Professional Documents

Culture Documents

Design and Fabrication of Multifunctional Furniture

Uploaded by

Alvaro SolisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Multifunctional Furniture

Uploaded by

Alvaro SolisCopyright:

Available Formats

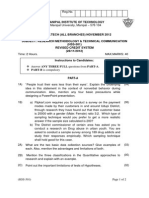

International Journal of Research in Engineering, Science and Management 442

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Design and Fabrication of Multifunctional

Furniture

A. R. Palanivel Rajan1, D. Elavarasan2, S. Balaji3, A. Dinesh4, K. Gowtham5

1

Assistant Professor, Dept. of Mechanical Engineering, Sri Eshwar College of Engineering, Coimbatore, India

2,3,4,5

UG Student, Dept. of Mechanical Engineering, Sri Eshwar College of Engineering, Coimbatore, India

Abstract: Majority of the Indian middle class population are

living in small flats and homes mostly because of their economy

scale as well as the lack of space availability for living. In the

present scenario, furniture occupies a majority of the space in the

home interior causing spaces congested. To overcome this problem

the furniture should have a multipurpose than their primary

function. It is mainly of generating a new concept in furniture.

This study is approached to design and develop a multipurpose

space saving dining table for Indian middle class homes.

A study was made to understand the lifestyle, need and comfort

in the Indian homes as well as different activities associated with

specific interiors. Several furniture design stores where visited in Fig. 1. Furniture table

order to understand the present market scenario, demand and

needs of the customers. Existing dining furniture was analyzed in A. In future

detail including its components and parts and their assembly and Many tables have tops that can be adjusted to change their

sub-assemblies. After the study, the product is created by

considering the cost reduction of the product height, position, shape, or size, either with foldable, sliding or

Drawings were developed for final concept, and designed using extensions parts that can alter the shape of the top. Some tables

SOLIDWORKS 2016 and analyzed using ANSYS software. A are entirely foldable for easy transportation, e.g. camping or

prototype was made and the ergonomic validation was done. The storage, e.g., TV trays. Small tables in trains and aircraft may

proposed concept is found to occupy just less than its deployed be fixed or foldable, although they are sometimes considered as

area. We thereby believe that the proposed design will largely suits simply convenient shelves rather than tables.

the constrained space conditions of the urban segment in India.

Keywords: multifunctional furniture 2. Space saving approach

Space-saving furniture designs are unique in our daily lives

1. Introduction and workplaces. Effective space saving does not depend on

Furniture refers to movable objects intended to support downscaling, but on smart ways of collapsing a piece of

various human activities such as seating (e.g., chairs, stools, and furniture or making it more collapsible. Among the many

sofas), eating (tables), and sleeping (e.g., beds). Furniture is space-saving mechanisms such as stacking, implosion, and

also used to hold objects at a convenient height for work (as bundling folding is perhaps the most frequently observed and

horizontal surfaces above the ground, such as tables and desks), best practiced on furniture.

or to store things (e.g., cupboards and shelves). Furniture can

be a product of design and is considered a form of decorative

art. In addition to furniture's functional role, it can serve a

symbolic or religious purpose. It can be made from many

materials, including metal, plastic, and wood. Furniture can be

made using a variety of woodworking joints which often reflect

the local culture.

The main motto of this paper is to make the work table as a Fig. 2. Space Saving Table

multi-purpose one. The work table can be dragged such that the

size of the table is increased which can be used for other 3. Design methodology

purposes. The dragged table can be used as a dining table A systematic design methodology is followed to achieve

otherwise it can be used for showcase etc. For long lifetime of reliable and most suitable solution. It involves the following

the product, good quality of material should be used. steps.

International Journal of Research in Engineering, Science and Management 443

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Survey Cost of the table should be with in Rs. 3000 to 5000.

Conceptual Development The table should occupy around two to four peoples

Design Dining table is not only used for dining but for other

Analysis purpose

Fabrication People not comfortable with the current dining table

Testing The Present dining table is immovable

Product Table occupying more space in the dining room

It’s not ergonomically designed; most of them are

A. Different types of dining table

manufactured by the local carpenter

Wood Dining Table People staying in flat have less space and keep big table

Metal Dining Table is very difficult.

Glass Dining Table

Plastic Dining Table E. Concept generation

For making the concepts more modular and flexible the

design of the table should be in such a way that it should be

folded and can be easily stored.

Fig. 3. Different types of table

Fig. 4. Concept Generation

All types of tables have some advantage and disadvantage.

The customer buys the dining table according to their F. Final Concept

requirement. In terms of aesthetics, the choice of dining table This concept is more modular and flexible that the design of

material affects the look surrounding. For example, a wooden the table should be in such a way that it should be folded and

table looks more classic and warm than the glass and metal can be easily dismantled stored. This concept was derived from

combination. Different types of dining table shown in the Fig. the laptop. The laptop is foldable making it handier. The main

B. Types of Material theme of the concept was the folding theme in which the table

was foldable; this makes the concept more flexible and

For manufacturing dining table commonly used materials are

modular. The working principle of this concept is shown in the

wood, plywood, glass, plastic, aluminium frame and stainless

Fig.

steel- frame.

C. Market Study

A market study has been conducted on the furniture segment

and studied the present market and collected various data for

the output. The market study is having importance role in

product design and new product development. So market trend

and study of new arrival of products have been understood by

conducting market study.

D. Main Observation of Study Fig. 5. Different stages of the concept

The main observations of the study are,

Existing one is analyzed in detail including its function, In the closed condition two people can sit comfortable and

assembly and. parts. have food. This concept comes in useful for entertaining guests.

Table is used as multipurpose like cutting vegetables, Folding table is great for dining or for use as a serving table.

sometimes used as writing purpose. Folding table made of wood are strong, durable, the

In flat and apartments people feel uncomfortable, if a combination of aesthetic as well as creative ideas. Wooden

large table occupied their maximum space in the dining folding tables have easy-slide action, with leg locks that gets

room space. engage when opened.

International Journal of Research in Engineering, Science and Management 444

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

4. Detailed design

Detailing of various parts of the selected concept has been

done. Detailed engineering drawing and CAD drawing was

done for making the prototype.

Fig. 9. Maximum extended structure

Fig. 6. Assembled structure overview

Fig. 10. Minimum foldable structure

B. Material properties

The following material for the Aluminium is provided below,

Table 1

Fig. 7. Side View 1 Material properties

Material Aluminium

Tensile strength(MPa) 89.6

Elongation % 60

Hardness (HB) 52

Yield Strength (MPa) 34.47

Poisson’s Ratio 0.33

Young’s modulus (GPa) 69

C. Analysis of the material

The detailed analysis is done using the analysis software

ANSYS, where the analysis of total deformation and Von

misses stress analysis is done.

Fig. 8. Side View 2

A. Prototype

Detailed drawing was created in SOLIDWORKS 2016.

This drawing was 1:1 model and used the same as template for

prototype.

Fig. 11. Meshing

International Journal of Research in Engineering, Science and Management 445

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

D. Pre-processing G. Applying 50 KG load

The pre-processing step is, quite generally, described as

defining the model and includes,

Define the geometric domain of the problem.

Define the element type(s) to be used.

Define the material properties of the elements.

Define the geometric properties of the elements (length,

area, and the like).

Define the element connectivity (mesh the model).

Define the physical constraints (boundary conditions).

Define the loadings.

E. Post processing

Analysis and evaluation of the solution results is referred to

as post processing. Postprocessor software contains

sophisticated routines used for sorting, printing, and plotting

selected results from a finite element solution. Examples of Fig. 14. Total Deformation of 100kg

operations that can be accomplished include:

Sort element stresses in order of magnitude.

Check equilibrium.

Calculate factors of safety.

Plot deformed structural shape.

Animate dynamic model behaviour.

F. Applying 25 KG load

Fig. 15. Von-Misses Stress of 100kg

Hence the analysis of the product is successfully done using

ANSYS software and the results are obtained in the software

and it favors for the productivity.

Fig. 12. Total Deformation of 25kg

5. Conclusion

The product is developed by generating concept for the

course of urbanization in India. This study has helped to

develop the product design skills. The product study, market

study and the user study helped to understand the present

modular dining table in the market. Digital modeling was done

using SOLID WORKS 2016 was used for better visualization.

The analysis of the product is done using ANSYS software. A

prototype of selected concept was made for validation. The

product is made which is surely a multipurpose by saving its

space when not in use. In stowed form, the proposed concept is

found to occupy just less than its deployed area. We thereby

believe that the proposed design will largely suit the constrained

space conditions of the urban segment in India.

Fig. 13. Von-Misses Stress of 25kg

International Journal of Research in Engineering, Science and Management 446

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

References [24] Ramamoorthi, R., Jeyakumar.R, &Ramakrishnan,T. (2017). Effect of

Nanoparticles on the Improvement of Mechanical Properties of Epoxy

[1] Farah Nasser “Multifunctional furniture for under privileged Based Fiber – Reinforced Composites - A Review. International Journal

communities: a milestone in sustainable development”, Purdue university for Science and Advance Research in Technology, 3(11), 1251- 1256.

West Lafayette, Indiana, May 2013. [25] Ramakrishnan, T., Sampath, P. S., & Ramamoorthi, R. (2016).

[2] Dhiraj V. Astonkar, Dr.Sanjay M. Kherde, “Development in various Investigation of Mechanical Properties and Morphological Study of the

multipurpose furniture’s by using space saving approach” international Alkali Treated Agave Angustifolia Marginata Fiber Reinforced Epoxy

research journal of engineering and technology (IRJET) volume: 02 issue: Polymer Composites. Asian Journal of Research in Social Sciences and

06 Sep-2015 Humanities, 6(9), 461-472.

[3] Talia Serrano Salazar, Lucía Aspizua Sáez, “Design of furniture for small [26] Ramakrishnan, T & Sampath, P.S. (2016). Thermogravimetric Analysis

places following inclusive design”, University of Skovde. (TGA) and the Effect of Moisture Absorption on the Mechanical

[4] “Multifunction and Space Saving Furniture for Small Apartments”, Properties of New Agave Angustifolia Marginata 3 Fiber (AAMF)

http://www.neathome.net/, retrieved on 20th Sept. 2010 Reinforced Epoxy Polymer Composite Material, International Journal of

[5] Douglas G. Wright, “Folding table and chair”, Publication number: US Printing, Packaging & Allied Sciences, 4(5), 3245-3256.

2008/0042475 A1, July23, 2007. [27] Ramakrishnan, T., Sathish, K., Sampath, P. S., &Anandkumar, S. (2016).

[6] www.indpipe.com, retrieved on 6th March. 2019. Experimental investigation and optimization of surface roughness of AISI

[7] Morris L. Tolleson, “Tiered space saver for dining table and the like”, 52100 alloy steel material by using Taguchi method. Advances in Natural

Patent number: 3951079, Issue date: Apr 20, 1976. and Applied Sciences, 10(6 SE), 130-138.

[8] Dhiraj V. Astonkar,Dr.Sanjay M. Kherde, “Modeling and Analysis of [28] Sathish, K., Ramakrishnan, T., &Sathishkumar, S. (2016). Optimization

multipurpose, space saving seating arrangements using CAD Approach”, of turning parameters to improve surface finish of 16 Mn Cr 5 material.

on IJPRET 2014, volume 2(9), Issue 1 May 2014, pp 504-520. Advances in Natural and Applied Sciences, 10(6 SE), 151-157.

[9] Shiyao Wang, “An analysis of transformable space saving furniture”, [29] 29. S. Karthik Raja S. Balasubramani, S. Venkatesh, T. Ramakrishnan

wood 493, 2013. (2015). Effect Of Cryogenic Tempering On Steel, International Journal of

[10] Muhammad zulfadli bin chezakaria, “Design and fabricate multipurpose Mechanical and Civil Engineering, 2 (6), 98-113.

portable desk”, Universiti Malaysia Pahan. [30] Venkatesh, S., & Sakthivel, M. (2017). 'Numerical Investigation and

[11] Dhiraj V. Astonkar, Dr. Sanjay M. Kherde,” Determination of Optimization for Performance Analysis in Venturi Inlet Cyclone

multipurpose, space saving seating arrangements with CAD & CAE Separator', Desalination and Water treatment, Vol. 90, No. 9, pp. 168-179.

Software”, on IJRISE, Volume2 (1), e-ISSN: 2394-8299, p-ISSN: 2394- [31] 31. Venkatesh, S., Sakthivel, M., Sudhagar, S.,&Ajith Arul Daniel,

8280, Dec.2015, pp 88-94. S.(2018). 'Modification of the cyclone separator geometry for improving

[12] Tan Boon Chai. “New concept of furniture design by using space saving the performance using Taguchi and CFD approach', Particulate Science

approach,” at University Teknikal Malaysia Melaka. and Technology.

[13] Tang, J.T., He, H.Y., Wu, X.,” Design and Implementation of the System [32] Venkatesh, S., Bruno Clement, I., Avinasilingam, M., &Arulkumar, E.

Based on the Mechanical Topology Smart Furniture”, Applied Mechanics (2017). “Design of Experiment Technique for Improving the Performance

and Materials, Vol. 329, pp. 497-502, (2013) of Stirling Engine”, International Research Journal of Engineering and

[14] Kumar, R. S., Alexis, J., &Thangarasu, V. S. (2017). Optimization of high Technology, Vol. 4, No. 5, pp. 62-65.

speed CNC end milling process of BSL 168 Aluminium composite for [33] Venkatesh, S., Balasubramani, S., Venkatramanan, S., &Gokulraj, L.

aeronautical applications. Transactions of the Canadian Society for “Standardization of hpx spool for lead time reduction of string test”,

Mechanical Engineering, 41(4), 609-625 Journal of Mechanical and Civil Engineering,Vol. 2, No. 6, pp. 62-79.

[15] Kumar, S. R., Alexis, J. S., &Thangarasu, V. S. (2017). Experimental [34] Kousalya Devi, S., Venkatesh, S., &Chandrasekaran. P. (2015).

Investigation of Influential Parameters in High Speed Machining of AMS “Performance Improvement of Venturi Wet Scrubber,”Journal of

4205. Asian Journal of Research in Social Sciences and Humanities, 7(2), Mechanical and Civil Engineering, Vol. 2, No. 4, pp. 1-9.

508-523. [35] Arunkumar, P., Dhachinamoorthi, P., Saravanakumar, K., &Venkatesh,

[16] Ganeshkumar, S., Thirunavukkarasu, V., Sureshkumar, R., Venkatesh, S., S. (2014). “Analysis and Investigation of Centrifugal Pump Impellers

& Ramakrishnan, T. Investigation of wear behaviour of silicon carbide Using CFD,” Engineering Science and Technology: An International

tool inserts and titanium nitride coated tool inserts in machining of en8 Journal, Vol. 4, No. 4, pp. 112-117.

steel [36] Dhana Balakrishnan, K. P., Abuthakir, J., Subramanian, R., Venkatesh, S.

[17] Kumar, S., Alexis, J., & Thangarasu, V. S. (2016). Prediction of (2015). “Evaluation of Tensile Properties of Particulate Reinforced Al-

machining parameters for A91060 in end milling. Advances in Natural Metal Matrix Composites,” Engineering Science and Technology: An

and Applied Sciences, 10(6 SE), 157-164 International Journal, Vol. 5, No. 1, pp. 173-175.

[18] Kumar, R. S., Thangarasu, V. S., & Alexis, S. J. (2016). Adaptive control [37] F. Justin Dhiraviam, V.Naveenprabhu, M.Santhosh,” Study the Effects of

systems in CNC machining processes--a review. Advances in Natural and Solar Assisted Vapour Compression Air Conditioning System for Winter

Applied Sciences, 10(6 SE), 120-130. Applications”, International Journal for Scientific Research &

[19] Kumar, S., Alexis, J., & Dhana Balakrishnank. P (2015). Application of Development|, Vol 4(11),(2017), pp. 505-508

ga&ann for the optimization of cutting parameters for end milling [38] V. NaveenPrabhu, K. SaravanaKumar, T. Suresh and M. Suresh,"

operation- a comparison. International Journal of Applied Engineering Experimental investigation on tube-in-tube heat exchanger using

Research, 10(20), 18092-18107. nanofluids", Advances in Natural and Applied Sciences, , Vol

[20] Ramakrishnan, T., &Pavayee Subramani, S. (2018). Investigation of 10(7),(2016), pp. 272-278

Physico-Mechanical and Moisture Absorption Characteristics of Raw and [39] V Naveen Prabhu, D Mugesh Kumaar, KB Pravin, V Ranjith, S Sanjay

Alkali Treated New Agave Angustifolia Marginata (AAM) Fiber. Arthanari Swamy,” A Review of Evaporative Cooling of Finned and Non-

Materials Science, 24(1), 53-58. Finned Heat Exchanger on Condenser”, International Journal for

[21] Ramakrishnan, T., & Sampath, P. S. (2017). Dry Sliding Wear Scientific Research & Development, Vol 6(2), (2018), pp. 459-461.

Characteristics of New Short Agave Angustifolia Marginata (AAM) [40] V. Naveen Prabhu, F. Justin Dhiraviam, A. Vimal, K. Kumarrathinam,”

Fiber-Reinforced Polymer Matrix Composite Material. Journal of Design of Common Header Line for Reduction of Process Time in Pump

Biobased Materials and Bioenergy, 11(5), 391-399. Testing”, International Research Journal of Engineering and Technology,

[22] 22. Jeyakumar, R., Sampath, P. S., Ramamoorthi, R., & Ramakrishnan, Vol 4(1), (2017), pp. 969-975.

T. (2017). Structural, morphological and mechanical behaviour of glass [41] B. Santhosh Kumar, et.al,” Effect of Load on Joint Efficiency and

fibre reinforced epoxy nanoclay composites. The International Journal of Hardness in Friction Stir Welding of AA6061 & AA6063 Aluminium

Advanced Manufacturing Technology, 93(1-4), 527-535. Alloys.”, International Journal for Scientific Research & Development,

[23] T., & Sampath, P. S. (2017). Experimental investigation of mechanical Vol 6(2), (2018), pp. 2669-2771.

properties of untreated new Agave Angustifolia Marginata fiber [42] Ganesh Kumar, S & Thirunavukkarasu, V, “Investigation of Tool Wear

reinforced epoxy polymer matrix composite material. Journal of and Optimization of Process Parameters in Turning of EN8 and EN 36

Advances in Chemistry, 13(4), 6120-6126.

International Journal of Research in Engineering, Science and Management 447

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Steels, Asian Journal of Research in Social Sciences and Humanities,” boron carbide-coconut shell fly ash reinforced hybrid metal matrix

vol. 6, no.11, pp. 237 - 243, 2016. composites. China Foundry, 15(6), 449-456.

[43] Kumar, S. D., Kumar, S. S., & Kumar, K. A. (2018). Investigation of [47] Suresh Babu, Y., & Ashoka Varthanan, P, “Study the emission

Forced Frequency in a Commercial Vehicle Suspension System. characteristics of catalytic coated piston and combustion chamber of a

Mechanics and Mechanical Engineering, 22(4), 967-974. four stroke spark ignition (SI) engine,” Journal of Chemical and

[44] Balasubramani, S., & Balaji, N. (2016). Investigations of vision Pharmaceutical Sciences, 2016.

inspection method for surface defects in image processing techniques-a [48] Suresh Babu, Y., & Ashoka Varthanan, P. (2018) Study the emission

review. Advances in Natural and Applied Sciences, 10(6 SE), 115-120. characteristics of catalytic coated piston and combustion chamber of a

[45] Balasubramani, S., Dhana Balakrishnan K.P., Balaji, N. (2015) four stroke spark ignition (SI) engine. International Journal for Scientific

Optimization of Machining parameters in Aluminium HMMC using Research & Development, 6(02), 1981-1983.

Response Surface Methodology. International journal of applied [49] F. Justin Dhiraviam, V. Naveen Prabhu, T. Suresh, and C. Selva Senthil

engineering research, 10(20), 19736-19739. Prabhu, “Improved Efficiency in Engine Cooling System by

[46] Subramaniam, B., Natarajan, B., Kaliyaperumal, B., & Chelladurai, S. J. Repositioning of Turbo Inter Cooler,” Applied Mechanics and Materials,

S. (2018). Investigation on mechanical properties of aluminium 7075- vol. 787, (2015), pp. 792–796.

You might also like

- Chapter 1Document33 pagesChapter 1krischaniNo ratings yet

- Chapter 1Document6 pagesChapter 1Mohamad Fadli MustafaNo ratings yet

- Management of Industrial Design ProcessDocument11 pagesManagement of Industrial Design ProcessBalaji BanumathiNo ratings yet

- Construction Materials-Wood DefectDocument3 pagesConstruction Materials-Wood DefectJeric WaldoNo ratings yet

- Interior Design Research Paper ThesisDocument8 pagesInterior Design Research Paper Thesisreneecountrymanneworleans100% (2)

- Design and TechnologiesDocument92 pagesDesign and TechnologiesAshokNo ratings yet

- Key of Language Assessment: Rubrics and Rubric Design: Ülkü AyhanDocument11 pagesKey of Language Assessment: Rubrics and Rubric Design: Ülkü Ayhancyberjohn2013No ratings yet

- Notes On Restaurant Furniture and LinenDocument3 pagesNotes On Restaurant Furniture and Linennina.ariano.tan100% (1)

- Marking SchemeDocument104 pagesMarking SchemeTSS DT100% (1)

- Presentation On Research DesignDocument31 pagesPresentation On Research DesigndiksangelNo ratings yet

- Parts of TimberDocument11 pagesParts of TimberAliNo ratings yet

- FangLing Shape Cutting Control System Operation and Installation Manual V2.2 - KTS MALLDocument162 pagesFangLing Shape Cutting Control System Operation and Installation Manual V2.2 - KTS MALLkevin fernandez100% (1)

- Module 4 - Conceptualization2Document108 pagesModule 4 - Conceptualization2Paul MendozaNo ratings yet

- List of Figures Fig - No Name Page NoDocument4 pagesList of Figures Fig - No Name Page NosanthiNo ratings yet

- Building Technology - Building MaintenanceDocument10 pagesBuilding Technology - Building MaintenanceYusuf kiptumNo ratings yet

- Importance of Product PackagingDocument6 pagesImportance of Product PackagingNormanBatesNo ratings yet

- 3i's Q4 Week6 Answer (Adlawan, PG)Document3 pages3i's Q4 Week6 Answer (Adlawan, PG)PegeeeyNo ratings yet

- 8 Things You Need To Know About ErgonomicsDocument4 pages8 Things You Need To Know About ErgonomicsAini Bin MurniNo ratings yet

- Different Kinds of Format in Research WritingDocument48 pagesDifferent Kinds of Format in Research WritingIra Mae Astadan100% (2)

- V13 Single Used Plastic Cigarette Butts and Clam Shells As A Partial Additive For Gravel and Sand in Making Concrete BricksDocument44 pagesV13 Single Used Plastic Cigarette Butts and Clam Shells As A Partial Additive For Gravel and Sand in Making Concrete Bricksjoshua bracerosNo ratings yet

- Green Practices in Restaurants PDFDocument5 pagesGreen Practices in Restaurants PDFJorge SanabriaNo ratings yet

- Development of Multifunctional FurnitureDocument40 pagesDevelopment of Multifunctional FurniturePercival Archer100% (2)

- The Effects of Technology in Society and EducationDocument66 pagesThe Effects of Technology in Society and EducationRowenaana RuizNo ratings yet

- Past Paper Answers 2 CSDocument15 pagesPast Paper Answers 2 CSLokuliyanaNNo ratings yet

- Types of Defects in Timber - 1Document20 pagesTypes of Defects in Timber - 1Joe NjoreNo ratings yet

- Final Paper 110218Document156 pagesFinal Paper 110218Bien Carlos Esteves ViaNo ratings yet

- 1 - Definition and Importance of Specification Writing - NewDocument16 pages1 - Definition and Importance of Specification Writing - Newprajoshi62No ratings yet

- Drafting TechnologyDocument80 pagesDrafting Technologyong0625No ratings yet

- Factors Affecting DesignDocument15 pagesFactors Affecting DesignRachel WintersNo ratings yet

- 40 Storey Mixed Used Commercial Center PDFDocument61 pages40 Storey Mixed Used Commercial Center PDFLuwella GumallaoiNo ratings yet

- Quest For QuestionDocument2 pagesQuest For Questionapi-339611548100% (4)

- Aluminium Doors - Doors - GharExpertDocument3 pagesAluminium Doors - Doors - GharExpertdishkuNo ratings yet

- A Phenomenological Study About The Effects of Technology On Academic Performance of StudentDocument8 pagesA Phenomenological Study About The Effects of Technology On Academic Performance of Studentannilyn100% (1)

- Research Methodology & Technical Communication (HSS-501) RCSDocument2 pagesResearch Methodology & Technical Communication (HSS-501) RCSjakk234No ratings yet

- Chapter 1 InternetDocument4 pagesChapter 1 InternetJasper John DoctoNo ratings yet

- Module Apply Quality StandardsDocument34 pagesModule Apply Quality StandardsDhealine JusayanNo ratings yet

- Design BriefDocument2 pagesDesign BriefSantosh KaurNo ratings yet

- Jute Products and EnvironmentDocument52 pagesJute Products and EnvironmentAbdus Salam RatanNo ratings yet

- Project On Factors Influencing Consumer BehaviorDocument17 pagesProject On Factors Influencing Consumer BehaviorMilind Joshi50% (2)

- 4 Basic Sculpture TechniquesDocument19 pages4 Basic Sculpture TechniquesKisma Jordan100% (1)

- Termite Control SystemDocument10 pagesTermite Control SystemVictor EvangelioNo ratings yet

- Design PhilosophyDocument3 pagesDesign Philosophygene2693No ratings yet

- Project Management: Casmir, R. (PH.D)Document23 pagesProject Management: Casmir, R. (PH.D)Rodric PeterNo ratings yet

- Ent530 Rubric Business Planning ReportDocument4 pagesEnt530 Rubric Business Planning Reporthns.fanaNo ratings yet

- Timber Assignment (Ruiles)Document12 pagesTimber Assignment (Ruiles)Mary Joy RuilesNo ratings yet

- Packaging DesignDocument45 pagesPackaging Designメルヴリッ クズルエタNo ratings yet

- The Story of The SkyscraperDocument3 pagesThe Story of The SkyscraperValentine Dreyti KawulusanNo ratings yet

- CH 2 Opportunity Recognition and New Idea GenerationDocument21 pagesCH 2 Opportunity Recognition and New Idea GenerationUsman TariqNo ratings yet

- OligopolyDocument16 pagesOligopolygipaworldNo ratings yet

- IKEA Service Marketing StrategyDocument2 pagesIKEA Service Marketing StrategyMUHAMMED RABIHNo ratings yet

- ICT Application To Technical Report Writing, RecordDocument14 pagesICT Application To Technical Report Writing, Recordanon_230653802No ratings yet

- Perdev 11Document7 pagesPerdev 11Rodalyn Dela Cruz NavarroNo ratings yet

- Answer The Following Questions. (INTRODUCTION TO INFORMATION ANDDocument3 pagesAnswer The Following Questions. (INTRODUCTION TO INFORMATION ANDalaisah dimaporoNo ratings yet

- Design Portfolio 2017-1Document12 pagesDesign Portfolio 2017-1api-320844972No ratings yet

- Materials Technology Wood Folio GuideDocument13 pagesMaterials Technology Wood Folio Guideapi-235431613No ratings yet

- Aesthetics of PackagingDocument8 pagesAesthetics of Packagingrajatesh1No ratings yet

- Development Processes and OrganizationsDocument41 pagesDevelopment Processes and OrganizationsPuneet GoelNo ratings yet

- (PDF) IRJET-Development in Various Multipurpose Furniture's by Using Space Saving ApproachDocument7 pages(PDF) IRJET-Development in Various Multipurpose Furniture's by Using Space Saving ApproachSaka YaneNo ratings yet

- An Analysis of Transformable SpaceDocument26 pagesAn Analysis of Transformable SpaceTuan Huy LeNo ratings yet

- Multipurpose TableDocument12 pagesMultipurpose TablesafonehazyqNo ratings yet

- Inventions: The Conceptualisation and Development of A Space-Saving Multipurpose Table For Enhanced Ergonomic PerformanceDocument35 pagesInventions: The Conceptualisation and Development of A Space-Saving Multipurpose Table For Enhanced Ergonomic PerformanceAlvaro SolisNo ratings yet

- 12A1HDocument11 pages12A1HAlvaro SolisNo ratings yet

- GDRV Momentum OwnersManual Rev0217Document212 pagesGDRV Momentum OwnersManual Rev0217Alvaro SolisNo ratings yet

- Annas MenuDocument1 pageAnnas MenuAlvaro SolisNo ratings yet

- Caramel Apple WrapDocument1 pageCaramel Apple WrapAlvaro SolisNo ratings yet

- Po Ram Gian Paschal - Activity 2.7 - Experiment 2 (PRE-LABORATORY)Document2 pagesPo Ram Gian Paschal - Activity 2.7 - Experiment 2 (PRE-LABORATORY)Po Ram Gian PaschalNo ratings yet

- Hilti HIT HY 70 Injection Mortar For MasonryDocument26 pagesHilti HIT HY 70 Injection Mortar For MasonryVenkatesh PadmanabhanNo ratings yet

- Effect of Cromiumonmechanicalpropertiesofa487steelpawarpprDocument8 pagesEffect of Cromiumonmechanicalpropertiesofa487steelpawarpprJasminNo ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Nanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersDocument13 pagesNanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersSirigiri ThrineshNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- PDF No Bake Asweseeit - CompressDocument132 pagesPDF No Bake Asweseeit - CompresssimphiweNo ratings yet

- Example. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedDocument4 pagesExample. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedJames NeoNo ratings yet

- SAMSUNG CapacitorDocument16 pagesSAMSUNG CapacitorFaraz ElectronicNo ratings yet

- Numerical Calculation of Buried Pipeline Impacted by Rockfalls and LandslideDocument10 pagesNumerical Calculation of Buried Pipeline Impacted by Rockfalls and LandslideGholamhossein Tavakoli MehrjardiNo ratings yet

- Chemical Energetics 2Document14 pagesChemical Energetics 2Shafqat ShakeelNo ratings yet

- D4206Document4 pagesD4206saifullah629No ratings yet

- Transferred Electron DevicesDocument48 pagesTransferred Electron DevicesShruti GirmalNo ratings yet

- Literature ReviewDocument36 pagesLiterature Reviewprakush_prakush0% (1)

- High Strength Micro ConcreteDocument4 pagesHigh Strength Micro ConcreteSantosh Kumar PatnaikNo ratings yet

- Design Software and Supporting Tool: Hydranautics - NittoDocument25 pagesDesign Software and Supporting Tool: Hydranautics - NittoAbdelhakim AkroucheNo ratings yet

- Detailed Estimates: Construction of Welcome Arch New Little Baguio, Brgy. Magsaysay, Infanta, QuezonDocument8 pagesDetailed Estimates: Construction of Welcome Arch New Little Baguio, Brgy. Magsaysay, Infanta, QuezonAiresh GoNo ratings yet

- COM800 Offshore CoatingsDocument21 pagesCOM800 Offshore CoatingsVicente RegulezNo ratings yet

- Surface & Coatings Technology: J. VetterDocument28 pagesSurface & Coatings Technology: J. VetterAlireza BagherpourNo ratings yet

- Pengantar Rekayasa Pertambangan: To MiningDocument30 pagesPengantar Rekayasa Pertambangan: To MiningSasaki HaiseNo ratings yet

- Water Spliting On Titanate Photocatalysts PDFDocument9 pagesWater Spliting On Titanate Photocatalysts PDFDanCosminNo ratings yet

- Lec#3 Pavement Materials - JMFDocument57 pagesLec#3 Pavement Materials - JMFUsama AliNo ratings yet

- Culvert (1x3.0x3.0)Document19 pagesCulvert (1x3.0x3.0)Shashank SrivastavaNo ratings yet

- Stable GlazesDocument8 pagesStable Glazesdamjan_mariničNo ratings yet

- Pipe Rolers and SupportDocument16 pagesPipe Rolers and SupportAhmed YousriNo ratings yet

- InstrumentacionDocument11 pagesInstrumentacionJOSE MARTIN MORA RIVEROSNo ratings yet

- Final Geological Report K-442 (KDN-16)Document30 pagesFinal Geological Report K-442 (KDN-16)AhmedNo ratings yet

- Determination Arsenic by AASDocument13 pagesDetermination Arsenic by AASMartuaHaojahanSaragihSidabutarNo ratings yet

- Mme405 PDFDocument129 pagesMme405 PDFkanakatharavijayanNo ratings yet