little Giant Tumble DryersDocument2 pagesLittle Giant Tumble DryersdemeterenikoNo ratings yet

- Product Sheet & Instruction Manual: Cimmic™ Cdi 0.1 Ml Disk (Carbonyldiimidazole) (2 Μm Channels) - Pack Of 3Document5 pagesProduct Sheet & Instruction Manual: Cimmic™ Cdi 0.1 Ml Disk (Carbonyldiimidazole) (2 Μm Channels) - Pack Of 3Antonio MoncayoNo ratings yet

- Pisgsfeoilxpxdcaoaa 02 enDocument8 pagesPisgsfeoilxpxdcaoaa 02 enJumaidi AbdyNo ratings yet

- Fuel PCB 1r 0749 Vs Donaldson Baldwin Fleetguard Wix Pejj0078Document9 pagesFuel PCB 1r 0749 Vs Donaldson Baldwin Fleetguard Wix Pejj0078Таалай МасадыковNo ratings yet

- Structured Packings GasDocument20 pagesStructured Packings GasBowo Edhi WibowoNo ratings yet

- Varicel RF C RF Cplus GPF 1 122Document2 pagesVaricel RF C RF Cplus GPF 1 122luisNo ratings yet

- 818 Series 0Document2 pages818 Series 0Jorge Luis VazquezNo ratings yet

- Hil Co Master CatalogDocument88 pagesHil Co Master CatalogMohamed Bin IerousNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersRafael PaivaNo ratings yet

- Dust Collector For Mica Undercutters-Dsh0Document1 pageDust Collector For Mica Undercutters-Dsh0FerozMujawarNo ratings yet

- FCP Carbon Pleat - Prod - Mark - SHT - GPF 1 142Document1 pageFCP Carbon Pleat - Prod - Mark - SHT - GPF 1 142FRAJCO9248No ratings yet

- GE Energy: Advancements in Particulate Emissions Control Technology For Industrial SourcesDocument43 pagesGE Energy: Advancements in Particulate Emissions Control Technology For Industrial Sourceszane truesdaleNo ratings yet

- HydroClear BrochureDocument12 pagesHydroClear BrochuremutazsalihNo ratings yet

- Bollfilter en 1dee04Document28 pagesBollfilter en 1dee04Arnaud Kevin Moussavou BivigouNo ratings yet

- Pellicon 3 Biomax Ds1324en00 7 M MKDocument8 pagesPellicon 3 Biomax Ds1324en00 7 M MKNurNo ratings yet

- Basic Filtration ConceptsDocument3 pagesBasic Filtration ConceptsAFLAC ............No ratings yet

- AAF Dripak 2000Document2 pagesAAF Dripak 2000kuraimundNo ratings yet

- Publication UASB+TechnologyDocument6 pagesPublication UASB+TechnologyecotechconsultantsNo ratings yet

- Varisorb HC GPF 1 126Document2 pagesVarisorb HC GPF 1 126luisNo ratings yet

- Filtri GP, HE, AC, DPDocument4 pagesFiltri GP, HE, AC, DPjuris.ligerisNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Test Report OD63mm PN12.5 PE100Document6 pagesTest Report OD63mm PN12.5 PE100Im ChinithNo ratings yet

- LESSO PVC-U Drainage Pipe and Fittings 2014.4Document59 pagesLESSO PVC-U Drainage Pipe and Fittings 2014.4Im Chinith100% (2)

- Rifeng PP R System EmailDocument18 pagesRifeng PP R System EmailIm ChinithNo ratings yet

- Quotation of PVC-U Drainage Pipe Sell3 Final2Document5 pagesQuotation of PVC-U Drainage Pipe Sell3 Final2Im ChinithNo ratings yet

- Bodycote SCG - H1000PCDocument1 pageBodycote SCG - H1000PCIm ChinithNo ratings yet

- TAP - TIS Standard Refer Cer ISO 4427Document1 pageTAP - TIS Standard Refer Cer ISO 4427Im ChinithNo ratings yet

- Certificated 1507-065 For 12-PPWSA-15Document2 pagesCertificated 1507-065 For 12-PPWSA-15Im ChinithNo ratings yet

- Iso4427 by Sgs-Hdpe Pipes-RehomeDocument4 pagesIso4427 by Sgs-Hdpe Pipes-RehomeIm ChinithNo ratings yet

- Gas Piping SystemDocument4 pagesGas Piping SystemIm ChinithNo ratings yet

- Rifeng Project References2020 压缩版Document38 pagesRifeng Project References2020 压缩版Im ChinithNo ratings yet

- PVC Drainage System CatalogueDocument13 pagesPVC Drainage System CatalogueIm ChinithNo ratings yet

- Controls: 1. Outline of Application ControlDocument11 pagesControls: 1. Outline of Application ControlIm ChinithNo ratings yet

- Wiring Design: 1. GeneralDocument5 pagesWiring Design: 1. GeneralIm ChinithNo ratings yet

- Welded Bevel Seal (AFP-1-401D)Document2 pagesWelded Bevel Seal (AFP-1-401D)Im ChinithNo ratings yet

- Pre FilterDocument8 pagesPre FilterIm ChinithNo ratings yet

- ISO15874 by SGS-PPR Pipes & Fittings-RehomeDocument15 pagesISO15874 by SGS-PPR Pipes & Fittings-RehomeIm ChinithNo ratings yet

- Varicel V (AFP-1-258H)Document4 pagesVaricel V (AFP-1-258H)Im ChinithNo ratings yet

- Home Central Air ConditioningDocument16 pagesHome Central Air ConditioningIm Chinith100% (1)

- Remote Controller: System OverviewDocument18 pagesRemote Controller: System OverviewIm ChinithNo ratings yet

- AAF Air Filter Selection Guide: en enDocument1 pageAAF Air Filter Selection Guide: en enIm ChinithNo ratings yet

- PCXSMT1604B R410A Inv Light Commercial Series Standard PDFDocument16 pagesPCXSMT1604B R410A Inv Light Commercial Series Standard PDFIm ChinithNo ratings yet

- EBDocument4 pagesEBIm ChinithNo ratings yet

- Product Line Sheet: Liquid Coatings Petrolatum Tapes & Protective OuterwrapsDocument3 pagesProduct Line Sheet: Liquid Coatings Petrolatum Tapes & Protective OuterwrapsIm ChinithNo ratings yet

- Premcote 101: Pipeline Corrosion Protection TapeDocument1 pagePremcote 101: Pipeline Corrosion Protection TapeIm ChinithNo ratings yet

- Air Curtant DewpointDocument4 pagesAir Curtant DewpointIm ChinithNo ratings yet

- Cast Resin Transformers Oil Immersed Transformer: Technical PerformanceDocument32 pagesCast Resin Transformers Oil Immersed Transformer: Technical PerformanceIm ChinithNo ratings yet

- Eq MASTER® AIR HANDLING UNITDocument2 pagesEq MASTER® AIR HANDLING UNITIm ChinithNo ratings yet

- Premier Coatings LTD.: Leaders in Corrosion PreventionDocument4 pagesPremier Coatings LTD.: Leaders in Corrosion PreventionIm ChinithNo ratings yet

- P B M T: Remcote Utyl Astic APEDocument2 pagesP B M T: Remcote Utyl Astic APEIm ChinithNo ratings yet

- Chapter 3 SolutionDocument29 pagesChapter 3 SolutionDaiChi J3SNo ratings yet

- Science Unit 4th GradeDocument6 pagesScience Unit 4th Gradeapi-616358938No ratings yet

- Biofilms Presentation Handouts 3-16-15Document62 pagesBiofilms Presentation Handouts 3-16-15Afan MirajNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological UniversityAnisha KizhppulliNo ratings yet

- Drat's Lux NotesDocument12 pagesDrat's Lux Notesfixov32615No ratings yet

- COC 12 DEMO ScriptDocument5 pagesCOC 12 DEMO ScriptEdward RaagasNo ratings yet

- Assignment 2 - EPGCOM-10-006Document18 pagesAssignment 2 - EPGCOM-10-006Akash Kumar SuryawanshiNo ratings yet

- Quadratic Forms and Definite MatricesDocument15 pagesQuadratic Forms and Definite MatricesWorkineh Asmare KassieNo ratings yet

- AV AidsDocument71 pagesAV AidsSHANTHIPRIYA BODANo ratings yet

- A Guide To Action Learning Along With Tools and TechniquesDocument26 pagesA Guide To Action Learning Along With Tools and TechniquesMaryreneeNo ratings yet

- Biogeochemical Cycles Powerpoint Quiz Game With Answer Key For Educators - Download Powerpoint at Www. Science PowerpointDocument104 pagesBiogeochemical Cycles Powerpoint Quiz Game With Answer Key For Educators - Download Powerpoint at Www. Science PowerpointRyan MurphyNo ratings yet

- Winmostar tutorial: Gromacs Vapor Pressure・Surface TensionDocument12 pagesWinmostar tutorial: Gromacs Vapor Pressure・Surface TensionEliasSMonteiroFilhoNo ratings yet

- Cybersemiotics: A Suggestion For A Transdisciplinary Framework For Description of Observing, Anticipatory and Meaning Producing Systems - Soren BrierDocument13 pagesCybersemiotics: A Suggestion For A Transdisciplinary Framework For Description of Observing, Anticipatory and Meaning Producing Systems - Soren BrierJoão ParentiNo ratings yet

- WST01 01 Que 20170120Document28 pagesWST01 01 Que 20170120Mohammed MaGdyNo ratings yet

- My Magazine AnalysisDocument2 pagesMy Magazine Analysisapi-626592060No ratings yet

- 3D Printed Versus Conventionally Cured ProvisionalDocument9 pages3D Printed Versus Conventionally Cured ProvisionalSaleh AlmohammadNo ratings yet

- CHEM-205 Analytical Chemistry-I: AnovaDocument20 pagesCHEM-205 Analytical Chemistry-I: AnovaTanya DilshadNo ratings yet

- Box Puzzles Questions Specially For Sbi Po PrelimsDocument22 pagesBox Puzzles Questions Specially For Sbi Po PrelimsabhijeetNo ratings yet

- B2 UNIT 8 Test StandardDocument6 pagesB2 UNIT 8 Test StandardAlondra MelNo ratings yet

- G5 Q3W6 DLL SCIENCE (MELCs)Document5 pagesG5 Q3W6 DLL SCIENCE (MELCs)MYLEEN P. GONZALESNo ratings yet

- Quiz3 SolDocument2 pagesQuiz3 SolmayqueencygonzalesNo ratings yet

- Exercise Sheet-3Document2 pagesExercise Sheet-3pauline chauveauNo ratings yet

- ICT Holiday's Homework: Grade 7Document3 pagesICT Holiday's Homework: Grade 7SCJ WORLD ACADEMY SOHNA DT GURGAON HRY R.O. PANCHKULANo ratings yet

- Through Night and DayDocument4 pagesThrough Night and Dayqwerty heroNo ratings yet

- The Cult of The Avant-Garde ArtistDocument185 pagesThe Cult of The Avant-Garde Artisthaydar.tascilarNo ratings yet

- Hobbes Hidden Monsters PDFDocument23 pagesHobbes Hidden Monsters PDFErika Gomes Peixoto100% (1)