Professional Documents

Culture Documents

CR C14 LD2420K

Uploaded by

Jaime222Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CR C14 LD2420K

Uploaded by

Jaime222Copyright:

Available Formats

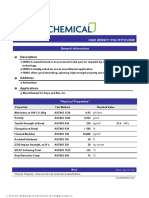

Technical Data Sheet

CirculenRenew C14 LD2420K

Low Density Polyethylene

Product Description

CirculenRenew C14 LD2420 K is part of the Circulen© product family of circular and sustainable solutions.

CirculenRenew C14 polymer reduces the carbon footprint as it replaces fossil feedstock through using renewable

raw materials made from bio-based waste and residue oils. The renewable content of CirculenRenew C14 is

measured by an accredited third party laboratory and stated as a parameter on the Certificate of Analysis (CoA).

CirculenRenew C14 LD2420 K is a drop-in solution and therefore doesn¶t require any adaptation of the existing

processing equipment.

CirculenRenew C14 LD2420 K is a non-additivated, low density polyethylene. It is characterized by a good

processability. Films made from CirculenRenew C14 LD2420 K exhibit good optical properties. It is delivered in

pellet form.

This product is not intended for use in medical and pharmaceutical applications.

Regulatory Status

For regulatory compliance information, see CirculenRenew C14 LD2420K Product Stewardship Bulletin (PSB)

and Safety Data Sheet (SDS).

Status Commercial: Active

Availability Africa-Middle East; Asia-Pacific; Europe

Application Coatings, Protective; Food Packaging Film; Hygiene Film; Shrink Film; Surface

Protection Film

Market Flexible Packaging

Processing Method Blown Film; Cast Film; Extrusion Coating; Injection Molding

Attribute Good Heat Seal; Good Optical Properties; Good Processability

Nominal

Typical Properties Value Units Test Method

Physical

Melt Flow Rate, (190 °C/2.16 kg) 4.0 g/10 min ISO 1133-1

Density 0.924 g/cm³ ISO 1183-1

Mechanical

Tensile Modulus 260 MPa ISO 527-1, -2

Tensile Stress at Yield 11 MPa ISO 527-1, -2

Film

Dart Drop Impact Strength, F50 100 g ASTM D1709

Tensile Strength

MD 22 MPa ISO 527-1, -3

TD 17 MPa ISO 527-1, -3

Tensile Strain at Break

MD 300 % ISO 527-1, -3

TD 600 % ISO 527-1, -3

Coefficient of Friction >0.7 ISO 8295

Impact

Failure Energy 3.5 J/mm DIN 53373

LyondellBasell CirculenRenew C14 LD2420K

Technical Data Sheet Recipient Tracking #:

Date: 2/6/2022 Page 1 of 3 Request #: 3452700

Thermal

Vicat Softening Temperature, (A/50 N) 92 °C ISO 306

Peak Melting Point 111 °C ISO 11357-3

Optical

Haze, (50 µm) <8 % ASTM D1003

Gloss

(20°) >60 ASTM D2457

(60°) >105 ASTM D2457

Additional Information

Test Specimen Film

Film properties tested using 50 µm thickness blown film extruded at a melt temperature of 170°C and a blow-up ratio of 2.5:1.

Processing Parameters

Extrusion Temperature 150-190 °C

Blown Film Extrusion

Notes

These are typical property values not to be construed as specification limits.

Processing Techniques

Users should determine the conditions necessary to obtain optimum product properties and suitability of the

product for the intended application.

In cases where higher temperatures are required, please contact your appropriate technical contact for support.

Further Information

Health and Safety:

The resin is manufactured to the highest standards, but special requirements apply to certain applications such

as food end-use contact and direct medical use. For specific information on regulatory compliance contact your

local representative.

Workers should be protected from the possibility of skin or eye contact with molten polymer. Safety glasses are

suggested as a minimal precaution to prevent mechanical or thermal injury to the eyes.

Molten polymer may be degraded if it is exposed to air during any of the processing and off-line operations. The

products of degradation may have an unpleasant odor. In higher concentrations they may cause irritation of the

mucus membranes. Fabrication areas should be ventilated to carry away fumes or vapours. Legislation on the

control of emissions and pollution prevention should be observed.

The resin will burn when supplied with excess heat and oxygen. It should be handled and stored away from

contact with direct flames and/or ignition sources. While burning, the resin contributes high heat and may

generate a dense black smoke.

Recycled resins may have previously been used as packaging for, or may have otherwise been in contact with,

hazardous goods. Converters are responsible for taking all necessary precautions to ensure that recycled resins

are safe for continued use.

For further information about safety in handling and processing please refer to the Safety Data Sheet.

Conveying:

Conveying equipment should be designed to prevent production and accumulation of fines and dust particles

that are contained in polymer resins. These particles can under certain conditions pose an explosion hazard.

Conveying systems should be grounded, equipped with adequate filters and regularly inspected for leaks.

LyondellBasell CirculenRenew C14 LD2420K

Technical Data Sheet Recipient Tracking #:

Date: 2/6/2022 Page 2 of 3 Request #: 3452700

Storage:

The resin is packed in 25 kg bags, octabins or bulk containers protecting it from contamination. If it is stored

under certain conditions, i. e. if there are large fluctuations in ambient temperature and the atmospheric humidity

is high, moisture may condense inside the packaging. Under these circumstances, it is recommended to dry the

resin before use. Unfavorable storage conditions may also intensify the resin's slight characteristic odor.

Resin should be protected from direct sunlight, temperatures above 40°C and high atmospheric humidity during

storage. Higher storage temperatures may reduce the storage time.

The information submitted is based on our current knowledge and experience. In view of the many factors that

may affect processing and application, these data do not relieve processors of the responsibility of carrying out

their own tests and experiments; neither do they imply any legally binding assurance of certain properties or of

suitability for a specific purpose. This information does not remove the obligation of the customer to inspect the

material on arrival and notify us of any faults immediately. It is the responsibility of those to whom we supply our

products to ensure that any proprietary rights and existing laws and legislation are observed.

Company Information

For further information regarding the LyondellBasell company, please visit http://www.lyb.com/.

© LyondellBasell Industries Holdings, B.V. 2018

Disclaimer

Information in this document is accurate to the best of our knowledge at the date of publication. The document is

designed to provide users general information for safe handling, use, processing, storage, transportation,

disposal and release and does not constitute any warranty or quality specification, either express or implied,

including any warranty of merchantability or fitness for any particular purpose. Users shall determine whether the

product is suitable for their use and can be used safely and legally.

In addition to any prohibitions of use specifically noted in this document, LyondellBasell may further prohibit or

restrict the sale of its products into certain applications. For further information, please contact a LyondellBasell

representative.

Trademarks

The Trademark referenced within the product name is owned or used by the LyondellBasell family of companies.

LyondellBasell CirculenRenew C14 LD2420K

Technical Data Sheet Recipient Tracking #:

Date: 2/6/2022 Page 3 of 3 Request #: 3452700

You might also like

- A Quick Guide To The FMD Pro PDFDocument24 pagesA Quick Guide To The FMD Pro PDFstouraNo ratings yet

- CirRenew C14 LD2420DDocument3 pagesCirRenew C14 LD2420DJaime222No ratings yet

- C C14 LD2420F PlusDocument3 pagesC C14 LD2420F PlusJaime222No ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetEmanuel TescheNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAdrián SánchezNo ratings yet

- Moplen: Technical Data SheetDocument3 pagesMoplen: Technical Data SheetMonica BoccaNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- High Density Polyethylene Product Data SheetDocument2 pagesHigh Density Polyethylene Product Data Sheetchirag.sanchetiNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetRobertoNo ratings yet

- Adflex Q100FDocument2 pagesAdflex Q100FAna Maria MuresanNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Riblene FC 30Document2 pagesRiblene FC 30Josevi Jiménez MerinoNo ratings yet

- Technical Data Sheet - ISO PE LYONDELLDocument3 pagesTechnical Data Sheet - ISO PE LYONDELLNur AzizahNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Lupolen: Technical Data SheetDocument3 pagesLupolen: Technical Data SheetJaime222No ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Material DataDocument3 pagesMaterial DataR.Ranjan PradhanNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- HD601CF PDS Reg - Europe en V7 PDS Eur 25659 10047542Document3 pagesHD601CF PDS Reg - Europe en V7 PDS Eur 25659 10047542李万福No ratings yet

- Adflex: Technical Data SheetDocument3 pagesAdflex: Technical Data Sheetnouman ashrafNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Product Datasheet BiohesiveDocument3 pagesProduct Datasheet Biohesivebolang cepuNo ratings yet

- Lexan Polycarbonate Embossed SheetDocument2 pagesLexan Polycarbonate Embossed SheetAmritraj CharlesNo ratings yet

- Moplen: Technical Data SheetDocument2 pagesMoplen: Technical Data SheetErsanİmamoğullarıNo ratings yet

- Purell ACP 6031 D Technical Data SheetDocument3 pagesPurell ACP 6031 D Technical Data SheetPiyush A JoshiNo ratings yet

- Technical Data Sheet - ISODocument2 pagesTechnical Data Sheet - ISONishant_s123No ratings yet

- HP552K DatasheetDocument2 pagesHP552K DatasheettranoNo ratings yet

- Technical Data Sheet Hifax CA 10 ADocument2 pagesTechnical Data Sheet Hifax CA 10 AafidyusufNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- 0210 Ibd - MSDS Reg - Europe en V4 ZPDS Eur 48808 10038429Document3 pages0210 Ibd - MSDS Reg - Europe en V4 ZPDS Eur 48808 10038429Mehdi SaouriNo ratings yet

- Technical Data Sheet - Original Hoop MaterialDocument2 pagesTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakNo ratings yet

- TITLE Fast Molding Polyamide for Thin Wall PartsDocument3 pagesTITLE Fast Molding Polyamide for Thin Wall PartsSATHISH KUMAR SNo ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- FT6230-PDS-REG_EUROPE-EN-V3-PDS-EUR-3388-10055311Document3 pagesFT6230-PDS-REG_EUROPE-EN-V3-PDS-EUR-3388-10055311Company EcoplastNo ratings yet

- ALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetDocument2 pagesALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetGufran AhmadNo ratings yet

- SABIC® LLDPE - 118WM - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WM - Global - Technical - Data - Sheethafidz 35No ratings yet

- Microthene: Technical Data SheetDocument2 pagesMicrothene: Technical Data SheetJaime222No ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- Repsol Alcudia PE046Document1 pageRepsol Alcudia PE046armandoestavanquitoNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- High Heat Resistance Polystyrene for ExtrusionDocument2 pagesHigh Heat Resistance Polystyrene for ExtrusionlyesNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- tds-hd5403pdfDocument2 pagestds-hd5403pdfAthonioMourinhoNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetUlises HernándezNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- SABICs P6006NDocument2 pagesSABICs P6006NroybharggavNo ratings yet

- Bassel 5052b BlackDocument3 pagesBassel 5052b BlackNaren RawatNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Technical Data Sheet - RIBLENE - FL 34 F - ITDocument2 pagesTechnical Data Sheet - RIBLENE - FL 34 F - ITEmanuele GizziNo ratings yet

- HFX 500P Rev 6 - 2018 PDFDocument2 pagesHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNo ratings yet

- Datasheet Moplen EP340K 3288 - 1531149020Document4 pagesDatasheet Moplen EP340K 3288 - 1531149020afidyusufNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- Hfi5110 300516Document2 pagesHfi5110 300516李万福No ratings yet

- Alathon: Technical Data SheetDocument3 pagesAlathon: Technical Data SheetJaime222No ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Microthene: Technical Data SheetDocument2 pagesMicrothene: Technical Data SheetJaime222No ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Lupolen: Technical Data SheetDocument3 pagesLupolen: Technical Data SheetJaime222No ratings yet

- Alathon: Technical Data SheetDocument2 pagesAlathon: Technical Data SheetJaime222No ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Lucalen: Technical Data SheetDocument3 pagesLucalen: Technical Data SheetJaime222No ratings yet

- Alathon: Technical Data SheetDocument2 pagesAlathon: Technical Data SheetJaime222No ratings yet

- Sabic Ldpe 2202U0: Low Density PolyethyleneDocument2 pagesSabic Ldpe 2202U0: Low Density PolyethyleneJaime222No ratings yet

- CirculenRenew C14 LD1800SDocument3 pagesCirculenRenew C14 LD1800SJaime222No ratings yet

- Datasheet Polystone P Homopolymer enDocument1 pageDatasheet Polystone P Homopolymer enJaime222No ratings yet

- Mdpe Dx800: Application / Use CaseDocument1 pageMdpe Dx800: Application / Use CaseJaime222No ratings yet

- PP Homo Basell - HP500NDocument2 pagesPP Homo Basell - HP500NJaime222No ratings yet

- Sun Conure IllnessesDocument1 pageSun Conure IllnessesJaime222No ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- 5000S (Eng.) PDFDocument1 page5000S (Eng.) PDFRyan Si AhmaddNo ratings yet

- LL 22402 Linear Low Density Polyethylene Properties and ApplicationsDocument1 pageLL 22402 Linear Low Density Polyethylene Properties and ApplicationsJaime222No ratings yet

- Technical Data Sheet - ISODocument3 pagesTechnical Data Sheet - ISOJaime222No ratings yet

- Drainage Systems For Road and Track Construction: With Perfectly Matched ComponentsDocument68 pagesDrainage Systems For Road and Track Construction: With Perfectly Matched ComponentsJaime222No ratings yet

- Sabic Ldpe 2102X0: Low Density PolyethyleneDocument2 pagesSabic Ldpe 2102X0: Low Density PolyethyleneJaime222No ratings yet

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222No ratings yet

- 1st Letter - Version 2Document1 page1st Letter - Version 2moregauravNo ratings yet

- Taborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionDocument1 pageTaborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionJaime222No ratings yet

- Sabic Ldpe 2202U0: Low Density PolyethyleneDocument2 pagesSabic Ldpe 2202U0: Low Density PolyethyleneJaime222No ratings yet

- Authentication and Single Sign-OnDocument48 pagesAuthentication and Single Sign-Onrengasamys100% (2)

- DSP Lect 11 Iir DesignDocument50 pagesDSP Lect 11 Iir DesignSayyeda UmbereenNo ratings yet

- Mobile Banking Prospects Problems BangladeshDocument20 pagesMobile Banking Prospects Problems BangladeshabrarNo ratings yet

- Nfpa Codes PDFDocument12 pagesNfpa Codes PDFphe zenNo ratings yet

- 9 Principles of Income Tax LawsDocument82 pages9 Principles of Income Tax LawsVyankatesh GotalkarNo ratings yet

- LAS IN ENTREPRENEURSHIP WEEK 4Document5 pagesLAS IN ENTREPRENEURSHIP WEEK 4IMELDA CORONACIONNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Ivent201 - Manual de Usuario (220-290)Document71 pagesIvent201 - Manual de Usuario (220-290)Wilber AleluyaNo ratings yet

- Tekla - DocumentDocument2,005 pagesTekla - DocumentTranタオNo ratings yet

- Razwan Iqbalcv1Document3 pagesRazwan Iqbalcv1razwaniqbalNo ratings yet

- Content Analysis Research Paper ExampleDocument5 pagesContent Analysis Research Paper Examplefvfzfa5d100% (1)

- Judicial Watch Vs State Dept Stephen Mull DepositionDocument415 pagesJudicial Watch Vs State Dept Stephen Mull DepositionThe Conservative Treehouse100% (1)

- 1 tb13 PDFDocument30 pages1 tb13 PDFClay MasonNo ratings yet

- C2 - Knowledge - and - Process - Management - v25 - n3 - Fernanda 2018 PDFDocument12 pagesC2 - Knowledge - and - Process - Management - v25 - n3 - Fernanda 2018 PDFThomazNo ratings yet

- Bangladesh Labour Rights ResearchDocument29 pagesBangladesh Labour Rights ResearchMd. Hasan Ali JoyNo ratings yet

- Chapter 3 - Excel SolutionsDocument8 pagesChapter 3 - Excel SolutionsHalt DougNo ratings yet

- Passive Fire Protection PDFDocument7 pagesPassive Fire Protection PDFVictor SampaNo ratings yet

- CSC V CADocument2 pagesCSC V CAAllen GrajoNo ratings yet

- Bernini OverviewDocument7 pagesBernini Overviewaberardo1No ratings yet

- DL 57 PDFDocument2 pagesDL 57 PDFmaheshm_erpNo ratings yet

- The Ultimate Experience With AvatradeDocument3 pagesThe Ultimate Experience With AvatradeAnonymous wk2GeJ8ERQNo ratings yet

- Quiz II - Company MissionDocument4 pagesQuiz II - Company MissionSuraj SapkotaNo ratings yet

- Model checking flight control systems experienceDocument11 pagesModel checking flight control systems experienceCORAL ALONSONo ratings yet

- Loan Agreement SummaryDocument13 pagesLoan Agreement SummaryKaran SharmaNo ratings yet

- OSN 9800 U64, U32, U16, UPS Installation GuideDocument157 pagesOSN 9800 U64, U32, U16, UPS Installation GuidedonekeoNo ratings yet

- Calculation of absorption properties of absorbent materialsDocument4 pagesCalculation of absorption properties of absorbent materialsRezaul Karim TutulNo ratings yet

- 07 Safety Culture Informed Just and FairDocument49 pages07 Safety Culture Informed Just and FairDaniel Gaspar SilvaNo ratings yet

- Q Asgt - Biz Law - A192Document10 pagesQ Asgt - Biz Law - A192otaku himeNo ratings yet

- Integral Abutment Bridge Design (Modjeski and Masters) PDFDocument56 pagesIntegral Abutment Bridge Design (Modjeski and Masters) PDFAnderson UrreaNo ratings yet