Professional Documents

Culture Documents

Osinski Journal of Crystal Growth 189 190 808 1998

Uploaded by

mstevka0 ratings0% found this document useful (0 votes)

13 views4 pagesThis document summarizes research on the effects of high electrical stress on GaN/InGaN/AlGaN single-quantum-well (SQW) light-emitting diodes (LEDs). Researchers subjected the LEDs to high current pulses and monitored their light output and electrical characteristics over time. They found that under high stress, the encapsulating plastic packaging would fail and carbonize before the LED itself showed degradation. This suggests that the SQW LED material quality and resilience to stress had improved compared to earlier double-heterostructure devices. However, continued stress still caused damage to the plastic that could eventually lead to electrical shorting of the diode.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes research on the effects of high electrical stress on GaN/InGaN/AlGaN single-quantum-well (SQW) light-emitting diodes (LEDs). Researchers subjected the LEDs to high current pulses and monitored their light output and electrical characteristics over time. They found that under high stress, the encapsulating plastic packaging would fail and carbonize before the LED itself showed degradation. This suggests that the SQW LED material quality and resilience to stress had improved compared to earlier double-heterostructure devices. However, continued stress still caused damage to the plastic that could eventually lead to electrical shorting of the diode.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views4 pagesOsinski Journal of Crystal Growth 189 190 808 1998

Uploaded by

mstevkaThis document summarizes research on the effects of high electrical stress on GaN/InGaN/AlGaN single-quantum-well (SQW) light-emitting diodes (LEDs). Researchers subjected the LEDs to high current pulses and monitored their light output and electrical characteristics over time. They found that under high stress, the encapsulating plastic packaging would fail and carbonize before the LED itself showed degradation. This suggests that the SQW LED material quality and resilience to stress had improved compared to earlier double-heterostructure devices. However, continued stress still caused damage to the plastic that could eventually lead to electrical shorting of the diode.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Journal of Crystal Growth 189/190 (1998) 808—811

Effects of high electrical stress on GaN/InGaN/AlGaN

single-quantum-well light-emitting diodes

Marek Osiński*, Daniel L. Barton1, Piotr Perlin2,3, Jinhyun Lee

Center for High Technology Materials, University of New Mexico, 1313 Goddard SE, Albuquerque, NM 87131-6081, USA

Abstract

We report on high-electrical-stress testing of Nichia GaN/InGaN/AlGaN single-quantum-well (SQW) light-emitting

diodes. In contrast to our earlier experiments with double-heterostructure LEDs, the present SQW devices have been

improved to the point that the encapsulating plastic fails under high electrical stress earlier than the diode itself. ( 1998

Published by Elsevier Science B.V. All rights reserved.

Keywords: Gallium nitride; Light-emitting diodes; Diode lasers; Electrical stress; Degradation; Device lifetime

1. Introduction diodes (LEDs), single-quantum-well (SQW) blue,

blue—green and green LEDs, and white LEDs [1].

For the last three years, we have witnessed Similarly, development of group-III nitride diode

remarkable progress in the development of group- lasers proceeded with a breathtaking speed during

III nitride optoelectronic devices, resulting in 1996, from the first demonstration of pulsed lasing

commercial availability of blue double-heterostr- to cw operation at room temperature [1]. The first

ucture (DH) GaN/InGaN/AlGaN light-emitting cw lasers reported in October 1996 lived only for

a few seconds. By December 1996, the laser lifetime

was extended to 35 h [2]. Yet, this rapid progress

seemed to have been stalled since then, and no

further improvement of device lifetime was re-

* Corresponding author. Tel.: #1 505 272 7812; fax: ported for more than six months. This situation

#1 505 272 7801; e-mail: osinski@chtm.unm.edu. started resembling that in the II—VI diode lasers,

1 Also at: Sandia National Laboratories, P.O. Box 5800, Al- where the maximum lifetime of &100 h has

buquerque, NM 87185-1081, USA.

not increased since early 1996. It was therefore

2 On leave from: High Pressure Research Center “Unipress”,

Soko"owska 29/37, PL-01142 Warsaw, Poland. important to conduct experiments aimed at eluci-

3 Present address: Lawrence Berkeley National Laboratory, dating the degradation processes in group-III ni-

1 Cyclotron Road, Mail stop 2-200, Berkeley, CA 94720, USA. tride devices.

0022-0248/98/$19.00 ( 1998 Published by Elsevier Science B.V. All rights reserved.

PII S 0 0 2 2 - 0 2 4 8 ( 9 8 ) 0 0 2 9 9 - 1

M. Osin& ski et al. / Journal of Crystal Growth 189/190 (1998) 808–811 809

2. Degradation of double-heterostructure blue LEDs, which indicated that a considerable progress

LEDs under high electrical stress had been achieved at Nichia in improving the ma-

terial quality and device resilience to high current

Already in 1994, we have performed high electri- pulses.

cal stress tests of Nichia NLPB-500 DH LEDs, While investigating the effects of longer-term ex-

aimed at determining prospects for forthcoming posure to reduced currents, we found that using

development of nitride diode lasers. At that time, we pulsed current amplitudes between 4 and 6 A

identified an important failure mechanism associa- would result in a much slower degradation, allow-

ted with a high density of extended defects present ing the LED to continue working for between 24

in group-III nitrides grown on sapphire substrates. and 90 h. Several LEDs were then stressed at a for-

Namely, at about 1.8—2 A pulsed current ampli- ward current of &5 A. Some of them were allowed

tude, the high voltage required to drive high-cur- to fail, while others were removed from the test

rent pulses would cause the metal to migrate from prior to failure.

the top semi-transparent contact to down defect An example of such a stress test is illustrated in

clusters, ultimately resulting in a short [3]. In this Fig. 1, showing the time evolution of output light

context, it was symptomatic that formation of intensity from a green SQW LED subjected to high

a short circuit was reported to cause the break- current pulses between 4.5 and 5.8 A. Two different

down of the longest-lived Nichia GaN/InGaN/ regions can be distinguished in this figure. First,

AlGaN multiple-quantum-well (MQW) diode for times shorter than &5 h, a relatively fast degra-

lasers after 35 h of cw operation [4]. dation is observed with the slope of !0.17%/h.

This is followed by a second region, for times

longer than 5 h, where the slope is only !0.03%/h.

3. High-electrical-stress experiments with SQW Similar behavior was also observed in the I—»

nichia LEDs characteristics, with most of the change shown

in Fig. 2 occurring in the initial stage of the stress

Our present study was aimed at determining the test.

effects of high electrical stress in Nichia SQW

LEDs and to compare their behavior to that of

early DH devices, with the main goal of updating

our understanding of high-current degradation

mechanisms in present-day state-of-the-art sam-

ples. The LEDs were stressed using rectangular

forward current pulses of 100 ns duration with

a small (0.01%) duty cycle (1 kHz repetition rate)

to minimize heating. The average power dissipa-

tion for pulses with 5 A amplitude was only

25 mW. Initial tests were performed on packaged

devices.

We have determined earlier in this study [5] that

the LEDs would degrade almost instantaneously

when they were subjected to current pulses with

amplitudes between 6 and 7.5 A. The degradation

took about 1 s to occur and was accompanied by

a visible electrical discharge between the electrodes.

At these currents, the voltage drop across the diode

Fig. 1. Light output of a stressed Nichia NSPG-500 green SQW

was between 70 and 80 V. It should be noticed that LED as a function of time. Notice a sudden failure without any

the corresponding current densities were three prior warning after 86 h of operation. Resistance after degrada-

times larger than those sustainable by the DH tion was 138 ).

810 M. Osin& ski et al. / Journal of Crystal Growth 189/190 (1998) 808–811

point of failure. Significantly, some of the plastic

packaging material became carbonized during the

stress test, to the point that it could not be removed

during the decapsulation. Thus, even though there

were no apparent changes in the light output or

I—» characteristics, there was a change in the plas-

tic composition. Optical micrograph images also

revealed several black spots, mostly at the edges of

the semi-transparent metallization on the p-contact

layer. We interpret these spots as damaged plastic

areas created when the junction below went into

a non-permanent breakdown under the electrical

stress. Under continued stress, more damaged plas-

tic sites will form, eventually creating a conductive

path that leads to a short circuit across the LED.

Fig. 2. I—» characteristics of a Nichia NSPG-500 green SQW

LED taken prior to and during the high-current stress test. Most

of the change in the I—» curve occurred during the first few 5. Discussion and conclusions

hours of the operation. Note that the sign of current value is

reversed in the negative voltage region.

In contrast to our earlier experiments with DH

LEDs, the present SQW devices have been im-

proved to the point that the encapsulating plastic

4. Failure analysis fails under high electrical stress earlier than the

diode itself. In order to eliminate the encapsulating

Failure analysis of devices degraded at currents material from consideration, we are now conduct-

exceeding 6 A revealed a massive damage to the top ing further tests on de-encapsulated LEDs. The

semitransparent p-type contacts and the plastic en- results of these test will be reported elsewhere.

capsulation material. The damage was, however, Very recently, a significant improvement in the

too extensive to identify its roots. The I—» charac- Nichia GaN/InGaN/AlGaN multiple-quantum-

teristics of degraded devices were all linear, with well (MQW) diode laser lifetime has been reported,

slopes indicating that the LEDs had resistive shorts with the best devices operating at a constant output

in the 18 to 140 ) range. power of 2 mW per facet for as long as 300 h [6].

Using a simple extrapolation of the data shown While this result is in itself remarkable and leaves

in Fig. 1 prior to the point of failure, the LED behind the ZnSe-based lasers with their lifetime of

lifetime under high-current stress should be as long 100 h [7], it should again be noticed that the end of

as 1000—1500 h (note that this translates into lasing was marked with creation of a short circuit,

6—9 min of real operation time). In reality, however, consistent with the metal migration degradation

the devices failed suddenly after 24—90 h of test. mechanism identified in our early experiments [3].

Neither electrical nor optical characteristics pro- Lower operating voltage (&4 V) in the 300 h laser

vided any advance warning that the catastrophic would indeed extend the time necessary for the

degradation was about to occur. Analysis of de- top-contact metal to migrate down towards the

graded samples showed the same type of damage as p—n junction along the defect clusters. However, as

found in LEDs subjected to pulsed currents with long as such defect clusters remain within the active

amplitudes higher than 6 A. Again, it was imposs- volume of the device, they may continue to act as

ible to pinpoint the origin of the extensive damage life-limiting agents in GaN-based diode lasers.

observed. Thus, it should remain a high priority to reduce the

The most useful information was extracted from threading dislocation density to levels comparable

devices that were removed from the test before the to other III—V optoelectronic materials.

M. Osin& ski et al. / Journal of Crystal Growth 189/190 (1998) 808–811 811

Acknowledgements [2] S. Nakamura, Presented at MRS Fall Meeting, Paper N1.1,

Boston, MA, 2—6 December 1996.

[3] D.L. Barton, J. Zeller, B.S. Phillips, P.-C. Chiu, S. Askar,

This work was supported by DARPA under the

D.-S. Lee, M. Osin̈ski, K.J. Malloy, Proc. 33rd Ann. IEEE

Optoelectronic Materials Center program. Part of Int. Reliability Physics Symp., Las Vegas, NV, 4—6 Apr.

this work performed at Sandia National Laborato- 1995, Paper 3B.3, pp. 191—199.

ries was also supported by the U.S. Department of [4] S. Nakamura, in: M. Osin̈ski, W.W. Chow (Eds.), Physics

Energy under contract DE-AC04-94AL8500. One and Simulation of Optoelectronic Devices V, San Jose, CA,

10—14 February 1997, SPIE Proc. 2994, pp. 2—12.

of the authors (M.O.) would like to express his

[5] M. Osinński, P. Perlin, P.G. Eliseev, G. Liu, D.L. Barton, in:

gratitude to Professor Shiro Sakai of the University F.A. Ponce, T.D. Moustakas, I. Akasaki, B.A. Monemar

of Tokushima for his hospitality and support. (Eds.), III—V Nitrides, Boston, MA, 2—6 December, 1996,

Mater. Res. Soc. Symp. Proc. 449, pp. 1179—1184.

[6] S. Nakamura, M. Senoh, S.-I. Nagahama, N. Iwasa, T.

Yamada, T. Matsushita, Y. Sugimoto, H. Kiyoku, Jpn. J.

References

Appl. Phys. Pt. 2 (Lett.) 36 (1997) L1059.

[1] S. Nakamura, G. Fasol, The Blue Laser Diode: GaN Based [7] S. Taniguchi, T. Hino, S. Itoh, K. Nakano, N. Nakayama, A.

Ishibashi, M. Ikeda, Electron. Lett. 29 (1996) 552.

Light Emitters and Lasers, Springer, Berlin, 1997.

You might also like

- Characterization and Simulation of 280 NM UV-LED DegradationDocument7 pagesCharacterization and Simulation of 280 NM UV-LED DegradationKéziaBarretoNo ratings yet

- Staebler 1980Document8 pagesStaebler 1980Matt OroszNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Tm"ions DeliveryDocument9 pagesTm"ions DeliveryAlan MartNo ratings yet

- Non-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationDocument9 pagesNon-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationHendi AfriyanNo ratings yet

- Rowland 2008ADocument9 pagesRowland 2008ASavvas KatemliadisNo ratings yet

- Good ReportDocument5 pagesGood ReportArun KumarNo ratings yet

- Simple Nanosecond Capacitive Voltage Divider: Additional Information On Rev. Sci. InstrumDocument4 pagesSimple Nanosecond Capacitive Voltage Divider: Additional Information On Rev. Sci. InstrumdankorankoNo ratings yet

- Surface Flashover of Oil-Immersed Dielectric Materials in Uniform and Non-Uniform FieldsDocument9 pagesSurface Flashover of Oil-Immersed Dielectric Materials in Uniform and Non-Uniform FieldsdaaanuNo ratings yet

- Research 2Document8 pagesResearch 2SYED HAMZA ALINo ratings yet

- Positive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesDocument11 pagesPositive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesAlberto OrtizNo ratings yet

- Silicon Integrated Circuits: Advances in Materials and Device ResearchFrom EverandSilicon Integrated Circuits: Advances in Materials and Device ResearchDawon KahngNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Current Leakage and Transients in Ferroelectric Ceramics Under High Humidity ConditionsDocument6 pagesCurrent Leakage and Transients in Ferroelectric Ceramics Under High Humidity ConditionsTuhinNo ratings yet

- Vacuum: 3 Zufang Lin, Huanjun Chen, Juncong She, Shaozhi Deng, Jun ChenDocument8 pagesVacuum: 3 Zufang Lin, Huanjun Chen, Juncong She, Shaozhi Deng, Jun ChenSahin CoskunNo ratings yet

- Philips Technical Review, Volume 19, 1957/58, No.1-2Document369 pagesPhilips Technical Review, Volume 19, 1957/58, No.1-2MarcoNo ratings yet

- Voltage Upgrading - An Insulation Coordination Challenge: June 2011Document9 pagesVoltage Upgrading - An Insulation Coordination Challenge: June 2011ManafNo ratings yet

- 06435039Document4 pages06435039Yesid MorenoNo ratings yet

- 0957 44842F21/215202Document10 pages0957 44842F21/215202Tejendra DixitNo ratings yet

- WILLIAMS Et Al, 1999 PDFDocument8 pagesWILLIAMS Et Al, 1999 PDFBruno Cesar XavierNo ratings yet

- ISH2015 419 Icing ImpulseDocument5 pagesISH2015 419 Icing ImpulseAdrianoNo ratings yet

- X-Ray Tube Arcing: Manifestation and Detection During Qualuty CONTROL (Journal Medical Physics International, 2018, v.6, P 157-162)Document6 pagesX-Ray Tube Arcing: Manifestation and Detection During Qualuty CONTROL (Journal Medical Physics International, 2018, v.6, P 157-162)Phan Hoàng NamNo ratings yet

- Polarity Charge 11Document4 pagesPolarity Charge 11Deepu MishraNo ratings yet

- 2006 Newroutes RTDocument5 pages2006 Newroutes RTEmilia MerinoNo ratings yet

- Science, Vol. 35, 6,: DecemberDocument5 pagesScience, Vol. 35, 6,: DecemberKay WhiteNo ratings yet

- Broadband Dielectric Response of CaCu3Ti4O12Document8 pagesBroadband Dielectric Response of CaCu3Ti4O12Alexandr BabaskinNo ratings yet

- Localization of Insulation Degradation in Voltage Distribution CablesDocument6 pagesLocalization of Insulation Degradation in Voltage Distribution CablesSilvia Perez DuranNo ratings yet

- AD0698720Document21 pagesAD0698720shivasraiNo ratings yet

- McNall 2018 J. Phys. D Appl. Phys. 51 445203Document13 pagesMcNall 2018 J. Phys. D Appl. Phys. 51 445203Yves CreyghtonNo ratings yet

- 2016 - Gupta - Art13 - Microstructure Evolution in Metal Nanostructures Under Extreme Conditions of Temperature and Strain RateDocument9 pages2016 - Gupta - Art13 - Microstructure Evolution in Metal Nanostructures Under Extreme Conditions of Temperature and Strain RateP. R. SREENIVASANNo ratings yet

- Measurement and Detection of Partial DisDocument5 pagesMeasurement and Detection of Partial DissunilNo ratings yet

- News Natphysresearchhighlight Feb2011Document1 pageNews Natphysresearchhighlight Feb2011StudioAbbaNo ratings yet

- AC Loss Analysis of Striated HTS Compact Cables For Low Loss Cable DesignDocument4 pagesAC Loss Analysis of Striated HTS Compact Cables For Low Loss Cable DesignCristian Daniel Antilao PizarroNo ratings yet

- 50 Years in Icing Performance of Outdoor InsulatorsDocument12 pages50 Years in Icing Performance of Outdoor Insulatorssridhar_gandra1253No ratings yet

- The Pre-History of Pulsed PowerDocument3 pagesThe Pre-History of Pulsed PowerUmer Farooq AzamNo ratings yet

- Diagnosis of Xlpe Insulated Cables Aged Under Conditions of MultDocument5 pagesDiagnosis of Xlpe Insulated Cables Aged Under Conditions of MultNoé Rafael Colorado SósolNo ratings yet

- Luminescence of An Ingan/Gan Multiple Quantum Well Light-Emitting DiodeDocument4 pagesLuminescence of An Ingan/Gan Multiple Quantum Well Light-Emitting Diode廖嘉哲No ratings yet

- CNT Ballistic TransistorDocument4 pagesCNT Ballistic TransistorSrijeet TripathyNo ratings yet

- 2007-SPRINGER-Chan-Effects of Bonding Frequency On Au Wedge Wire BondabilityDocument8 pages2007-SPRINGER-Chan-Effects of Bonding Frequency On Au Wedge Wire Bondabilityketab_doostNo ratings yet

- Power: Insulator LinesDocument9 pagesPower: Insulator Linesmadridi2003No ratings yet

- High Voltage in Vacuum CERNDocument3 pagesHigh Voltage in Vacuum CERNLAKIS PAVNo ratings yet

- Pierella 2022 J. Phys. Conf. Ser. 2362 012030Document13 pagesPierella 2022 J. Phys. Conf. Ser. 2362 012030rubesh2316No ratings yet

- Review of Partial Discharge and Dielectric Loss Te PDFDocument6 pagesReview of Partial Discharge and Dielectric Loss Te PDFSuprit PradhanNo ratings yet

- Dependence of Magnetic Penetration Depth On The THDocument9 pagesDependence of Magnetic Penetration Depth On The THAlessandro AlvesNo ratings yet

- The Problem of Pollution On InsulatorsDocument3 pagesThe Problem of Pollution On InsulatorsjamalNo ratings yet

- 1 s2.0 S0026271421001773 MainDocument5 pages1 s2.0 S0026271421001773 MainHafiz UmairNo ratings yet

- Space Charge Development and Breakdown in Crosslinked PolyethyleDocument4 pagesSpace Charge Development and Breakdown in Crosslinked PolyethyleDanielNo ratings yet

- Twodimensional Electron Gas Magnetic Field Sensors: 128.248.155.225 On: Sat, 22 Nov 2014 08:08:06Document4 pagesTwodimensional Electron Gas Magnetic Field Sensors: 128.248.155.225 On: Sat, 22 Nov 2014 08:08:06George AcostaNo ratings yet

- High Voltage Vacuum Insulation: Basic Concepts and Technological PracticeFrom EverandHigh Voltage Vacuum Insulation: Basic Concepts and Technological PracticeNo ratings yet

- Propagation of Microcracks at Stress Amplitudes Below The Conventional Fatigue Limit in Ti-6Al-4VDocument9 pagesPropagation of Microcracks at Stress Amplitudes Below The Conventional Fatigue Limit in Ti-6Al-4VsenthilNo ratings yet

- Douglas G. Tasker, Richard J. Lee and Paul K. Gustavson-The Measurement of Electrical Conductivity in Detonatiing Condensed ExplosivesDocument59 pagesDouglas G. Tasker, Richard J. Lee and Paul K. Gustavson-The Measurement of Electrical Conductivity in Detonatiing Condensed ExplosivesGhoree23456No ratings yet

- Marra - 1989 - Sharkbite Submarine CableDocument8 pagesMarra - 1989 - Sharkbite Submarine Cableetejada00No ratings yet

- Development of Multi-Chamber Insulator-Arresters For Lightning Protection of 220 KV Overhead Transmission LinesDocument6 pagesDevelopment of Multi-Chamber Insulator-Arresters For Lightning Protection of 220 KV Overhead Transmission LinesSutan P A SitorusNo ratings yet

- 1984 - G. MonDocument11 pages1984 - G. Mondenet.solerNo ratings yet

- Journal of CatalysisDocument5 pagesJournal of CatalysisANTONIO C.MNo ratings yet

- Microfabrication of DC Microarcjets With UV Lasers - 2007 - Thin Solid FilmsDocument6 pagesMicrofabrication of DC Microarcjets With UV Lasers - 2007 - Thin Solid FilmsShivaNatarajNo ratings yet

- 1 4829432 PDFDocument6 pages1 4829432 PDFKadu BritoNo ratings yet

- Observationof Patterns Createdbythe Standing Wavesona Plateandthe Molecular Motionof GasesDocument5 pagesObservationof Patterns Createdbythe Standing Wavesona Plateandthe Molecular Motionof GasesfuyoungNo ratings yet

- Scientific ProgrammingDocument73 pagesScientific ProgrammingmstevkaNo ratings yet

- How MOCVD WorksDocument8 pagesHow MOCVD WorksmstevkaNo ratings yet

- ShengYi - S3116 - CEM-IDocument2 pagesShengYi - S3116 - CEM-ImstevkaNo ratings yet

- MASER Decapsulation Leaflet V1aDocument2 pagesMASER Decapsulation Leaflet V1amstevkaNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Plexiglas Led 0V200 - enDocument2 pagesPlexiglas Led 0V200 - enmstevkaNo ratings yet

- Brian-Morrison Design For ExcelenceDocument42 pagesBrian-Morrison Design For ExcelencemstevkaNo ratings yet

- Fundamentals of Plastics Thermoforming (PDFDrive)Document98 pagesFundamentals of Plastics Thermoforming (PDFDrive)mstevkaNo ratings yet

- Gesamt EN WebDocument76 pagesGesamt EN WebmstevkaNo ratings yet

- Nap CN Games PlayDocument37 pagesNap CN Games PlaymstevkaNo ratings yet

- Sciences An Integrated Approach 6th Edition Trefil Test BankDocument25 pagesSciences An Integrated Approach 6th Edition Trefil Test BankMissKellieSmithMDfqsb100% (43)

- Solar Steamer.Document15 pagesSolar Steamer.AadarshNo ratings yet

- Class 12 Maths (Commerce) Summer Vacation HomeworkDocument7 pagesClass 12 Maths (Commerce) Summer Vacation HomeworkVridhi AroraNo ratings yet

- 01-Pressurization Fan Calculation SheetDocument8 pages01-Pressurization Fan Calculation SheetHamdy AdelNo ratings yet

- Capacitance and DielectricsDocument27 pagesCapacitance and Dielectricsainie khalim100% (1)

- Ece Correl 1 Quiz 2Document6 pagesEce Correl 1 Quiz 2pclr07No ratings yet

- B737-Flight Controls Systems SummaryDocument24 pagesB737-Flight Controls Systems SummaryTrailblazer487100% (1)

- MindsLight 16Document10 pagesMindsLight 16Bobby BlackNo ratings yet

- LAB 6 CalculationDocument11 pagesLAB 6 CalculationFarah NurHusnaNo ratings yet

- BTech Alloy Weld On Instructions WebDocument1 pageBTech Alloy Weld On Instructions Webwalid mahmoudNo ratings yet

- CLPAK628H Series Installation Manual 20150907 PDFDocument27 pagesCLPAK628H Series Installation Manual 20150907 PDFmauroschilling100% (6)

- W200 Manual enDocument48 pagesW200 Manual enkhangduongda2No ratings yet

- Cambridge IGCSE Mathematics - Core & Extended, 3rd EditionDocument511 pagesCambridge IGCSE Mathematics - Core & Extended, 3rd EditionAnderson Alfred86% (21)

- TurboGen ConstructionDocument71 pagesTurboGen Constructiondevanand_sawantNo ratings yet

- TIF009 - HF Integrity Test and Repair - 20121101Document4 pagesTIF009 - HF Integrity Test and Repair - 20121101Campos LucasNo ratings yet

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- Alarmes CTX310 Eco PDF Switch MachinesDocument1 pageAlarmes CTX310 Eco PDF Switch MachinessegapozNo ratings yet

- Yuzik Jesse 202001 MSCDocument130 pagesYuzik Jesse 202001 MSCLong An ĐỗNo ratings yet

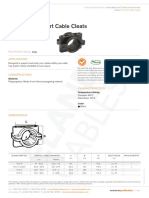

- Two Part Cable CleatsDocument1 pageTwo Part Cable Cleatssaghaee.rezaNo ratings yet

- Tips Howard Robert e Kull The Striking of The GongDocument4 pagesTips Howard Robert e Kull The Striking of The GongJOAO VITOR DOS SANTOS SILVANo ratings yet

- Elastomod Kit Installation PDFDocument20 pagesElastomod Kit Installation PDFishakNo ratings yet

- Mitsubishi Manuals A 500Document257 pagesMitsubishi Manuals A 500Amador AguilaNo ratings yet

- Step-By-Step Guide To Painting LM-BS004Document58 pagesStep-By-Step Guide To Painting LM-BS004Silverio JuniorNo ratings yet

- Design Proposal and Optimization Potential For An Electric Drive Motor in A 50 PAX Hybrid-Electric Regional Aircraft ApplicationDocument9 pagesDesign Proposal and Optimization Potential For An Electric Drive Motor in A 50 PAX Hybrid-Electric Regional Aircraft ApplicationAlfred PedersendsNo ratings yet

- Centrifuge Modeling of The Cyclic Lateral Behavior of Large-Diameter Monopiles in Soft Clay Effects of Episodic Cycling and ReconsolidationDocument17 pagesCentrifuge Modeling of The Cyclic Lateral Behavior of Large-Diameter Monopiles in Soft Clay Effects of Episodic Cycling and ReconsolidationSunil Ranjan MohapatraNo ratings yet

- Creation Pro-2020Document2 pagesCreation Pro-2020Owais AhmedNo ratings yet

- ISC Chemistry Question Paper 2019 For Class 12Document21 pagesISC Chemistry Question Paper 2019 For Class 12Jimmy IlyasNo ratings yet

- Installation, Operation: Client: FRIEM Project: E436 - SNC - ES Serial Number: 35707-8Document24 pagesInstallation, Operation: Client: FRIEM Project: E436 - SNC - ES Serial Number: 35707-8Vladimir Q. MéndezNo ratings yet

- GLASSWARESDocument26 pagesGLASSWARESandie maxeyNo ratings yet

- PPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionDocument16 pagesPPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionAndreas KNo ratings yet