Professional Documents

Culture Documents

ABB Safe Plus Compact 12kV MV Switchgear for 1MW Solar Plant

Uploaded by

Luis Fernando PaniaguaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB Safe Plus Compact 12kV MV Switchgear for 1MW Solar Plant

Uploaded by

Luis Fernando PaniaguaCopyright:

Available Formats

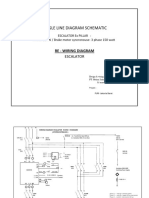

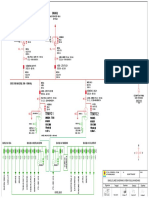

MV SWITCHGEAR 12kV TS 1 - ABB Safe Plus Compact

PHASE 1 = 595 KW LV COMP.

1. INCOMING LINE 1

LV COMP.

2. TR1

LV COMP.

3. TR2

-OCR1 -OCR2 -OCR3

ABB REF 615 ABB REF 615 ABB REF 615

MB1

ENERGY METERING

SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A

-C1 20kA 3s -C2 20kA 3s -C3 20kA 3s

1MW

kWh kVArh

-QF1 -QF2 -QF3

630A M 630A M 630A M

-QS1

630A

-QS2

630A

-QS3

630A

SOLAR PLANT

-VTM1

11.8kV/ √3 / 110V/ √3

-VT1

11.8kV/ √3 / 110V/ √3

-VT2

11.8kV/ √3 / 110V/ √3

-VT3

11.8kV/ √3 / 110V/ √3

6 inverters x 100 KW

MCT 1 - 100/1A-5P20 MCT 3 - 100/1A-5P20 MCT 4 - 100/1A-5P20

MCT 2 - 100/1A-CL 0.5

MV COMP. MV COMP. MV COMP.

38.5 A 38.5 A

3 x N2XS(F)2Y 1x50mm2, 12kV 3 x N2XS(F)2Y 1x50mm2, 12kV 6x(3x240/120 mm2) XLPE

Duty + Standby

-1TR1 -1TR2

OIL IMMERSED OIL IMMERSED

800kVA 800kVA

12/0.4kV 12/0.4kV

uk=6% uk=6%

Dyn5 Dyn5

1215 A 1155 A

LV SWITCHGEAR 0.38kV BUSBAR 1250A

BUSBAR 1250A

MLVSDB.TS1 FORM 3B -PFC1

-1QT1 -1QT2 -1QT3

1250A 1250A 1250A

50kA 50kA 50kA

LSIN LSIN LSIN

-1F1 -1PE1 -1F2 -1PE2 -1F3 -1PE3

NETWORK NETWORK NETWORK

-1TC1,2,3 2A -2TC1,2,3 2A -3TC1,2,3 2A

2000/5A ANALYZER 2000/5A ANALYZER 2000/5A ANALYZER

cl 0.5 5VA cl 0.5 5VA cl 0.5 5VA

Ikmax= 21.3kA

TN-C L1 L2 L3 400/230V 2000A 50kA Ikmin= 15.6kA

-1Q1 -1Q2 -1Q3 -1Q4 -1Q5 -1Q6 -1Q7 -1Q8 -1Q9 -1Q10 -1Q11 -1Q12 -1Q13 -1Q14 -1Q15 -1Q16

400A 160A 63A 100A 160A 160A 160A 160A 160A 160A 80A 25A 40A 250A 160A 160A

50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 100kVAr

LSI LSI LI LI LSI LSI LSI LSI LSI LSI LI LI LI LSI LSI LSI

PEN

NYY-J 1x95mm2

-1Q27

250A

50kA

EQUIPOTENTIAL

BONDING RAIL

-EBR1

EARTHING

W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14

MCC-47 MCC-43 MDB.57 MCC-54.2 MCC-CNT1 MCC-CNT2 MCC-CNT3 MCC-CNT4 MCC-CNT5 MCC-CNT6 TSGS UPS RECT 110DC

47-DCU-01 47-DCU-02 47-DCU-03 47-DCU-04 47-DCU-05 47-DCU-06

Dewatering

Primary sludge PS Outdoor light 1 Centrifuge 1 Centrifuge 2 Centrifuge 3 Centrifuge 4 Centrifuge 5 Centrifuge 6

Power Factor

Future Propulsors 1Future Propulsors 2

LEGEND

Building Odor Control TSGS UPS Rectifier

Correction

Installed power (kW) 232.50 50.69 10.00 25.00 56.00 56.00 56.00 56.00 56.00 56.00 35.00 9.00 20.00 60 60 DISTRIBUTION BOARD (HVAC, LIGHTNING, SOCKETS)

Ks 0.83 0.70 0.80 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

Simultaneous Power (kW) per cabinet 192.98 35.48 8.00 25.00 56.00 56.00 56.00 56.00 56.00 56.00 35.00 9.00 20.00

240

MAIN CONTROL PANEL (PROCESS EQUIPMENT)

Power Supply Cable 2x(XLPE 3x 120 ) XLPE 3x120 70 XLPE 4x16 XLPE 4x25 XLPE 3x70 50 XLPE 3x70 50 XLPE 3x70 50 XLPE 3x70 50 XLPE 3x70 50 XLPE 3x70 50 NYY-J 4X25 NYY-J 4X4 NYY-J 4X10 NYY-J 4x1x70

Lenght (m) 80 100 10 40 25 27 28 30 32 34 10 10 10 5.00

Total installed power (kW) 718.1900 LOCAL CONTROL PANEL (THIRD PARTY DELIVERY)

Plant coincidence factor 0.9000

Max Simultaneous Power (kW) - sum 661.4580

Total simulateneous power with coincedence

595.3122

factor applied (kW)

Total Current before PFC (A) 984.2995

Power factor before compensation 0.9200

Power factor after compensation 0.9600

Total Current after PFC (A) 943.2870

E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

B 2da Revisión

A 1era Revisión NM 04.2021.

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Ercóle Marelli Impianti Tecnologici S.R.L

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

UCP-PSLT No.69

Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 1 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-001-A 1/2

MCC47 Dewatering Building

FORM 2B Type 1

Ikmax= 19kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin=13.3kA

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 SDF1 SDF2 SDF3 SDF4 SDF5 SDF6 SDF7 SDF8 SDF9 SDF10 SDF11 SDF12 SDF13 SDF14 SDF15 SDF16 SDF17 SDF18 -QM1 -QM2 -QM3 -QM4 -QM5 -QM6 -QM7 -QM8 -QM9 -QM10 SDF21 SDF22 SDF23 SDF24 SDF25 SDF26 SDF27 SDF28 SDF29 SDF30 SDF31 -QCB1 -QCB2 -QCB3 -QCB4 -QCA

CONTROL 10A 10A 125A 5A 5A 6.3A 6.3A 6.3A 6.3A 4A 4A 6.3A 6.3A C25A C25A C25A C63A 6A

2A gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG gG

RELAY 25KA 25KA

-KF1 25KA 50A 50A 50A 50A 50A 50A 50A 50A 50A 16A 16A 16A 16A 16A 16A 16A 16A 16A 16A 16A 16A 16A 80A 80A 80A 25A 25A 25A 25A 25KA 25KA 25KA 25KA 25KA

-ST2

-F1,F2,F3 -PE1 T<5°C

START START START START START START START START START START

NETWORK -S1 STOP STOP STOP STOP STOP STOP STOP STOP STOP STOP 7Ah

ANALYZER 230V

2A

PAC 3200 -S1 -S2 -S3 -S4 -S5 -S6 -S7 -S8 -S9 -S10 DC

-CT1

-CT2 400/5A 10VA -H21 -H23 -H25 -H27 250W UPS

-H1 -H3 -H5 -H7 -H9 -H11 -H13 -H15 -H17 -H19 -H22 -H24 -H26 -H28 10A 10A

-CT3 -HS1 -EH1

11W 80W -FP1 -H2 -H4 -H6 -H8 -H10 -H12 -H14 -H16 -H18 -H20 24V

-SE1 -KM7-8 -KM9-10 PLC OP ETHS INSTRUMENTATION

-MQ1 4kW 4kW -QCAB EM

400A EMERGENCY

-SS3 -SS4 -SS5 -SS6 10A

SHUTDOWN

-KM1 -KM2 -KM3 -KM4 -KM5 -KM6 -KM11 -KM12 20A 20A 20A 20A

4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW Danfoss Danfoss Danfoss Danfoss

VLT VLT VLT VLT

MCD600 MCD600 MCD600 MCD600

Cabinet IP Cabinet IP Cabinet IP Cabinet IP

N 21 21 21 21

PE

EQUIPOTENTIAL

-EBR BONDING RAIL

M M M M M M M M M M M M M M

-W09.1/9.2 -FC1 -FC2 -FC3 -FC4 -FC5 -FC6 -FC7 -FC8 -FC9 -FC10 -FC11 -FC12 -FC13 -FC14 -FC15 -FC16 -FC17 -FC18 -FC21 -FC22 -FC23 -FC24 -FC25 -FC26 -FC27

EARTHING 3kW

2x(XLPE 4x240) 11kW 11kW 11kW 11kW 11kW 11kW 11kW 11kW 11kW 3kW 3kW 3kW 3kW 3kW 3kW 3kW 3kW 1.1kW 1.1kW 1.1kW 1.1kW 22kW 22kW 22kW -LCP.PP1 -LCP.PP2 -LCP.PP3 -MDB.47

Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss

FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301 FC301

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted

Wall

mounted Note:

IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55 IP 55

· Variable frequency drives (IP55) will be wall

mounted outside cabinet.

M M M M M M M M M M M M M M M M M M M M M M M M M

· VFD's will be equiped with Profibus interface.

47-ESP-01 47-ESP-02 47-ESP-03 47-ESP-04 47-ESP-05 47-ESP-06 47-ESP-07 47-ESP-08 47-ESP-09 47-DP-01 47-DP-02 47-DP-03 47-DP-04 47-DP-05 47-DP-06 47-DP-07 47-DP-08 47-DP-09 47-BEC-01 47-BEC-02 63-BEC-01 63-BEC-02 63-BEC-03 63-BEC-04 63-BEC-05 63-BEC-06 49-MIX-01 49-MIX-02 63-SCC-01 63-SCC-02 63-SCC-03 63-SCC-04 49-SCP-01 49-SCP-02 49-SCP-03 46.1-MIX-01 46.1-MIX-02 46.2-MIX-01 46.2-MIX-02 47-PPU-01 47-PPU-02 47-PPU-03 · Local control (Start/Stop) will be possible from

HMI.

MCC47 Feed Pump 1 Feed Pump 2 Feed Pump 3 Feed Pump 4 Feed Pump 5 Feed Pump 6 Feed Pump 7 Feed Pump 8 Feed Pump 9 Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump Poly Feed Pump

1 2 3 4 5 6 7 8 9

Belt conveyor

1

Belt conveyor

2

Belt conveyor

3

Belt conveyor

4

Screw conveyor Screw conveyor

3 4

Belt conveyor

5

Belt conveyor

6

Mixer in Mixer in

supernatant tank supernatant tank

Metering

Conveyor 1

Metering

Conveyor 2

Metering

Conveyor 3

Metering

Conveyor 4

Supernatant

Pump 1

Supernatant

Pump 2

Supernatant

Pump 3

Submerisbile

Mixer 1

Submerisbile

Mixer 2

Submerisbile

Mixer 3

Submerisbile

Mixer 4

Poly preparation Poly preparation Poly preparation Main distribution

unit 1 unit 2 unit 3 board

PLC

· Remote mode will be controled by PLC over

1 2

Mechanical power (kW) 5.50 5.50 5.50 5.50 5.50 5.50 5.50 5.50 5.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 4.00 1.50 1.50 2.20 2.20 2.20 2.20 1.50 1.50 1.80 1.80 0.55 0.55 0.55 0.55 22.00 22.00 22.00 4.00 4.00 4.00 4.00 2.50 2.50 2.50 30.00 1.00

Profibus.

Power Factor (cos φ) 0.84 0.84 0.84 0.84 0.84 0.84 0.84 0.84 0.84 0.79 0.79 0.79 0.79 0.79 0.79 0.79 0.79 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.80 0.98 0.98 0.98 0.98 0.83 0.83 0.83 0.98 0.98 0.98 0.98 1.00 1.00 1.00 0.95 0.80 · DOL motors will have selector switch for

Efficiency 0.89 0.89 0.89 0.89 0.89 0.89 0.89 0.89 0.89 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.70 0.70 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.85 0.85 0.85 1.00 1.00 selecting mode of operation (local/off/remote).

Simultaneous Current (A) 10.63 10.63 10.63 10.63 10.63 10.63 10.63 10.63 10.63 3.23 3.23 3.23 3.23 3.23 3.23 3.23 3.23 8.50 3.19 3.19 4.68 4.68 4.68 4.68 3.19 3.19 4.64 4.64 0.92 0.92 0.92 0.92 43.53 43.53 43.53 6.70 6.70 6.70 6.70 4.25 4.25 4.25 45.63 1.90

Installed power(kW) 6.18 6.18 6.18 6.18 6.18 6.18 6.18 6.18 6.18 1.76 1.76 1.76 1.76 1.76 1.76 1.76 1.76 4.71 1.76 1.76 2.59 2.59 2.59 2.59 1.76 1.76 2.57 2.57 0.63 0.63 0.63 0.63 25.00 25.00 25.00 4.55 4.55 4.55 4.55 2.94 2.94 2.94 30.00 1.00

Power Supply Cable NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYCY 03X2.5/2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYY 04X2.5 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X4/4 NYCY 03X10/10 NYCY 03X10/10 NYCY 03X10/10 NYY 04X4 NYY 04X4 NYY 04X4 NYY 04X4 NYY-J 5X4 NYY-J 5X4 NYY-J 5X4 NYY-J 5X10 NYY-J 4X2.5

Lenght (m) 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 15.00 40.00 45.00 50.00 55.00 50.00 50.00 50.00 50.00 60.00 60.00 60.00 60.00 60.00 60.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 15.00 1.00

Total Installed Power (kW) 232.5015

Plant coincidence factor 0.8300

Total Simultaneous Power (kW) 192.9762

325.4530

MCC 43 Primary sludge PS

FORM 2B Type 1 Note:

Ikmax= 8.4kA Variable frequency drives (IP21) will be wall mounted inside cabinet.

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 2.7kA Cabinet will be heavy duty type outdoor cabinet

with double door simmilar or equal to Thalassa PLA from Schneider

Electric:

-Q1 -Q2 -Q3 -Q4 -QCA

-F4,F5,F6 PHASE

CONTROL 10A 10A 125A

SDF1 SDF2 SDF3 SDF4 SDF5 SDF6 -QM1

4A

-QM2

4A

-QM3

6.3A

-QM4

6.3A C6A 6A · Polyester reinforced with fibreglass) floor-standing cabinet with

2A gG gG gG gG gG gG

-KF1

RELAY

63A 63A 63A 63A 63A 63A 2-door (IP55).

-ST2 -ST

-F1,F2,F3 -PE1 T<5°C

START START START START

T>25°C · VFD's will have Profibus interface.

NETWORK -S1 STOP STOP STOP STOP 7Ah

2A ANALYZER 230V · Local control (Start/Stop) will be possible from HMI mounted

PAC 3200 -S1 -S2 -S3 -S4 DC

-CT1

-H1 -H3 -H5 -H7 -H9 -H11 250W UPS

on internal doors.

-CT2 100/5A 10VA

-CT3 -HS1 -EH1 -H2 -H4 -H6 -H8 -H10 -H12 -H1 -H3 -H5 -H7 M 10A 10A

11W 80W -FP1 -H2 -H4 -H6 -H8 24V

2X PLC OP ETHS INSTRUMENTATION

Ventilation will be provided with special side ventilation module

-SE1

-MQ1

EMERGENCY

-QCAB EM (IP55) and ventilated plinth.

160A 10A

SHUTDOWN -FC1 -FC2 -FC3 -FC4 -FC5 -FC6

11kW 11kW 11kW 11kW 11kW 11kW -KM1 -KM2 -KM3 -KM4

Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss 4kW 4kW 4kW 4kW

FC301 FC301 FC301 FC301 FC301 FC301

Cabinet Cabinet Cabinet Cabinet Cabinet Cabinet

IP 21 IP 21 IP 21 IP 21 IP 21 IP 21

N

PE

EQUIPOTENTIAL

-EBR BONDING RAIL

M M M M M M M M M M

-W11

EARTHING

XLPE 3X70/50

43.1-ESP-01 43.1-ESP-02 43.1-ESP-03 43.2-ESP-01 43.2-ESP-02 43.2-ESP-03 43.1-ESP-03 43.2-ESP-01 43.2-ESP-02 43.2-ESP-03

MCC 43 Pump 1 Pump2 Pump3 Pump4 Pump5 Pump6 Scraper Bridge 1 Scraper Bridge 2 Scraper Bridge 3 Scraper Bridge 4 Cabinet fans PLC

Mechanical power (kW) 7.50 7.50 7.50 7.50 7.50 7.50 0.75 0.75 0.75 0.75 0.10 1.00

Power Factor (cos φ) 0.77 0.77 0.77 0.77 0.77 0.77 0.75 0.75 0.75 0.75 0.75 0.80

Efficiency 0.98 0.98 0.98 0.98 0.98 0.98 0.82 0.82 0.82 0.82 0.82 1.00

Simultaneous Current (A) 15.12 15.12 15.12 15.12 15.12 15.12 1.86 1.86 1.86 1.86 0.25 1.90

Installed power (kW) 7.65 7.65 7.65 7.65 7.65 7.65 0.91 0.91 0.91 0.91 0.12 1.00

Power Supply Cable NYCY 03X6/6 SW NYCY 03X6/6 SW NYCY 03X6/6 SW NYCY 03X6/6 SW NYCY 03X6/6 SW NYCY 03X6/6 SW NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-1 3x1.5

Lenght (m) 15.00 15.00 15.00 15.00 15.00 15.00 25.00 25.00 25.00 25.00 1.00

Total Installed Power (kW) 50.6989

Plant coincidence factor 0.7000

Total Simultaneous Power (kW) 35.4892

Total Simultaneous Current (A) 70.1969

E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

B 2da Revisión

A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Ercóle Marelli Impianti Tecnologici S.R.L

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

UCP-PSLT No.69

Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 1 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-001-A 2/2

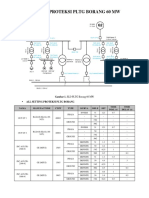

MV SWITCHGEAR 12kV TS 2 - ABB Safe Plus Compact

PHASE 1 674 KW + 1270KW= 1944 KW LV COMP.

1. INCOMING LINE 1

LV COMP.

2. TR1

LV COMP.

3. TR2

LV COMP.

4. TR3

LV COMP.

5. TR4

-OCR1 -OCR2 -OCR3 -OCR4 -OCR5

ABB REF 615 ABB REF 615 ABB REF 615 ABB REF 615 ABB REF 615

MB1

ENERGY METERING

SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A

-C1 20kA 3s -C2 20kA 3s -C3 20kA 3s -C4 20kA 3s -C5 20kA 3s

kWh kVArh

-QF1 -QF2 -QF3 -QF4 -QF5

630A M 630A M 630A M 630A M 630A M

-QS1 -QS2 -QS3 -QS4 -QS5

-VTM

630A 630A 630A 630A 630A

11.8kV/ √3 / 110V/ √3

-VT1 -VT2 -VT3 -VT4 -VT5

11.8kV/ √3 / 110V/ √3 11.8kV/ √3 / 110V/ √3 11.8kV/ √3 / 110V/ √3 11.8kV/ √3 / 110V/ √3 11.8kV/ √3 / 110V/ √3

MCT 1 - 600/1A-5P20 MCT 3 - 200/1A-5P20 MCT 4 - 200/1A-5P20 MCT 4 - 100/1A-5P20 MCT 4 - 100/1A-5P20

MCT 2 - 600/1A-CL 0.5

MV COMP. MV COMP. MV COMP. MV COMP. MV COMP.

192.45 A 192.45 A 60.2 A 60.2 A

3 x N2XS(F)2Y 1x50mm2, 12kV 3 x N2XS(F)2Y 1x50mm2, 12kV

3 x N2XS(F)2Y 1x95mm2, 12kV

Duty + Standby 3 x N2XS(F)2Y 1x95mm2, 12kV

Duty + Standby

-TR3 -TR4

OIL IMMERSED OIL IMMERSED

1250kVA 1250kVA

12/0.4kV 12/0.4kV

-TR1 -TR2 uk=5% uk=5%

Dyn5 Dyn5

4000kVA 4000kVA 1899A 1899A

12/6kV 12/6kV

uk=6% uk=6% BUSBAR 2000A BUSBAR 2000A

Dyn5 Dyn5 LV SWITCHGEAR 0.38kV

385A 385A

MLVSDB.TS2 FORM 3B -PFC1

XLPE 3x1x185mm2 -1QT1 -1QT2

2000A 2000A

50kA 50kA

LSIN LSIN

XLPE 3x1x185mm2

PHASE II (FUTURE)

-1F1 -1PE1 -1F2 -1PE2

NOT IN SCOPE OF DELIVERY NETWORK NETWORK

-1TC1,2,3 2A -1TC2,2,3 2A

2000/5A ANALYZER 2000/5A ANALYZER

cl 0.5 5VA cl 0.5 5VA

SF6 / 6 kV / 630A SF6 / 6 kV / 630A

-C1 63kA / 25kA 1s -C2 63kA / 25kA 1s -C3 -C4 -C5 -C4 -C5 -C6

-Q1 -Q2 Ikmax= 34.2kA

630A 630A -SW3 -SW4 -SW5 -SW6 -SW7 -SW8 TN-С-S L1 L2 L3 400/230V 2000A 50kA Ikmin= 24.5kA

XXkA XXkA 630A 630A 630A 630A 630A 630A

-SW1 -SW2

630A 630A -MF3 -MF4 -MF5 -MF6 -MF7 -MF8

200A 200A 200A 200A 200A 200A

-1Q1 -1Q2 -1Q3 -1Q4 -1Q5 -1Q6 -1Q7 -1Q8 -1Q9 -1Q10 -1Q11 -1Q12 -1Q13 -1Q14 -1Q15

100A 630A 160A 250A 250A 100A 100A 100A 100A 80A 25A 40A 250A 250A 250A

50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 100kVAr 4x25kVAr

LSI LSI LSI LSI LSI LSI LSI LSI LSI LI LI LI LSI LSI LSI physical steps: 4

electrical steps: 3

PEN

NYY-J 1x95mm2

71 A 71 A 71 A 71 A 71 A 71 A -1QC1

250A

50kA

EQUIPOTENTIAL

3 x N2XS(F)2Y 1x50mm2, 12kV BONDING RAIL

-EBR1

EARTHING

W01 W02 W03 W04 W05 W06 W09 W10 W11 W13 W14 W15

MCC-52 MCC-35 MCC-40 MCC-28.1 MCC-28.2 MCC-25 MDB-58 MCC-55 MCC-56 TSGS UPS RECT 110DC

PHASE II (FUTURE)

MOCOTECH MOCOTECH MOCOTECH NOT IN SCOPE OF DELIVERY

VFS 150/7.2 VFS 150/7.2 VFS 150/7.2 Chlorination Washing PS for PS for sludge MCC for blower

Outdoor light MDB Fire Fighting PS

Power Factor LEGEND

Building RAS&ES PS 28.1 RAS&ES PS 28.2 building Service Water PS TSGS UPS Rectifier Future PS 1 Future PS 2

filters BWWL Correction

Installed power (kW) 45.00 583.00 100.96 195.88 166.02 39.00 10.00 60.00 60.00 35.00 9.00 20.00 120.00 120.00 DISTRIBUTION BOARD (HVAC, LIGHTNING, SOCKETS)

Ks 0.70 0.35 0.70 0.70 0.70 1.00 0.80 0.65 0.65 1.00 1.00 1.00

-RSS -RSS -RSS -RSS -RSS -RSS Simultaneous Power (kW) per cabinet 31.50 204.05 70.67 137.12 116.21 39.00 8.00 39.00 39.00 35.00 9.00 20.00 MAIN CONTROL PANEL (PROCESS EQUIPMENT)

Power Supply Cable XLPE 3x120 70 3x(XLPE 3x120 70 ) XLPE 3x185 95 XLPE 3x240 120 XLPE 3x240 120 XLPE 3x50 25 NYY-J 4x10 XLPE 3x50 25 XLPE 3x50 25 NYY-J 5x16 NYY-J 5x10 NYY-J 5x10 NYY-J 4x1x70

Lenght (m) 220.00 250.00 360.00 400.00 340.00 50.00 10.00 180.00 180.00 10.00 10.00 10.00 5.00

Total Installed Power (kW) 1323.8600 LOCAL CONTROL PANEL (THIRD PARTY DELIVERY)

Plant coincidence factor 0.9000

Max Simultaneous Power (kW) 748.5520

Total simulateneous power with coincedence

factor applied (kW) 673.6968

Total Current Uncompensated (A) 1113.9019

Power factor before compensation 0.9200

Power factor after compensation 0.9700

Total current Compensated (A) 1056.4843

SS1 SS2 SS3 SS4 SS5 SS6

71 A 71 A 71 A 71 A 71 A 71 A

M M M M M M

-M1 -M2 -M3 -M4 -M5 -M6

Blover 1 Blover 2 Blover 3 Blover 4 Blover 5 Blover 6

635kW 635kW 635kW 635kW 635kW 635kW

71 A 71 A 71 A 71 A 71 A 71 A

0.91 0.91 0.91 0.91 0.91 0.91

95 % 95 % 95 % 95 % 95 % 95 %

E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

B 2da Revisión

A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Ercóle Marelli Impianti Tecnologici S.R.L

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

UCP-PSLT No.69

Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 2 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-002-A 1/3

MCC 52 Chlorination Building

FORM 2B Type 1

Ikmax= 5.7kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin=1.7kA

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 -QM1 -QM2 -QCB1 -QCB2 -QM3 -QM4 -QCB4 -QCA

CONTROL 10A 10A 125A 1A 1A C32A C32A 4-6.3A 4-6.3A C25A C6A 6A

2A RELAY

-KF1

-ST2 -ST

-F1,F2,F3 -PE1 START -PB1 START -PB3 START -PB5 START -PB7

T<5°C T>25°C

NETWORK -S1 STOP -PB2 STOP -PB4 STOP -PB6 STOP -PB8 7Ah

ANALYZER 230V

2A

PAC 3200 -S1 -S2 -S3 -S4 DC

-CT1

-CT2 100/5A 10VA 250W UPS

-CT3 -HS1 -EH1 -H1 -H3 -H5 -H7 M 10A 10A

11W 80W -FP1 -H2 -H4 -H6 -H8 24V

-QCAB PLC OP ETHS INSTRUMENTATION

-SE1 2X 10A

-MQ1 EM

160A EMERGENCY

SHUTDOWN

-KM1 -KM2 -KM3 -KM4

4kW 4kW 4kW 4kW

N

PE

EQUIPOTENTIAL

-EBR BONDING RAIL

M M M M

-W01

EARTHING

(XLPE 3x120/70)

-LCP53.1 -LCP53.2 -MDB.53

Note:

Variable frequency drives (IP21) will be wall mounted inside cabinet.

Cabinet will be heavy duty type outdoor cabinet

with double door simmilar or equal to Thalassa PLA from Schneider

Electric:

· Polyester reinforced with fibreglass) floor-standing cabinet with

2-door (IP55).

MCC 52 Ferric Sulphate

Dosing Pump 1

Ferric Sulphate

Dosing Pump 2

Chlorination

Panel

Gas neutralization

Panel

Mixer 1 Mixer 2

Main distribution

board

Cabinet fan 1 PLC

· VFD's will have Profibus interface.

· Local control (Start/Stop) will be possible from HMI mounted

Installed power (kW) 0.25 0.25 8.00 11.00 2.20 2.20 20.00 0.10 1.00 on internal doors.

Power Factor (cos φ) 0.72 0.72 0.72 0.78 0.83 0.83 0.80 0.75 0.80

Efficiency 0.75 0.75 1.00 1.00 0.86 0.86 1.00 0.82 1.00

Simultaneous Current (A) 0.70 0.70 16.90 21.45 4.69 4.69 38.03 0.25 1.90

Ventilation will be provided with special side ventilation module

Power Supply Cable NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYY-J 5X6 NYY-J 5X10 NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYY-J 4X2.5 NYY-1 3x1.5 NYY-J 4X2.5 (IP55) and ventilated plinth.

Lenght (m) 15.00 15.00 1.00 1.00 15.00 15.00 4.00 1.00 1.00

Total Installed Power (kW) 45.0000

Plant coincidence factor 0.7000

Total Simultaneous Power (kW) 31.5000

Total Simultaneous Current (A) 62.5213

MCC 35 Filter Washing PS with blowers

FORM 2B Type 1

Ikmax= 12.15kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 4.5kA

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 SDF1 SDF2 SDF3 SDF4 SDF5 SDF6 -QM1 -QM2 -QCB1 -QCA

CONTROL 10A 10A 125A 12.5A 12.5A C40A 6A

gG gG gG gG gG gG

2A

-KF1

RELAY

400A 400A 400A 300A 300A 300A Note:

-ST2

-F1,F2,F3 -PE1 T<5°C

START START · Variable frequency drives (IP55) will be wall mounted outside cabinet.

NETWORK -S1 STOP STOP 7Ah

ANALYZER 230V

2A

PAC 3200 -S1 -S2 DC

-CT1

250W UPS

· VFD's will be equiped with Profibus interface.

-CT2 630/5A 10VA

-CT3 -HS1 -EH1 -H1 -H3 10A 10A · Local control (Start/Stop) will be possible from HMI.

11W 80W -FP1 -H2 -H4 24V

PLC OP ETHS INSTRUMENTATION

· Remote mode will be controled by PLC over Profibus.

-SE1

-MQ1

EMERGENCY

-QCAB EM · DOL motors will have selector switch for selecting mode of operation

630A 10A

SHUTDOWN

-KM1 -KM2

(local/off/remote). In local mode START/STOP push buttons will be used for start

5.5kW 5.5kW and stop.

· Each drive will have emergency stop push button

N

PE

EQUIPOTENTIAL

-EBR BONDING RAIL

E 5ta Revisión

-FC1 -FC2 -FC3 -FC4 -FC5 -FC6 D 4ta Revisión

90kW 90kW 90kW 132kW 132kW 132kW M M

-W02 C 3ra Revisión

EARTHING Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss

3x(XLPE 3x120/70) FC202

Wall

FC202

Wall

FC202

Wall

FC202

Wall

FC202

Wall

FC202

Wall

Mounted Mounted Mounted Mounted Mounted Mounted

B 2da Revisión

IP 55 IP 55 IP 55 IP 55 IP 55 IP 55

-MDB.53 A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

M M M M M M Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

MCC 35 Pump 1 Pump 2 Pump 3 Blower 1 Blower 2 Blower 3 Air Compressor 1 Air Compressor 2 Distribution Panel Spare PLC

Mechanical power (kW) 60.00 60.00 60.00 110.00 110.00 110.00 5.50 5.50 20.00 1.00

Power Factor (cos φ) 0.73 0.73 0.73 0.87 0.87 0.87 0.84 0.84 0.80 0.80

Efficiency 0.89 0.89 0.89 0.95 0.95 0.95 0.89 0.89 1.00 1.00 Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Simultaneous Current (A) 133.60 133.60 133.60 192.33 192.33 192.33 10.63 10.63 36.13 1.81

Ercóle Marelli Impianti Tecnologici S.R.L

Installed power (kW) 67.49 67.49 67.49 115.79 115.79 115.79 6.18 6.18 20.00 1.00

Power Supply Cable NYCWY 03X120/70 SW NYCWY 03X120/70 SW NYCWY 03X120/70 SW NYY-J 04X120 NYY-J 04X120 NYY-J 04X120 NYY-J 04X4 NYY-J 04X4 NYY-J 5X10

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

Lenght (m) 20.00 22.00 24.00 20.00 22.00 24.00 22.00 24.00 10.00 PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

Total Installed Power (kW) 583.2027 UCP-PSLT No.69

Plant coincidence factor 0.3500

Total Simultaneous Power (kW) 204.1209 Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Total Simultaneous Current (A) 362.9482 Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 2 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-002-A 2/3

MCC 40 Waste Backwash Water PS MCC 25 MCC for blower building

FORM 2B Type 1 FORM 2B Type 1

Ikmax= 4.7kA Ikmax= 10.7kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 1.4kA L1,L2,L3 - 400/230V TN-C-S

Ikmin= 2.9kA

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 SDF1 SDF2 SDF3 -Q4 -QCA -F4,F5,F6 PHASE -Q1 -Q2 -Q3 -QCB1 -QCB2 -QCB3 -QCB4 -QCB5 -QCA

CONTROL 10A 10A 125A C6A 6A CONTROL 10A 10A 125A C25A C25A C25A C25A C63A 6A

2A gG gG gG 2A

RELAY RELAY

-KF1 160A 160A 160A -KF1

-ST2 -ST -ST2

-F1,F2,F3 -PE1 T<5°C T>25°C -F1,F2,F3 -PE1 T<5°C

NETWORK -S1 7Ah NETWORK -S1 7Ah

ANALYZER 230V ANALYZER 230V

2A 2A

PAC 3200 DC PAC 3200 DC

-CT1 -CT1

-CT2 160/5A 10VA -H1 -H3 -H5 250W UPS -CT2 100/5A 10VA 250W UPS

-CT3 -HS1 -EH1 -H2 -H4 -H6 M 10A 10A

-CT3 -HS1 -EH1

10A 10A

11W 80W -FP1 24V 11W 80W -FP1 24V

-SE1 2X PLC OP ETHS INSTRUMENTATION -SE1 PLC OP ETHS INSTRUMENTATION

-MQ1 -QCAB EM -MQ1 -QCAB EM

160A EMERGENCY 100A EMERGENCY

-FC1 -FC2 -FC3 10A 10A

SHUTDOWN SHUTDOWN

45kW 45kW 45kW

Danfoss Danfoss Danfoss

FC301 FC301 FC301

Cabinet Cabinet Cabinet

IP 21 IP 21 IP 21

N R5 R5 R5 N

PE PE

EQUIPOTENTIAL EQUIPOTENTIAL

-EBR BONDING RAIL

-EBR BONDING RAIL

-W03 M M M -W07

EARTHING EARTHING -LCP 25.1 -LCP 25.2 -LCP 25.3 -MCS-3 -MDB.25

XLPE 3x185/95 XLPE 3x25/16

40-SCP-01 40-SCP-02 40-SCP-03

Note:

Variable frequency drives (IP21) will be mounted inside cabinet.

Cabinet will be heavy duty type outdoor cabinet

with double door simmilar or equal to Thalassa PLA from Schneider

Electric:

· Polyester reinforced with fibreglass) floor-standing cabinet with

2-door (IP55).

MCC 40 Pump 1 Pump 2 Pump 3 Cabinet fans PLC · VFD's will have Profibus interface. MCC 25 Blower Control

Panel 1

Blower Control

Panel 2

Blower Control

Panel 3

Master control Main distribution

panel for blowers board

PLC

· Local control (Start/Stop) will be possible from HMI mounted

Mechanical power (kW) 30.00 30.00 30.00 0.15 1.00 Mechanical power (kW) 2.00 2.00 2.00 2.00 30.00 1.00

Power Factor (cos φ) 0.82 0.82 0.82 0.75 0.80

on internal doors. Power Factor (cos φ) 1.00 1.00 1.00 1.00 0.95 0.80

Efficiency 0.90 0.90 0.90 0.82 1.00 Efficiency 1.00 1.00 1.00 1.00 1.00 1.00

Simultaneous Current (A) 58.61 58.61 58.61 0.35 1.81 Ventilation will be provided with special side ventilation module Simultaneous Current (A) 3.04 3.04 3.04 3.04 48.04 1.90

Installed power (kW) 33.26 33.26 33.26 0.18 1.00 Installed power (kW) 2.00 2.00 2.00 2.00 30.00 1.00

(IP55) and ventilated plinth.

Power Supply Cable NYCY 03X6/6 SW NYCY 03X6/6 SW NYCY 03X6/6 SW NYY-1 3x1.5 Power Supply Cable NYY-J 5X4 NYY-J 5X4 NYY-J 5X4 Prefabricated NYY-J 5X10

Lenght (m) 15.00 15.00 15.00 1.00 Lenght (m) 10.00 10.00 10.00 10.00 15.00

Total Installed Power (kW) 100.9612 Total Installed Power (kW) 39.0000

Plant coincidence factor 0.7000 Plant coincidence factor 1.0000

Total Simultaneous Power (kW) 70.6728 Total Simultaneous Power (kW) 39.0000

Total Simultaneous Current (A) 124.5987 Total Simultaneous Current (A) 62.1067

PHASE II (FUTURE) PHASE II (FUTURE)

MCC 28.1 RAS&ES PS 1 NOT IN SCOPE OF DELIVERY MCC 28.2 RAS&ES PS 2 NOT IN SCOPE OF DELIVERY

FORM 2B Type 1 FORM 2B Type 1

Ikmax= 5.27kA Ikmax= 5.7kA

Ikmin= 1.5kA L1,L2,L3 - 400/230V TN-C-S

Ikmin= 1.5kA

L1,L2,L3 - 400/230V TN-C-S

-Q1 -Q2 -Q3 -Q4 -QCA -F4,F5,F6 PHASE -Q1 -Q2 -Q3 SDF1 SDF2 SDF3 SDF4 SDF5 SDF6 -QM1 -QM2 SDF7 SDF8 -Q4 -QCA

-F4,F5,F6 PHASE SDF1 SDF2 SDF3 SDF4 SDF5 -QM1 -QM2 SDF6 SDF7 10A 10A 125A C6A 6A

CONTROL 10A 10A 125A C6A 6A CONTROL gG gG gG gG gG gG 8A 8A gG gG

gG gG gG gG gG 8A 8A gG gG 2A

2A RELAY RELAY

-KF1 100A 100A 100A 80A 80A 50A 50A -KF1 100A 100A 80A 80A 63A 63A 50A 50A

-ST2 -ST -ST2 -ST

-F1,F2,F3 -PE1 START START -F1,F2,F3 -PE1 T<5°C

START START

T>25°C

T<5°C T>25°C NETWORK -S1 STOP STOP

NETWORK -S1 STOP STOP 7Ah 230V 7Ah

ANALYZER 230V 2A ANALYZER

2A PAC 3200 -S1 -S2 DC

PAC 3200 -S1 -S2 DC -CT1

-CT1

250W UPS -CT2 100/5A 10VA -H1 -H3 -H5 -H7 -H9 -H11 -H17 -H19 250W UPS

-CT2 100/5A 10VA -H1 -H3 -H5 -H7 -H9 -H15 -H17 M 10A 10A

-CT3 -HS1 -EH1 -H2 -H4 -H6 -H8 -H10 -H11 -H13 -H16 -H18 M 10A 10A -CT3 -HS1 -EH1 -H2 -H4 -H6 -H8 -H10 -H12 -H13 -H15 -H18 -H20

-H12 -H14 24V 11W 80W -FP1 -H14 -H16 24V

11W 80W -FP1

-KM1 -KM2

PLC OP ETHS INSTRUMENTATION -SE1 2X PLC OP ETHS INSTRUMENTATION

-SE1 -AF65 -AF65 2X

-MQ1 -QCAB EM

-MQ1 -QCAB EM EMERGENCY

EMERGENCY 250A 10A

250A

-FC1 -FC2 -FC3 -FC5 -FC6 10A SHUTDOWN -FC1 -FC2 -SS1 -SS2 -SS1 -SS2 -FC3 -FC4

SHUTDOWN -SS1 -SS2 -KM1 -KM2

45kW 45kW 45kW -KM1 -KM2 15kW 15kW 45kW 45kW 42A 42A 34A 34A 15kW 15kW

63A 63A 4kW 4kW

Danfoss Danfoss Danfoss Danfoss Danfoss

4kW 4kW Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss

FC301 FC301 VLT VLT VLT VLT

FC301 FC301 FC301 VLT VLT Cabinet Cabinet MCD600 MCD600 MCD600 MCD600

Cabinet Cabinet Cabinet MCD600 MCD600 IP 21 IP 21 Cabinet IP Cabinet IP Cabinet IP Cabinet IP

IP 21 IP 21 IP 21 Cabinet IP Cabinet IP

N 21 21

N 21 21 21 21

PE PE

EQUIPOTENTIAL EQUIPOTENTIAL

-EBR -EBR BONDING RAIL

BONDING RAIL

M M M M M M M M M M M M

-W05 M M M M M M M -W06

EARTHING EARTHING

XLPE 3x240/120 XLPE 3x240/120

28.1-SCP-01 28.1-SCP-02 28.1-SCP-03 28.1-SCP-04 28.1-SCP-05 28.2-SCP-01 28.2-SCP-02 28.2-SCP-03 28.2-SCP-04 31-SCP-01 31-SCP-02

Note:

Note:

Variable frequency drives (IP21) will be wall mounted inside cabinet.

Variable frequency drives (IP21) will be wall mounted inside cabinet.

Cabinet will be heavy duty type outdoor cabinet

Cabinet will be heavy duty type outdoor cabinet

with double door simmilar or equal to Thalassa PLA from Schneider

with double door simmilar or equal to Thalassa PLA from Schneider

MCC 28.1 RAS Pump 1 RAS Pump2 RAS Pump3 ES Pump 1 ES Pump 2

Scrapper Scrapper

RAS Future 1 RAS Future 2 Cabinet fans PLC

Electric: MCC 28.2 RAS Pump 1 RAS Pump2 ES Pump 1 ES Pump 2 ES Pump 3 ES Pump 4 FTS scraper 1 FTS scraper 2 RAS Future 1 RAS Future 2 Cabinet fans PLC Electric:

Bridge 1 Bridge 2 · Polyester reinforced with fibreglass) floor-standing cabinet with

· Polyester reinforced with fibreglass floor-standing cabinet with

Mechanical power (kW) 2-door (IP55). Mechanical power (kW) 37.00 37.00 15.00 15.00 11.00 11.00 3.00 3.00 7.50 7.50 0.10 1.00

37.00 37.00 37.00 22.00 22.00 3.00 3.00 7.50 7.50 0.10 1.00

Power Factor (cos φ)

2-door (IP55).

Power Factor (cos φ) 0.84 0.84 0.84 0.83 0.83 0.82 0.82 0.84 0.84 0.75 0.80 · VFD's and softstarters will have Profibus interface. 0.84 0.84 0.83 0.83 0.80 0.80 0.83 0.83 0.84 0.84 0.75 0.80

Efficiency 0.91 0.91 0.87 0.87 0.85 0.85 0.87 0.87 0.90 0.90 0.82 1.00 · VFD's will have Profibus interface.

Efficiency 0.91 0.91 0.91 0.88 0.88 0.92 0.92 0.90 0.90 0.82 1.00 · Softstarters will be equiped with integrated bypass contactors

Simultaneous Current (A) 69.72 69.72 69.72 43.53 43.53 5.75 5.75 14.34 14.34 0.23 1.81

Simultaneous Current (A) 69.72 69.72 29.95 29.95 23.38 23.38 6.00 6.00 14.34 14.34 0.23 1.81 · Local control (Start/Stop) will be possible from HMI mounted

· Local control (Start/Stop) will be possible from HMI mounted Installed power (kW) 40.53 40.53 17.20 17.20 12.94 12.94 3.45 3.45 8.33 8.33 0.12 1.00

Installed power (kW) 40.53 40.53 40.53 25.00 25.00 3.26 3.26 8.33 8.33 0.12 1.00 on internal doors.

Power Supply Cable Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated NYY-1 3x1.5 on internal doors. Power Supply Cable Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated Prefabricated NYY-1 3x1.5

Lenght (m) 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 30.00 30.00 1.00

Lenght (m) 10.00 10.00 10.00 10.00 10.00 10.00 10.00 30.00 30.00 1.00

Total Installed Power (kW) Total Installed Power (kW) 166.0227 Ventilation will be provided with special side ventilation module

195.8876 Ventilation will be provided with special side ventilation module Plant coincidence factor

Plant coincidence factor 0.7000 0.7000 (IP55) and ventilated plinth.

Total Simultaneous Power (kW) (IP55) and ventilated plinth. Total Simultaneous Power (kW) 116.2159

137.1213

Total Simultaneous Current (A) Total Simultaneous Current (A) 202.1664

236.8903

E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

B 2da Revisión

A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Ercóle Marelli Impianti Tecnologici S.R.L

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

UCP-PSLT No.69

Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 2 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-002-A 3/3

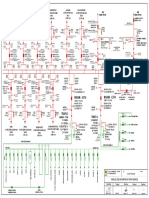

TS 3

MV SWITCHGEAR 12kV TS 3 - ABB Safe Plus Compact

PHASE 1 370 KW LV COMP.

1. INCOMING LINE 1

LV COMP.

2. TR1

LV COMP.

3. TR2

-OCR1 -OCR2 -OCR3

ABB REF 615 ABB REF 615 ABB REF 615

MB1

ENERGY METERING

SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A SF6 / 17.5kV / 630A

-C1 20kA 3s -C2 20kA 3s -C3 20kA 3s

1MW

kWh kVArh

-QF1 -QF2 -QF3

630A M 630A M 630A M

-QS1

630A

-QS2

630A

-QS3

630A

SOLAR PLANT

-VTM1

11.8kV/ √3 / 110V/ √3

-VT1

11.8kV/ √3 / 110V/ √3

-VT2

11.8kV/ √3 / 110V/ √3

-VT3

11.8kV/ √3 / 110V/ √3

4 inverters x 100 KW

MCT 1 - 100/1A-5P20 MCT 3 - 100/1A-5P20 MCT 4 - 100/1A-5P20

MCT 2 - 100/1A-CL 0.5

MV COMP. MV COMP. MV COMP.

30.3 A 30.3 A

3 x N2XS(F)2Y 1x50mm2, 12kV 3 x N2XS(F)2Y 1x50mm2, 12kV 4x(3x240/120 mm2) XLPE

Duty + Standby

-1TR1 -1TR2

OIL IMMERSED OIL IMMERSED

630kVA 630kVA

12/0.4kV 12/0.4kV

uk=4% uk=4%

Dyn5 Dyn5

957 A 957 A

LV SWITCHGEAR 0.38kV BUSBAR 1250A

BUSBAR 1250A

MLVSDB.TS3 FORM 3B -PFC1

-1QT1 -1QT2 -1QT3

1000A 1000A 1000A

50kA 50kA 50kA

LSIN LSIN LSIN

-1F1 -1PE1 -1F2 -1PE2 -1F3 -1PE3

NETWORK NETWORK NETWORK

-1TC1,2,3 2A -1TC2,2,3 2A -3TC1,2,3 2A

1000/5A ANALYZER 1000/5A ANALYZER 2000/5A ANALYZER

cl 0.5 5VA cl 0.5 5VA cl 0.5 5VA

Ikmax= 24.4kA

TN-C L1 L2 L3 400/230V 2000A 50kA Ikmin= 17.77kA

-1Q1 -1Q2 -1Q3 -1Q4 -1Q5 -1Q6 -1Q7 -1Q8 -1Q9 -1Q10 -1Q11

100A 100A 250A 160A 400A 40A 80A 25A 40A 250A 100A

50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 50kA 100kVAr 4x25kVAr

LSI LSI LSI LSI LSI LI LI LI LI LI

physical steps: 4

electrical steps: 3

PEN

NYY-J 1x95mm2

-1Q27

250A

50kA

EQUIPOTENTIAL

BONDING RAIL

-EBR1

EARTHING E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

W01 W02 W03 W04 W05.1/5.2 W06 W7 W8 W9 W10 B 2da Revisión

A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

MDB-60 MDB-59 MCC-9 MCC-13 MCC-4 MDB-TS FINANCIADO POR:

TSGS UPS RECT 110DC Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Worshop and Administration Primary sludge PS Emergency lagoon Mechanical

Outdoor light

Power Factor LEGEND

Garage buildning pretreatment TSGS UPS Rectifier SPARE SPARE

9.1 & 9.2 PS 13 Correction

Installed power (kW) 24.00 42.00 127.48 68.10 220.56 10.00 35.00 9.00 20.00 DISTRIBUTION BOARD (HVAC, LIGHTNING, SOCKETS)

Ks 0.75 0.75 0.70 0.70 0.80 0.80 1.00 1.00 1.00

Simultaneous Power (kW) per cabinet 18.00 31.50 89.24 47.67 176.45 8.00 35.00 9.00 20.00 MAIN CONTROL PANEL (PROCESS EQUIPMENT) Asociación Accidental

Power Supply Cable XLPE 3x25 16 XLPE 3x25 16 XLPE 3x185 95 XLPE 3x95 50 2x(XLPE 3x240 120 ) NYY-J 4X6 NYY-J 4X16 NYY-J 4X6 NYY-J 4X10 NYY-J 4x1x70

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Lenght (m) 200 160 200 120 350 10 10 10 10 5.00 Ercóle Marelli Impianti Tecnologici S.R.L

Total installed power (kW) 556.1400 LOCAL CONTROL PANEL (THIRD PARTY DELIVERY)

Plant coincidence factor 0.8500

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

Max Simultaneous Power (kW) - sum 434.8540

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

Total simulateneous power with coincedence

369.6259 UCP-PSLT No.69

factor applied (kW)

Total Current before PFC (A) 580.5886

Power factor before compensation 0.9200 Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Power factor after compensation 0.9500

Total Current after PFC (A) 562.2542

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 3 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-003-A 1/2

MCC4 Mechanical pretreatment MCC 50 Chemical Building

FORM 2B Type 1 FORM 2B Type 1

Ikmax= 8.42kA Ikmax= 3.36kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 2.83kA Ikmin= 1.1kA

L1,L2,L3 - 400/230V TN-C-S

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 SDF1 SDF2 SDF3 SDF4 -QCB1 -QCB2 -QCB3 -QM5 -QM6 -QM7 -QM8 -QM9 -QM10 -QCB4 -QCB5 -QCB6 -QCB7 -QCB8 -QM11 -QM12 -QM13 -QM14 -QM15 -QM16 -QCB9 -1Q11 -QCA -Q1 -Q2 -Q3 -QCB3 -QCA

-F4,F5,F6 PHASE -QM1 -QM2 -SDF3 -SDF4 -SDF5 -QM3 -QM4 -QCB1 -QCB2

CONTROL 10A 10A 125A C25A C25A C25A 4-6.3A 4-6.3A 4-6.3A 1.6-2.5A 1.6-2.5A 1.6-2.5A C25A C25A C25A C63A C32A 4A 4A 4A 9-12A 9-12A 9-12A C32A 40A 6A 10A 10A 125A 6A

2A gG gG gG gG CONTROL 4-6.3A 4-6.3A gG gG gG 4-6.3A 4-6.3A C25A C25A C25A

RELAY LI 2A RELAY

-KF1 63A 63A 63A 63A -KF1 6A 6A 6A

-ST2 -ST2

-F1,F2,F3 -PE1 START -PB9 START -PB11 START -PB13 START -PB15 START -PB17 START -PB19 START -PB21 START -PB23 START -PB25 START -PB27 START -PB29 START -PB31 -PB1 -PB3 -PB5 -PB7

NETWORK

T<5°C

STOP -PB10 STOP -PB12 STOP -PB14 STOP -PB16 STOP -PB18 STOP -PB20 STOP -PB22 STOP -PB24 STOP -PB26 STOP -PB28 STOP -PB30 STOP -PB32 -F1,F2,F3 -PE1 T<5°C

START START START START

-S1 230V 7Ah NETWORK -S1 STOP -PB2 STOP -PB4 STOP -PB6 STOP -PB8 7Ah

2A ANALYZER ANALYZER 230V

PAC 3200 DC 2A

-S5 -S6 -S7 -S8 -S9 -S10 -S11 -S12 -S13 -S14 -S15 -S16 PAC 3200 -S1 -S2 -S3 -S4 DC

-CT1

-CT2 400/5A 10VA 250W UPS -CT1

250W UPS

10A 10A -CT2 100/5A 5VA -H5 -H7 -H9

-CT3 -HS1 -EH1 -H9 -H11 -H13 -H15 -H17 -H19 -H21 -H23 -H25 -H27 -H29 -H31 -H1 -H3 -H6 -H8 -H10 -H11 -H13 10A 10A

-FP1 -H10 -H12 -H14 -H16 -H18 -H20 -H22 -H24 -H26 -H28 -H30 -H32 24V -CT3 -HS1 -EH1

11W 80W 11W 80W -FP1 -H2 -H4 -H12 -H14 24V

-QCAB PLC OP ETHS INSTRUMENTATION -QCAB

-SE1 10A -SE1 PLC OP ETHS INSTRUMENTATION

-MQ1 10A

EM -MQ1 EM

400A EMERGENCY EMERGENCY

SHUTDOWN 80A

LSI SHUTDOWN -VFD1 -VFD2 -VFD3

-KM1 -KM2 -KM3 -KM4 -KM5 -KM6 -KM7 -KM8 -KM9 -KM7 -KM8 -KM9 LSI -KM1 -KM2 -KM3 -KM4

4kW 4kW 4kW 4kW 4kW 4kW 5.5kW 5.5kW 4kW 5.5kW 5.5kW 4kW 7.5kW 7.5kW 7.5kW

4kW 4kW Danfoss Danfoss Danfoss 4kW 4kW

FC301 FC301 FC301

Cabinet Cabinet Cabinet

IP 21 IP 21 IP 21

N N

PE PE

EQUIPOTENTIAL EQUIPOTENTIAL

-EBR BONDING RAIL -EBR

XLPE 5x25mm2 BONDING RAIL

M M M M M M M M M M M M M M M M M M M

-W05.1/5.2 -FC1 -FC2 -FC3 -FC4

EARTHING EARTHING

2x(XLPE 3x240/120) 22kW 22kW 22kW 22kW

Danfoss Danfoss Danfoss Danfoss -LCP.CS1 -LCP.CS2 -LCP.FS1 03-SCP-01 03-SCP-02 03-SCP-03 03-FCP-01 03-FCP-02 03-FCP-03 -LCP.SB1 -LCP.SB2 -LCP.SB3 -MDB2 -MDB4 65-SCP-01 65-SCP-02 65-SCP-03 65-SCP-01 65-SCP-02 65-SCP-03

FC 301 FC 301 FC 301 FC 301

Wall Wall Wall Wall

mounted mounted mounted mounted -LCP.PP1 -LCP.PP2 -MDB.50

IP 55 IP 55 IP 55 IP 55

Note: Note:

M M M M · Variable frequency drives (IP55) will be wall · Variable frequency drives (IP55) will be

mounted outside cabinet. wall mounted outside cabinet.

04-AB-01 04-AB-02 04-AB-03 04-AB-04

· VFD will be equiped with Profibus interface. · VFD will be equiped with Profibus

MCC4 Blower 1 Blower 2 Blower 3 Blower 4

Coarse screen

cabinet 1

Coarse screen

cabinet 2

Fine screen

cabinet 3

Grit pump 1 Grit pump 2 Grit pump 3 Grease pump 1 Grease pump 2 Grease pump 3 Scraper bridge 1 Scraper bridge 2 Scraper bridge 3 MBD.2 MBD.4 Sand classifier 1 Sand classifier 2 Sand classifier 3

Pump 1 - sand

classifiers PS

Pump 2 - sand

classifiers PS

Pump 3 - sand

classifiers PS

MCC.2 MCC.50 PLC · Local control (Start/Stop) will be possible from MCC 50 Ferric Sulfate

Dosing Pump 1

Ferric Sulfate

Dosing Pump 2

Poly Dosing

Pump 1

Poly Dosing

Pump 2

Poly Dosing

Pump 3 Mixer 1 Mixer 1

Poly preparation Poly preparation Main distribution

unit 1 unit 2 board

PLC interface.

HMI. · Local control (Start/Stop) will be possible

Installed power (kW) 22.00 22.00 22.00 22.00 8.00 8.00 8.00 1.67 1.67 1.67 0.55 0.55 0.55 1.85 1.85 1.85 30.00 4.00 1.50 1.50 1.50 4.15 4.15 4.15 2.10 42.30 1.00

· DOL motors will have selector switch for Installed power (kW) 0.25 0.25 4.00 4.00 4.00 2.20 2.20 2.20 2.20 20.00 1.00

from HMI.

Power Factor (cos φ) 0.84 0.82 0.82 0.82 0.80 0.80 0.80 0.83 0.83 0.83 0.75 0.75 0.83 0.80 0.80 0.80 0.80 0.95 0.80 0.80 0.80 0.75 0.75 0.75 1.00 Power Factor (cos φ) 0.72 0.72 0.83 0.83 0.83 0.80 0.80 0.80 0.80 0.80 0.80

Efficiency 0.93 0.93 0.93 0.93 1.00 1.00 1.00 0.78 0.78 0.78 0.86 0.86 0.86 1.00 1.00 1.00 1.00 1.00 0.85 0.85 0.85 0.76 0.76 0.76 1.00

selecting mode of operation (local/off/remote). · DOL motors will have selector switch for

Efficiency 0.75 0.75 0.90 0.90 0.90 0.90 0.90 1.00 1.00 1.00 1.00

Simultaneous Current (A) 40.70 41.69 41.69 41.69 14.45 14.45 14.45 3.71 3.71 3.71 1.23 1.23 1.11 3.34 3.34 3.34 54.19 6.08 3.19 3.19 3.19 10.48 10.48 10.48 3.34 44.39 1.45 In local mode START/STOP push buttons will Simultaneous Current (A) 0.67 0.67 7.74 7.74 7.74 4.42 4.42 3.97 3.97 36.13 1.90 selecting mode of operation

Power Supply Cable NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-J 5X10 NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-J 5X6 NYY-J 4X4 NYY-J 4X4 NYY-J 4X4 NYY-J 5X6 XLPE 5x25 be used for start and stop. Power Supply Cable NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYCY 03X1.5/1.5 NYY-J 4X4 NYY-J 4X4 NYY-J 4X2.5 NYY-J 4X2.5 NYY-J 4X2.5 (local/off/remote). In local mode

Lenght (m) 10.00 15.00 20.00 25.00 80.00 80.00 80.00 25.00 35.00 45.00 28.00 29.00 30.00 35.00 40.00 45.00 80.00 5.00 25.00 25.00 25.00 30.00 30.00 30.00 80.00 70.00

Total Installed Power (kW) 220.5600

· Each drive will have emergency stop push Lenght (m) 15.00 15.00 15.00 15.00 15.00 20.00 20.00 10.00 10.00 4.00

START/STOP push buttons will be used

Total Installed Power (kW) 42.3000

Coincidence factor 0.8000 button for start and stop.

Plant coincidence factor 0.7000

Total Simultaneous Power (kW) 176.4480

Total Simultaneous Current (A)

Total Simultaneous Power (kW) 29.6100 · Each drive will have emergency stop push

307.4495 Total Simultaneous Current (kW) 55.5520

button

MCC13 Emergency lagoon PS MCC 2 Fine screen building

FORM 2B Type 1 FORM 2B Type 1

Ikmax= 7.55kA Ikmax= 2.61 kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 2.3kA L1,L2,L3 - 400/230V TN-C-S

Ikmin= 814 A

-F4,F5,F6 PHASE -Q1 -Q2 -Q3 -QM1 -QM2 -QM3 -QM4 -QM5 -QM6 -Q4 -QCA -F4,F5,F6 PHASE -Q1 -Q2 -Q3 -QM1 -QM2 -QM3 -QM4 -QM5 -QM6 -QM7 -QM8 -QM9 -QM10 -QM11 -QM12 -QM13 -QM14 -QM15 -QM16 -QM17 -QM18 -QM19 -Q4 -QCA

CONTROL 10A 10A 125A 100A 100A 100A 4-6.3A 4-6.3A 4-6.3A C6A 6A CONTROL 10A 10A 125A 4-6.3A 4-6.3A 4-6.3A 4-6.3A 2.2-3.2A 2.2-3.2A 2.2-3.2A 2.2-3.2A 2.2-3.2A 2.2-3.2A 2.2-3.2A 2.2-3.2A 4-6.3A 4-6.3A 4-6.3A 4-6.3A 4-6.3A 4-6.3A 4-6.3A C6A 6A

2A RELAY 2A RELAY

-KF1 -KF1

-ST2 -ST -ST2 -ST

-F1,F2,F3 -PE1 OPEN -PB1 OPEN -PB3 OPEN -PB5 -F1,F2,F3 -PE1

T<5°C T>25°C T<5°C T>25°C

NETWORK -S1 CLOSE -PB2 CLOSE -PB4 CLOSE -PB6 7Ah NETWORK -S1 7Ah

ANALYZER 230V ANALYZER 230V

2A 2A

PAC 3200 -S1 -S2 -S3 DC PAC 3200 DC

-CT1 -CT1

-CT2 160/5A 10VA 250W UPS -CT2 160/5A 10VA 250W UPS

-CT3 -HS1 -EH1 -H1 -H3 -H5 -H7 -H10 -H13 M 10A 10A

-CT3 -HS1 -EH1 -H1 -H4 -H7 -H10 -H11 -H14 -H17 -H20 -H23 -H26 -H29 -H32 -H35 -H38 -H41 -H44 -H47 -H50 -H53 M 10A 10A

11W 80W -FP1 -H2 -H4 -H6 -H8 -H9 -H11 -H12 -H14 -H15 24V 11W 80W -FP1 -H2 -H3 -H5 -H6 -H8 -H9 -H11 -H12 -H12 -H13 -H15 -H16 -H18 -H19 -H21 -H22 -H24 -H25 -H27 -H28 -H30 -H31 -H33 -H34 -H36 -H37 -H39 -H40 -H42 -H43 -H45 -H46 -H48 -H49 -H51 -H52 -H54 -H55 24V

-SE1 2X PLC OP ETHS INSTRUMENTATION -SE1 2X PLC OP ETHS INSTRUMENTATION

-MQ1 -QCAB EM -MQ1 -QCAB EM

160A EMERGENCY -KM1 -KM2 -KM3 -KM4 -KM5 -KM6 63A EMERGENCY -KM1 -KM2 -KM3 -KM4 -KM5 -KM6 -KM7 -KM8 -KM9 -KM10 -KM11 -KM12 -KM13 -KM14 -KM15 -KM16 -KM17 -KM18 -KM19 -KM20 -KM21 -KM22 -KM23 -KM24 -KM25 -KM26 -KM27 -KM28 -KM29 -KM30 -KM31 -KM32 -KM33 -KM34 -KM35 -KM36 -KM37 -KM38

-FC1 -FC2 -FC3 10A 10A

LSI SHUTDOWN LI SHUTDOWN

37kW 37kW 37kW

Danfoss Danfoss Danfoss 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW

FC301 FC301 FC301

Cabinet Cabinet Cabinet

IP 21 IP 21 IP 21

N N I> CMR 1 I> CMR 2 I> CMR 3 I> CMR 4 I> CMR 5 I> CMR 6 I> CMR 7 I> CMR 8 I> CMR 9 I> CMR 10 I> CMR 11 I> CMR 12 I> CMR 13 I> CMR 14 I> CMR 15

PE PE

EQUIPOTENTIAL EQUIPOTENTIAL

-EBR BONDING RAIL

-EBR BONDING RAIL CU 1 CU 2 CU 3 CU 4 CU 5 CU 6 CU 7 CU 8 CU 9 CU 10 CU 11 CU 12 CU 13 CU 14 CU 15 CU 16 CU 17 CU 18 CU 19

II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6 II 2G EEx ed IIC T6

EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1 EMS 1

M M M -PB1 -PB1 -PB1 -PB1

-W04 M M M OPEN

CLOSE -PB2

OPEN

CLOSE -PB2

OPEN

CLOSE -PB2

OPEN

CLOSE -PB2

EARTHING EARTHING -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1 -SS1

1x(XLPE 3x95/50) XLPE 5x25mm2

-S1 -S1 -S1 -S1

13-SCP-01 13-SCP-02 13-SCP-03 11-PSV-01 15-PSV-01 15-PSV-01 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2 -SS2

Note: Note:

· Variable frequency drives (IP21) will be mounted

inside cabinet. M M M M M M M M M M M M M M M M M M M · Local control (Start/Stop) will be possible from HMI

· Cabinet will be heavy duty type outdoor cabinet with and localy from local control box

double door simmilar or equal to Thalassa PLA from 02-PSV-01 02-PSV-02 02-PSV-03 02-PSV-04 02-CSV-01 02-CSV-02 02-CSV-03 02-CSV-04 02-CSV-05 02-CSV-06 02-CSV-07 02-CSV-08 02-FSV-01 02-FSV-02 02-FSV-03 02-FSV-04 02-BEC-01 02-SCC-01 02-SCC-02 · Local control (Start/Stop) for coarse and fine screens

Schneider Electric(Polyester reinforced with will be possible from HMI and localy from local control

fibreglass). Floor-standing cabinet with 2-door (IP55). box. Local control box will contain:

MCC13 Pump1 Pump2 Pump3 Penstock Penstock Penstock Penstock Cabinet fans PLC · VFD's will have Profibus interface. MCC13 Penstock 1 Penstock 2 Penstock 3 Penstock 4 Coarse Screen 1.1 Coarse Screen 1.2 Coarse Screen 1.3 Coarse Screen 1.4 Coarse Screen 1.5 Coarse Screen 1.6 Coarse Screen 1.7 Coarse Screen 1.8 Fine Screen 1.1 Fine Screen 1.2 Fine Screen 1.3 Fine Screen 1.4 Conveyor 1 Conveyor 2 Conveyor 3 Cabinet fans PLC 1. Selector switch 1-0-2 (local-0-remote)

· Local control (Start/Stop) will be possible from HMI 2. Selector switch 1-0-2 (forward-0-reverse)

Installed power (kW) 22.00 22.00 22.00 0.25 0.25 0.25 0.25 0.10 1.00 mounted on internal doors. Installed power (kW) 0.25 0.25 0.25 0.25 1.10 1.10 1.10 1.10 1.10 1.10 1.10 1.10 1.50 1.50 1.50 1.50 1.50 1.50 1.50 0.10 1.00 3. Emergency stop pushbutton

Power Factor (cos φ) 0.83 0.83 0.83 0.83 0.83 0.83 0.83 0.75 0.80 Power Factor (cos φ) 0.72 0.72 0.72 0.72 0.78 0.78 0.78 0.78 0.78 0.78 0.78 0.78 0.73 0.73 0.73 0.73 0.73 0.73 0.73 0.75 0.80

Efficiency 0.88 0.88 0.88 0.88 0.88 0.88 0.88 0.82 1.00 Efficiency 0.74 0.74 0.74 0.74 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.82 1.00

· Motors for screens and conveyors will be protected

Simultaneous Current (A) 43.53 43.53 43.53 0.49 0.49 0.49 0.49 0.23 1.81 · Ventilation will be provided with special side Simultaneous Current (A) 0.68 0.68 0.68 0.68 2.72 2.72 2.72 2.72 2.72 2.72 2.72 2.72 3.96 3.96 3.96 3.96 3.96 3.96 3.96 0.23 1.81 by current monitoring relay (CMR) like Siemens

Power Supply Cable Prefabricated Prefabricated Prefabricated NYY-J 7x1.5 NYY-J 7x1.5 NYY-J 7x1.5 NYY-J 7x1.5 NYY-1 3x1.5 Prefabricated ventilation module (IP55) and ventilated plinth. Power Supply Cable NYY-1 7x1.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-J 4x2.5 NYY-1 3x1.5 Prefabricated 3UG46221AW30

Lenght (m) 10.00 10.00 15.00 30.00 30.00 30.00 30.00 1.00 1.00 Lenght (m) 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 1.00 1.00

Total Installed Power (kW) 68.1000 Total Installed Power (kW) 21.4000

· Local control units will be II 2G EEx ed IIC certified.

Plant coincidence factor 0.7000 Plant coincidence factor 1.0000

Total Simultaneous Power (kW) 47.6700 Total Simultaneous Power (kW) 21.4000

Total Simultaneous Current (A) 94.2200 Total Simultaneous Current (A) 54.2241

MCC9 Primary sludge PS

FORM 2B Type 1

Ikmax= 6.84kA

L1,L2,L3 - 400/230V TN-C-S

Ikmin= 2.03kA

-Q1 -Q2 -Q3 -QCA

-F4,F5,F6 PHASE SDF1 SDF2 SDF3 SDF4 SDF4 SDF4 -QM1 -QM2 -QM3 -QM4 -QM5 -QM6 -QM7 -QM8 -QCB1 -QCB2

10A 10A 125A 6A

CONTROL gG gG gG gG gG gG 5A 5A 5A 5A 1.6A 1.6A 1.6A 1.6A C32A C32A

2A RELAY

-KF1 100A 100A 100A 100A 100A 100A 25KA 25KA

-ST2

-F1,F2,F3 -PE1 START -PB1 START -PB3 START -PB5 START -PB7 START -PB9 START -PB11 START -PB13 START -PB15

T<5°C

NETWORK -S1 STOP -PB2 STOP -PB4 STOP -PB6 STOP -PB8 STOP -PB10 STOP -PB12 STOP -PB14 STOP -PB16 7Ah

ANALYZER 230V

2A

PAC 3200 -S1 -S2 -S3 -S4 -S5 -S6 -S7 -S8 DC

-CT1

-CT2 100/5A 10VA 250W UPS

-H1 -H3 -H7 -H9 -H10 -H12 -H14 -H16 10A 10A

-CT3 -HS1 -EH1

11W 80W -FP1 -H2 -H4 -H8 -H10 -H11 -H13 -H15 -H17 24V

-SE1 PLC OP ETHS INSTRUMENTATION

-MQ1 CABINET -QCB EM

250A EMERGENCY

LIGHT AND 10A

LSI SHUTDOWN

HEATER -KM1 -KM2 -KM3 -KM4 -KM5 -KM6 -KM7 -KM8

4kW 4kW 4kW 4kW 4kW 4kW 4kW 4kW

N

PE

EQUIPOTENTIAL

-EBR BONDING RAIL

M M M M M M M M

-W03 -FC1 -FC2 -FC3 -FC4 -FC5 -FC6

EARTHING

1x(XLPE 3x185/95) 37kW 37kW 37kW 37kW 37kW 37kW

Danfoss Danfoss Danfoss Danfoss Danfoss Danfoss 10.1-SCP-01 10.1-SCP-02 10.2-SCP-01 10.2-SCP-02 8.1-SB-01 8.1-SB-02 8.1-SB-03 8.1-SB-04 -MDB.9.1 -MDB.9.2

FC301 FC301 FC301 FC301 FC301 FC301

Wall Wall Wall Wall Wall Wall

mounted mounted mounted mounted mounted mounted

IP 55 IP 55 IP 55 IP 55 IP 55 IP 55

Note:

M M M M M M · Variable frequency drives (IP55) will be wall mounted outside

cabinet.

9.1-ESP-01 9.1-ESP-02 9.1-ESP-03 9.2-ESP-01 9.2-ESP-02 9.2-ESP-03

· VFD's will be equiped with Profibus interface.

MCC9 Pump 9.1.1 Pump 9.1.2 Pump 9.1.3 Pump 9.2.1 Pump 9.2.2 Pump 9.2.3 Pump 10.1.1 Pump 10.1.2 Pump 10.2.1 Pump 10.2.2 Scraper CEPT 1 Scraper CEPT 2 Scraper CEPT 2 Scraper CEPT 2

Distribution

board

Distribution

board

PLC

· Local control (Start/Stop) will be possible from HMI.

Installed power (kW) 18.50 18.50 18.50 18.50 18.50 18.50 1.67 1.67 1.67 1.67 1.10 1.10 1.10 1.10 2.20 2.20 1.00

· Remote mode will be controled by PLC over Profibus.

Power Factor (cos φ) 0.84 0.84 0.84 0.84 0.84 0.84 0.83 0.83 0.83 0.83 0.78 0.78 0.78 0.78 0.95 0.95 0.80 · DOL motors will have selector switch for selecting mode of operation

Efficiency 0.93 0.93 0.93 0.93 0.93 0.93 0.78 0.78 0.78 0.78 0.84 0.84 0.84 0.84 1.00 1.00 1.00 (local/off/remote). In local mode START/STOP push buttons will be

Simultaneous Current (A) 34.22 34.22 34.22 34.22 34.22 34.22 3.71 3.71 3.71 3.71 2.42 2.42 2.42 2.42 3.35 3.35 1.81

used for start and stop.

Power Supply Cable NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYCY 03X10/10 SW NYY-J 4X4 NYY-J 4X4 NYY-J 4X4 NYY-J 4X4 NYY-J 5X4 NYY-J 5X2.5 NYY-J 5X2.5 NYY-J 5X2.5 NYY-J 5X2.5 NYY-J 5X4

Lenght (m) 15.00 15.00 15.00 15.00 15.00 15.00 30.00 30.00 30.00 30.00 40.00 40.00 40.00 40.00 5.00 30.00

· Each drive will have emergency stop push button

Total Installed Power (kW) 127.4800

Plant coincidence factor 0.7000

Total Simultaneous Power (kW) 89.2360

Total Simultaneous Current (A) 166.8639

E 5ta Revisión

D 4ta Revisión

C 3ra Revisión

B 2da Revisión

A 1era Revisión NM 04.2021

Revision: Descripción: Nombre Fecha

FINANCIADO POR:

Banco Interamericano de Desarrollo

Aprobado por el

EMPLEADOR: Ministerio de Medio Ambiente y Agua Empleador

Unidad Coordinadora del Programa (UCP-PAAP)

Asociación Accidental

CONTRATISTA: Ludwig Pfeiffer Hoch-Und Tiefbau GmbH & Co. KG - GRUPO Emit

Ercóle Marelli Impianti Tecnologici S.R.L

PROYECTO: DISEÑO Y CONSTRUCCIÓN DE OBRAS CIVILES PARA EL PROYECTO “MEJORAMIENTO Y AMPLIACIÓN DE LA

PLANTA DE TRATAMIENTO DE AGUAS RESIDUALES (PTAR) PUCHUKOLLO - EL ALTO

UCP-PSLT No.69

Estado de Diseño: Final design-Diseño Final Disciplina: Electrical design-Diseño Eléctrico

Nombre Firma Fecha Nombre del Dibujo:

Diseño principal: A.Morejon 04.2021 Transformer Station 3 - Single line diagram with

MCC's

Diseño: N. Miletic 04.2021

Revisado: A.Morejon 04.2021 Escala Formato Dibujo Nro.: Lamina

Aprobación: Hans Störtz 04.2021 NTS A1 BO802-LP-ELE-GE-003-A 2/2

You might also like

- Single Line Diagram (AFC) (Approved)Document1 pageSingle Line Diagram (AFC) (Approved)bambang sugitoNo ratings yet

- Shahpur Grid SLD Layout DRWNG New With NGRDocument3 pagesShahpur Grid SLD Layout DRWNG New With NGRIndraneel MukherjeeNo ratings yet

- SST 1 & 2 - Wilayah Indonesia Power: MTR 2.1 MTR 2.2,3Document1 pageSST 1 & 2 - Wilayah Indonesia Power: MTR 2.1 MTR 2.2,3irfanNo ratings yet

- Side View of Consumer DP Structure: 11Kv HG Fuse Set DetailsDocument1 pageSide View of Consumer DP Structure: 11Kv HG Fuse Set DetailsDevidas JaijarNo ratings yet

- Ee FinalsDocument3 pagesEe FinalsJILIANE LUISZ SOLANOYNo ratings yet

- Incoming 3P4W 22Kv 50Hz: Change New CtsDocument1 pageIncoming 3P4W 22Kv 50Hz: Change New CtsDuong Thai BinhNo ratings yet

- 16 Bar Bridge Design DetailsDocument1 page16 Bar Bridge Design DetailsShivam SharmaNo ratings yet

- 2DG & 2 SOLAR-nugal WaterDocument1 page2DG & 2 SOLAR-nugal WaterMajeed aliNo ratings yet

- Unifilar 15052022 Op2-ModeloDocument1 pageUnifilar 15052022 Op2-Modelocamilo artetaNo ratings yet

- 00 Ec D 43105 - 5Document1 page00 Ec D 43105 - 5ganesh kumarNo ratings yet

- A01 LLEGADA (1250A) A02 Salida 1 (630A) A03 Salida 2 (630A) A04 MediciónDocument3 pagesA01 LLEGADA (1250A) A02 Salida 1 (630A) A03 Salida 2 (630A) A04 MediciónRoberto Carlos Bernaola ChuquillanquiNo ratings yet

- 15kw - SN College - SLDDocument1 page15kw - SN College - SLDmebin k XavierNo ratings yet

- Simplificado Sep02Document2 pagesSimplificado Sep02José Martínez reynelNo ratings yet

- Binder Wiring Puri Ex Pillar RewiringDocument10 pagesBinder Wiring Puri Ex Pillar RewiringWiratama MudaNo ratings yet

- Setting Proteksi PLTG Borang 60 MW PDFDocument4 pagesSetting Proteksi PLTG Borang 60 MW PDFMuhammad Alif AlfajriNo ratings yet

- AAAAAAAcoctionDocument22 pagesAAAAAAAcoctionOswaldoFigueroaNo ratings yet

- 33Kv Main Gis MV Panel Loc: Switchgear Room (MCR) : To Amin 132Kv Switchyard (Pdo) To Amin 132Kv Switchyard (Pdo)Document1 page33Kv Main Gis MV Panel Loc: Switchgear Room (MCR) : To Amin 132Kv Switchyard (Pdo) To Amin 132Kv Switchyard (Pdo)Comsip400No ratings yet

- 2Document1 page2amir amirNo ratings yet

- 2.silicon - 5MW - SLD-2Document1 page2.silicon - 5MW - SLD-2designNo ratings yet

- Hasbih HasibuanDocument1 pageHasbih HasibuanCoppyNo ratings yet

- 20150402522.electrical SLD-Model PDFDocument1 page20150402522.electrical SLD-Model PDFjaianit89No ratings yet

- 230 VOLTS, 3000 AT 3-PHASE, 65KAIC: First Private PoleDocument1 page230 VOLTS, 3000 AT 3-PHASE, 65KAIC: First Private PoleAngelo SergantesNo ratings yet

- DighaDocument1 pageDighaPriya JhaNo ratings yet

- Ice E083-E-Pjw-101-3a - Electrical Single Line Diagram - Sheet 3 - Mv-t2, Mvsb-t3, Mvsb-pb1, Mvsb-pb2, Mvsb-T4a, Mvsb-t4bDocument1 pageIce E083-E-Pjw-101-3a - Electrical Single Line Diagram - Sheet 3 - Mv-t2, Mvsb-t3, Mvsb-pb1, Mvsb-pb2, Mvsb-T4a, Mvsb-t4bAn BuiNo ratings yet

- Nissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BDocument1 pageNissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BirfanNo ratings yet

- Final SLD of BarapukuriaDocument1 pageFinal SLD of Barapukuriatanvir arafinNo ratings yet

- 0000 e 201 PDFDocument1 page0000 e 201 PDFcarlosNo ratings yet

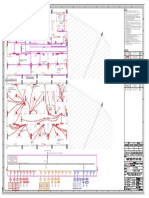

- ELECTRICAL CONDUIT AND FITTING LAYOUT PLANDocument1 pageELECTRICAL CONDUIT AND FITTING LAYOUT PLANSatya Vamsi DorapalliNo ratings yet

- 3.5X70 sq.mm. Cu UA cable from MDB to 125A TP MCCBDocument1 page3.5X70 sq.mm. Cu UA cable from MDB to 125A TP MCCBKrishna ManandharNo ratings yet

- Posisi Normal sebelum di RunDocument1 pagePosisi Normal sebelum di RunDwiky PurbacNo ratings yet

- MK13-R-Ex0 Isolation Switch AmplifierDocument3 pagesMK13-R-Ex0 Isolation Switch AmplifierAjin-Johnson VijayaNo ratings yet

- Panel Utama General Automatic Transfer Switch Panel Utama EmergencyDocument1 pagePanel Utama General Automatic Transfer Switch Panel Utama Emergencyade suhendar sutisnaNo ratings yet

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Document20 pagesOne-Line Diagram - OLV1 (Short-Circuit Analysis)Yogesh MittalNo ratings yet

- One-Line Diagram Short-Circuit Analysis PDC-4 BusesDocument19 pagesOne-Line Diagram Short-Circuit Analysis PDC-4 BusesYogesh MittalNo ratings yet

- SLD KOKOKU-ModelDocument1 pageSLD KOKOKU-ModelDeepali TayalNo ratings yet

- One-Line Diagram - OLV1 (Motor Acceleration Analysis)Document18 pagesOne-Line Diagram - OLV1 (Motor Acceleration Analysis)Yogesh MittalNo ratings yet

- Sub Station in HSLDocument8 pagesSub Station in HSLMaipali Jyoshna DeviNo ratings yet

- EFSESBFSFDocument1 pageEFSESBFSFFadil AdliNo ratings yet

- s8d59005-_ Power Diagram Camargue Magnum c Droc Room (2)Document1 pages8d59005-_ Power Diagram Camargue Magnum c Droc Room (2)Олег КлиновойNo ratings yet

- IEC - SC Output DatablockDocument1 pageIEC - SC Output DatablockTosikur RahmanNo ratings yet

- Option 2Document1 pageOption 2ttNo ratings yet

- Lawang Bangil substation upgrade projectDocument1 pageLawang Bangil substation upgrade projectirfanNo ratings yet

- Single Line PLTD 1Document1 pageSingle Line PLTD 1Asri AbrialdiNo ratings yet

- Maharajpura Ac SLD 1 MWDocument1 pageMaharajpura Ac SLD 1 MWMarco Antonio SalazarNo ratings yet

- Cisco Power Calculator ASR9010Document2 pagesCisco Power Calculator ASR9010Carlos Hoyos RosembluthNo ratings yet

- SC TRF 2 60 MVA PLTD BOO Blok 78 PLTD BODocument3 pagesSC TRF 2 60 MVA PLTD BOO Blok 78 PLTD BOenergi baratNo ratings yet

- Single Line Diagram PSUDocument1 pageSingle Line Diagram PSUFadil AdliNo ratings yet

- 411-Extracted-As Equired..removed L&T Letter PageDocument8 pages411-Extracted-As Equired..removed L&T Letter PageBilal JavaidNo ratings yet

- SLD PLTMH 3x3,3MWDocument1 pageSLD PLTMH 3x3,3MWErhamNo ratings yet

- ESQUEMA UNIFILAR MEDIA TENSIÓN.RevCDocument1 pageESQUEMA UNIFILAR MEDIA TENSIÓN.RevCAlejandro gonzalo libradoNo ratings yet

- ESQUEMA UNIFILAR MEDIA TENSIÓN.RevDDocument1 pageESQUEMA UNIFILAR MEDIA TENSIÓN.RevDAlejandro gonzalo libradoNo ratings yet

- CANBOX R157 APM-POW ACC-DET ACC-DET circuit diagramDocument11 pagesCANBOX R157 APM-POW ACC-DET ACC-DET circuit diagramSergey VissarionovNo ratings yet

- MK3-6942 Weld Mapmk2-2416: MK2-2463 +MK3-7036 (Ocs) MK3-7036 (Ocs) +Document3 pagesMK3-6942 Weld Mapmk2-2416: MK2-2463 +MK3-7036 (Ocs) MK3-7036 (Ocs) +Anonymous 80tirCcvNo ratings yet

- Ee-100 MV Switchgear Single Line DiagramDocument1 pageEe-100 MV Switchgear Single Line DiagramVo Minh ThongNo ratings yet

- SLD Layout1Document1 pageSLD Layout1Robert TiinNo ratings yet

- Tesys K ContactorsDocument22 pagesTesys K ContactorsAlpha CentaurusNo ratings yet

- From Pdp-Acx1 From Ups Panel Pdp-Atsx3: Fhi 1 2W 110V-60HzDocument11 pagesFrom Pdp-Acx1 From Ups Panel Pdp-Atsx3: Fhi 1 2W 110V-60Hzpepenapao1217No ratings yet

- FS08 - Elec - Tender DrawingDocument5 pagesFS08 - Elec - Tender Drawinglkt_pestechNo ratings yet

- Differential Scanning Calorimetry: For All RequirementsDocument14 pagesDifferential Scanning Calorimetry: For All RequirementsNdra PompomorinNo ratings yet

- Belajar Bahasa Inggris Online tentang Penyebab dan Dampak TsunamiDocument3 pagesBelajar Bahasa Inggris Online tentang Penyebab dan Dampak Tsunamihasyima mazyaNo ratings yet

- Argon PDFDocument18 pagesArgon PDFPavan KumarNo ratings yet

- Ernest RutherfordDocument4 pagesErnest RutherfordyusufNo ratings yet

- Water-Lithium Bromide Vapor Absorption SystemDocument15 pagesWater-Lithium Bromide Vapor Absorption SystemSagar MoreNo ratings yet

- Int Mech Practice Exam 2Document9 pagesInt Mech Practice Exam 2Kevin ApodacaNo ratings yet

- EXIDE Classic SolarDocument12 pagesEXIDE Classic Solarradu_dobreNo ratings yet

- Velammal Institute of Technology: Velammal Gardens, Panchetti, Chennai-601204Document5 pagesVelammal Institute of Technology: Velammal Gardens, Panchetti, Chennai-601204Suseel Jai KrishnanNo ratings yet

- Lab 5 Agr231Document4 pagesLab 5 Agr231aressaamilNo ratings yet

- SAHIL ACHARYA (Water Wheel) - EnergyConversion - AsdDocument3 pagesSAHIL ACHARYA (Water Wheel) - EnergyConversion - AsdSahil AcharyaNo ratings yet

- HY Material EDocument4 pagesHY Material Eschumiizz2best0% (1)

- Hydrogen Enrichment On Diesel Engine With Biogas in Dual Fuel ModeDocument13 pagesHydrogen Enrichment On Diesel Engine With Biogas in Dual Fuel ModeRonnie GenezNo ratings yet

- Class-Xiii Safal (MR) : Target: Neet AiimsDocument4 pagesClass-Xiii Safal (MR) : Target: Neet AiimsMir MusaibNo ratings yet

- Intercambiador de CalorDocument55 pagesIntercambiador de Calorandy pandaNo ratings yet

- Siyensikula ScriptDocument3 pagesSiyensikula ScriptJay PasajeNo ratings yet

- History of Vertical FarmingDocument7 pagesHistory of Vertical FarmingPreetiNo ratings yet

- BB Shs Phy01 Topic12 1Document10 pagesBB Shs Phy01 Topic12 1The BluemanNo ratings yet

- CO2 Hydrogenation To MethanolDocument11 pagesCO2 Hydrogenation To MethanolMuhammad AliNo ratings yet

- Micro GridDocument15 pagesMicro GridSantosh Kumar Buyya100% (1)

- Physical Science Week 1Document15 pagesPhysical Science Week 1veive merlinNo ratings yet

- Chapter1 PDFDocument21 pagesChapter1 PDFabimanaNo ratings yet

- Profil Beban COVID-19 SISTEM TIMOR 19-25 MAR 2020 NewDocument17 pagesProfil Beban COVID-19 SISTEM TIMOR 19-25 MAR 2020 NewrendroyokoNo ratings yet

- Brazilian Journal of Chemical Engineering combustion vinasseDocument9 pagesBrazilian Journal of Chemical Engineering combustion vinasseRachel HechanovaNo ratings yet

- 1 Sep 2020 Renewable Energy ResourcesDocument54 pages1 Sep 2020 Renewable Energy ResourcesRohit kannojiaNo ratings yet

- Q. Papers ME2015 PDFDocument1,669 pagesQ. Papers ME2015 PDFKamleshNo ratings yet

- Abiotic Oil - J F KenneyDocument6 pagesAbiotic Oil - J F KenneyzaroiaNo ratings yet

- Physical Principles of Thermal SensorsDocument15 pagesPhysical Principles of Thermal SensorsMichelle TannaganNo ratings yet

- Zhejiang Chao Sensor Group Meteorological Monitoring SensorsDocument17 pagesZhejiang Chao Sensor Group Meteorological Monitoring SensorsMMBNo ratings yet

- 3 Basic Concept of HazardDocument43 pages3 Basic Concept of HazardJezrael SaetNo ratings yet

- Elrctrical Power Engineering SyllabusDocument75 pagesElrctrical Power Engineering Syllabusgishi_sjdc6983No ratings yet