Professional Documents

Culture Documents

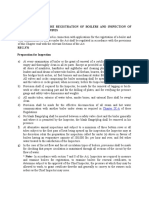

Form XIX: (See Regulation 376 (FF) and 376 (FFF) )

Uploaded by

amol shinde0 ratings0% found this document useful (0 votes)

18 views2 pagesOriginal Title

Form-XIX

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views2 pagesForm XIX: (See Regulation 376 (FF) and 376 (FFF) )

Uploaded by

amol shindeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Form XIX

[See regulation 376 (ff) and 376 (fff)]

DETAILS TO BE FURNISHED ALONGWITH APPLICATION FOR INSPECTION OF BOILER AFTER TWELVE/

TWENTY FOUR MONTHS OF THE CERTIFICATION UNDER REGULATION 390 AS PER APPENDIX ‘JA’ AND

APPENDIX ‘JB’

1. Name and address of the owner

2. Registry number of the boiler

3. Steam pressure and temperature

4. Rate of steam generation

5. Heating surface

6. Year of make

7. Brief description of boiler

8. Type of construction (Whether riveted or welded)

9. Whether fired or waste heat boiler

10. Date of registration

11. Details of past exemption granted by the Government, if any

12. Date of last annual inspection

13. Expiry date of current certificate

14. Working pressure at which last certificate was issued

15. Details of past repairs (year-wise)

16. Remarks as entered in the last certificate

17. Quality of boiler feed water

18. Whether requisite number of feed pumps are in satisfactory

working condition at present

19. Number of safety valves mounted on shell/drum and super

heater

20. Total number of soot blowers provided in boiler

21. Number of soot blowers in working condition

22. Whether safety valves are blowing satisfactorily at or below

design pressure?

23. Whether safety valve assembly is free from jamming as

verified by operating casing lever?

24. Whether high and low water level alarm is in good

condition?

25. Whether main steam stop valves, feed check valves, blow down

valves and master pressure gauge in working condition?

26. Whether additional requirements for automatic boilers as per

regulation 281A are complied with? (If 'No', give details)

27. Last date of calibration for master pressure gauge, temperature

indicator/recorder for superheater, hot reheat, cold reheat and

main steam line

28. a) Last date when boiler protection devices were satisfactorily

tested and details thereof

b) Last date when boiler protection devices were tested by

simulation

29. Details of the boiler stoppages in the lasrt twelve months with

reasons and remedies thereof

30. Present irregularities in Instruments and controls if any observed

in control-room of boiler house

31. Details of present boiler leakage

32. Present operating pressure of the boiler

33. Whether water quality is tested on-line (enclose copy of test

report showing values of analysis including Total Dissolved Solids

(TDS)

34. State at what intervals such test is carried out

35. When boiler was last opened for internal and/or external

cleaning?

36. State at what intervals such cleaning is carried out

37. Whether there was any shut down since last inspection when

the boiler could have been offered for inspection?

38. Whether working pressure of the boiler ever exceeded in the

past beyond certified limit? If any give details

39. Details of boiler accident which took place in the past, if any

40. List of Boiler Operation Engineers/Attendants

41. Irregularities, if any, noticed in the past in compliance of the Act

42. Whether guidelines laid down by Central Boilers Board for

granting exemption to the waste heat boilers are fulfilled or not?

General Manager (Generation)

Remarks of the Competent Person who verified correctness of above statement paying check visit to the Boiler House.

Competent Person

You might also like

- Reg. 375 Regulations For The Registration of Boilers and Inspection of Boilers and Steam-PipesDocument18 pagesReg. 375 Regulations For The Registration of Boilers and Inspection of Boilers and Steam-PipesAlanka PrasadNo ratings yet

- Boilers: - Asit MondalDocument29 pagesBoilers: - Asit MondalAJITSPATILNo ratings yet

- Boiler Inspection267142Document31 pagesBoiler Inspection267142raj.clarence7No ratings yet

- Accord Boiler Safety Program Infopack PDFDocument10 pagesAccord Boiler Safety Program Infopack PDFTimeNo ratings yet

- Standard Technical Features of BTG System For Supercritical 660/800 MW Thermal UnitsDocument11 pagesStandard Technical Features of BTG System For Supercritical 660/800 MW Thermal UnitsnareshvkkdNo ratings yet

- Indian Boiler Act 1923Document10 pagesIndian Boiler Act 1923parthi20065768No ratings yet

- Boe Exam Preparation PDFDocument12 pagesBoe Exam Preparation PDFAnand Swami78% (18)

- Standard Requirements: Regulation 386Document5 pagesStandard Requirements: Regulation 386Arunachalam NagarajanNo ratings yet

- Indian Boiler Regulation: Reulation. 4 Standard RequirementsDocument7 pagesIndian Boiler Regulation: Reulation. 4 Standard Requirementssandi1111No ratings yet

- IBRDocument33 pagesIBRBrijraj Pandey100% (5)

- Inspection Procedure of Low Risk Installed Boilers As Per IBR, 1950Document1 pageInspection Procedure of Low Risk Installed Boilers As Per IBR, 1950ratanNo ratings yet

- Inspecton ProcedureDocument3 pagesInspecton ProcedureSanthosh ReddyNo ratings yet

- Handbook of Corrosion DataDocument22 pagesHandbook of Corrosion DatametroroadNo ratings yet

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- SOP - Start-Up & Shut Down Procedure of Thermal Craker Heater De-CokingDocument10 pagesSOP - Start-Up & Shut Down Procedure of Thermal Craker Heater De-CokingsaadNo ratings yet

- Amended Rule in Boiler 1160Document18 pagesAmended Rule in Boiler 1160dnageshm4n244No ratings yet

- RULE 1160 - BoilerDocument24 pagesRULE 1160 - Boilerteddy tavaresNo ratings yet

- SP Grade 2 SB Course MaterialsDocument23 pagesSP Grade 2 SB Course MaterialsChia Hock ChuanNo ratings yet

- Internal Inspection Checklist - Fire Tube Boiler PDFDocument2 pagesInternal Inspection Checklist - Fire Tube Boiler PDFWaqar Dar100% (1)

- Standard Commissioning Procedure For Water Loop Heat Pump SystemsDocument15 pagesStandard Commissioning Procedure For Water Loop Heat Pump Systemszorro31No ratings yet

- Report SectionsDocument36 pagesReport SectionsJohny Lou LuzaNo ratings yet

- TR-036 Trane Chiller Rehab Ilia Ti OnDocument3 pagesTR-036 Trane Chiller Rehab Ilia Ti OnJoel Maximo Javines MangaoangNo ratings yet

- Standard Commissioning Procedure For Exhaust Air Heat Recovery SystemsDocument14 pagesStandard Commissioning Procedure For Exhaust Air Heat Recovery SystemsAbdul Mohid SheikhNo ratings yet

- Boiler Mock Test 1 With AnswersDocument5 pagesBoiler Mock Test 1 With AnswersQuinton Tendai NyamhungaNo ratings yet

- Power Transformers - OverviewDocument29 pagesPower Transformers - Overviewmundra2010No ratings yet

- Model Questions Mod-2.Document21 pagesModel Questions Mod-2.sachin mathewNo ratings yet

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Rohit Dave: Wednesday, February 17, 2010Document78 pagesRohit Dave: Wednesday, February 17, 2010Sérgio CruzNo ratings yet

- Aux Boiler Start UpDocument35 pagesAux Boiler Start UpFauzan KurniaNo ratings yet

- Pre - LTJ5123TGL6Boiler TruckDocument7 pagesPre - LTJ5123TGL6Boiler Truckchtoil2020No ratings yet

- Common Points To Trac Fujico.Document2 pagesCommon Points To Trac Fujico.venka07No ratings yet

- Inspection of Steam BoilersDocument2 pagesInspection of Steam Boilersavksk22No ratings yet

- Pwer TransformerDocument17 pagesPwer Transformerrossikada100% (2)

- Method of Statement For Precommissioning & Commissioning of ChillersDocument4 pagesMethod of Statement For Precommissioning & Commissioning of Chillersvin ssNo ratings yet

- Facility Company/Address: Boiler Model No.: Fuel: Sales Order No. Serial No.: Date: Installing ContractorDocument4 pagesFacility Company/Address: Boiler Model No.: Fuel: Sales Order No. Serial No.: Date: Installing ContractorHenry CoronadoNo ratings yet

- AGuideforFireTubeBoiler PDFDocument23 pagesAGuideforFireTubeBoiler PDFsidikNo ratings yet

- BoilerDocument36 pagesBoilerGanesh MuruganNo ratings yet

- Occupational Safety and Health Standards-Rule 1160 On BroilerDocument17 pagesOccupational Safety and Health Standards-Rule 1160 On BroilerRosa GamaroNo ratings yet

- Common Points To Blue StarDocument2 pagesCommon Points To Blue Starvenka07No ratings yet

- Hot Water Test ProceduresDocument18 pagesHot Water Test Procedures3piNo ratings yet

- 2 Factories Ordinance IIDocument38 pages2 Factories Ordinance IILasantha DadallageNo ratings yet

- Boiler Maintenancetasks PDFDocument15 pagesBoiler Maintenancetasks PDFMachineryeng100% (1)

- Specification For Gas Fired BoilerDocument7 pagesSpecification For Gas Fired BoilerBashir Abdullah100% (1)

- Wall-Mounted Condensing Boilers: Installer's and User's InstructionsDocument36 pagesWall-Mounted Condensing Boilers: Installer's and User's InstructionsDana BarnettNo ratings yet

- Inspection Manual For Types of Heat ExchangersDocument83 pagesInspection Manual For Types of Heat ExchangersarisandiyusufNo ratings yet

- Checklist Boiler and TurbineDocument17 pagesChecklist Boiler and Turbinekeerthi dayarathna50% (2)

- Stress Relieving Procedure 01Document6 pagesStress Relieving Procedure 01VikasShelkeNo ratings yet

- Barmer To Salaya Pipeline Project: Material RequisitionDocument12 pagesBarmer To Salaya Pipeline Project: Material Requisitionsajeesh5113699No ratings yet

- FMA Steam Boiler and UPV 1970 MalaysiaDocument59 pagesFMA Steam Boiler and UPV 1970 MalaysiaarifhonNo ratings yet

- Heat Exchanger ManualDocument84 pagesHeat Exchanger ManualChaitanya Sai T100% (3)

- 2.ibr Related TheoryDocument29 pages2.ibr Related TheoryRaag SNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Rla 2Document38 pagesRla 2RAMAN SHARMANo ratings yet

- Chiller Testing Procedure Rev 3 PDFDocument11 pagesChiller Testing Procedure Rev 3 PDFOanh NguyenNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Asme SectionsDocument56 pagesAsme SectionsalperbogaNo ratings yet

- CP Maintenance-Alfa LavalDocument2 pagesCP Maintenance-Alfa Lavalamol shindeNo ratings yet

- Heat Exchanger Design Training - Course ContentDocument6 pagesHeat Exchanger Design Training - Course Contentamol shindeNo ratings yet

- Nozzle Pro FEA TrainingDocument1 pageNozzle Pro FEA Trainingamol shindeNo ratings yet

- Pressure Vessel Design Training - Course ContentDocument13 pagesPressure Vessel Design Training - Course Contentamol shindeNo ratings yet

- I24.KK36.01UGD.0.AB - DS.PR010 - Sulphuric Acid Supply Pump - Rev - R01Document12 pagesI24.KK36.01UGD.0.AB - DS.PR010 - Sulphuric Acid Supply Pump - Rev - R01amol shindeNo ratings yet

- Vessel Technical PointsDocument3 pagesVessel Technical Pointsamol shindeNo ratings yet

- The Production of Magnets by FFF - Fused Filament FabricationDocument7 pagesThe Production of Magnets by FFF - Fused Filament Fabricationamol shindeNo ratings yet

- Forest and Farm Producer Organizations Improve Income and Access To MarketsDocument2 pagesForest and Farm Producer Organizations Improve Income and Access To Marketsamol shindeNo ratings yet

- Vessel Technical PointsDocument3 pagesVessel Technical Pointsamol shindeNo ratings yet

- Intro 2 Me ChengDocument25 pagesIntro 2 Me ChengLakshmiVishwanathanNo ratings yet

- Project ManagementDocument24 pagesProject ManagementPooja TripathiNo ratings yet

- Materials 12 00895Document25 pagesMaterials 12 00895amol shindeNo ratings yet

- Vessel Technical PointsDocument3 pagesVessel Technical Pointsamol shindeNo ratings yet

- 2 Reversed Carnot CycleDocument2 pages2 Reversed Carnot CycleAlok GargNo ratings yet

- Juice Heater 1Document1 pageJuice Heater 1vijendrNo ratings yet

- ULM Access Control ConfigurationDocument10 pagesULM Access Control Configurationamol shindeNo ratings yet

- Non-Linear Finite Element Analysis of Solids and Structures Vol.1 - M.A. CrisfieldDocument360 pagesNon-Linear Finite Element Analysis of Solids and Structures Vol.1 - M.A. CrisfieldKarthick Murugesan100% (2)

- TowerDocument133 pagesToweramol shindeNo ratings yet

- TowerDocument133 pagesToweramol shindeNo ratings yet

- Objectives of Conduction AnalysisDocument30 pagesObjectives of Conduction AnalysisnachappaNo ratings yet

- Mos Material 3Document3 pagesMos Material 3ravi tejaNo ratings yet

- 4 Ericsson CycleDocument2 pages4 Ericsson CyclecaptainhassNo ratings yet

- PV Elite Vessel Analysis ProgramDocument13 pagesPV Elite Vessel Analysis Programamol shindeNo ratings yet

- Otto CycleDocument5 pagesOtto CycleSaraju NandiNo ratings yet

- Methods of RefrigerationDocument2 pagesMethods of RefrigerationAnkur Yash100% (1)

- 1 Carnot VPC Iit LectureDocument2 pages1 Carnot VPC Iit LectureKapil GoyalNo ratings yet

- Multiple Choice Question Material ScienceDocument2 pagesMultiple Choice Question Material Sciencemanish_agr8567% (3)

- Materials Science: Course Motivation and HighlightsDocument4 pagesMaterials Science: Course Motivation and Highlightskh_gallardoNo ratings yet

- EX200Document7 pagesEX200shubbyNo ratings yet

- IQAc 04-05Document10 pagesIQAc 04-05ymcacollegewebsiteNo ratings yet

- Openvpn ReadmeDocument7 pagesOpenvpn Readmefzfzfz2014No ratings yet

- Motivation Theories Description and CriticismDocument14 pagesMotivation Theories Description and CriticismAhmed Elgazzar89% (18)

- Description and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15ADocument34 pagesDescription and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15APablo Barboza0% (1)

- Backwards Design - Jessica W Maddison CDocument20 pagesBackwards Design - Jessica W Maddison Capi-451306299100% (1)

- Vygotsky EssayDocument3 pagesVygotsky Essayapi-526165635No ratings yet

- 105 2Document17 pages105 2Diego TobrNo ratings yet

- Taoist Master Zhang 张天师Document9 pagesTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)

- Seizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Document14 pagesSeizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Sulaman AbdelaNo ratings yet

- CAREDocument11 pagesCARELuis SementeNo ratings yet

- X - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanDocument7 pagesX - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanAnonymous dIjB7XD8ZNo ratings yet

- A Semi-Detailed Lesson Plan in MAPEH 7 (PE)Document2 pagesA Semi-Detailed Lesson Plan in MAPEH 7 (PE)caloy bardzNo ratings yet

- Raksha Mantralaya Ministry of DefenceDocument16 pagesRaksha Mantralaya Ministry of Defencesubhasmita sahuNo ratings yet

- Advertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133Document4 pagesAdvertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133dineshNo ratings yet

- MCQ Floyd ElexDocument87 pagesMCQ Floyd ElexnicoleNo ratings yet

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDocument10 pagesAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNo ratings yet

- Lab Manual Switchgear and Protection SapDocument46 pagesLab Manual Switchgear and Protection SapYash MaheshwariNo ratings yet

- DR S GurusamyDocument15 pagesDR S Gurusamybhanu.chanduNo ratings yet

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocument11 pagesA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- Lesson 1: Composition: Parts of An EggDocument22 pagesLesson 1: Composition: Parts of An Eggjohn michael pagalaNo ratings yet

- Fake News Infographics by SlidesgoDocument33 pagesFake News Infographics by SlidesgoluanavicunhaNo ratings yet

- Unbound DNS Server Tutorial at CalomelDocument25 pagesUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreNo ratings yet

- What You Need To Know About Your Drive TestDocument12 pagesWhat You Need To Know About Your Drive TestMorley MuseNo ratings yet

- Song LyricsDocument13 pagesSong LyricsCyh RusNo ratings yet

- Classification of Books Using Python and FlaskDocument5 pagesClassification of Books Using Python and FlaskIJRASETPublicationsNo ratings yet

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 pagesJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollNo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Paul Spicker - The Welfare State A General TheoryDocument162 pagesPaul Spicker - The Welfare State A General TheoryTista ArumNo ratings yet

- Alphabetic KnowledgeDocument8 pagesAlphabetic KnowledgejsdgjdNo ratings yet