Professional Documents

Culture Documents

Course Assignment ME-GTI

Uploaded by

Adam KuryłaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Assignment ME-GTI

Uploaded by

Adam KuryłaCopyright:

Available Formats

Course Assignment ME-GTI, Autumn 2020

Version 1.0

Background:

This GTI course assignment is focusing on practical use of GPS tolerance system, and you will engineer, design, tolerance, build

and inspect your own designed parts for the assignment.

Your task:

• The first task is to define and create 2 seperate parts, that are planned to be assembled with as tight a tolerances as

possible. To control the assemble proces, you need to define either planes, taps or pilot pins- or a combination. Beside that,

you create geometry, that is toleranced using GPS. Your parts should also include a pattern of tap/holes. Before you start

the final design proces you need approval for the selected design, so email a short description to CMS and KRP for

approvement. Deadline is Friday 30’th October

• Your designed parts should be 3D designed in CAD and documented in 2D drawings with all relevant tolerances and GPS

types and values annotated on the drawing. Also defining and explaining the used Datum System is very important. If you

can hand in PMI data, that is of course considered positive.

• The partsize should be max 100x100x100 mm due to the scanning.

• You will manufacturer your parts and are free to decide, which proces you want to use. Probably either 3D printing or CAM

manufacturing. In both cases, you need a realistic estimation of the tolerances to expect, and the level should of course

influence your tolerances for both GPS and dimensions. Also, if you decide to 3D print, then use the same 3D printer and

dont ”mix” between printers. You are encouriged to use testprint to gain level for the expected tolerances from 3D printing or

CAM manufacturing.

Course Assignment ME-GTI

• Manufacture your parts by either 3D print or milling. If you find it relevant, you could consider to manufactere one of the 2

parts with different print technologies and inspect the difference between different manufacturing solutions. But this is

considered an add-on option.

• After manufacturing then scan your parts with GOM scanner – and please book time for scanning in proper time at Erik

Karsten Hougaard (294353@via.dk). Erik is joining the GTI course, so you can discuss scan issues during lessons.

• Inspect the final result from your scanning in GOM Inspect and document the results, either by GOM reports or your own

designed result sheet

• The entire project is described and documented in a report , that includes reflections of all phases described in this

assignment. The length of the report is max 15 pages. You hand in:

- Report in PDF format

- All CAD files and Drawings. You are free to use any CAD system, but if you dont use Inventor, then hand in

STEP files.

- GOM Projectfiles

• Deadline for handing in is Monday 30’th November on ItsLearning

• As a group, you will receive one mark for the Course ssignment , and that mark counts 60% of the final personal mark.

Have fun and we look forward to the final result.

Carsten Mejer Schmidt / Kim Rask Petersen

11’th October 2020

Course Assignment ME-GTI

You might also like

- Ref Drawing 2. Ref Code: 3. Design DatasDocument3 pagesRef Drawing 2. Ref Code: 3. Design DatasJoe Nadakkalan100% (3)

- MDESIGN Mathcad WhitepaperDocument25 pagesMDESIGN Mathcad WhitepaperYury0% (1)

- Legends & Lairs - Giant LoreDocument66 pagesLegends & Lairs - Giant LoreGary DowellNo ratings yet

- SBR 2019 Revision KitDocument513 pagesSBR 2019 Revision KitTaskin Reza Khalid100% (1)

- GP 43-45-DRAFT - Site RestorationDocument48 pagesGP 43-45-DRAFT - Site Restorationmengelito almonte100% (1)

- Inclusions in Gross IncomeDocument2 pagesInclusions in Gross Incomeloonie tunesNo ratings yet

- CimatronDocument20 pagesCimatronsagarbolisettiNo ratings yet

- GRADE 1 MUSIC Week 1 Learning PacketsDocument16 pagesGRADE 1 MUSIC Week 1 Learning PacketsQuennie Rose EderNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Electric Vehicle Charging Station BplanDocument19 pagesElectric Vehicle Charging Station BplanAjithNo ratings yet

- MazaCAM InfoDocument3 pagesMazaCAM InfodavoudyNo ratings yet

- Faithful Love: Guitar SoloDocument3 pagesFaithful Love: Guitar SoloCarol Goldburg33% (3)

- General Sewing DataDocument18 pagesGeneral Sewing DataMard Geer100% (1)

- General Sewing Data: Industrial Engineering, Work Study & ErgonomicsDocument18 pagesGeneral Sewing Data: Industrial Engineering, Work Study & ErgonomicsPrinceNo ratings yet

- CAD - CAM - CAE Notes PDFDocument101 pagesCAD - CAM - CAE Notes PDFgoreabhayNo ratings yet

- Rubber DamDocument78 pagesRubber DamDevanshi Sharma100% (1)

- Comsol 2 Day Advanced Day1Document130 pagesComsol 2 Day Advanced Day1George Opar100% (1)

- General Sewing DataDocument29 pagesGeneral Sewing DataMard GeerNo ratings yet

- DGA Furan AnalysisDocument42 pagesDGA Furan AnalysisShefian Md Dom100% (10)

- Mathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenDocument7 pagesMathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenJosh Brewer100% (3)

- General LPG Installation Guide PDFDocument60 pagesGeneral LPG Installation Guide PDFgheorghe garduNo ratings yet

- Sample Assessment Cadcam Ca2Document4 pagesSample Assessment Cadcam Ca2api-403437084No ratings yet

- Workbook For Project Works in Mechatronics and Robotics: Master of EngineeringDocument29 pagesWorkbook For Project Works in Mechatronics and Robotics: Master of EngineeringRahul GaneshNo ratings yet

- CNC Milling: Adam YouensDocument21 pagesCNC Milling: Adam YouensGundhi AsmoroNo ratings yet

- Computer Aided Design and Manufacturing Module 5 - Vikranth KannanthDocument35 pagesComputer Aided Design and Manufacturing Module 5 - Vikranth KannanthRavi Shankar mrNo ratings yet

- Creality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.From EverandCreality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.Rating: 3 out of 5 stars3/5 (1)

- OpenMPCoursework2Document5 pagesOpenMPCoursework2Jaokd100% (1)

- Tutorial New CalibrationDocument10 pagesTutorial New CalibrationMárcio DiuriNo ratings yet

- NX Sylabus R1 by Mike W2018 HandoutDocument29 pagesNX Sylabus R1 by Mike W2018 Handoutmanuelq9No ratings yet

- A Presentation On: Unit 1:3D Modeling and Viewing ByDocument43 pagesA Presentation On: Unit 1:3D Modeling and Viewing Byvishwajeet patilNo ratings yet

- Name-Roll No. - Assignment No. DateDocument6 pagesName-Roll No. - Assignment No. DatePratik Vitthalrao Jagtap-PatilNo ratings yet

- Unit IDocument6 pagesUnit IDhaneshNo ratings yet

- Abhay Pratap Singh Sengar: Phone: - +91-9329883200Document4 pagesAbhay Pratap Singh Sengar: Phone: - +91-9329883200fiemsabyasachiNo ratings yet

- DETC2003/CIE-48198: A General Decision-Making Method For The Rapid Manufacturing of Customized PartsDocument11 pagesDETC2003/CIE-48198: A General Decision-Making Method For The Rapid Manufacturing of Customized PartsDragana RajicNo ratings yet

- Manufacturing of Helical Gears by Using Fused Deposite Modelling-An Additive Manufacturing ApproachDocument22 pagesManufacturing of Helical Gears by Using Fused Deposite Modelling-An Additive Manufacturing ApproachSri Nadh PadavalaNo ratings yet

- CNC Router TutorialDocument15 pagesCNC Router TutorialM ShabbirNo ratings yet

- CAD / Computer-Aided DesignDocument3 pagesCAD / Computer-Aided Designsatya prakash mallNo ratings yet

- Cad Cam Destools v2 WebDocument6 pagesCad Cam Destools v2 Weblaro76No ratings yet

- A Presentation On: Unit VI: CAD Customization & Automation By, ByDocument41 pagesA Presentation On: Unit VI: CAD Customization & Automation By, Byvishwajeet patilNo ratings yet

- CCEC Lec04 Contracts CH 5Document17 pagesCCEC Lec04 Contracts CH 5Mustafa ZahidNo ratings yet

- Annexure 7: Apparel Cad Evaluation Format: Section A: Questionnare Segment - I (Organization)Document11 pagesAnnexure 7: Apparel Cad Evaluation Format: Section A: Questionnare Segment - I (Organization)Anonymous AW6fl3UKnuNo ratings yet

- Engine Design ProjectDocument1 pageEngine Design ProjectHenry SantosNo ratings yet

- Computer-Aided Process Planning (CAPP)Document26 pagesComputer-Aided Process Planning (CAPP)Akatew Haile MebrahtuNo ratings yet

- The Integrated Cad/Cam Solution For The Wood IndustryDocument8 pagesThe Integrated Cad/Cam Solution For The Wood IndustrySalvador Severino CascoNo ratings yet

- 3D Blueprint in Daily LifeDocument14 pages3D Blueprint in Daily LifeTonpai DolnapaNo ratings yet

- Digital ManufacturingDocument43 pagesDigital ManufacturingRamesh Kumar ANo ratings yet

- Computer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)Document15 pagesComputer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)mech118No ratings yet

- Naukri AjayGawai (8y 0m)Document4 pagesNaukri AjayGawai (8y 0m)deepakpushpadNo ratings yet

- ArtCAM 3D ManufactureDocument6 pagesArtCAM 3D ManufactureLoon StNo ratings yet

- Appendix 1 CAD/CAM (Computer-Assisted Design Computer - Assisted Manufacturing)Document3 pagesAppendix 1 CAD/CAM (Computer-Assisted Design Computer - Assisted Manufacturing)Gerardo ArroyoNo ratings yet

- The Basics of 3D Printing: 2-Day Intensive Hands-On 3D WorkshopDocument3 pagesThe Basics of 3D Printing: 2-Day Intensive Hands-On 3D WorkshopNashikEnggCluster clusterNo ratings yet

- Computer 2112Document12 pagesComputer 2112zxcccz100% (2)

- Ppce Unit - I Process Planning and Cost EstimationDocument14 pagesPpce Unit - I Process Planning and Cost EstimationJacob RubasinghNo ratings yet

- Schulung 2024 EN 1Document9 pagesSchulung 2024 EN 1Narongrit BaiyaiNo ratings yet

- Additive Manufacturing - 18me741 - Mamatha K M Module 4Document20 pagesAdditive Manufacturing - 18me741 - Mamatha K M Module 4zroranoa3No ratings yet

- Mold Making: CAD/CAM Solution For From Quoting To DeliveryDocument20 pagesMold Making: CAD/CAM Solution For From Quoting To DeliveryRami NehmeNo ratings yet

- Unit I: 3D Modeling & Viewing (08 HRS)Document26 pagesUnit I: 3D Modeling & Viewing (08 HRS)vishwajeet patilNo ratings yet

- CIM ProjectDocument18 pagesCIM ProjectVinay MishraNo ratings yet

- Mill Design and Toolpaths: Course DescriptionDocument2 pagesMill Design and Toolpaths: Course DescriptionCristian Jhair PerezNo ratings yet

- Milan Blagojevic Miroslav ZivkovicDocument6 pagesMilan Blagojevic Miroslav ZivkovicDragana RajicNo ratings yet

- Process DiagramDocument1 pageProcess Diagramambandu74No ratings yet

- FE-309: Computer Aided Design and Pattern Making: Md. Mukter AlamDocument15 pagesFE-309: Computer Aided Design and Pattern Making: Md. Mukter AlamShahadat HossainNo ratings yet

- DT WJEC Revision NotesDocument13 pagesDT WJEC Revision Notessnimr100% (2)

- CAD CAM CAE Notes PDFDocument101 pagesCAD CAM CAE Notes PDFSatyaprakash Dinesh VisputeNo ratings yet

- Basic Manufacturing Process Assignment (Me204) : Cad, Cam and CimDocument20 pagesBasic Manufacturing Process Assignment (Me204) : Cad, Cam and CimRaghunath VeeramaniNo ratings yet

- RPREDocument4 pagesRPREArun PrasadNo ratings yet

- NCG CAM V11 Press ReleaseDocument6 pagesNCG CAM V11 Press ReleaseGanesh DelhiNo ratings yet

- ML Project - M1 - ISII - 2021 2022 1 1 2 1 1Document4 pagesML Project - M1 - ISII - 2021 2022 1 1 2 1 1Ikhlas CherbiNo ratings yet

- Lecture 2 Software Review Part 2Document15 pagesLecture 2 Software Review Part 2justin.tsaoNo ratings yet

- CADCAM ManualDocument74 pagesCADCAM Manualccritam100% (1)

- What Is Your Understanding of The Terms Cad, Cam and Cim ?Document11 pagesWhat Is Your Understanding of The Terms Cad, Cam and Cim ?Abdcareem MohdNo ratings yet

- Autodesk 3ds Max 2018 for Beginners: A Tutorial Approach, 18th EditionFrom EverandAutodesk 3ds Max 2018 for Beginners: A Tutorial Approach, 18th EditionNo ratings yet

- Tower PresentationDocument8 pagesTower PresentationAdam KuryłaNo ratings yet

- CalendarDocument2 pagesCalendarAdam KuryłaNo ratings yet

- Lab 4Document7 pagesLab 4Adam KuryłaNo ratings yet

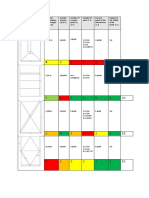

- Frames TableDocument2 pagesFrames TableAdam KuryłaNo ratings yet

- 5.126 5.128Document2 pages5.126 5.128Adam KuryłaNo ratings yet

- Ukraine SongDocument1 pageUkraine SongAdam KuryłaNo ratings yet

- Robotics Report - 17.01 Ver1Document36 pagesRobotics Report - 17.01 Ver1Adam KuryłaNo ratings yet

- Fusion CycleDocument2 pagesFusion CycleAdam KuryłaNo ratings yet

- Problem 5.62: Automatically Loading The Units (Simple) SubpackageDocument5 pagesProblem 5.62: Automatically Loading The Units (Simple) SubpackageAdam KuryłaNo ratings yet

- Thermodynamics EnthalpyDocument3 pagesThermodynamics EnthalpyAdam KuryłaNo ratings yet

- Thermo Energy of EngineDocument2 pagesThermo Energy of EngineAdam KuryłaNo ratings yet

- Project Report SEP4Document72 pagesProject Report SEP4Adam KuryłaNo ratings yet

- Adam Kuryla-Gti-examDocument1 pageAdam Kuryla-Gti-examAdam KuryłaNo ratings yet

- Training and Homework - Lesson 9 GOM Inspect - AssignmentDocument4 pagesTraining and Homework - Lesson 9 GOM Inspect - AssignmentAdam KuryłaNo ratings yet

- GTI - Problem With Calculating PerpendicularityDocument1 pageGTI - Problem With Calculating PerpendicularityAdam KuryłaNo ratings yet

- Subprograms For A, B and C Are Similar, They Are Different Only With Different Waypoints Position and Naming (F.ex A1 Can Be b1 or c1 Etc.)Document2 pagesSubprograms For A, B and C Are Similar, They Are Different Only With Different Waypoints Position and Naming (F.ex A1 Can Be b1 or c1 Etc.)Adam KuryłaNo ratings yet

- Exercise With Colar: Adam Kuryła 267892Document3 pagesExercise With Colar: Adam Kuryła 267892Adam KuryłaNo ratings yet

- Main Program For PolyScopeDocument4 pagesMain Program For PolyScopeAdam KuryłaNo ratings yet

- Appendix 3Document3 pagesAppendix 3Adam KuryłaNo ratings yet

- Glossario - GETTY - IngDocument24 pagesGlossario - GETTY - IngFabio ZarattiniNo ratings yet

- Lesson Plan Outline - Rebounding - Perez - JoseDocument7 pagesLesson Plan Outline - Rebounding - Perez - JoseJose PerezNo ratings yet

- Yusuf Mahmood CVDocument3 pagesYusuf Mahmood CVapi-527941238No ratings yet

- Unknown 31Document40 pagesUnknown 31Tina TinaNo ratings yet

- Luigi Cherubini Requiem in C MinorDocument8 pagesLuigi Cherubini Requiem in C MinorBen RutjesNo ratings yet

- Statement 1680409132566Document11 pagesStatement 1680409132566úméshNo ratings yet

- CFA L1 Ethics Questions and AnswersDocument94 pagesCFA L1 Ethics Questions and AnswersMaulik PatelNo ratings yet

- Comparison of Offline and Online Partial Discharge For Large Mot PDFDocument4 pagesComparison of Offline and Online Partial Discharge For Large Mot PDFcubarturNo ratings yet

- BMW Engine Wiring 2 OxDocument4 pagesBMW Engine Wiring 2 OxTomáš TdcNo ratings yet

- Preprints201808 0216 v1Document15 pagesPreprints201808 0216 v1Baptista Jaime MilioneNo ratings yet

- SrsDocument7 pagesSrsRahul Malhotra50% (2)

- Check Out The Buyers Guide On FacebookDocument28 pagesCheck Out The Buyers Guide On FacebookCoolerAdsNo ratings yet

- 127 Bba-204Document3 pages127 Bba-204Ghanshyam SharmaNo ratings yet

- E34-1 Battery Charging and Dishcharging BoardDocument23 pagesE34-1 Battery Charging and Dishcharging BoardGanesa MurthyNo ratings yet

- 11-Potential Use of Volcanic Pumice As A Construction Materialhossain2004Document7 pages11-Potential Use of Volcanic Pumice As A Construction Materialhossain2004afzal taiNo ratings yet

- UTM Firewalls: AR3050S and AR4050SDocument8 pagesUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranNo ratings yet

- CHECK - Chapter 11 TCD AnswersDocument6 pagesCHECK - Chapter 11 TCD AnswersbonolomphaNo ratings yet

- Acc 13 Februari 23 PagiDocument19 pagesAcc 13 Februari 23 PagisimbahNo ratings yet