Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping

Uploaded by

pravinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping

Uploaded by

pravinCopyright:

Available Formats

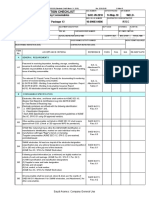

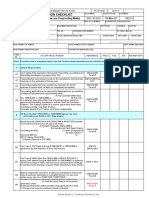

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (Complete SATR-A-2007, listed as Attachment 5 & use SATR-A-2011 & SATR-A-6133)

Post Test Reinstatement Procedure & Checklist is required

to be developed in accordance with & as part of pressure testing.

This is a pressure testing procedure & test package component to

be developed during package creation as based on workscope &

SAEP-1160,

A1 specific "system" requirements.

Section 8

Comment: A standard post-test checklist

does not provide a procedure for reinstatement. A detailed

procedure to give clear field direction along with a checklist for

this activity shall be submitted before the start of work.

Inspection strategies & plans shall be prepared and agreed on prior to

SAES-L-350,

A2 commencing of fabrication and erection. This is in common with

Para. 17.2

Pipelines. Pipelines simply follow their reinstatement procedure.

Specifically, Procedure shall detail PLAN or STRATEGY to reach

"SYSTEM" COMPLETION (Quality Certification) as efficiently as

possible while accomplishing critical goals of:

A) Effective Water

Removal, Disposal & System Lay-Up (Post Test)

No test fluid shall remain in low spots. Specifically, valve cavities. SAES-L-350,

B) Test Vents and Drains (plugged, seal welded & Para. 17.2 &

A3 PT'd) C) Removal & reconnection of

components All SAES-A-004,

temporary items installed for testing (e.g., manifolds, valves, Section 10

blinds, spacers, supports) shall be removed. Valves Installed. Items that

were removed from testing shall be reinstalled. Items, such as

instrument air tubing, check valve discs reconnected (witnessed). Valve

line-up & gasket installations meet specifications.

Effective Corrosion Control & Preservation Measures

Inspection Coverage and

Responsibilities (Package Clearance) SAES-L-350,

A4

Clearly detailed provisions for Retesting after reinstatement Para. 17.2

Evaluations by Inspection. Construction related provisions.

Saudi Aramco: Company General Use

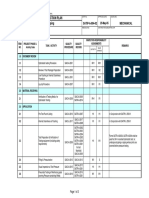

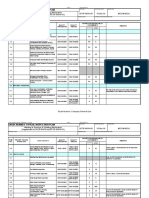

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B SAIC-A-2010 Checklist (Reinstatement Procedure & Checklist item required when bold.)

All joints including welded shall be left exposed for visual leak detection

during the strength test. External coating and priming of such joints are SAES-L-150,

B1 not allowed unless approved by the Manager of Inspection Department Para. 7.3

and the proponent Organization representative. The pipe itself can be

externally primed and coated to a final coat.

The assembly of bolted flange joints shall be in accordance with SAEP- SAES-L-450,

B2

351. Para. 9.4

Drains: Excluding submarine and buried pipelines, drains shall be SAES-L-150,

B3

provided at all low points of the piping system. Para. 6.2

Vents and drain valves, both temporary and permanent, conforms with SAES-L-105,

B4

the piping class or rating. ( Refer SAES-L-108) Para. 5.9

Supports: For above ground installation, the piping system shall be

analyzed to foresee whether temporary supports are required during

hydrostatic testing to limit the sustained longitudinal stresses to SAES-L-150,

B5

acceptable limits by the code. If temporary supports are found to be Para. 6.3

needed and more economical than permanent supports, this should be

highlighted in the hydrotesting procedure.

Expansion joints and spring hangers or spring supports shall be

SAES-L-150,

B6 provided with temporary restraints where needed to prevent excessive

Para. 6.4

travel or deformation under the test loads.

Arc strikes, gouges, and other indications of careless workmanship

SAES-W-011,

(such as surface porosity, uneven weld profiles, and undercut) shall be

B7 Para. 11.6 and

removed by grinding and inspected by magnetic particle or liquid

11.9

penetrant method.

SAES-W-011,

Temporary welded attachments to the pipe were ground off and

B8 Para. 11.7 and

inspected by magnetic particle or liquid penetrant method

11.9

All threaded joints and faying surfaces shall be seal welded by a SAES-W-011,

B9

continuous fillet weld (required weep holes shall be left unwelded). Para. 11.15.1

If requested by the proponent, all new valves designated for isolation

SAES-L-108,

B10 service (as specified by the Proponent) shall be subjected to a high

Section 4.7.2

pressure hydrostatic seat test prior to installation in the line.

Filling and pressurizing shall be done on the upstream side of check

valves in the system. The test fluid shall be injected at the lowest point

in the system to minimize entrapped air. When filling at the lowest point SAES-A-004,

B11

is not practical, the Inspection Department/ Operations Inspection Para. 9.1.1

Engineering Unit shall be consulted. All vents shall be open during

filling.

No one shall approach the test area for a minimum of 10 minutes after

the test pressure is reached and before commencement of inspection of

the system, the isolation valve between the temporary test SAES-A-004,

B12

manifold/piping and the piping/equipment under pressure test shall be Para. 9.1.2

closed and the test pump disconnected. The isolation valve downstream

of the manifold shall be opened after the pump is disconnected.

Saudi Aramco: Company General Use

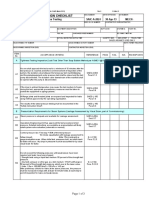

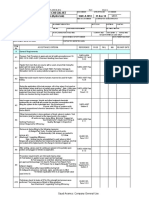

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

During the application of the test pressure, all in-line valves if not used SAES-A-004,

B13

as test isolation valves shall be in a partially open position. Para. 9.1.3

Vents shall be provided at all high points in the tested system as SAES-A-004,

B14

needed. Para 8.4.1

Excluding scrapable, submarine and buried pipelines, drains shall be

SAES-A-004,

B15 provided at all low points in the system and immediately above check

Para 8.4.2

valves in vertical lines.

Unless the check valve has a by-pass valve, the disc of the check valve

SAES-A-004,

B16 shall be removed, and securely attached to the outside of the check

Para 8.4.3

valve prior to the pressure test.

Flanged connections shall be avoided when butt-welded joints can be

used in services and locations where leaks are likely to occur (e.g.,

cyclic or vibration services), or will cause serious hazard (e.g.,

potentially toxic material), or are difficult to control, such as the

following:

SAES-L-110,

B17 a) Steam in ASME class 900 pressure rating

Para. 8.1

b) In the fully restrained portion of cross-country pipelines and in

underwater pipelines

c) In locations where the piping will be subjected to large bending or

other external loads

d) On buried piping system

Flanged connections with long exposed bolts for sandwiched

components, other than standard spectacle plates and blinds, shall not

SAES-L-110,

B18 be used in fire hazardous areas unless the bolting is protected by a fire

Para. 8.2

resistant shield such as illustrated on Standard Drawing AC-036404 or

equivalent method. (Ref. SAES-B-006).

Soft seated valves and control valves shall not be installed until after the SAES-A-004,

B19

lines have been thoroughly flushed. Para. 8.1.3

Before employing the pressure testing manifold in the actual system

pressure test, it shall be separately pressure tested to at least 1.2 times SAES-A-004,

B20

the system test pressure but not less than the discharge pressure of the Para. 5.5.4

pump used for the pressure testing.

Buried pipeline are adequately bermed or covered to anchor the line SAES-L-450

B21

during pressure test. Appendix C

All gauges and recorders shall be calibrated prior to use. The calibration

interval shall not exceed one (1) month prior to the test date and SAES-A-004,

B22 calibration certificates shall be made available to Inspection personnel Para. 8.1.5.1 and

prior to commencement of the pressure test. Stickers shall be applied 8.1.5.2

indicating the latest calibration date.

All gauges shall have a range such that the test pressure is within 30 to SAES-A-004,

B23

80% of the full range. Para. 8.1.5.3

A minimum of two pressure gauges are required for the test system.

SAES-A-004,

B24 One pressure gage shall be on the test manifold and the other(s) on the

Para. 8.1.5.4

test system. Their accuracy shall be within 5% of one another.

When large systems are tested, Inspection personnel will determine the SAES-A-004,

B25

need for additional gauges. Para. 8.1.5.5

Pressure and temperature recording gauges shall be used for all buried SAES-A-004,

B26

piping systems on plot and per SAES-L-150 for pipelines. Para. 8.1.5.6

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 Piping-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Blind flanges, Paddle or spectacle blinds shall be used to isolate test SAES-A-004,

B27

sections. Para. 8.3

A bleed valve readily accessible is provided in case immediate SAES-A-004,

B28

depressurization is required. Para. 5.5.2

Draining of Test Fluid- Release of pressure and draining shall be done

on the downstream side of check valves. All vents shall be opened SAES-A-004,

B29

before draining to facilitate drainage and to prevent formation of a Para. 10.1

vacuum. No test fluid shall remain in low spots.

Disposal of Test Fluid-The test fluid shall be disposed in accordance SAES-A-004,

B30

with SAEP-327 or as directed by the Owner. Para. 10.2

Test Vents and Drains-Vents and drains used only for the pressure test SAES-A-004,

B31

shall be plugged, seal welded and penetrant tested. Para. 10.3

Removal and Reconnection of Components- All temporary items

installed for testing purposes (e.g., manifolds, valves, blinds, spacers,

supports) shall be removed. Items that were removed from testing shall

be reinstalled. Items, such as instrument air tubing, check valve discs SAES-A-004,

B32

which were disconnected before testing shall be reconnected. Isolation Para. 10.4

valves closed for the test purposes and that are required to be in the

open position for process reasons shall be opened. If the valve cavity

has a drain, the cavity shall be drained.

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (30 January 2011)

2. SAES-L-105, Piping Material Specifications, (22 December, 2012)

3. SAES-L-108, Selection of Valves, (11 Oct, 2010)

4. SAES-L-110, Limitations on Pipe Joints and Components, (11 July, 2012)

5. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (25 April 2010)

6. SAES-L-350, Construction of Plant Piping, (22 April 2009)

7. SAES-L-450, Construction of On-Land and Near-Shore Pipelines, (10 Nov, 2012)

8. SAES-W-011, Welding Requirements for On-Plot Piping, (4 October, 2009)

9. SAEP-1160 , Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects (10 July 2011)

10. SAEP-351, Bolted Flange Joints Assembly (12 May 2012)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

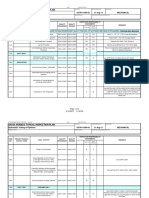

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Pre-Pressure Test Checklist (Form) SATR-A-2007 31-Dec-14 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION TEST SYSTEM No./Test Pack No. PLANT NO.

DRAWING NUMBER (P&ID/ISO) / REV. No. PRESSURE TEST DIAGRAM NATURE OF TEST WORK PERMIT REQD?

SAUDI ARAMCO TIP (SATIP) NUMBER SATIP Activity No. SUPPORTING SAIC Number SAIC QR No.

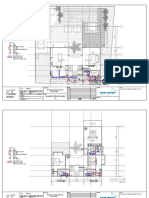

ATTACHMENT 1 (Guide for Post-Test Reinstatement Checklist by Contractor)

Notes:

1) This Form shall be used in conjunction with applicable Pre-Pressure Test Checklist. Refer to applicable SATIPs & See Attachment 1

2) "A" items are items required to be completed before pressure test can proceed.

3) "B" items are post-test items to be cleared immediately after pressure test (within 24 hours) with Inspection witness per procedure.

4) "B" items are completed during re-instatement per an approved Procedure before final inspection by Company (per procedure).

Note: "B" items not complete during re-instatement (by approved procedure) shall be transferred to "zFEIL Form 6133" (Attachment 2)

5) See SATR-A-2011 for Re-instatement Checklist Form.

6) ETC = Expected Time of Completion or Expected Start-up Date if ETC date is unknown (affects lay-up considerations)

I

T Pre-Pressure Test Checklist Items & A or Origi- ETC

Verified

Concur

Q

E

Description Reference

B nator (Note 6)

complete by

PID Insp

QC A

1M Seal weld threaded nipples from headers to root valves at (5) locations (hydrocarbon SAES-L-109, RLC

service) per SAES-L-109, Section 8. A ABC/QC 1/1/2007 DEF-1/1/07

Section 8 1/1/07

2 Guides are in direct contact with piping horizontal run at 3 locations (6mm gap req'd).

SAES-L-109, RLC

Relocate guides per drawing. These are welded to the pressure boundary. A ABC/QC 1/1/2007 DEF-1/1/07

Section 8 1/1/07

3 Check valve upstream clearance is not five (5) pipe diameters (40" req'd, 20" actual),

in violation of SAES-L-108. SAES-L-108, RLC

A ABC/QC 1/1/2007 DEF-1/1/07

Section 5 1/1/07

4 Check valve is oriented in the wrong direction (flow arrow). Reverse check valve to

assure correct flow direction. Reposition valve & restore internals immediately after SAES-L-108, RLC

test, COMPANY to witness. B ABC/QC 1/4/2007 DEF-1/4/07

Section 6 1/4/07

5 Piping clearance to structural bracing is 15 mm in violation of SAES-L-310, Sect 12. SAES-L-110, RLC

(50 mm spacing req'd). Engineering! A ABC/QC 1/1/2007 DEF-1/1/07

Section 5 1/1/07

6 Install permanent gaskets at flange sets 1, 4, 5, 6 on ISO dwgs per approved torque

SAEP-351, Start-up date =

tables and install spectacle blinds oriented as per approved P&ID. B ABC/QC

Proj Dwgs 5/1/2007

7 Completely remove all water and debris from low point/valve cavity for the (3) in-line

Valves (8" - 300 #) with SS 400 trim, do so immediately after test. Clean with dry

SAES-A-007, RLC

compressed air and relubricate sealing surfaces with approved lubricant in B ABC/QC 1/4/2007 DEF-1/4/07

Para 6.2 1/4/07

preparation for "ambient" lay-up specified in test package.

8 NOTES: a. Above Items are samples for form use.

b. Indicate " No Punch items. " as applicable

c. QA col is reviewed/initialed/dated prior to package certification

I to verify completeness

T Reinstatement (Post-Test) Checklist Items & Q

Reference & A Verified

Origi- ETC Concur

Description (Option per Note 5 Above) Applicable or

nator (Note 6)

complete

PID Insp

SATIP B by QC

E A

1M Flushing & hydrotest complete and documented as accepted. Reinstatement

Procedure

2 All test vents & drains plugged and seal welded ditto

3 Lines drained and lay-up per customer approved specification ditto

4 Valves (400 SS Trim) tested in-line removed, cleaned, & lubricated for Amb lay-up ditto

5 Jacking screws, process blinds (spectacles, spades, etc) correctly installed ditto

6 Spring Hangers & components (bellows, etc) adjusted per mfg instructions. ditto

7 Weepholes plugged with heavy grease (reinforcement pad air test complete) ditto

8 Chain wheel operators installed ditto

9 All instruments, control valves & check valves reinstalled in correct flow position ditto

10 Restriction orifice/flow elements installed ditto

11 Relief Valves are Pop tested/calibrated, tagged and SAP approved/installed ditto

12 All Temporary Test Components (spools, test blinds, gaskets etc) are removed ditto

13 Correct bolts/gaskets are installed and torqued per SAEP-351 requirements ditto

14 Check Valves and internals reinstalled (Internal Cleanliness & gasket check) ditto

15 All Start-up items installed (strainers, filters, other items restricted from test) ditto

16 Chemical Cleaning completed and documented

17 Final Line Check complete & meets all special process specs. See Spec Check.

NOTES: a. Above Items are samples for form use only.

b. Re-instatement Procedure shall detail specific items to be used in this Re-

Instatement checklist (per SAEP-1160, Sect. 8). The above 17 items are a

sample of such a procedure checklist.

c) Indicate " No Post Test items. " as applicable

d). QA col is reviewed/initialed/dated prior to

package certification to verify completeness

Saudi Aramco: Company General Use

You might also like

- Chapter 3 Plumbing FixturesDocument21 pagesChapter 3 Plumbing FixturesJasleneDimarananNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Architectural Science I (Water)Document223 pagesArchitectural Science I (Water)Muluken MelesseNo ratings yet

- Double Block and Bleed: What Can You Do?Document1 pageDouble Block and Bleed: What Can You Do?Triod jacksonNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- SWAS System DrawingDocument140 pagesSWAS System DrawingWWE LIVE TV50% (2)

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- SAIC-L-2014 Rev. 5Document10 pagesSAIC-L-2014 Rev. 5Jagadeesh PuppalaNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- SAIC-A-2020 Rev 2Document3 pagesSAIC-A-2020 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATIP-A-004-01 Rev 7Document2 pagesSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocument13 pagesSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- SAIC-A-2015 Rev 7Document8 pagesSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 Mechanicalpravin0% (1)

- Saic A 2001Document21 pagesSaic A 2001Dilshad AhemadNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- 1044 Plant Inspection Career Poster March 2015 PDFDocument1 page1044 Plant Inspection Career Poster March 2015 PDFHoque Anamul100% (1)

- SAIC-D-2002 Rev 2Document5 pagesSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNo ratings yet

- Saic MPT 2004 Rev 0Document6 pagesSaic MPT 2004 Rev 0philipyapNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- SAIC-W-2043 Rev 0Document3 pagesSAIC-W-2043 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- 175 012300Document2 pages175 012300Abu Anas M.SalaheldinNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- 175 018200 PDFDocument2 pages175 018200 PDFAbu Anas M.SalaheldinNo ratings yet

- 00 Saip 12Document8 pages00 Saip 12aamirtec301No ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-X-3104 Rev 3Document4 pagesSAIC-X-3104 Rev 3Imran khanNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010doyenofcastleNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- Saudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 31-Dec-14Document2 pagesSaudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 31-Dec-14pravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalDocument4 pagesSaudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Custody Metering Skid Installation For Hydrocarbon Gases SATIP-Y-101-01 MechanicalDocument4 pagesSaudi Aramco Typical Inspection Plan: Custody Metering Skid Installation For Hydrocarbon Gases SATIP-Y-101-01 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument4 pagesSaudi Aramco Typical Inspection PlanpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNo ratings yet

- Saep 1125Document6 pagesSaep 1125pravinNo ratings yet

- Storage ReservoirDocument6 pagesStorage Reservoirmaaz hussainNo ratings yet

- Tender Notice PDF RRR Phase VIDocument2 pagesTender Notice PDF RRR Phase VIKeruthiga KaliaperumalNo ratings yet

- DrainageVijayawadaSPL02080283 83 113Document6 pagesDrainageVijayawadaSPL02080283 83 113Manjul KothariNo ratings yet

- Ud AssignmentDocument17 pagesUd AssignmentMohamed AzimNo ratings yet

- Sophen Presentation Water Week 21 March-Hotel Shankar AnuzDocument25 pagesSophen Presentation Water Week 21 March-Hotel Shankar AnuzAnoj KhanalNo ratings yet

- Waste Water Treatment in Middle EastDocument19 pagesWaste Water Treatment in Middle EastSV SANKARAMOORTHYNo ratings yet

- Groundsurface WaterDocument1 pageGroundsurface WaterSophie BaromanNo ratings yet

- Pre-Inspection Checklist For Low Pressure Steam Boilers: Chapter 296-104 WAC Chapter 70.79 RCWDocument4 pagesPre-Inspection Checklist For Low Pressure Steam Boilers: Chapter 296-104 WAC Chapter 70.79 RCWMohammedNo ratings yet

- Description Brand Supplier Thickness PriceDocument45 pagesDescription Brand Supplier Thickness PriceGlenn CalingasanNo ratings yet

- Diagrama HidraulicoDocument4 pagesDiagrama HidraulicoFabrizio GiaimoNo ratings yet

- Case Study Teaching Material Headloss Friction 0Document4 pagesCase Study Teaching Material Headloss Friction 0Hasanul KabirNo ratings yet

- Lesson Plan Ecw435 Sept2016Document2 pagesLesson Plan Ecw435 Sept2016Firdaus Nordin SyaabanNo ratings yet

- 200 3-VXDocument109 pages200 3-VXRobles Dresch100% (1)

- Homeroom Pta Resolution No. 01, S. 2021: Department of EducationDocument2 pagesHomeroom Pta Resolution No. 01, S. 2021: Department of EducationMara Ciela Cajalne100% (1)

- Wisa2016 A110Document1 pageWisa2016 A110Musa We' Nkosi NxeleNo ratings yet

- Sewage and Waste WaterDocument4 pagesSewage and Waste WaterMuhammad DzikrulNo ratings yet

- JopDocument10 pagesJopAnonymous nHT1rzjmcNo ratings yet

- 9 Flow in Pipes - With FiguresDocument59 pages9 Flow in Pipes - With FiguresCarlos SerranoNo ratings yet

- Secondary ClarifiersDocument51 pagesSecondary ClarifiersmakortoNo ratings yet

- Attach 4Document6 pagesAttach 4akbarmulangathNo ratings yet

- Topic Identification Assignment: Gabriel Greco A00201829Document3 pagesTopic Identification Assignment: Gabriel Greco A00201829GabrielGrecoNo ratings yet

- Cabin Stores: (Bathroom Equipment - Bathroom Accessories)Document2 pagesCabin Stores: (Bathroom Equipment - Bathroom Accessories)AlexanderNo ratings yet

- Mixed Liquor Suspended Solids in Wastewater PDFDocument2 pagesMixed Liquor Suspended Solids in Wastewater PDFLouay MansourNo ratings yet

- Pipe AppurDocument44 pagesPipe Appurvikram100% (2)

- Attachment B3 HSE Manager Sardar Updated CV December 2020Document3 pagesAttachment B3 HSE Manager Sardar Updated CV December 2020أحمد خيرالدين عليNo ratings yet

- Combined-Cycle Water Treatment System: Power - Case StudyDocument1 pageCombined-Cycle Water Treatment System: Power - Case Studynermeen ahmedNo ratings yet