Professional Documents

Culture Documents

Petrothene: Technical Data Sheet

Petrothene: Technical Data Sheet

Uploaded by

Jaime222Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Petrothene: Technical Data Sheet

Petrothene: Technical Data Sheet

Uploaded by

Jaime222Copyright:

Available Formats

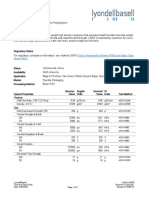

Technical Data Sheet

Petrothene NA340013

Ethylene Vinyl Acetate

Product Description

Petrothene NA340 is a series of LDPE/EVA copolymer resins selected by customers for film applications that

require clarity and good impact strength. Typical applications include heavy produce, textile, frozen food

packaging and sealant films.

Regulatory Status

For regulatory compliance information, see Petrothene NA340013 Product Stewardship Bulletin (PSB) and

Safety Data Sheet (SDS).

Status Commercial: Active

Availability North America

Application Clarity Film

Market Flexible Packaging

Processing Method Blown Film; Cast Film

Nominal English Nominal SI

Typical Properties Value Units Value Units Test Method

Physical

Melt Flow Rate, (190 °C/2.16 kg) 1.0 g/10 min 1.0 g/10 min ASTM D1238

Vinyl Acetate Content 4.0 % 4.0 % LYB Method

Film

Dart Drop Impact Strength, F50 140 g 140 g ASTM D1709

Tensile Strength at Break

MD 3700 psi 25.5 MPa ASTM D882

TD 3100 psi 21.4 MPa ASTM D882

Tensile Elongation at Break

MD 340 % 340 % ASTM D882

TD 500 % 500 % ASTM D882

1% Secant Modulus

MD 21000 psi 145 MPa ASTM D882

TD 24000 psi 165 MPa ASTM D882

Elmendorf Tear Strength

MD 180 g 180 g ASTM D1922

TD 250 g 250 g ASTM D1922

Thermal

Vicat Softening Temperature 203 °F 95 °C ASTM D1525

Optical

Haze 4.0 % 4.0 % ASTM D1003

As measured on NA340141 (high slip, medium antiblock).

Gloss, (45°) 75 75 ASTM D2457

As measured on NA340141 (high slip, medium antiblock).

Additive

Slip None None LYB Method

Antiblock None None LYB Method

LyondellBasell Petrothene NA340013

Technical Data Sheet Recipient Tracking #:

Date: 2/6/2022 Page 1 of 2 Request #: 3452887

Processing Parameters

Melt Temperature 330 - 375 °F 165 - 191 °C

Antiblock

Product Slip(ppm) (ppm)

NA340013 None None

NA340141 1000 1700

NA340163 500 2000

NA340185 850 3000

NA340212 None 2000

Notes

Film data obtained from sample produced on a 3 1/2" (89mm) blown film line, commercially available 8" (203

mm) die, 375°F (191°C) melt extrusion temperature, 2:1 BUR, 1.25 mil (32 micron) gauge, 0.025" die gap at 130

lbs/hr.

These are typical property values not to be construed as specification limits.

Processing Techniques

Specific recommendations for resin type and processing conditions can only be made when the end use,

required properties and fabrication equipment are known.

Company Information

For further information regarding the LyondellBasell company, please visit http://www.lyb.com/.

© LyondellBasell Industries Holdings, B.V. 2018

Disclaimer

Information in this document is accurate to the best of our knowledge at the date of publication. The document is

designed to provide users general information for safe handling, use, processing, storage, transportation,

disposal and release and does not constitute any warranty or quality specification, either express or implied,

including any warranty of merchantability or fitness for any particular purpose. Users shall determine whether the

product is suitable for their use and can be used safely and legally.

In addition to any prohibitions of use specifically noted in this document, LyondellBasell may further prohibit or

restrict the sale of its products into certain applications. For further information, please contact a LyondellBasell

representative.

Trademarks

The Trademark referenced within the product name is owned or used by the LyondellBasell family of companies.

LyondellBasell Petrothene NA340013

Technical Data Sheet Recipient Tracking #:

Date: 2/6/2022 Page 2 of 2 Request #: 3452887

You might also like

- Build-A-Bear Workshop Collectors Guide 4/2012Document98 pagesBuild-A-Bear Workshop Collectors Guide 4/2012BuildABearWorkshop79% (24)

- Lecture 01 HoDocument51 pagesLecture 01 HodarrenNo ratings yet

- Showboat - History and SignificanceDocument6 pagesShowboat - History and SignificanceJohnny Watt100% (3)

- Arena Codex Scientia PDFDocument162 pagesArena Codex Scientia PDFМаксим Дьяконенко100% (1)

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- Petrothene: Technical Data SheetDocument3 pagesPetrothene: Technical Data SheetEli DelgadoNo ratings yet

- LLGA1810Document2 pagesLLGA1810KAKI BELANGNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetEndayenew MollaNo ratings yet

- Lldpe Petrothene Ga502-024Document2 pagesLldpe Petrothene Ga502-024Noe floresNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetihscribedNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- Technical Data Sheet - Original Hoop MaterialDocument2 pagesTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakNo ratings yet

- Alathon: Technical Data SheetDocument3 pagesAlathon: Technical Data SheetJaime222No ratings yet

- Basell Hdpe Pe100 Pipe Alathon l4904Document3 pagesBasell Hdpe Pe100 Pipe Alathon l4904Josiola MariledoNo ratings yet

- Technical Data Sheet 2021-09-09 05 - 27 - 06Document2 pagesTechnical Data Sheet 2021-09-09 05 - 27 - 06AnderssonNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- Technical Data Sheet - ASTMDocument2 pagesTechnical Data Sheet - ASTMwida acNo ratings yet

- Dow Elite 5401G TDSDocument3 pagesDow Elite 5401G TDSAli RazuNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Lotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneDocument2 pagesLotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneMamdouhNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Technical Data Sheet - ASTM PDFDocument2 pagesTechnical Data Sheet - ASTM PDFnielNo ratings yet

- DOW™ Butene 1220P: Polyethylene ResinDocument1 pageDOW™ Butene 1220P: Polyethylene Resinvantuan17792No ratings yet

- Exceed 3518Document2 pagesExceed 3518Jimmys GothiqueNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- Wpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetDocument2 pagesWpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetankitNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- SABIC PP 5703P Polypropylene Homopolymer For Injection MoldingDocument2 pagesSABIC PP 5703P Polypropylene Homopolymer For Injection MoldingMédi ChegmaNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- TKC 2007N NA 82V TITAN Technical Data SheetDocument1 pageTKC 2007N NA 82V TITAN Technical Data SheetEduardo MazariegosNo ratings yet

- Microthene: Technical Data SheetDocument2 pagesMicrothene: Technical Data SheetJaime222No ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Enable™ 3505MC: Performance PolymerDocument2 pagesEnable™ 3505MC: Performance PolymerSiti Susi SulastriNo ratings yet

- Enable™ 4002MC Blown: Performance PolymerDocument2 pagesEnable™ 4002MC Blown: Performance PolymerCristian RodriguezNo ratings yet

- Exceed™ XP 8346PA: Performance PolymerDocument2 pagesExceed™ XP 8346PA: Performance PolymerMaram YasserNo ratings yet

- Exxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene Resinabdelmoumene djafer beyNo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- C C14 LD2420F PlusDocument3 pagesC C14 LD2420F PlusJaime222No ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- B6401 JarDocument1 pageB6401 JarStella KazanciNo ratings yet

- Exxon LD 100 BWDocument2 pagesExxon LD 100 BWAli KüçükNo ratings yet

- LG Chemical LG 501 Styrene Butadiene Styrene PDFDocument1 pageLG Chemical LG 501 Styrene Butadiene Styrene PDFcarlosNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Nghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnDocument1 pageNghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnJimmy NguyenNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Lupolen: Technical Data SheetDocument3 pagesLupolen: Technical Data SheetJaime222No ratings yet

- Microthene: Technical Data SheetDocument2 pagesMicrothene: Technical Data SheetJaime222No ratings yet

- C C14 LD2420F PlusDocument3 pagesC C14 LD2420F PlusJaime222No ratings yet

- Alathon: Technical Data SheetDocument3 pagesAlathon: Technical Data SheetJaime222No ratings yet

- CR C14 LD2420KDocument3 pagesCR C14 LD2420KJaime222No ratings yet

- BiologiaDocument1 pageBiologiaJaime222No ratings yet

- CirRenew C14 LD2420DDocument3 pagesCirRenew C14 LD2420DJaime222No ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- Mdpe Dx800: Application / Use CaseDocument1 pageMdpe Dx800: Application / Use CaseJaime222No ratings yet

- PP Homo Basell - HP500NDocument2 pagesPP Homo Basell - HP500NJaime222No ratings yet

- Drainage Systems For Road and Track Construction: With Perfectly Matched ComponentsDocument68 pagesDrainage Systems For Road and Track Construction: With Perfectly Matched ComponentsJaime222No ratings yet

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222No ratings yet

- Linear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Document1 pageLinear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Jaime222No ratings yet

- Taborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionDocument1 pageTaborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionJaime222No ratings yet

- Cervical Spondylotic Myelopathy: Aditya Iyer, MD, MS, Tej D. Azad, Ba, and Suzanne Tharin, MD, PHDDocument7 pagesCervical Spondylotic Myelopathy: Aditya Iyer, MD, MS, Tej D. Azad, Ba, and Suzanne Tharin, MD, PHDMây Trên TrờiNo ratings yet

- LG LAVADORA FH496TDAD - MFL68585950-Spain PDFDocument45 pagesLG LAVADORA FH496TDAD - MFL68585950-Spain PDFA Eugenio RiosNo ratings yet

- Review of Literature On Investment Behaviour of InvestorsDocument7 pagesReview of Literature On Investment Behaviour of Investorsc5jxjm5mNo ratings yet

- Operation Management CompressedDocument17 pagesOperation Management CompressedEugenie FebbyNo ratings yet

- Axial Compressor - Wikipedia, The Free EncyclopediaDocument11 pagesAxial Compressor - Wikipedia, The Free EncyclopediaSurendra ReddyNo ratings yet

- Iwwwfb27 16Document4 pagesIwwwfb27 16rickyspaceguyNo ratings yet

- Spiritualityinhealthassessment nsg316 SareeceguerreroDocument6 pagesSpiritualityinhealthassessment nsg316 Sareeceguerreroapi-520930030No ratings yet

- Zapata Siui Phased ArrayDocument3 pagesZapata Siui Phased ArrayEdgar Javier Cepeda AmadoNo ratings yet

- Chlorine Energy 2520 BalanceDocument4 pagesChlorine Energy 2520 Balancetonzz10No ratings yet

- Morning MantrasDocument52 pagesMorning MantrasEsteban Ariza RangelNo ratings yet

- SpreadSheets - Conditional FormattingDocument67 pagesSpreadSheets - Conditional FormattingRonex KandunaNo ratings yet

- Tuesday With MorrieDocument60 pagesTuesday With MorrieKyoko IwaseNo ratings yet

- Akij Group 3Document4 pagesAkij Group 3Dewan Abdul GaffarNo ratings yet

- The Lazy Students Guide To Writing A Dissertation by Ben RobinsonDocument72 pagesThe Lazy Students Guide To Writing A Dissertation by Ben RobinsonnhanscribdNo ratings yet

- EM 1110-1-3500 31 Jan 95: B. Chemical Grouting. Chemical Grouting Is TheDocument3 pagesEM 1110-1-3500 31 Jan 95: B. Chemical Grouting. Chemical Grouting Is TheChetan SabadraNo ratings yet

- Flat BettingDocument2 pagesFlat Bettingdickin abox100% (1)

- NCP 3A Nutritional Imbalance Less ThanDocument3 pagesNCP 3A Nutritional Imbalance Less ThanCee Sanchez100% (3)

- SIWAREX MS Library Add V1d0 enDocument16 pagesSIWAREX MS Library Add V1d0 enasim89_No ratings yet

- Shaping The Panama Canal by Blasting - Pacific Complex's WorksDocument10 pagesShaping The Panama Canal by Blasting - Pacific Complex's WorksMulti Nitrotama KimiaNo ratings yet

- Pediatric Cardiac Arrest Algorithm: Yes NoDocument1 pagePediatric Cardiac Arrest Algorithm: Yes NoRatna TambaNo ratings yet

- Hardware Design: Test Project DocumentDocument16 pagesHardware Design: Test Project Document4hw4nn00rNo ratings yet

- AMF 3.4L Connection Diagram - enDocument1 pageAMF 3.4L Connection Diagram - enMohamed Hasan Ali HasanNo ratings yet

- BỘ ĐỀ LỚP 6 KÌ 2 - HOÀN CHỈNHDocument15 pagesBỘ ĐỀ LỚP 6 KÌ 2 - HOÀN CHỈNHGấm NguyễnNo ratings yet

- MegaBrain Report Volume 3 Number 3Document74 pagesMegaBrain Report Volume 3 Number 3Jason Youngquist100% (6)

- Selected Topic Table Finale BDocument2 pagesSelected Topic Table Finale BAutumnNo ratings yet

- AdityaaaDocument43 pagesAdityaaaswatisahani829No ratings yet