Professional Documents

Culture Documents

WPS-05 TIG Welding Stainless Steel Butt and Fillet Joints

Uploaded by

murshid badshah0 ratings0% found this document useful (0 votes)

22 views2 pagesOriginal Title

WIC-WPS-05 Rev. 00_TIG_8.1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views2 pagesWPS-05 TIG Welding Stainless Steel Butt and Fillet Joints

Uploaded by

murshid badshahCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

contact@bck.

vn

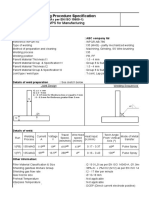

WELDING PROCEDURE SPECIFICATION

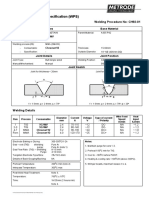

WPS number WPS-05 Rev. 00 (E) Qualified to BS EN ISO 15614-1:2017 (E), Level 2

Date 26-May-2021 Company Name BCK Engineering Co., Ltd

Supporting WPQR(s) PQR-05 Dated 20-Jun-2018

References documents ISO 15609-1:2019 (E)

MATERIAL / JOINTS QUALIFIED

Joint type Butt plate ss mb bs gg; Butt-pipe ss mb bs gg; Fillet-plate; Fillet-pipe

Parent metal(s) Any group 8.1~8.1

Notes Detailed joint sketch sees in the next page

TEST PIECE MATERIAL SPECIFICATION MATERIAL SIZE QUALIFIED Min. Max.

Type Plate ASTM A240 TP304 Gr-no. 8.1 Material thickness fillet (mm) 3 8

Welded to Plate ASTM A240 TP304 Gr-no. 8.1 Material thickness butt (mm) 3 8

Backing With or without Outside diameter (mm) 150 No Min.

Surface preparation Mechanical, back gouging or grinding Throat thickness (mm) No Min. No Max.

WELDING PROCESS

Welding process TIG / 141

Type Manual

FILLER METALS

Manufacturer / trade name KUANGTAI KTS-308L or equivalent

Classification BS EN ISO 14343 W 19 9 L or AWS A5.9 ER308L, equivalent

Size 1.6~2.4 mm

Deposited thickness 3.0~8.0 mm

POSITION

Position PA, PB, PC, PD, PE, PF, H-L045; Pipe OD >150 mm in PC, in PF, PA rotated

PREHEAT

Min. preheat temperature 10º C

Preheat maintenance temperature -

Max. inter-pass temperature 150º C

PWHT

Temperature range None

GAS

Shielding gas / type ISO 14175-I1

Flow rate 10~16 l/minute

Composition 100% Argon

Backing ISO 14175-I1

Flow rate 14~22 l/minute

Composition 100% Argon

ELECTRICAL (root) (hot) (fill) (cap)

Filler size (mm) 2.4 2.4 2.4 2.4

Amperages 80~110 80~110 80~110 80~110

Voltages 9~12 9~12 9~12 9~12

Travel speed (mm/minute) 40~60 40~60 40~60 40~60

Heat input (kJ/mm) 0.43~1.19 0.43~1.19 0.43~1.19 0.43~1.19

Current & polarity DCEN DCEN DCEN DCEN

Tungsten electrode EWTh-2, 2.4 mm EWTh-2, 2.4 mm EWTh-2, 2.4 mm EWTh-2, 2.4 mm

DC pulsing current None None None None

TECHNIQUE

String or weave Weave

Orifice/gas cup size (mm) 6~12 mm

Multi or Single pass per side Multi-pass

Method of preparation and clean. Degreased, grinding, chipping, or brushing

Legends: fb = flux backing, gg = gouging or griding, bs = welding from both sides, ss = single side welding, gb = gas

backing, mb = metal/non-metal backing, nb = welding with no material backing, sl = single layer, ml = multi-layers,

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

contact@bck.vn

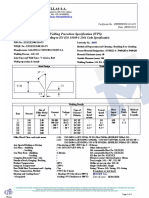

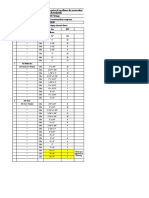

JOINT SKETCH

α=55º~70º

f=0~3.0 mm α=55º~70º

R=0~5.0 mm R=0~3.0 mm

t=thickness of base metal f=0~3.0 mm

t=thickness of base metal

R=0~3.0 mm

t=thickness of base metal

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

You might also like

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Document2 pagesWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahNo ratings yet

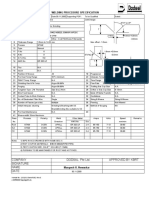

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints QualifiedFernando LlontopNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPSDocument5 pagesWPSParshottam Brahmxatriya100% (1)

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Welding Procedure Qualification Records (WPQR) GuideDocument3 pagesWelding Procedure Qualification Records (WPQR) Guideramesh rajaNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- Datasheet PGDocument1 pageDatasheet PGIlhamBintangNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Dockweiler BPE SpecDocument1 pageDockweiler BPE SpecRey LieNo ratings yet

- Product Data Sheet Low Smoke Halogen-Free Fire-Retardant Jumper Cable: NX-1/2-L-NXDocument1 pageProduct Data Sheet Low Smoke Halogen-Free Fire-Retardant Jumper Cable: NX-1/2-L-NXBao Quoc MaiNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Twi LTD: Welding Procedure Specification (WPS) - Page 1Document2 pagesTwi LTD: Welding Procedure Specification (WPS) - Page 1Anonymous SLI4aGNo ratings yet

- WPS Updated PDFDocument2 pagesWPS Updated PDFRaja Muaz Ahmad KhanNo ratings yet

- Technical Data Sheet - Draft 7/16 Straight Jack (1/2'' R) 60K1C7-C03N1Document8 pagesTechnical Data Sheet - Draft 7/16 Straight Jack (1/2'' R) 60K1C7-C03N1nguyentraihdNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- Fisa Electrozi Bazici 7018 - EngDocument2 pagesFisa Electrozi Bazici 7018 - EngGeorgeBungarzescuNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Twi LTD: Welding Procedure Specification (WPS) - Page 1Document2 pagesTwi LTD: Welding Procedure Specification (WPS) - Page 1joehodohNo ratings yet

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- 螢幕截圖 2022-12-30 上午9.17.25Document1 page螢幕截圖 2022-12-30 上午9.17.25Dave CheungNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Product Specification: 4310M-4310M HCF1/2 LMDocument1 pageProduct Specification: 4310M-4310M HCF1/2 LMlatinocomm2009No ratings yet

- 4310M-4310M HCF12 LM PDFDocument1 page4310M-4310M HCF12 LM PDFlatinocomm2009No ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Datasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Document4 pagesDatasheet For Pressure Transmitter - Stg74S: (No. RP19-009)Dhananjay BhaldandNo ratings yet

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Robust Stainless Steel Pressure Transmitters for Harsh EnvironmentsDocument4 pagesRobust Stainless Steel Pressure Transmitters for Harsh EnvironmentsRodica PuscauNo ratings yet

- Pos 0,5 DatasheetDocument7 pagesPos 0,5 DatasheetDoğa Tuğçe DurmuşNo ratings yet

- LUNNIMAG - Magnetic Level Gauge PDFDocument3 pagesLUNNIMAG - Magnetic Level Gauge PDFachmad arifNo ratings yet

- Technical Data Scaba Frielas PDFDocument1 pageTechnical Data Scaba Frielas PDFNicole FelicianoNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Product Data Sheet Low Smoke Halogen-Free Fire-Retardant Jumper Cable: NX-1/2SF-L-NXDocument1 pageProduct Data Sheet Low Smoke Halogen-Free Fire-Retardant Jumper Cable: NX-1/2SF-L-NXBao Quoc MaiNo ratings yet

- WPS 1-SS 316 Rudder Stock With Letter HeadDocument2 pagesWPS 1-SS 316 Rudder Stock With Letter HeadNuwan RanaweeraNo ratings yet

- PREQUALIFIED WELDING PROCEDURE SPECIFICATIONDocument1 pagePREQUALIFIED WELDING PROCEDURE SPECIFICATIONErick VazquezNo ratings yet

- Draft WPS Welder R0Document51 pagesDraft WPS Welder R0R Bernanda Argandhi SaputraNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Masico M025 ResealDocument4 pagesMasico M025 ResealDEIVYNo ratings yet

- WPS 2-A36 Rudder Shaft To FlangeDocument2 pagesWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Sensor Box - Data SheetDocument2 pagesSensor Box - Data SheetŁukasz OlszewskiNo ratings yet

- Plastick WeldDocument35 pagesPlastick WeldsuronocaturatmojoNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Risk Assesment Existing Process HallDocument5 pagesRisk Assesment Existing Process Hallmurshid badshahNo ratings yet

- MS Flanges and Gaskets Purchase OrderDocument2 pagesMS Flanges and Gaskets Purchase Ordermurshid badshahNo ratings yet

- VCDs Submitted in IPC # 4Document7 pagesVCDs Submitted in IPC # 4murshid badshahNo ratings yet

- Cable's Record Used at SiteDocument1 pageCable's Record Used at Sitemurshid badshahNo ratings yet

- ESTABLISHMENT OF 200 BED CENTER HVAC WORKS DAILY PLANDocument1 pageESTABLISHMENT OF 200 BED CENTER HVAC WORKS DAILY PLANmurshid badshahNo ratings yet

- Fire Fighting FittingsDocument3 pagesFire Fighting Fittingsmurshid badshahNo ratings yet

- Operator Certification: Muhammad Kaleem CNIC NO: 34201-4900936-5Document1 pageOperator Certification: Muhammad Kaleem CNIC NO: 34201-4900936-5murshid badshahNo ratings yet

- HVAC Works Calculations / Estimation (Own Team & Sub Contractor's) Labour CastDocument2 pagesHVAC Works Calculations / Estimation (Own Team & Sub Contractor's) Labour Castmurshid badshahNo ratings yet

- Asme Sec IxDocument46 pagesAsme Sec Ixmurshid badshahNo ratings yet

- PROJECT: 200 Beds Hospital Rawalpindi Date 7/7/2020 Demand Fior Stationary Alawan Electric Works & Construction CompanyDocument1 pagePROJECT: 200 Beds Hospital Rawalpindi Date 7/7/2020 Demand Fior Stationary Alawan Electric Works & Construction Companymurshid badshahNo ratings yet

- HSA G-Delivey Challan - 2022-02-07T134705.512Document1 pageHSA G-Delivey Challan - 2022-02-07T134705.512murshid badshahNo ratings yet

- Demand For Consultant Office and Site OfficeDocument1 pageDemand For Consultant Office and Site Officemurshid badshahNo ratings yet

- 200 Bed Centre of ExcellenceDocument2 pages200 Bed Centre of Excellencemurshid badshahNo ratings yet

- ESTABLISHMENT OF 200 BED CENTRE OF EXCELLENCE FOR GYNAECOLOGY AND OBSTETRICSDocument1 pageESTABLISHMENT OF 200 BED CENTRE OF EXCELLENCE FOR GYNAECOLOGY AND OBSTETRICSmurshid badshahNo ratings yet

- 200 Bed Centre of ExcellenceDocument2 pages200 Bed Centre of Excellencemurshid badshahNo ratings yet

- Demand For Duct Sealent Aluminium Tape and GlueDocument1 pageDemand For Duct Sealent Aluminium Tape and Gluemurshid badshahNo ratings yet

- Advance Requisition For 200 Beds. June 2020Document1 pageAdvance Requisition For 200 Beds. June 2020murshid badshahNo ratings yet

- Project Demand 2status - 6-20Document1 pageProject Demand 2status - 6-20murshid badshahNo ratings yet

- Demand For MS Fitting1 GF From TenderDocument1 pageDemand For MS Fitting1 GF From Tendermurshid badshahNo ratings yet

- Demand For Petty CashDocument1 pageDemand For Petty Cashmurshid badshahNo ratings yet

- Establishment of 200 bed centre of excellence for gynacology and obstetricsDocument1 pageEstablishment of 200 bed centre of excellence for gynacology and obstetricsmurshid badshahNo ratings yet

- Demand For StationaryDocument1 pageDemand For Stationarymurshid badshahNo ratings yet

- Project Demand 2-6-20Document1 pageProject Demand 2-6-20murshid badshahNo ratings yet

- Project: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at RawalpindiDocument1 pageProject: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at Rawalpindimurshid badshahNo ratings yet

- 200 Bed Gynacology Centre ValvesDocument4 pages200 Bed Gynacology Centre Valvesmurshid badshahNo ratings yet

- Electrical Demand For Site and WorkshopDocument1 pageElectrical Demand For Site and Workshopmurshid badshahNo ratings yet

- Electrical Demand For Site and WorkshopDocument1 pageElectrical Demand For Site and Workshopmurshid badshahNo ratings yet

- Project: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at RawalpindiDocument1 pageProject: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at Rawalpindimurshid badshahNo ratings yet

- 200 Bed Gynacology Centre ValvesDocument4 pages200 Bed Gynacology Centre Valvesmurshid badshahNo ratings yet

- Project: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at RawalpindiDocument1 pageProject: Establishment of 200 Bedsss Centre of Excellencr For Gynacology and Obstetrics at Rawalpindimurshid badshahNo ratings yet

- Design of Concrete Mixes .Hw3Document12 pagesDesign of Concrete Mixes .Hw3RawandAlbarodyNo ratings yet

- Friction and Wear of PTFE - A Review: S. K. BiswasDocument19 pagesFriction and Wear of PTFE - A Review: S. K. BiswasAnnamalai PalaniappanNo ratings yet

- Chapter 6-Well CompletionDocument49 pagesChapter 6-Well Completionjorge_h_rivero100% (2)

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- SANHA - Therm SANHA - Therm Industry - Press Systems in Carbon SteelDocument8 pagesSANHA - Therm SANHA - Therm Industry - Press Systems in Carbon SteelaalbertshuNo ratings yet

- Engineering Properties AggregatesDocument4 pagesEngineering Properties AggregatessuryakantameNo ratings yet

- 1227 AppG PDFDocument2 pages1227 AppG PDFCecilio MtzNo ratings yet

- Group 3 - Recyle Process PT. Tjiwi KimiaDocument15 pagesGroup 3 - Recyle Process PT. Tjiwi Kimiafabian tanuwijayaNo ratings yet

- Industrial Training Presentation on Spare Parts of Hot Mix PlantDocument19 pagesIndustrial Training Presentation on Spare Parts of Hot Mix PlantRiya Tripathi100% (1)

- Jake Joonyong Choi Balancing Equations Master Problem Set KISJ 2022 2Document17 pagesJake Joonyong Choi Balancing Equations Master Problem Set KISJ 2022 2Jonghyun (Justin) YangNo ratings yet

- A Review On The Thermomechanical Properties and Biodegradation BehaviourDocument31 pagesA Review On The Thermomechanical Properties and Biodegradation BehaviourvalentinaNo ratings yet

- Panlite® L-1225YDocument3 pagesPanlite® L-1225YLiew FongNo ratings yet

- Model: P830 Series (316L Type) : High Purity Pressure Gauge (BA Grade)Document6 pagesModel: P830 Series (316L Type) : High Purity Pressure Gauge (BA Grade)민성규No ratings yet

- TDS For Epoxy SystemDocument4 pagesTDS For Epoxy SystemhemantrulzNo ratings yet

- Physical and Chemical Properties of Water2Document41 pagesPhysical and Chemical Properties of Water2أبو أسامة حمديNo ratings yet

- Slow Sand Filter DesignDocument4 pagesSlow Sand Filter Designvisali garikapatiNo ratings yet

- Class PS 46 Polyvinyl Chloride (PVC) Pipe: Standard Specification ForDocument4 pagesClass PS 46 Polyvinyl Chloride (PVC) Pipe: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- ACID TITLESDocument41 pagesACID TITLESAditi MishraNo ratings yet

- Polymer Next PDFDocument31 pagesPolymer Next PDFali100% (2)

- FormulaShell SAE 10W 40 Motor Oil DatasheetDocument3 pagesFormulaShell SAE 10W 40 Motor Oil DatasheetAnonymous YjoCCKNo ratings yet

- International Care SymbolsDocument12 pagesInternational Care SymbolsBincy AbrahamNo ratings yet

- Dycote 1000 PyrotekDocument1 pageDycote 1000 Pyrotekjose.figueroa@foseco.comNo ratings yet

- Week010 LaboratoryExercise003 AcidsandBasesSolubilityEquilibriaDocument9 pagesWeek010 LaboratoryExercise003 AcidsandBasesSolubilityEquilibriarejlarracasNo ratings yet

- Lecture 01-03Document15 pagesLecture 01-03Fayaz AhmedNo ratings yet

- Incoloy & Monel CorrosionDocument3 pagesIncoloy & Monel CorrosionAbbasNo ratings yet

- Production of Drying OilDocument136 pagesProduction of Drying Oilali abdulrahman al-ezziNo ratings yet

- Ammonia Handbook PDFDocument28 pagesAmmonia Handbook PDFValerZLNo ratings yet

- Density Worksheet Physics Class 9Document3 pagesDensity Worksheet Physics Class 9vectors academyNo ratings yet

- Elemental Analysis of Organic CompoundsDocument4 pagesElemental Analysis of Organic CompoundsJessica Margaux Mercado0% (1)

- 9485 & 926 Transfer Tapes: Product Data SheetDocument3 pages9485 & 926 Transfer Tapes: Product Data SheetvijaygalaxyNo ratings yet