Professional Documents

Culture Documents

50 Years in Icing Performance of Outdoor Insulators

Uploaded by

sridhar_gandra1253Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50 Years in Icing Performance of Outdoor Insulators

Uploaded by

sridhar_gandra1253Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/260712278

50 Years in Icing Performance of Outdoor Insulators

Article in IEEE Electrical Insulation Magazine · January 2014

DOI: 10.1109/MEI.2014.6701103

CITATIONS READS

39 928

2 authors:

Masoud Farzaneh William Chisholm

University of Québec in Chicoutimi Kinectrics

537 PUBLICATIONS 11,214 CITATIONS 134 PUBLICATIONS 2,949 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

CIGRE B2.007 View project

Flashover Characteristics of Silicone Rubber Materials under Various Contaminated Conditions for Application in Outdoor Polymeric Insulators View project

All content following this page was uploaded by William Chisholm on 26 February 2015.

The user has requested enhancement of the downloaded file.

F E A T U R E A R T I C L E

50 Years in Icing Performance

of Outdoor Insulators

Key words: history, insulator, bushing, icing, fog, outdoor

Introduction Masoud Farzaneh

Outdoor insulators are exposed to a wide range of conditions,

leading to build-up of pollution from the air by dry deposition.

and William A. Chisholm

Following rain, most insulator surfaces are cleared of preexisting Université du Québec à Chicoutimi

deposit, but the electrical conductivity of the rain itself may lead

to wet flashover problems. Insulator standards and application

guides suggest appropriate metal-to-metal dry-arc and leakage

distances along the insulator profile to ensure that the normal Solving the switching-surge issues

ac line voltage does not follow a conductive path, across the

surfaces or through a heavy cascade of water drops, from line

for extra-high-voltage systems led to

to ground. levels of insulator stress that caused

Ice and snow accretion are special cases of exposure to operational problems with line-

pollution. There is usually no significant difference between the

electrical conductivity of various forms of precipitation so that voltage flashover, under ice and

the same issues of wet flashover occur when icicles bridge the snow conditions.

sheds of an insulator. Freezing will reduce the conductivity of

a water jet by a factor of 100 or more, but the process will also

reject all the impurities to the ice surface. A thin ice layer can

also stabilize preexisting surface pollution, acting as an effective recurrence of problems in several countries [1], [2], a sustained

and thick nonsoluble deposit, and thus depressing flashover level of publication in IEEE PES and DEIS started in 2003.

strength across insulator leakage distances. One of the reasons for the lack of early interest in icing

performance of extra-high-voltage (EHV) and UHV insulators

can also be inferred from Figure 1. Although identified as a

Origin of Icing Electrical-Flashover problem by Bewley in 1939 [3], it was not until the early 1960s

Problems at Extra-High Voltage [4]–[8] that new EHV laboratories in Japan, USA, Canada,

The technical literature in IEEE Xplore contains much Italy, and other countries evaluated switching-surge overvoltage

discussion of the effects of ice on overhead transmission lines. flashover at insulator dimensions exceeding 3 m. Figure 2

In the AIEE transactions, such discussion is almost exclusively shows how a switching surge with a critical 250-μs rise time

related to the static mechanical-loading aspects. There is may exhibit meandering streamer formation, contrasting with

additional focus on dynamic mechanical problems, such as the direct path from rod to ground for a long-tail, lightning-type

conductor galloping, in the IEEE Transactions on Power surge (Figure 3).

Apparatus and Systems. Figure 1 shows that a few papers on Switching-surge testing in the early 1960s demonstrated

electrical effects of icing were published in the 1960s, presenting clearly to utilities that increased clearance and insulator dry-arc

test results for ice-covered, ultra-high-voltage (UHV) insulators. distance would not be effective in ensuring reliable performance

There was increasing interest in the 1980s, and following of new EHV and UHV systems. At 540 kV/m, lightning-surge

impulse strength scales linearly with gap distance in the range 1

to 6 m, with similar flashover stress of 500 kVpk/m value for crest

flashover of 60 Hz sine waves. Similar strength was postulated

The eleventh of a series of invited reviews for switching overvoltages of any waveshape. However, testing

marking the 50th anniversary of DEIS. in 1963 [5] showed that the long-tail 5/4,700 impulse (Figure

3) had a rod–plane flashover stress of 330 kV/m, whereas the

14 0883-7554/12/$31/©2014/IEEE IEEE Electrical Insulation Magazine

Figure 1. Number of IEEE publications on electrical flashover

under switching-surge and icing conditions.

slower-front and shorter-tail 250/2,500 wave flashed over at Figure 3. Full-wave flashover for +1,610-kV 5/4,700 surge in

250 kV/m. These results, and the observation that flashover 4.9-m rod-to-plane gap [5].

stress decreased with increasing gap distance (Figure 4), were

important.

It was more effective to modify the power system by reducing The 50 years from 1963 to 2013 have shown an impressive

the magnitude of likely surge magnitudes than to increase improvement in our understanding and control of power-

clearances. In this way, improved switching-surge performance system switching-surge overvoltages, as demonstrated in IEEE

of power systems to match the relatively low switching-surge literature. This improvement was fundamental to successful

strength of insulators became the main preoccupation of any design and operation of overhead transmission lines and stations

utility adopting EHV technology. at EHV voltages, reaching 500 kV in the early 1960s and 735 kV

Switching-surge magnitudes are expressed using the per-unit in 1965. The technical achievement of switching-surge control

system (pu), in which 1 pu is the peak line-to-ground voltage, or started with measurement campaigns [13]. Digital computer

the system voltage multiplied by √2 /√3. Switching at the peak tools were developed, including the Electro Magnetic Transients

of an ac voltage wave, and reflection of the voltage transient at Program (EMTP/ATP) [14], [15]. After cross-calibration these

an open point, can lead to a 2-pu surge at the open terminal. eventually replaced analog computers and transient network

analyzers in modeling the statistical distributions of switching-

overvoltage waveshapes and amplitudes. The overall result

was that switching surges could be effectively predicted and

controlled to levels below 2 pu by combining closing resistors in

circuit breakers and carefully selected surge arresters.

Interest in icing flashover was limited to the IEEE technical

group on electrical insulation, chaired by Perkins starting in

Figure 2. Full-wave streamer (A) and flashover (B) for

+1,540-kV 250/2,500 switching surge in 6.1-m rod-to-plane Figure 4. Switching-surge flashover stress versus gap distance

gap [5]. (m) [8]–[12].

January/February — Vol. 30, No. 1 15

Increased Exposure to Road Salting

Another factor in many EHV-insulator flashovers in winter

conditions was the increasing use of road salt to maintain safe

road conditions. Figure 5 shows that the use of salt doubled in

Sweden over the period 1976 to 1999.

While the main focus of road-salt research was the damage

to the environment, as shown in Figure 6, the effects on EHV-

line flashovers were also studied. In particular, measurements

of the background, spray, and splash content showed that

elevated expressways and substations made poor neighbors.

This problem was compounded by land-use practices that often

placed substations on land of minimum value, near expressways,

or routed expressways over land of depressed value adjacent to

substations.

Figure 5. Seasonal use of road salt on the Swedish national

AC Operating Experience at EHV

road network [17].

In-service experience was generally good, with few line-

voltage flashovers at higher EHV electrical-stress levels.

September 1963, and the Electrical Insulation Society formed

However, some utilities began to report degraded reliability and

under Bartnikas in 1978. However, since 1986, when Tanaka

unexplained flashovers under some ice and snow conditions. In

chaired the reformation of DEIS, there has been a sustained

the period 1984 to 1996 a total of 17 severe insulator-flashover

level of publication concerned with icing effects, especially

events were recorded in the National Electric Reliability Council

following a special issue on the topic in 2007 [16]. After a series

database. These occurred in the winter season, between mid-

of line-voltage flashover problems in 2008 and again in 2012,

October and mid-April. The most serious problems involved

the topic has been of particular interest in China and has been

substation insulators and bushings rather than overhead lines.

well supported by specialized laboratories.

Consequences included the triggering of a blackout of the west

coast of the USA on December 14, 1994, after flashover of a

Operational Experience With EHV 345-kV substation insulator.

Insulators in Winter Conditions EHV line and station insulators proved vulnerable to specific

winter weather conditions that did not affect electrical reliability

Increased Line-Voltage Stress of adjacent HV systems. For example, in southern Ontario,

One consequence of the innovations to reduce switching- Canada, a modest amount of freezing rain, less than 1 cm, led

surge magnitude was that, in the late 1970s and early 1980s, to partial ice bridging and flashovers only on 500-kV insulators

electrical designers began to increase normal operating operating at line-voltage stresses of about 90 kV/m of dry-arc

electrical stress on EHV-system bushings, post insulators, and distance. Figure 7 shows that the ice was present on the insulators

insulator strings, deriving cost advantage from reduced dry-arc for approximately eight hours (00:00 to 08:00), but flashovers

distance. The typical stress of about 70 kV ac line to ground indicated by the shaded rectangles occurred only when the dew-

per meter of dry-arc distance, which had given reliable winter point temperature approached 0°C.

operation for 230-kV systems for 80 years, was increased to Widespread 500-kV flashover problems (Figure 7) led to a

levels exceeding 100 kV/mdry arc. For example, in the Canadian program of field studies that confirmed the important role of

province of Ontario, the first 500-kV lines went into service dew-point temperature and corresponding relative humidity

with an insulation level of 1,800 kV BIL (basic impulse level); above 92% in the transition from freezing to melting. As shown

this was lowered to 1,550 kV BIL for urban stations that took in Figure 8, fog dissipated as the ambient temperature rose

advantage of switching-surge control measures. above 0°C, and dew-point temperature stayed below the freezing

point. There were no flashover problems under these ice-melting

conditions in relatively dry air with 86% relative humidity.

In another case in 1992, 500-kV flashovers occurred during

ice accretion, stopped when the weather turned colder, even

though ice remained on the insulator, and resumed four days

later when the ambient temperature and dew point rose above

the freezing point.

EHV DC Lines

An EPRI report [19] summarized the performance of

five EHV DC transmission lines using horizontal bipolar

configuration. Insulator flashovers from the combined effects of

Figure 6. Splash, spray, and background deposition of road salt pollution and icing were reported on a Hydro-Québec ±450-kV

(adapted from [17]). line with 29 insulators in a V-string (4.2 m dry arc) but not on the

16 IEEE Electrical Insulation Magazine

Figure 7. Weather during 1986 ice storm with fifty-seven 500- Figure 8. Weather during 1988 ice storm with no flashovers: 86

kV flashovers in a 10-hour period: 390 hours without rain fol- hours without rain followed by partial ice bridging [18].

lowed by partial ice bridging [18].

Manitoba Hydro ±500-kV lines with 21 insulators (3.07 m dry Development of Specialized Indoor

arc). In both cases, insulator length was selected on the basis of

Laboratories

well-controlled switching-surge levels of 1.7 pu.

Diagnostic Field Work During Flashover Events Outdoor-Testing-Program Results

Field studies in the 1980s and 1990s,which included Most of the early icing testing was conducted outdoors. Udo

collection and chemical analysis of drip water after natural ice [7] was the first to report switching-surge test results for iced

accretion (Figure 9), showed clearly that road salt could be a insulators in 1966, and most of the EPRI Project EHV and Project

dominant contributor to flashover problems, even at stress levels UHV work [20] in the early years of DEIS was conducted in an

of 70 kV/m of dry arc. outdoor test yard. This restricted testing to typically two months

Figure 9. Collection of drip water from iced insulators naturally precontaminated with road salt

(December 1989) [18].

January/February — Vol. 30, No. 1 17

Figure 10. Insulator profiles in outdoor icing tests [21].

of the year and in addition did not allow precise control of suggests that the desired temperature transition from below to

temperature or relative humidity. As shown in Figures 7 and 8, above freezing, with high relative humidity, occurs infrequently

high relative humidity from a close match of ambient and dew- outdoors, and led to the development of a number of specialized

point temperature, both rising slowly to melting at 0°C, proved indoor icing-test laboratories and standard procedures [23].

to be critical conditions leading to flashovers under normal ac

operating voltage. Indoor Testing With Dry-Arc Distance of 0.5 to 2 m

Icing flashovers under dc conditions were studied by EPRI as In 1967 Khalifa and Morris [29] used a 4.5 m × 7.6 m ×

part of Project UHV in January and February 1982 [21]. Three 3.7 m refrigerated chamber to apply rime ice with density of about

types of insulators, P3, G1, and NC1, were dc-energized outdoors 0.4 g/cm3 to insulators with up to 1.3 m of dry-arc distance.

and coated with ice on one side using a fire hose (Figure 10). With a 200-kV source, they found that long rod insulators were

An accretion period of up to five hours at temperatures below inferior to equivalent strings of porcelain discs. This observation

−4°C was used, similar to the ice progressive stress approach was confirmed later when field experience showed that station

described in [22] and [23], so that flashover was achieved post insulators and bushings were inferior to overhead line

in most tests. Ice thicknesses were up to 10 cm. In order to insulation under the same icing conditions.

compare results with different insulator profiles, a so-called A HV and icing research laboratory was constructed

icing stress product (ISP) is defined as the product of the ice, at Tempere University, in Finland, consisting of a 3.3 m ×

snow, or frost layer mass per centimeter of length, multiplied by 2.8 m × 5 m climate room with minimum temperature of

the electrical conductivity of the layer when removed, melted −65°C, 300 kVac, 100 and 130 kVdc test-voltage sources, and a

and measured at a reference temperature of 20°C. The ISP

values for outdoor test results [21] were estimated using the ice

thickness, insulator diameter, and 0.9 g/cm3 density for glaze-

ice weight per centimenter of dry-arc distance. The ice weights

were multiplied by the specified applied water conductivity of

41.5 μS/cm corrected to 20°C.

Figure 11 shows the dispersion in the 1982 outdoor test

results [21], plotted as dc voltage stress (kV per m of dry-arc

distance) against ISP, with green diamonds for withstand results

and brown squares for flashovers. More recent test results

for HVDC, using a well-controlled laboratory method with

no melting phase [24], which achieves typically 4% relative

standard deviation in the critical flashover stress E50, are also

shown. The circles relate to five different water conductivities,

and the dashed curve represents consolidated ac and dc+ results

from a standard icing-test method that incorporates a melting

phase [18], [25]–[28]. This curve indicates lower stresses than

all the other test results, since melting yields the minimum

flashover level. Only 1 of the 44 outdoor flashover results Figure 11. Outdoor and indoor icing-test results for HVDC

from [21] coincides with this minimum level. This observation [18], [21], [24].

18 IEEE Electrical Insulation Magazine

950 kV impulse-voltage source. A 3.6 m × 2.7 m × 2.6 m icing

laboratory is available at the Kitami Institute of Technology

in Japan, equipped with a 120 kVac, 120 kVA transformer; its

minimum operating temperature is −30°C.

Icing research at the Université du Québec à Chicoutimi

(UQAC) dates from the 1970s, when a 4.8 m × 2.8 m ×

2.6 m cold room with a minimum temperature of −35°C and a

100 kVac, 120 kVA source was commissioned. Since then

research in this field expanded steadily with the support of

Hydro-Québec, the governments of Quebec and Canada, and

industrial partners throughout the world. With the establishment

of the Natural Science and Engineering Research Council/

Hydro-Québec/UQAC Industrial Research Chair CIGELE in

1997, and the advent of the Great Ice Storm of 1998 in North

America, which hit Quebec particularly hard, icing research

Figure 12. Electrical sources in the Université du Québec à

has assumed considerable importance. Extra-high-voltage test

Chicoutimi icing pavilion.

capability at UQAC was established in 2000, as described in the

next section.

A small icing-test laboratory was constructed at the Shenzen

Graduate School, Tsinghua University, in 2005. Its height is floor and 3 m to the heat exchangers, were reported in 1996

2.8 m, and a central bushing allows testing of insulator strings [30].

with seven standard discs at temperatures as low as −20°C. As Important improvements were made to HV and icing

in Quebec, severe problems in 2008 and 2012 with electrical research facilities at UQAC in 2000, including construction of

flashovers in winter conditions led to increased importance a dedicated building. In 2005 this infrastructure was recognized

of icing research in China. Additional test chambers were by the Natural Science and Engineering Research Council

constructed, as described below. of Canada as the most important of its kind worldwide. The

Under outdoor and artificial indoor conditions, the ice- building includes an icing wind tunnel and three climate rooms

temperature range lies between ambient and dew-point capable of reaching temperatures as low as −62°C, which can

temperatures. Thus, in Figure 7, the ice was warmer than −0.5°C accurately simulate rime, glaze, and wet snow. One of these

when most flashovers occurred. Small icing chambers using rooms, measuring 5.7 m × 5.7 m × 9 m, is also equipped with

Freon-based chillers depress the dew-point temperature, and this a sliding roof, which allows capture of icing precipitation. The

changes the ambient temperature at which the dew point reaches HV equipment supplying the icing facilities consists of an

the melting point. Direct measurement on the ice surface can 800-kV impulse generator, two transformers (350 kVac,

resolve this temperature offset. The flashover strength of icicles 700 kVA and 120 kVac, 240 kVA), a 300 kVdc, 600 kVA source

falls dramatically in the narrow ice surface temperature range operating with both voltage polarities, and a modular 240 kVac,

from −1 to 0°C [30]. Consequently it was recognized [22], [23] dc and impulse voltage system (Figure 12).

that maintaining high relative humidity, including visible fog, The UQAC laboratory is also equipped with specialized

during the melting phase of an icing test is an effective way of equipment to monitor icing and discharge activities on insulators

controlling the icicle, ice, or frost layer temperature in a large using enhanced UV and high-speed cameras. Other laboratories

test chamber. are equipped to test mechanical behavior of ice and its effects,

icing and deicing of conductors and other structures, and to

develop superhydrophobic and icephobic coatings.

Indoor Testing With Dry-Arc Distance of 2 to 5 m The State Key Laboratory of Power Transmission Equipment

At Ontario Hydro a fog chamber was equipped with Freon- and System Security at Chongqing University incorporates a

based chillers in the late 1970s in order to facilitate icing tests multifunctional artificial climate chamber with a diameter of

on polymer insulators [31]. The chamber was modified during 7.8 m and a height of 11.6 m, as shown in Figure 13. The climate

the period 1988 to 1991; the Freon-based chillers were replaced controls include a refrigeration system, air pressure from 30 to

by a glycol-loop system that limited the temperature drop across 100 kPa, wind-speed regulation from 0 to 12 m/s, and a water-

the heat exchangers, and thereby reduced the spread between spraying system with 14 nozzles at a distance of 3.65 m from

ambient and dew-point temperature. This was the first electrical the insulator under test. The wall bushing is rated at 330 kV. A

icing-test chamber to integrate the heat exchanger function power supply (500 kV, 2,000 kVA, 75 A short-circuit current)

with realistic wind-speed turbulence across the energized minimizes problems with voltage regulation during heavy arcing

insulators. The resulting high and well-controlled relative activity under icing conditions.

humidity gave the precise control of ice temperature needed to An artificial climate chamber with a diameter of 8 m and a

reproduce line-voltage flashovers. Test results obtained using a height of 7 m (Figure 14) is used (with an outdoor HV source)

370-kVac, 1,666-kVA power supply feeding a chamber with central for icing tests at the China Electric Power Research Institute

800-kV BIL bushing, and clearances of 5 m to the ceiling and [34].

January/February — Vol. 30, No. 1 19

can be achieved, and air pressure can be reduced to simulate

elevations up to 6,000 m.

State Grid Electric Power Research Institute

A climate chamber, with dimensions very similar to those of

the China Electric Power Research Institute chamber in Beijing,

has been constructed at Wuhan University in cooperation with

the State Grid Electric Power Research Institute (Figure 16).

The minimum temperature is −19°C, and the simulated altitude

range is 0 to 5,500 m.

Typical Icing-Test Results

It seems that at least two different test methods have been

used in each of the laboratories undertaking ice and snow testing.

However, some important conclusions have led to refinement

of test methods [22] and eventual standardization under DEIS

sponsorship [23].

Glaze-Ice Accretion and Melting

Figure 17 shows critical flashover stress in kilovolts per

meter of dry-arc distance, as a function of the ISP, for five types

of winter precipitation conditions.

Accretion of 10 mm of radial ice on a reference cylinder may

generate an ice layer with 40 g/cm of dry-arc distance, and if the

water conductivity after melting has the standard value 100 μS/

cm [11], [23], the ISP will be 4,000 (g/cm)(μS/cm). Figure 17

Figure 13. Artificial climate chamber at the State Key Laborato-

ry, Chongqing University; (a) HV source, (b) potential divider,

(c) climate chamber [32], [33].

Indoor Testing With Dry-Arc Distance

Exceeding 5 m

At present, at least three climate chambers are being used to

conduct icing-flashover tests on insulators with dry-arc distances

exceeding 5 m.

Swedish Transmission Research Institute

Over many years the Swedish Transmission Research

Institute in Ludvika has developed considerable expertise in the

reproduction of natural pollution accumulation. A dust cycle

method for testing outdoor insulators was described in 1994

[35]. This led to the construction of the Swedish Transmission

Research Institute climate hall, with a –10 to 40°C temperature

range, diameter of 18 m, free height of 20 m, and 860-kVac,

1,200-kVdc, and 2,200-kV lightning-impulse power supplies

[36].

China Electric Power Research Institute

Figure 15 shows a cylindrical environmental chamber with

20-m internal radius and 25-m height, and the associated UHV

outdoor power supply, constructed at the China Electric Power Figure 14. Artificial climate chamber used by Shenzhen

Research Institute, Beijing. A minimum temperature of −20°C Graduate School, Tsinghua University [34].

20 IEEE Electrical Insulation Magazine

Figure 17. Flashover stress for five typical winter precipitation

Figure 15. Cylindrical environmental chamber and ultra-high-

types [18], [24], [39].

voltage outdoor power supply at China Electric Power Re-

search Institute, Beijing [37].

Many careful researchers in the past have included sufficient

experimental detail in their publications to enable calculation

shows that, for this ISP, glaze ice with a melting phase will have of the ISP and comparison of their results with those published

a median flashover stress of about 82 kV/mdry arc, well below more recently. Thus Watanabe [41] reported that the ice thickness

typical line-voltage stress levels on EHV systems. varied from 1 to 3 cm on his suspension discs with 146 mm of

Compared with the other four materials, glaze ice with a connection length, but the ice weight was constant at 2 kg per

melting phase gives the lowest flashover stress for a given ISP disk or 137 g/cm of dry-arc distance. Combining these values

and seems to be the only winter condition that results in flashover with a water conductivity of 35 μS/cm at 20°C gives an ISP

at ac line-voltage stress less than 100 kV/m for ISP values below of 4,800. Watanabe’s observed ac flashover level of 147 kV/m

10,000 (g/cm)(μS/cm). for single insulator strings compares well with those presented

in Figure 17 for snow, rime, and dc glaze ice tests without a

Glaze-Ice Accretion Without Melting melting phase.

The role of a melting phase in establishing the minimum ac

or dc flashover level of an insulator has been debated [22]. The Rime and Snow Accretion

consensus [23] is that results for glaze ice without a melting It has proved difficult to simulate natural snow accretion

phase can play an important role in insulator selection, because in the laboratory. Usually a low-density, opaque, rime ice is

tests without a melting phase are faster and thus more economical produced. However, tests using natural snow packed around

than tests with a melting phase. It is vital to show equivalence insulators have been shown to yield more reliable results and

among test methods, say by fitting different scale factors and a are endorsed in IEEE Standard 1783 [23]. Figure 17 shows that

common power-law exponent in order to relate critical flashover flashover levels for various types of winter precipitation can be

stress E50 to ISP. The scale factor may differ between different compared using an ISP model that incorporates a correction for

test methods by more than 20% [40]. the rime or snow density (0.2–0.5 g/cm3), compared with 0.9 g/

cm3 for glaze ice.

Cold Fog Accretion

The behavior of frozen insulators, when transferred to a warm

room to promote condensation on precontaminated surfaces,

was well understood even during the development of the

standard clean-fog test [11][42]. Complete and stable wetting of

all surfaces in any fog test gives a high exponent in the power-

law relation between flashover stress and surface contamination

level, expressed using an equivalent salt deposit density (ESDD).

The equation U50 = KESDD−0.25, relating the critical flashover

stress per meter of leakage distance U50 to ESDD, where K is a

constant, was representative among many test laboratories [42].

A method of slow fog generation, reaching maximum density

Figure 16. Artificial climate chamber and outdoor ultra-high- in 120 minutes, gave the highest (negative) exponent, i.e., U50 =

voltage power supply at State Grid Electric Power Research KESDD−0.32. The clean-fog test method using frozen insulators

Institute, Wuhan, China [38]. [42] gave an exponent of −0.29, and this method was improved

January/February — Vol. 30, No. 1 21

in a cold-fog test method [30], yielding an exponent of −0.37 [6] D. E. Alexander and E. W. Boehne, “Switching-surge insulation level

[18], [39]. The high exponent indicates effective wetting of all of porcelain insulator strings,” IEEE Trans. Power App. Syst., pp. 1145–

1157, 1964.

insulator surfaces, which is normally achieved only with heavy, [7] T. Udo, “Switching surge sparkover characteristics of air gaps and

inert insoluble deposits. insulator strings under practical conditions,” IEEE Trans. Power App.

The cold-fog flashover stress is converted to an ISP by Syst., vol. PAS-85, no. 8, pp. 859–864, Aug. 1966.

assuming that there is a uniform coating of pure ice on a [8] L. Paris and R. Cortina, “Switching and lightning impulse discharge

characteristics of large air gaps and long insulator strings,” IEEE Trans.

preexisting contaminated layer (ESDD), covering the entire Power App. Syst., vol. PAS-87, no. 4, pp. 947–957, Apr. 1968.

insulator leakage distance. If the ice thickness is doubled, the [9] CIGRE Working Group 33.07, Guidelines for the Evaluation of the

resulting conductivity is reduced by a factor of two, giving Dielectric Strength of External Insulation, CIGRE Technical Brochure

a constant value for any assumed thickness. The cold-fog 72, 1992.

[10] EPRI, Transmission Line Reference Book, 345 kV and Above (Red Book),

flashover strength, normally expressed in kilovolts per meter of 2nd ed. Palo Alto, CA: EPRI, 1982.

leakage distance, is plotted in Figure 17 using a typical insulator [11] Standard Techniques for High-Voltage Testing, IEEE Standard 4/1995TM,

creepage factor of 2.5 to relate the leakage to dry-arc distance. Apr. 1995.

[12] A. R. Hileman, Insulation Coordination for Power Systems. Boca Raton,

FL: CRC/Taylor and Francis, 1999.

Standards [13] D. A. Gillies, R. E. Deitrich, H. C. Ramberg, and F. G. Schaufelberger,

There were three milestones in the movement toward global “Field switching surge instrumentation and results of two-step switching

standards for testing and evaluating ice and snow performance of tests conducted by the Bonneville Power Administration,” IEEE Trans.

outdoor insulators. The first was the consolidation of worldwide Power App. Syst., pp. 258–279, 1963.

[14] H. W. Dommel, “Digital computer solution of electromagnetic transients

experience in a pair of Electra papers [1], [2] that established in single-and multiphase networks,” IEEE Trans. Power App. Syst., vol.

many of the common features of winter flashovers. The second PAS-88, no. 4, pp. 388–399, Apr. 1969.

was marked by some very valuable work done by three IEEE [15] H. W. Dommel, “Nonlinear and time-varying elements in digital

task forces; the first task force recommended icing test methods simulation of electromagnetic transients,” IEEE Trans. Power App. Syst.,

vol. PAS-90, pp. 2561–2567, Jun. 1971.

in 2003 [22], the second suggested methods for selecting [16] M. Farzaneh and W. A. Chisholm, “Editorial: Flashover of ice- and snow-

suitable dry-arc and leakage distances for substation insulators covered insulators,” IEEE Trans. DEIS, vol. 14, no. 6, p. 1333, Dec. 2007.

and bushings [25], [26], and the third made corresponding [17] G. Blomqvist, De-icing Salt and the Roadside Environment. Stockholm,

suggestions for overhead line insulation [27], [28]. The third Sweden: Royal Institute of Technology (KTH), 2001.

[18] M. Farzaneh and W. A. Chisholm, Insulators for Icing and Polluted

milestone was the refinement of the icing test methods presented Environments. New York, NY: IEEE/Wiley, 2009.

in IEEE Standard 1783/2009, cosponsored by DEIS and PES [19] EPRI, Advanced HVDC Systems for Voltage at ±800 kV and Above. Palo

[23]. Alto, CA: EPRI, 2007. 1013857.

[20] M. Kawai, “AC flashover tests at project UHV on ice-coated insulators,”

Conclusions IEEE Trans. Power App. Syst., vol. PAS-89, no. 8, pp. 1800–1804, Nov.

1970.

During the last 50 years a significant technical advance, [21] M. G. Comber, R. J. Nigbor, and L. E. Zaffanella, “HVDC transmission-

namely in our understanding and control of switching-surge line research, interim report,” EPRI Technical Report EL-2419, May 1982.

overvoltages, has had some unintended and adverse consequences [22] IEEE Task Force on Insulator Icing Test Methods, “Insulator icing test

when designers took full advantage of the possibility of reduced methods and procedures: A position paper,” IEEE Trans. Power Del., vol.

18, no. 3, pp. 1503–1515, Oct. 2003.

insulator dimensions. Glaze ice accretion can produce harmful [23] IEEE Standard 1783/2009TM, Guide for Test Methods and Procedures to

effects, especially on closely spaced or large-diameter station Evaluate the Electrical Performance of Insulators in Freezing Conditions,

post insulators and bushings. Partial or full bridging of the October 2009.

leakage distance occurs for moderate ice-accretion levels [24] X. Jiang, L. Chen, Z. Zhang, C. Sun, and J. Hu, “Equivalence of influence

of pollution simulating methods on DC flashover stress of ice-covered

and reduces insulator reliability during melting in saturated insulators,” IEEE Trans. Power Del., vol. 25, no. 4, pp. 2113–2120, Oct.

conditions. Colocation of HV or EHV substations with roads 2010.

or expressways on which deicing salt is spread has proved [25] IEEE Task Force on Icing Performance of Station Insulators, “Selection

particularly problematic. The DEIS has played an important role of station insulators with respect to ice and snow—Part I: Technical

context and environmental exposure,” IEEE Trans. Power Del., vol. 20,

as a forum for exploring icing flashover physics and as a sponsor no. 1, pp. 264–270, Jan. 2005.

of improved test methods and applications guidance. [26] IEEE Task Force on Icing Performance of Station Insulators, “Selection

of station insulators with respect to ice and snow—Part II: Methods of

References selection and options for mitigation,” IEEE Trans. Power Del., vol. 20,

[1] CIGRE Task Force 33.04.09, “Influence of Ice and snow on the flashover no. 1, pp. 271–277, Jan. 2005.

performance of outdoor insulators, Part I: Effects of ice,” Electra, no. [27] IEEE Task Force on Icing Performance of Line Insulators, “Selection

187, pp. 91–111, Dec. 1999. of line insulators with respect to ice and snow—Part I: Context and

[2] CIGRE Task Force 33.04.09, “Influence of ice and snow on the flashover stresses,” IEEE Trans. Power Del., vol. 22, no. 4, pp. 2289–2296, Oct.

performance of outdoor insulators, Part II: Effects of snow,” Electra, no. 2007.

188 pp. 55–69, Jan. 2000. [28] IEEE Task Force on Icing Performance of Line Insulators, “Selection of

[3] L. V. Bewley, “Traveling waves initiated by switching,” AIEE Trans., vol. line insulators with respect to ice and snow—Part II: Selection methods

58, pp. 19–26, Jan. 1939. and mitigation options,” IEEE Trans. Power Del., vol. 22, no. 4, pp.

[4] H. L. Hill and A. L. Kinyon, “A laboratory study of switching surge 264–270, Oct. 2007.

flashover characteristics of EHV line insulation,” IEEE Trans. Power App. [29] M. M. Khalifa and R. M. Morris, “Performance of line insulators under

Syst., pp. 476–490, 1963. rime ice” IEEE Trans. Power App. Syst.,vol. PAS-86, no. 6, pp. 692–698,

[5] J. W. Kalb, “How the switching-surge family affects line insulation,” Jun. 1967.

AIEE Trans., pp. 1024–1033, Dec. 1963.

22 IEEE Electrical Insulation Magazine

[30] W. A. Chisholm, K. G. Ringler, C. C. Erven, M. A. Green, O. Melo, Y. [52] H. M. Schneider, “Artificial ice tests on transmission line insulators—A

Tam, O. Nigol, J. Kuffel, A. Boyer, I. K. Pavasars, F. X. Macedo, J. K. progress report,” IEEE PES Summer Meeting, Paper A75 491-1, Jul.

Sabiston, and R. B. Caputo, “The cold fog test,” IEEE Trans. Power Del., 1975.

vol. 11, no. 4, pp. 1874–1880, Oct. 1996. [53] F. A. M. Rizk, “Mathematical models for pollution flashover,” Electra,

[31] E. A. Cherney, “Flashover performance of artificially contaminated and vol. 78, pp. 71–103, 1981.

iced long-rod transmission line insulators,” IEEE Trans. Power App. Syst., [54] J. P. Nova and G. Ellena, “Arc field measurement with a simple experi-

vol. PAS-99, no. 1, pp. 46–52, Jan. 1980. mental apparatus,” J. Phys. D: Appl. Phys., vol. 20, no. 4, pp. 462–467,

[32] J. Hu, C. Sun, X. Jiang, Z. Zhang, and L. Shu, “Flashover performance Apr. 1987.

of pre-contaminated and ice-covered composite insulators to be used in [55] W. A. Chisholm, P. G. Buchan, and T. Jarv, “Accurate measurement of

1000 kV UHV AC transmission lines” IEEE Trans. DEIS , vol. 14 , no. 6, low insulator contamination levels,” IEEE Trans. Power Del., vol. 9, no.

pp. 1347–1356, Dec. 2007. 3, pp. 1552–1557, Jul. 1994.

[33] B. Dong, X. Jiang, J. Hu, L. Shu, and C. Sun, “Effects of artificial [56] M. Farzaneh and J. Kiernicki, “Flashover problems caused by ice build-

polluting methods on AC flashover voltage of composite insulators,” up on insulators,” IEEE Electr. Insul. Mag., vol. 11, no. 2, pp. 5–17, Mar.

IEEE Trans. DEIS, vol. 19, no. 2, pp. 714–722, Apr. 2012. 1995.

[34] Y. Deng, Z. Jia, X. Wei, H. Su, Z. Guan, T. Wang, and K. Wang, [57] M. Farzaneh, J. Zhang, and X. Chen, “Modeling of the AC arc discharge

“Mechanism of salt migration and its impact on ice flashover,” IEEE on ice surfaces,” IEEE Trans. Power Del., vol. 12, pp. 325–338, 1997.

Trans. DEIS, vol. 19, no. 5, pp. 1700–1707, Oct. 2012. [58] I. Fofana and A. Béroual, “A predictive model of the positive discharge

[35] A. Elkund, I. Gutman, and R. Hartings, “The dust cycle method: A in long air gaps under pure and oscillating impulse shapes,” J. Phys. D:

new pollution test method for ceramic and non-ceramic insulators,” Appl. Phys., vol. 30, pp. 1653–1667, 1997.

in Proceedings of the International Conference on Power System [59] Y. Li, M. Farzaneh, and J. Zhang, “Effects of voltage type and polarity on

Technology, vol. 2., Oct. 18–21, 1994, pp. 1254–1257. flashover performances at low atmospheric pressure on an ice surface,”

[36] D. Wu and R. Hartings, “Correlation between the AC withstand voltage in Proceedings of the 8th International Offshore and Polar Engineering

and insulator lengths under icing tests,” in Proceeding of the 2000 Conference, vol. 11, 1998, pp. 543–546.

International Workshop on Atmospheric Icing of Structures, 2000, p. 6. [60] J. S. Wettlaufer, “Ice surfaces: Macroscopic effects of microscopic struc-

[37] Y. Xinzhe, Z. Jun, L. Bo, and S. Zhiyi, “Icing flashover characteristic of ture,” Phil. Trans. Royal Soc. A 357, pp. 3403–3425, 1999.

full-scale EHV and UHV AC insulator strings,” High Voltage Eng., vol. [61] M. Farzaneh, “Ice accretion on high voltage conductors and insulators

39, no. 6, pp. 1454–1459, Jun. 30, 2013. and related phenomena,” Phil. Trans. Royal Soc. vol. 358, no. 1776, pp.

[38] Z. Xu, X. Wu, Y. Chen, Y. Liu, and T. Yao, “Study of the flashover 2971–3005, 2000.

process on ice-covered insulator string,” presented at the 9th International [62] V. Sadtchenko and G. E. Ewing, “New approach to the study of inter-

Conference on the Properties and Applications of Dielectric Materials, facial melting of ice: Infrared spectroscopy,” Can. J. Phys., vol. 81, pp.

Harbin, China, Jul. 19–23, 2009. 333–341, 2003.

[39] EPRI, EPRI AC Transmission Line Reference Book—200 kV and Above, [63] M. Farzaneh, I. Fofana, C. Tavakoli, and X. Chen, “Dynamic modeling of

3rd ed. Palo Alto, CA: EPRI 1011974, 2005. DC arc discharge on ice surfaces,” IEEE Trans. DEIS, vol. 10, no. 3, pp.

[40] X. Jiang, M. Bi, J. Hu, Z. Zhang, and Y. Xia, “Influence of test methods 463–474, 2003.

on DC flashover performance of ice-covered composite insulators and [64] M. Farzaneh and I. Fofana, “Study of insulator flashovers caused by

statistical analysis,” IEEE Trans. DEIS, vol. 19, no. 6, pp. 2019–2028, atmospheric ice accumulation,” J. Iranian Assoc. Electr. Electron. Eng.,

Dec. 2012. vol. 1, no. 1, pp. 10–23, Spring 2004.

[41] Y. Watanabe, “Flashover tests of insulators covered with ice or snow,” IEEE [65] M. Farzaneh and I. Fofana, “Experimental study and analysis of corona

Trans. Power App. Syst., vol. PAS-97, no. 5, pp. 1788–1794, Sep. 1978. discharge parameters on an ice surface,” J. Phys. D: Appl. Phys., vol. 37,

[42] E. A. Cherney, Chair, IEEE Working Group on Insulator Contamination, pp. 721–729, 2004.

Task Force on Testing IEEE Insulators, “The AC clean-fog test for [66] I. Fofana and M. Farzaneh, “A simplified model of corona discharge

contaminated insulators,” IEEE Trans. Power App. Syst., vol. PAS-102, development on an ice surface,” in Proceedings of the 2004 IEEE Confer-

no. 3, pp. 604–611, Mar. 1983. ence on Electrical Insulation and Dielectric Phenomena, Oct. 17–20th

2004, pp. 667–670.

Bibliography—For Further Information [67] M. Farzaneh, J. Zhang, and Y. Li, “Effects of low air pressure on ac and

dc arc propagation on ice surface,” IEEE Trans. DEIS, vol. 12, no. 1, pp.

Books 60–71, Feb. 2005.

[43] P. V. Hobbs, Ice Physics. Oxford, UK: Clarendon Press, 1974. [68] C. S. Engelbrecht, I. Gutman, and R. Hartings, “A practical implementa-

[44] V. F. Petrenko and R. W. Whitworth, Physics of Ice. Oxford, UK: Oxford tion of statistical principles to select insulators with respect to polluted

University Press, 1999. conditions on overhead ac lines,” presented at IEEE PowerTech 2005, St.

[45] M. Farzaneh and W. A. Chisholm, “Effects of ice and snow on the electri- Petersburg, Russia, paper 129, Jun. 27–30, 2005.

cal performance of power network insulators,” Chapter 7 in Atmospheric [69] C. Tavakoli, M. Farzaneh, I. Fofana, and A. Beroual, “Dynamics and

Icing of Power Networks. Berlin, Germany: Springer, 2008, pp. 269–325. modeling of AC arc on surface of ice,” IEEE Trans. DEIS, vol. 13, no. 6,

pp. 1278–1285, Dec. 2006.

Standards and IEEE Guides [70] P. Li, J. Fan, W. Ki, Z. Su and J. Zhou, “Flashover performance of HVDC

[46] Standard for High-Voltage Testing Techniques, IEEE Standard 4/2013TM, iced insulator strings,” IEEE Trans. DEIS, vol. 14, no. 6, pp. 1334–1338,

May 2013. Dec. 2007.

[47] Draft Guide for Selection of Transmission and Distribution Insulators [71] M. Farzaneh and J. Zhang, “A multi-arc model for predicting AC critical

With Respect to Icing, IEEE P1820™/D7, Dec. 2012. flashover voltage of ice-covered insulators,” IEEE Trans. DEIS, vol. 14,

[48] A. C. Baker, M. Farzaneh, R. S. Gorur, S. M. Gubanski, R. J. Hill, G. G. no. 6, pp. 1401–1409, Dec. 2007.

Karady, and H. M. Schneider, “Insulator selection for AC overhead lines [72] S. Farokhi, M. Farzaneh, and I. Fofana, “Study of ultraviolet emission

with respect to contamination,” IEEE Trans. Power Del., vol. 24, no. 3, and visible discharge along an ice surface,” IEEE Conf. Electr. Insul.

pp. 1633–1641, Jul. 2009. Dielectr. Phenomena (CEIDP), pp. 654–657, 2008.

[73] S. Farokhi, M. Farzaneh, and I. Fofana, “Experimental investigation of

Technical Papers the process of arc propagation over an ice surface,” IEEE Trans. DEIS,

[49] J. S. Forrest, “The electrical characteristics of 132-kV line insulators

vol. 17, no. 2, pp. 458–464, Apr. 2010.

under various weather conditions,” IEE J., vol. 79, pp. 401–423, 1936.

[74] X. Jiang, Y. Chao, Z. Zhang, J. Hu, and L. Shu, “DC flashover perfor-

[50] R. Wilkins, “Flashover voltage of high-voltage insulators with uniform

mance and effect of shed configuration on polluted and ice-covered

surface-pollution films,” Proc. IEE, vol. 116, no. 3, pp. 457–465, 1969.

composite insulators at low atmospheric pressure,” IEEE Trans. DEIS,

[51] P. E. Renner, H. L. Hill, and O. Ratz, “Effects of icing on DC insula-

vol. 18, no. 1, pp. 97–105, Feb. 2011.

tion strength” IEEE Trans. Power App. Syst., vol. PAS-90, no. 3, pp.

1201–1206 , May 1971.

January/February — Vol. 30, No. 1 23

[75] Z. Xu, Z. Jia, Z. Li, X. Wei, Z. Guan, and M. MacAlpine, “Anti-icing [96] A. K. Andersson, “Winter road conditions and traffic accidents in Sweden

performance of RTV coatings on porcelain insulators by controlling the and UK: Present and future climate scenarios,” Doctoral thesis, Univer-

leakage current,” IEEE Trans. DEIS, vol. 18, no. 3, pp. 760–766, Jun. sity of Gothenburg, 2010.

2011. [97] A. Nekahi, “Étude spectroscopique de l’arc à la surface de la glace,”

[76] A. Nekahi and M. Farzaneh, “Rotational temperature measurement of doctorat en ingénierie, UQAC, Sep. 2011.

an arc formed over an ice surface,” IEEE Trans. DEIS, vol. 18, no. 3, pp. [98] N. Ravelomanantsoa, “Effet du vent sur l’accumulation de pollution à la

755–759, Jun. 2011. surface des isolateurs dans les conditions hivernales,” doctorat en ingénie-

[77] A. Nekahi and M. Farzaneh, “Excitation temperature determination of rie, UQAC, Dec. 2012.

an arc formed over an ice surface using optical emission spectroscopy,”

IEEE Trans. DEIS, vol. 18, no. 6, pp. 1829–1834, Dec. 2011.

[78] T. Xu, H.-M. Wang, L.-L. Wang, Z.-M. Xu, T. Yao, and L. Cai, “Flash- Masoud Farzaneh is director-founder

over performance of 500 kV ice-covered porcelain post insulators with

composite assistant shed,” High Voltage Eng., vol. 38, no. 1, pp. 167–172,

of the International Research Center

Jan. 2012. CENGIVRE, chair holder of the Natural

[79] Q. Hu, L. Shu, X. Jiang, C. Sun, Z. Zhang, and J. Hu, “Effects of shed Science and Engineering Research

configuration on AC flashover performance of ice-covered composite Council/Hydro-Quebec/Université du

long-rod insulators,” IEEE Trans. DEIS, vol. 19, no. 1, pp. 200–207, Feb.

2012.

Québec à Chicoutimi Industrial Research

[80] C. Potvin, W. A. Chisholm, P. Prud’homme, M. Farzaneh, D. Lepley, Chair CIGELE, and chair holder of the

and E. Del Bello, “Laboratory testing of EGLA and NGLA under icing Canada Research Chair INGIVRE related

and dry conditions for Hydro-Québec TransÉnergie transmission system to power transmission engineering in cold

application,” presented at the CIGRE International Colloquium on Power

Quality and Lightning, Sarajevo, May 13–16, 2012.

climate regions, at University of Québec at Chicoutimi. His field

[81] H. Akkal, C. Volat, and M. Farzaneh, “Improving electrical performance of research encompasses HV and power engineering, including

of EHV post station insulators under severe icing conditions using modi- the impact of cold climate on overhead transmission lines. He has

fied grading rings,” IEEE Trans. DEIS, vol. 20, no. 1, pp. 221–228, Feb. authored or coauthored more than 500 technical papers and 17

2013.

books or book chapters. To date Professor Farzaneh has trained

Doctoral Theses more than 100 postgraduate students and postdoctoral fellows.

[82] X. Chen, “Modeling of electrical arc on ice surfaces,” doctorat en génie Actively involved with IEEE and CIGRÉ, he is immediate past

électrique, UQAC-École Polytechnique de Montréal, Feb. 2000. president of IEEE DEIS, member of the editorial board of IEEE

[83] S. Brettschneider, “Contribution à l’étude de l’apparition et du développe-

ment des décharges visibles à la surface de la glace,” doctorat en génie Transactions on Dielectrics and Electrical Insulation, convenor

électrique, l’Université du Québec à Chicoutimi, Nov. 2000. of CIGRE WG B2.44 on coatings for protection of overhead

[84] Yu Li, “Étude de l’influence de l’altitude sur les caractéristiques de l’arc lines during winter conditions, and member of the executive

électrique à la surface de glace polluée,” PhD en ingénierie, UQAC, Jun. committee of CIGRE Canada. He is Fellow of IEEE, Fellow

2002.

[85] C. Volat, “Calcul de la distribution du potentiel du champ électrique le of The Institution of Engineering and Technology, and Fellow

long des surfaces de glace recouvrant les isolateurs haute-tension et dans of the Engineering Institute of Canada. His contributions and

les intervalles d’air entre celles-ci,” PhD en ingénierie, UQAC, Jun. 2002. achievements in research and teaching have been recognized

[86] R. Chaarani, “Étude de l’influence des caractéristiques des isolateurs sur by several prestigious prizes and awards at national and

leurs performances électriques dans des conditions de givrage,” PhD en

ingénierie, UQAC, Jan. 2003. international levels.

[87] C. Tavakoli-Zaniani, “Modélisation dynamique du développement de

l’arc électrique à la surface de la glace en courant alternatif,” PhD en

ingénierie, Nov. 2004. William A. Chisholm (M ’78, SM ’90, F

[88] V. Jaiswal, “Modélisation de la distribution du champ électrique autour

des isolateurs de poste pour l’amélioration de leur performance électrique ’07) was born in Plattsburgh, New York,

sous conditions givrantes,” PhD en ingénierie, Jul. 2005. in 1955. He received the BASc and MEng

[89] H. Hemmatjou, “Modélisation du développement de l’arc électrique en degrees from the University of Toronto in

courant alternatif à l’intérieur de la neige fondante,” doctorat en ingénie- 1977 and 1979, respectively, and the PhD

rie, UQAC, Oct. 2006.

[90] D. Yu, “Étude des processus des décharges électriques et formation de degree from the University of Waterloo in

charges d’espace dans les intervalles d’air d’un isolateur recouvert de 1983. He worked at Kinectrics, formerly

glace à l’aide d’une configuration d’électrodes glaçon/plaque recouverte the Ontario Hydro Research Division,

de glace,” doctorat en ingénierie, UQAC, Jun. 2007. from 1977 to 2007 and as a research

[91] F. Meghnefi, “Développement d’un système de surveillance et de prédic-

tion en temps réel du contournement électrique des isolateurs recouverts professor at the University of Quebec at Chicoutimi. He is chair

de glace,” doctorat en ingénierie, UQAC, Oct. 2007. of the Transmission and Distribution Committee of the IEEE

[92] I. Ndiaye, “Approche physique du développement de streamers positifs Power and Energy Society and has made many contributions to

sur une surface de glace,” doctorat en ingénierie, UQAC, Oct.2007. the Lightning and Insulator Subcommittee and to CIGRE work

[93] A. Lundmark, “Monitoring transport and fate of de-icing salt in the road-

side environment—Modelling and field measurements,” Royal Institute of in lightning protection and selection of weather parameters

Technology (KTH), Stockholm, Sweden, Jan. 2008. for transmission line thermal rating. With coauthor Masoud

[94] Y. Sabri, “Modélisation statique de contournement électrique en courant Farzaneh he published the reference book Insulators for Icing

alternatif sur les isolateurs contaminés couverts avec la glace en utilisant and Polluted Environments in the Wiley/IEEE Press Series on

des méthodes d’identification intelligentes,” doctorat en ingénierie,

UQAC, Dec. 2009. Power Engineering. He also contributed to recent revisions of

[95] S. Farokhi, “Mécanismes de propagation de l’arc électrique à la surface the EPRI Red, Blue, and Grey Books and to the CRC/IEEE

de glace,” doctorat en génie, UQAC, Dec. 2010. Electric Power Engineering Handbook.

24 IEEE Electrical Insulation Magazine

View publication stats

You might also like

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Wet Aging of MV XLPE CablesDocument7 pagesWet Aging of MV XLPE CablesiiscbangaloreNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- ISH2015 419 Icing ImpulseDocument5 pagesISH2015 419 Icing ImpulseAdrianoNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Various Types of Insulators Used in Power System For Safe Operations of The Transmission LinesDocument10 pagesVarious Types of Insulators Used in Power System For Safe Operations of The Transmission LinesNamandeep ShawNo ratings yet

- Leakage Current and Trapped Charge Characteristics For Glass Insulator String Under Contaminated ConditionsDocument5 pagesLeakage Current and Trapped Charge Characteristics For Glass Insulator String Under Contaminated ConditionsFiras AryanNo ratings yet

- Lightning Performance of Compact LinesDocument21 pagesLightning Performance of Compact LinesJuanjo Gonzales PerezNo ratings yet

- Lightning Performance of Compact LinesDocument21 pagesLightning Performance of Compact LinesJuanjo Gonzales PerezNo ratings yet

- Influence of Humidity On Positive Impulse Flashover Along Cylindrical Insulating Surfaces Bridging A Short Rod-Plane GapDocument5 pagesInfluence of Humidity On Positive Impulse Flashover Along Cylindrical Insulating Surfaces Bridging A Short Rod-Plane GapPantelis N. MikropoulosNo ratings yet

- EDOC-Technology & Testing of Interphase SpacersDocument27 pagesEDOC-Technology & Testing of Interphase SpacersEl Comedor BenedictNo ratings yet

- Contamination Design Flashover Theory and InsulatorDocument18 pagesContamination Design Flashover Theory and InsulatorAjeng PratiwiNo ratings yet

- Sun Etal TDEI2018 Acoustic Impulses Generated by Air Bubble Stimulated PDFDocument9 pagesSun Etal TDEI2018 Acoustic Impulses Generated by Air Bubble Stimulated PDFmostafa1alaahobaNo ratings yet

- Wind-Induced Vibration of Structural CablesDocument72 pagesWind-Induced Vibration of Structural CablessazradNo ratings yet

- 2016 - SVL Connection at TerminationsDocument8 pages2016 - SVL Connection at Terminationseng_zidNo ratings yet

- The Pollution Flashover On High Voltage InsulatorsDocument8 pagesThe Pollution Flashover On High Voltage Insulatorshalel111No ratings yet

- Electrical Stress On The Outer Insulation of Buried Cables Due To A Nearby Lightning Strike To Ground (Kumar2016)Document7 pagesElectrical Stress On The Outer Insulation of Buried Cables Due To A Nearby Lightning Strike To Ground (Kumar2016)daegerteNo ratings yet

- Ipst PDFDocument6 pagesIpst PDFalexanderlimaNo ratings yet

- Insulator For 1500kVDocument13 pagesInsulator For 1500kVdc12dcNo ratings yet

- Induced MedPowerDocument9 pagesInduced MedPowerbhargavNo ratings yet

- Electric Power Systems Research: Alexandre PiantiniDocument8 pagesElectric Power Systems Research: Alexandre PiantiniTomas Camilo EstupiñanNo ratings yet

- Polymers 14 01236Document24 pagesPolymers 14 01236KarthikNo ratings yet

- Efect of Sag On Transmission LineDocument4 pagesEfect of Sag On Transmission LineGabriel Barriga JaqueNo ratings yet

- Modified Peek Formula For Calculating Positive DC Corona Inception Voltage On Polluted InsulatorDocument9 pagesModified Peek Formula For Calculating Positive DC Corona Inception Voltage On Polluted InsulatorJosé Miguel Martínez ValerNo ratings yet

- IEEEMag 24 1 2008 HVDCdesignpart2Document12 pagesIEEEMag 24 1 2008 HVDCdesignpart2César Díaz LiberonaNo ratings yet

- Icolim 2017 07964144 PDFDocument5 pagesIcolim 2017 07964144 PDFmateescu elenaNo ratings yet

- Report MainDocument42 pagesReport Mainayabulela421No ratings yet

- Electric Fuses Operation, A Review: 1. Pre-Arcing PeriodDocument30 pagesElectric Fuses Operation, A Review: 1. Pre-Arcing PeriodFerran MunyósNo ratings yet

- Development of Multi-Chamber Insulator-Arresters For Lightning Protection of 220 KV Overhead Transmission LinesDocument6 pagesDevelopment of Multi-Chamber Insulator-Arresters For Lightning Protection of 220 KV Overhead Transmission LinesSutan P A SitorusNo ratings yet

- Voltage Upgrading - An Insulation Coordination Challenge: June 2011Document9 pagesVoltage Upgrading - An Insulation Coordination Challenge: June 2011ManafNo ratings yet

- Lightning Performance of Cmpact Lines PDFDocument20 pagesLightning Performance of Cmpact Lines PDFABRAHAMNo ratings yet

- Surface Flashover of Oil-Immersed Dielectric Materials in Uniform and Non-Uniform FieldsDocument9 pagesSurface Flashover of Oil-Immersed Dielectric Materials in Uniform and Non-Uniform FieldsdaaanuNo ratings yet

- Non-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationDocument9 pagesNon-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationHendi AfriyanNo ratings yet

- Unit 1Document32 pagesUnit 1Deadly SpyderNo ratings yet

- Flashover Performance of Ice-Covered Post Insulators With Booster Sheds Using Experiments and Partial Arc ModelingDocument8 pagesFlashover Performance of Ice-Covered Post Insulators With Booster Sheds Using Experiments and Partial Arc ModelingDavid GutierrezNo ratings yet

- Experimental Assessment On Air Clearance of MultipDocument13 pagesExperimental Assessment On Air Clearance of MultipFirdaus AzmiNo ratings yet

- TD2010 000116Document5 pagesTD2010 000116VirnaNo ratings yet

- Effects of High Altitude and Atmospheric IcingDocument6 pagesEffects of High Altitude and Atmospheric IcingMilton CuscoNo ratings yet

- Use of Leakage Currents of Insulators To Determine The Stage Characteristics of The Flashover Process and Contamination Level PredictionDocument12 pagesUse of Leakage Currents of Insulators To Determine The Stage Characteristics of The Flashover Process and Contamination Level PredictionMansoor AsifNo ratings yet

- Rowland 2008ADocument9 pagesRowland 2008ASavvas KatemliadisNo ratings yet

- INT Switchgear Developments For IMEDocument7 pagesINT Switchgear Developments For IMEcarlos vidalNo ratings yet

- Unit I Over Voltages in Electrical Power SystemsDocument20 pagesUnit I Over Voltages in Electrical Power Systemsblessedgeraldie78No ratings yet

- Impulse Flashover Voltages at Low PressuresDocument4 pagesImpulse Flashover Voltages at Low PressuresentropifiedNo ratings yet

- Study On The Electrical Equivalent Circuit Models of Polluted Outdoor InsulatorsDocument5 pagesStudy On The Electrical Equivalent Circuit Models of Polluted Outdoor Insulatorswaluyo perwalianelektroNo ratings yet

- Voltage and E-Field Distribution of UHV Composite Insulator With Connection of Porcelain InsulatorsDocument4 pagesVoltage and E-Field Distribution of UHV Composite Insulator With Connection of Porcelain Insulatorsdemy antonyNo ratings yet

- B1 108Document14 pagesB1 108Hoang NamNo ratings yet

- Comparison On Space Charge and Voltage Distribution of High Voltage Insulator Subjected To Different Contamination LevelsDocument8 pagesComparison On Space Charge and Voltage Distribution of High Voltage Insulator Subjected To Different Contamination LevelsFiras AryanNo ratings yet

- Cigre Insulated Cable Energy TransmissionDocument15 pagesCigre Insulated Cable Energy TransmissionllovarNo ratings yet

- Paper On InsulatorsDocument9 pagesPaper On InsulatorsNamandeep ShawNo ratings yet

- Experimental Investigation of The Aging Process On ADSS Optical Fiber CablesDocument4 pagesExperimental Investigation of The Aging Process On ADSS Optical Fiber CablesJeremyNo ratings yet

- Met Is 123209Document9 pagesMet Is 123209shahinNo ratings yet

- Space Charge Development and Breakdown in Crosslinked PolyethyleDocument4 pagesSpace Charge Development and Breakdown in Crosslinked PolyethyleDanielNo ratings yet

- 2002 - Filamentary Patterned and Diffuse Barrier Discharges - KogelschatzDocument9 pages2002 - Filamentary Patterned and Diffuse Barrier Discharges - KogelschatzAlessandroNo ratings yet

- Experimental Study of Electrical Breakdown Voltage of A Glass Insulator Strings With Different Numbers of Broken UnitsDocument4 pagesExperimental Study of Electrical Breakdown Voltage of A Glass Insulator Strings With Different Numbers of Broken UnitsBoby GintingNo ratings yet

- Back-To-Back Energization of A 60kV Cable Network - Inrush Currents PhenomenonDocument7 pagesBack-To-Back Energization of A 60kV Cable Network - Inrush Currents PhenomenonNational Institute of Safety EngineersNo ratings yet

- Modeling Flashover of AC Outdoor Insulators Under Contaminated Conditions With Dry Band Formation and Arcing PDFDocument7 pagesModeling Flashover of AC Outdoor Insulators Under Contaminated Conditions With Dry Band Formation and Arcing PDFdaaanuNo ratings yet

- Energies 15 04684Document15 pagesEnergies 15 04684Philippe SingletonNo ratings yet

- 05996151experimental Investigation of Dry Band Arcing OnDocument5 pages05996151experimental Investigation of Dry Band Arcing OnARCC2030No ratings yet

- Proof 1 PDFDocument21 pagesProof 1 PDFJulián GarcíaNo ratings yet

- Influence of Lightning Flashover Criterion On The Calculated Lightning Withstand Level of 800 KV UHVDC Transmission Lines at High AltitudeDocument7 pagesInfluence of Lightning Flashover Criterion On The Calculated Lightning Withstand Level of 800 KV UHVDC Transmission Lines at High Altitudeqais652002No ratings yet

- 01 Patnayak 84-87Document6 pages01 Patnayak 84-87sridhar_gandra1253No ratings yet

- BusaDocument1 pageBusasridhar_gandra1253No ratings yet

- Inv - Comments 14 56Document43 pagesInv - Comments 14 56sridhar_gandra1253No ratings yet

- 44 C001xxx JD - Project EngineeringDocument25 pages44 C001xxx JD - Project Engineeringsridhar_gandra1253No ratings yet

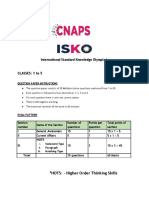

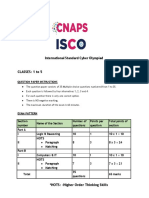

- ISKO PatternDocument2 pagesISKO Patternsridhar_gandra1253No ratings yet

- Typical 33kV GTPDocument9 pagesTypical 33kV GTPsridhar_gandra1253No ratings yet

- ISCO Exam PatterenDocument2 pagesISCO Exam Patterensridhar_gandra1253No ratings yet

- ISEO SyllabusDocument10 pagesISEO Syllabussridhar_gandra1253No ratings yet

- ISSO SyllabusDocument10 pagesISSO Syllabussridhar_gandra1253No ratings yet

- Telangana SolarPower PolicyDocument12 pagesTelangana SolarPower PolicyKiran KumarNo ratings yet

- Hauptkatalog 12-42kv GBDocument64 pagesHauptkatalog 12-42kv GBrabchabNo ratings yet

- Tr01 10e Power Transformes 2mva and Above Revision 9Document109 pagesTr01 10e Power Transformes 2mva and Above Revision 9Emanuel CondeNo ratings yet

- 1.10 Commissioning Procedures (Site Test Manual)Document14 pages1.10 Commissioning Procedures (Site Test Manual)hesby vbNo ratings yet

- IEEE STD C57.129-1999Document39 pagesIEEE STD C57.129-1999abdou samiNo ratings yet

- MV and LV Overhead Connectors 2017Document57 pagesMV and LV Overhead Connectors 2017Hồ ThànhNo ratings yet

- Catalogue Jiangsu Sieyuan HertzDocument24 pagesCatalogue Jiangsu Sieyuan HertzdaminhvienNo ratings yet

- Arteche CT Trafhv enDocument60 pagesArteche CT Trafhv enAhmed MostafaNo ratings yet

- 8DH10 enDocument44 pages8DH10 enRohit ShrivastavaNo ratings yet

- CSP Transformer in IndiaDocument56 pagesCSP Transformer in Indiavinay kumarNo ratings yet

- 4.0 User Manual For TBS Sensors v6Document18 pages4.0 User Manual For TBS Sensors v6Alexandre MandettaNo ratings yet

- Nesco Odisha Technical Specification of 8 MVA Power TransformerDocument52 pagesNesco Odisha Technical Specification of 8 MVA Power TransformerMPCZ ASSETMAPPINGNo ratings yet

- CEDASPE® Overview Brochure Flyer enDocument8 pagesCEDASPE® Overview Brochure Flyer enkashifNo ratings yet

- ABB - 52kV To 550kV - OIP Bushing (En)Document12 pagesABB - 52kV To 550kV - OIP Bushing (En)Nitish KumarNo ratings yet

- Substation Insulation Coordination Studies-Sparacino PDFDocument42 pagesSubstation Insulation Coordination Studies-Sparacino PDFPaco Mj100% (1)

- Fundamentals of Condenser BushingsDocument8 pagesFundamentals of Condenser Bushingswaqas_a_shaikh4348No ratings yet

- Distribution Transformers PS202003ENDocument15 pagesDistribution Transformers PS202003ENDiana Rose TapelNo ratings yet

- General Back Ground of Switchyard: Presenter: Sonam Tobgay Head, SmuDocument38 pagesGeneral Back Ground of Switchyard: Presenter: Sonam Tobgay Head, Smusherub wangdiNo ratings yet

- Collar Test For BushingDocument21 pagesCollar Test For Bushingfajar9nugraha-2100% (1)

- Guidelines For Conducting Design Reviews For HVDC Converter TransformersDocument22 pagesGuidelines For Conducting Design Reviews For HVDC Converter TransformersAnonymous CqddyPpbNo ratings yet

- AMR 416 VR SeriesDocument44 pagesAMR 416 VR Seriesjoel osortoNo ratings yet

- IEEE C57.12.00 Test Tables 1 & 2Document6 pagesIEEE C57.12.00 Test Tables 1 & 2Galih Trisna NugrahaNo ratings yet

- HV Equipment Failure Data 2017Document164 pagesHV Equipment Failure Data 2017ipraoNo ratings yet

- A Summary of NEETRAC On-Line Frequency Response Analysis (FRA) A New EPRI Commercial Prototype FRA Installation at First EnergyDocument24 pagesA Summary of NEETRAC On-Line Frequency Response Analysis (FRA) A New EPRI Commercial Prototype FRA Installation at First EnergyTung Nguyen AnhNo ratings yet

- Instrument Transformers Catalogue PDFDocument12 pagesInstrument Transformers Catalogue PDFErdyNo ratings yet

- Substations Maintenance PlanDocument8 pagesSubstations Maintenance PlanGurudatt SHNo ratings yet

- ETI - PSI - 124 (07-95) - ScottDocument60 pagesETI - PSI - 124 (07-95) - ScottaniketpawasheNo ratings yet

- 2015 Inmr World Congress Final ProgramDocument3 pages2015 Inmr World Congress Final ProgramAbdou AbdellahNo ratings yet

- TRENCHDocument13 pagesTRENCHSimon Caceres100% (1)

- Switch BoardDocument20 pagesSwitch BoardAkhil NairNo ratings yet

- BS 159 1992Document16 pagesBS 159 1992Kalaimany ArumuggamNo ratings yet

- AWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamFrom EverandAWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamRating: 5 out of 5 stars5/5 (1)

- Computer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityFrom EverandComputer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityRating: 4.5 out of 5 stars4.5/5 (13)

- The Compete Ccna 200-301 Study Guide: Network Engineering EditionFrom EverandThe Compete Ccna 200-301 Study Guide: Network Engineering EditionRating: 5 out of 5 stars5/5 (4)

- Alcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsFrom EverandAlcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsNo ratings yet

- PHP BLUEPRINT: An Essential Beginners Guide to Learn the Realms of PHP From A-ZFrom EverandPHP BLUEPRINT: An Essential Beginners Guide to Learn the Realms of PHP From A-ZNo ratings yet

- ITIL 4: Digital and IT strategy: Reference and study guideFrom EverandITIL 4: Digital and IT strategy: Reference and study guideRating: 5 out of 5 stars5/5 (1)

- Microsoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsFrom EverandMicrosoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsNo ratings yet

- Hacking Network Protocols: Complete Guide about Hacking, Scripting and Security of Computer Systems and Networks.From EverandHacking Network Protocols: Complete Guide about Hacking, Scripting and Security of Computer Systems and Networks.Rating: 5 out of 5 stars5/5 (2)

- Concise Guide to OTN optical transport networksFrom EverandConcise Guide to OTN optical transport networksRating: 4 out of 5 stars4/5 (2)

- Evaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsFrom EverandEvaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsRating: 5 out of 5 stars5/5 (1)

- Designing and Building Security Operations CenterFrom EverandDesigning and Building Security Operations CenterRating: 3 out of 5 stars3/5 (3)

- Software-Defined Networks: A Systems ApproachFrom EverandSoftware-Defined Networks: A Systems ApproachRating: 5 out of 5 stars5/5 (1)

- CCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationFrom EverandCCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationNo ratings yet

- Mastering Linux Security and Hardening - Second Edition: Protect your Linux systems from intruders, malware attacks, and other cyber threats, 2nd EditionFrom EverandMastering Linux Security and Hardening - Second Edition: Protect your Linux systems from intruders, malware attacks, and other cyber threats, 2nd EditionNo ratings yet

- Amazon Web Services (AWS) Interview Questions and AnswersFrom EverandAmazon Web Services (AWS) Interview Questions and AnswersRating: 4.5 out of 5 stars4.5/5 (3)

- FTTx Networks: Technology Implementation and OperationFrom EverandFTTx Networks: Technology Implementation and OperationRating: 5 out of 5 stars5/5 (1)