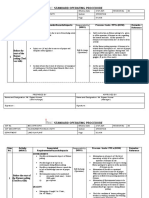

DOCUMENT: Checklist DOC. NO.

DIVISION: SH & S REV. NO. 02

DEPARTMENT: Workplace Safety SHEET 1 of 12

SECTION: Safety Standard

TITLE: GAP Assessment in Deployment of Relevant Safety Standards

DEPARTMENT / LOCATION: …………………...................... DATE: ……………………..

HIGH-Good Compliance

Sl. No. POINTS TO (above 80%) /TO

BE CHECKED MEDIUM- Needs

IMPROVE Improvement

SCORE CARD (50High

to-79 %) / LOW- System

Medium Low Inconsistent (below 50%)

Remarks

1 Field Safety Management – Safety leadership % Compliance =

Is safety visit conducted in planned approach and

1.1

compliance being monitored?

Union committee members/ Contractor proprietors /

1.2 Front line officers or supervisors accompanied during

safety visit by leadership team

Is there any tracking of compliance of various safety

campaigns/ CFT audit report by leadership team in

1.3

monthly safety committee meeting or any other review

forum?

Coverage of safety visit in process safety, contractor

1.4

safety, peripheral areas and logistics.

Quality of investigation of High potential incidents / near

1.5 misses and LTIs cases are reviewed and deployment of

recommendations are being tracked.

Leadership chair and review the safety performance of

1.6 department in their AIC/ DIC /safety committee

meetings.

Based on analysis of safety observations/ Line walk

reports and other safety audit reports, department is

1.7

driving focussed safety campaign to improve the

compliance of safety standards.

The consequence management is applied on officers as

1.8 per consequence management guideline for the LTIs and

high potential incidences and near misses.

Reward and recognition to employees, officers,

1.9 supervisors, contractors are done on regular basis based

on their safety performance.

2 Work Permit System % Compliance =

Are our own as well as contract employees adequately

aware about work permit system, their responsibilities as

2.1

executor, issuer and working agency as per work permit

system standard?

Whether all the pre-requisite forms & work permits are

being issued as per the process flow mentioned in the

work permit system for different conditions (central

2.2

agency involvement, ownership transfer to Maintenance/

Engineering Projects, daily supply contract, ownership

transfer to vendor etc.)?

Is positive isolation for all energy sources, followed

2.3 before issuing work permit and lock numbers being

mentioned in the work permit wherever applicable?

2.4 Whether all the hazards related to work are identified

through SOP/JHA/six directional method

communicated to workforce before start of job?

� Whether work permit copies are being kept with

2.5

concerned agencies and retained for record purpose?

Compliance of work permit is part of safety audit and

2.6 noncompliance is monitored and consequence

management applied.

3 Positive Isolation % Compliance =

Whether Concept of Positive Isolation Procedure is clear

3.1

among own as well as among contractor employees?

Availability & condition of Locks & P.I. tools at the shop

3.2

floor is OK?

Do approved Energy Source Identification document &

3.3 approved control stop list (If applicable) with related SOP

available at shop floor?

Whether all the energy sources are isolated at the job

3.4 site? Whether company’s Employees and Contract

supervisors have put their locks?

Is ESI document available & linkage with SOP done and

3.5

deployed?

Do all equipment like Electrical Panels, Hydraulic &

3.6 Pneumatic Valves, Gas Line valves have provisions of

locking after Isolation?

As per specific Positive Isolation task, records of person

3.7 trained in Isolation Level-1, Level-1A & Level-2 are

available or not?

4 Confined Space Management % Compliance =

Has confined space master list been documented by the

4.1 department and being updated annually once? Are

display with Confined space number available?

Has training of each employee involved in Confined space

4.2

work been completed and documented?

Verify implementation of confined space standard

4.3 through past record of confined space work permit, In-

out register etc.

Verify awareness about the working procedure &

4.4

precautions in confined space among the employees.

Is Rescue arrangement (Oxy pack, stretcher, Rescue kit

4.5 and team, Oxygen / Multi Gas detectors) provided while

working in confined space job?

Are risks related to confined space identified in HIRA

documents? (Verify HIRA documents of job in confined

4.6

space and check whether all hazard related to confined

space are identified or not.

Are block diagrams with all isolation points marked,

4.7

available for all confined space?

Is ESI (Energy Source Identification) document available

4.8

for isolation of all energy sources for confined space?

5 Chemical & Gas Safety % Compliance =

Are the chemicals stored in safe manner and away from

5.1

heat or direct sun light?

5.2 Is the container / drum labelled and coded?

5.3 Is the storage area well ventilated?

5.4 Is grounding adequate in flammable liquids storage area?

Is safety shower available in working condition near the

storage area?

Is safety shower available in working condition near the

5.5

storage area?

Page 2 of 12

� Has Risk assessment been done for the chemical handling

5.6

& unloading job? (Verify HIRA documents).

Is dyke wall provided surrounding the storage tank?

5.7 (Minimum capacity of dyke should be 110% capacity of

the largest tank/storage).

Are MSDS (Material safety data sheet) displayed near the

5.8

chemical storage area?

Are all precautions or suggestions implemented as per

5.9

the MSDS at storage location?

Are visual signage’s related to hazards and PPEs displayed

5.10

at site as per the MSDS?

Is Gas cylinder storage area protected from direct

5.11

sunlight? Are full and empty cylinders stored separately?

Is minimum 3-meter distance maintained between two

Incompatible gas cylinders at storage? (Example bulk DA

5.12

& bulk Oxygen; bulk Hydrogen & bulk Oxygen, bulk LPG &

bulk Oxygen, toxic and flammable gas cylinders)

Are gas cylinders kept in upright position with proper

5.13

chaining and cap ?

Are adequate warning signs / labelling / no smoking

5.14 caution / safety instructions displayed in the gas cylinder

storage area?

Are the gas prone areas identified in the department? If

5.15 yes, is there provision to take gas clearance for working in

that area?

Do all the employees use portable gas detector in gas

5.16

prone area?

Does the area with gas has sufficient numbers of fixed

5.17

type calibrated CO detectors?

Whether gas safety emergency equipment's like Oxy-

pack, ELBA (Emergency Life Breathing apparatus), etc. are

5.18

available in healthy condition at the shop floor at

designated places?

Are all Gas pipe lines colour coded as per standard (IS

5.19

2379)?

Is procedure of gas line isolation available? (Verify ESI

5.20

documents)

Have locking arrangements for positive isolation been

5.21

made in all U-seals?

6 Working at Height % Compliance =

Has the entire fall arresting system used for working at

6.1 height been designed and approved by a qualified

person?

Does company has a system of regular inspection/audit

for the fall arresting equipment (Fall arrestor, lanyards,

6.2

retractable lifeline and full body harness) as per standard

checklist?

Employees and contract employees have been issued

6.3

Working at height Pass

Employees involved in the erection, dismantling, moving,

6.4 repairing, etc. of scaffolding have received training from a

competent person?

6.5 All scaffoldings are provided with “Safe to Use” tag?

7 Material Handling & Storage % Compliance =

Does the lifting tools & tackles (e.g. Chain blocks, shackle,

7.1

Hook, bearing safe working load and date of last

Page 3 of 12

� test/inspection? Has the lifting machinery been tested by

competent person yearly? Does the test record

maintained & available?

Does the driver / Operator of material handling mobile

7.2 equipment are trained and having license in the

operation of the particular lifting appliance?

Are any person/s found working below suspended load

7.3 while material handling and measures have been taken to

alert people such as siren display etc.

Whether the lifting tools & tackles are free from any

7.4 visible defect at site? Are all the wire ropes used for the

job free from knots, bird caging, kinks or core protrusion?

Whether the material handling related safety awareness

7.5

is satisfactory amongst own & contractor employees?

Whether materials stored at site, obstructing fire& smoke detectors and

fire detection panels, fire extinguishers, fire hydrant points,

7.6 first-aid equipment, lights, electrical switches, gas line drip pots,

Water seals and other emergency items? and clearance

of 1 meter is maintained

Are materials stored adequately secured to prevent

7.7 sliding, falling or collapse? Does the storage area is

barricaded? And SOP exists for material handling

Is the loading/ unloading area properly demarcated and

7.8 barricaded to prevent unauthorised person’s entry in

loading/unloading zone?

8 Electrical Safety % Compliance =

Are the people aware about the PPEs to be used while

entering in LV Electrical room, working in LV Electrical

8.1

system, working in HV Electrical system etc and

complying with it?

Is minimum PPE requirement, Hazards & precautions to

be taken, Electrical area layout diagram, Electrical Danger

8.2

Notice with Maximum Voltage Level are displayed at the

entrance of Electrical Room?

Are Danger boards confirming to IS, Shock treatment

chart in English / Hindi/Local Languages, Emergency

8.3 Action Plan with Emergency contact numbers, List of

Persons trained on CPR & first aid, Single Line Diagram

etc are displayed in Electrical Room?

Are the earth pits properly maintained, tested and test

value displayed? Are the Combined values within

8.4 maximum permissible 1 ohm? Whether proper earth

fault protection provided for the metallic body

equipment/ lighting etc?

Are there no loose wirings, exposed joints, Distribution

8.5 Box or Junction box in cover open condition in the

workplace?

Whether Emergency safety shower with drinking water

connection is provided & in operating condition in all HT

8.6

& Extra HT substation? Whether running drinking water

connection available at all HT & Extra HT substation?

Are the List of authorized SCC (supervisory competency

certificate) holders along with their License No. and

8.7

validity period & list of Positive Isolation Level#1, Level 1A

& Level #2 person displayed in the electrical control

Page 4 of 12

� room/Substation

Are proper LT & HT power testing devices, Insulation

mats and Emergency equipment’s (Oxy pack, stretcher,

8.8

First Aid box considering burn injury ) available at

Electrical sub stations?

Are All 220 volt light fitting (or incomer in DB feeding

more number of lights in case of existing installation)

which are permanently installed having RCBO (Residual

circuit breaker with overload) with maximum 100 milli

8.9

ampere and tripping time 100 millisecond protections?

Are all window and split AC fitted with P2 class capacitor

which is fire safe and power supply given through 30 mA

RCBO?

Are incoming barrier, phase barriers, positive isolation

8.10 locking facility etc available in the switchgears above

220V?

Are Fire Retardant Painting applied on Electrical cables as

per standard? Are Cable vault, cable tunnel areas kept

free from accumulation of materials that constitute

8.11 hazards from tripping, fire or explosion and is used as a

restricted entry place? Whether adequate precautions

taken for preventing Water logging in the cable vaults

and cable tunnels?

Are DCP & CO2 fire extinguishers in adequate numbers

8.12 available near the entrance and at strategic places in the

electrical rooms?

Are the HV & LV power cutting and getting procedures

8.13 being religiously followed along with positive isolation

procedure?

Are Fire alarms provided in all Electrical rooms, cable

vaults, cable tunnels, analyser rooms, PRS rooms and its

hooter are sounded at a 24x7 manned area like control

8.14

room, shift office etc and checked on regular interval? Are

combustible materials like grease, paint etc not

present in close proximity with live electrical equipment?

Are the electrical equipment like circuit breakers,

transformers, relays, busbars, cables, motors, generators,

8.15

lightning arrestor, measuring instruments etc regularly

tested and record maintained?

9 Temporary Electrical Connections % Compliance =

Are the temporary wiring powers cables laid with proper

safety measures so that they are not liable to physical

9.1

damage e.g. from sharp corners, doors & pinch points

etc?

Whether temporary cable which is laid overhead is

supported with insulated support structure and it is

9.2

ensured that the cable should be out of human and

equipment reach throughout its length?

If temporary cable is lying on floor is it properly covered

9.3 with insulation mat or passed through cable protector to

prevent physical damage as well as Slip/Trip/ Fall Hazard?

Are the temporary electrical joints properly covered with

9.4 insulation tape and over that with abrasive resistance

tape for mechanical protection as per standard?

Are the temporary electrical light fittings properly

9.5

clamped and metallic body structure earthed?

Page 5 of 12

� Whether in no case the Twin twisted wires is used for

9.6

temporary connections?

Whether it is ensured that even for the extension boards

and for temporary lighting, minimum TRS (Toughened

9.7

rubber sheath) cables, having continuous current rating

suitable for the required load, is being used?

Whether for temporary wiring also all safety

requirements like fuse protection, over current

protection, earth fault protection is provided as in the

9.8 case of permanent wiring as per the relevant Indian

Standards and IE Rules.?

Are all hand-held tools (such as handheld drill machine,

hand held grinder etc.) is protected through maximum

30mA rating double pole earth fault protection with 200

milliseconds Fault clearing time. Are the Portable

9.9 equipment/ tools which are not hand held (like

submersible pumps, dewatering pump, 415V & 240V

welding set etc.) protected through maximum 100mA

rating double pole earth fault protection with maximum

fault clearing time 100 milliseconds?

Whether Temporary wiring is being removed immediately

upon completion of the construction or the purpose for

9.10

which the wiring was installed?

10 Welding & Gas Cutting % Compliance =

Is the gas cylinder storage area isolated, protected from

10.1

sun light, with adequate ventilation?

10.2 Are full and empty cylinders being stored separately?

10.3 Are the cylinders being kept upright and chained?

10.4 Are cylinder caps in proper position, when not in use?

10.5 Are there any provisions to conduct leak test?

Are the falling of spatters from height being restricted by

10.6

proper barricading?

Are all arc welding and cutting cables completely

10.7

insulated?

Are the exposed portion of welding cable protected by

10.8

rubber and friction tape?

Are all frames of arc welding machine grounded

10.9

properly?

Is Wesguard safety device put in place, wherever

10.10

required?

10.11 Is the fire extinguisher readily available in working area?

Is the welding machine connected with separate circuit

10.12

breaker or switch fuse unit?

10.13 Is earth leakage protective device used?

10.14 Is Hot work permit in use wherever applicable?

Are Employees engaged in welding, cutting and other hot

10.15 jobs trained and capable to use fire equipment in case of

any fire emergency?

Are the Flash-Back arrestors with cut-off valves fitted to

10.16 the pressure regulator outlet of the oxygen outlet, and

other fuel gas outlets?

10.17 Welding Competency Certificate is available with Welder

Page 6 of 12

� or not?

11 Contractor Safety Management % Compliance =

Are the contractor workforce capable and competent

11.1 enough (Skilled manpower, Competent Supervisor, Site

Safety Supervisors etc.

Are Toolbox meeting conducted regularly before

initiating the job daily and the mass meeting being

conducted regularly? (Look for compliance of previous

11.2

TBM points raised by the contractor employees. Check

for the participation of CA/CO during TBM to verify (at

least once in a month)

Are standard (IS/EN) and right PPEs while performing the

job is being provided & usage is ensured for the

11.3

contractor workers? Are PPEs timely replaced? (Verify

through issue/replace records)

Are standard, certified and right tools & tackles,

equipment’s and calibrated safety gadgets (e.g. Gas

detectors) while performing the job? Are they aware of

11.4

the banned tools & tackles like an adjustable spanner,

Neon type pen tester etc. and whether they are using the

same?

Is a good housekeeping free from any slip / trip / fall

11.5

hazards at the working site are being maintained?

Does the contractor's supervisor & job owner conduct

safety audit at the site and corrective and preventive

11.6

action taken based on self-audit report specifically on 4 &

5 severity potential?

Does the six directional & proximity hazards are

communicated to all contract employees before starting

11.7

of a job?. Locational Emergency preparedness is known

to the contractor employees?

Does the contractor supervisor understand the SOP?

Does SOP briefing done by him to the workers before

11.8

starting the job? Risk assessment done by contractor

supervisor through JHA or re-calibrated risk matrix?

Are the contractor workers provided with good amenities

like toilet rest place, eating place etc.? What are the

11.9

Contribution to safety campaigns by the contractor for

promoting safety culture?

Reward & Recognition of CO, CA , CP, Contractor

11.10

supervisor and contractor worker.

12 PPE Management % Compliance =

Has a PPE gap assessment been conducted of the

12.1 workplace to determine if hazards are present, or are

likely to be present, that would require the use of PPE?

Has PPE been selected to protect employees from

12.2

hazards identified in the hazard assessment?

Are personal were wearing Safety Helmet with chin strap,

12.3 Safety Shoes with steel toe, Safety Goggle/Eye Protection

at work place?

Are safety belts used at site are approved quality and

12.4

checked periodically?

Respirator / Dust preventer is being used as desired

12.5

wherever applicable

12.6 Is hand Gloves of desired quality as per job requirement

Page 7 of 12

� ensured?

Is defective or damaged PPE removed from service

12.7

immediately?

Is PPE satisfaction index survey completed and Gaps are

12.8

used for improvement. ?

How the PPE related grievances are captured and

12.9

resolved systematically?

13 Fire Safety % Compliance =

Is Floor Plan with location of Fire Equipment (Fire Ext. &

13.1 Fire Hydrant) and type of extinguishers properly placed at

a prominent place/entrance of the Plant?

Are extinguishers available within 15M & Fire Hydrant

13.2

within 30M?

Are extinguisher placed near to the exit or near to

13.3

staircase without hindering the escape route?

Are Fire Extinguishers & Fire Hydrant installed (one) 1M

13.4

above ground level as per norms?

Is the date of inspection, next date of refill & party’s

13.5

signature available on the extinguisher?

Is HP (High Pressure) test of extinguishers done as per

13.6

standard norms?

13.7 Fire Hydrant inspection report available or not?

FDA system mapped and installed and FDA inspection

13.8

report is available.

Is smoking prohibited at all fuel source storage areas? Is

13.10 “No smoking” warning sign displayed at all these

locations?

Are waste bins located at safe distance from heat sources

and electrical equipment? Are waste bins emptied

13.11

regularly to avoid piling of waste material?

Is MSDS sheet available for all flammable/combustible

13.12

materials?

Are all flammable/combustible materials stored at

13.13

designated place?

Is Hazard warning sign and guideline board displayed at

13.14

storage area?

13.15 On site Emergency Preparedness plan available or not?

Mock Drill Plan available and conducted as per plan or

13.16

not?

Training conducted on Fire Extinguishers & Fire Hydrant

13.17

Operation or not?

List of First aider & ERT trained person available and

13.18

displayed at conspicuous places or not?

13.19 Fire Safety Measures at Vital Installation areas, if any?

14 Machine Guarding % Compliance =

14.1 Are all rotating parts of machines guarded?

Rotating parts of hand tools, such as grinder machine, are

14.2

guarded or not?

Are protective safety guards provided all around the

14.3 conveyor system (e.g. Head –ends, drives, tail-end, Idlers

& Belt side)?

14.4 Is pull chord available outside the guard?

In case of opening of the floor below, is necessary toe-

14.5

guard provided along the edge?

14.6 Is the small opening on guards provided for oiling and

Page 8 of 12

� greasing or for bolt tightening purpose?

14.7 Are the guards firmly secure and removable?

Does the machine automatically shut down when the

14.8

conveyor or machine guard is removed?

Does the guarding fulfill the purpose (Height/width/No

14.9

gap/Hands can not be inserted) of guarding?

Whether all pedestals fans or man cooler are guarded by

14.10

a Galvanized wire mesh?

15 A Standard for Cranes (EOT) % Compliance =

Safe Working Load, inspection date and due date

15 A.1

displayed on the EOT crane with identification number.

Annual inspection within 1 year maintained and record

15 A.2

maintained or not (Load Test due date/ Expiry date).

Display board for narrow gantry of EOT cranes if it is

15 A.3

narrow (Less than 50 cm).

Defined & displayed parking place of crane for safe

15 A.4

maintenance/Operation /Safety.

Over Hoist Limit switch, trial/ checking register is

15 A.5

available/ maintained or not?

Maintenance records of safety critical equipment (Safety

15 A.6

Switch, alarm, etc.) are available and working.

Safe access ladders with hand rails shall be provided at

convenient place for the crane operator or any other

15 A.7

person going to or coming out from the crane and record

maintained by crane Owner?

Minimum four lights shall be hung from the girder of the

15 A.8 crane so that the working area under the crane is

properly illuminated.

Work permit procedure followed or not for Crane

15 A.9

Maintenance?

If crane is under shutdown, red flag and wheel stopper

15 A.10

must be provided.

Crane operator Eye Testing followed and record

15 A.11

maintained as per legal requirement.

15 A.12 Is Trained Crane Operator operating crane?

Caution signage to be put at various locations on the

15 A.13

crane gantry/ walkway?

15 B Inspection of Mobile Cranes % Compliance =

Is record of Inspection done by competent persons of all

15 B.1 mobile cranes available & due date of inspection is

displayed on crane?

Does the operator has been trained from a Govt.

15 B.2

recognized institute/ SNTI/OEM?

Does the operator possess a valid Heavy Motor Vehicles

15 B.3 Driving License, Eye Test Certificate for wheel type mobile

cranes?

Is the appropriate load chart, angle indicator and safe

15 B.4 load indicator, related to the crane in use and displayed

on the crane as per applicability?

Does the crane operator having adequate understanding

15 B.5 & is proficient to use the load charts as related to the

equipment in use and the loads being lifted?

Daily inspection and maintenance records are maintained

15 B.6

and should be verified as per operator's manual.

Page 9 of 12

�15 B.7 Structural Integrity: The crane's main frame,

(Gantry/platform) crawler, track and outrigger supports,

boom sections, attachments all wire ropes, including

stationary supports, are all considered part of structural

components of operation. 100% NDT test to be done by

Govt. recognized agency once in a year as per checklist.

15 B.8 Trained Flag man/Operator deployed or Not?

15 B.9 Lifting plan is included with the Safety Task Analysis and

approved by competent person or the user department &

service provider.

15 B.10 Is area barricaded while mobile crane is in operation?

16 Safety & Safety Planning Review in MSD % Compliance =

When was the last major shutdown in the dept.? Was

16.1 MSD ( Shut down more than 48 hrs) PSSR done in Shut

down? Check the compliance status.

Is pre-shutdown planning meeting carried with all

stakeholders? Is formation of cross functional PSSR/ Audit

16.2

team done (Refer Tata Steel safety standard Annexure #4

as per SS/GEN-49? Check MoM record of the same.

Are spares, tools, tackles, safety gadgets (to be used)

16.3 checked for good quality, right specification and

calibration?

What are the measures to ensure the pre-shutdown

16.4 activities completed before starting of Major shutdown

as per as per SS/GEN-49?

Is there training to contractor employees covering all

16.5 applicable SOPs & standards before MSD? Check record

for the same.

Does the audit & review process during MSD exists? How

16.6 many observations were identified and closed? Verify the

applicable document.

Are all the Major shutdown learnings reviewed in

16.7 departmental AIC? Are there any preventive actions

planned, to be incorporated for next Major shutdown?

Is waste management planned and executed on daily

16.8 basis and housekeeping maintained properly during shut

down?

Is amenities of contractor employees (Rest, taking food,

16.9 toilet facility) planned in advance as per amenities

standard? Check the deployment, if possible.

Is there any MOC identified through PSSR during MSD?

16.10

Check the progress/ status of MOC, if identified?

Restricted Entry of Unwanted & Unauthorized Personnel at Workplace/ in Hazardous Areas

17

% Compliance =

Department has provision to restrict entry of unwanted/

unauthorized persons in their high hazard area by

providing access control, displaying visual cautionary

17.1

signage at prominent location, CCTV at entrance and the

restricted places to identify and control unauthorized

entry.

Is there any provision to identify of unauthorized persons

17.2

and monitoring system for access control in an area?

Pathways and signage for safe access to the drinking

17.3 water, canteen/ eating place, toilets, urinals, movement

to workplace, rest area etc. are clearly marked/

Page 10 of 12

� identified.

Adequate and suitable lighting are provided and

maintained in every part of the department including

17.4

yards and open spaces where any person may be

deployed to work or he/ she may have to pass through.

System is there to check that all employees/ contract

employees leave the work place after completion of their

17.5 duty hours with information to their respective superior

and go out of Factory premises unless they are asked to

overstay.

Department’s employees stop unauthorized entry of

17.6 people in their area and the same is being discussed and

reviewed in departmental meetings.

Does the area have sufficient opening to escape during

17.7

any emergency?

Are the drop gates and other means of access control

17.8

operational?

18 Pre-Start Up Safety Review (New Installation) % Compliance =

Officers are aware and trained on PSSR ( Pre start up

18.1

safety review) safety standard

Is PSSR conducted for the new facility or after major shut

18.2

downs (shut down more than 48 hrs).

19 Management of Change % Compliance =

How does department identify the critical safety

Changes? Does system exist for monitoring and checking

19.1

the safety suggestions and improvement through MoC

system applicability?

19.2 Check the awareness on MOC standard at field ?

Does Cross Functional Team, Technical Review

19.3

Committee Team defined in dept. as per section/area?

Check the status of logged MOC (Approval process,

19.4

overdue, etc.) for its completion

How many MoC for which Risk Assessment- PHA (Process

19.5 safety) / HIRA (Workplace safety) has been conducted?

Check out the quality of the Risk Assessment.

Do all applicable documents pertaining to any particular

19.6 MoC such as PSI, SOP, PI&D, Training etc. are updated

and communicated to relevant stakeholders.

20 Road & Transportation Safety % Compliance =

Whether any road safety standard violation by

20.1 departmental vehicles/ employees/ contract partners

observed during the audit? (%)

Are supervisors, drivers and others, including contractors

20.2 and visiting drivers, aware of the SOP followed in that

area?

Whether the load is properly secured during

20.3 transportation by vehicle and adequate spillage

protection measures are taken?

Whether the heavy vehicle condition is as per norms &

20.4 the driver is conducting daily inspection & filling the

checklist?

20.5 Does the Loading / Unloading done at designated place

Does the loading/ unloading points marked and displayed

20.6

with safety precautions.

Page 11 of 12

� Is there a safe route for pedestrian and kept apart from

20.7

the path of movement of vehicles?

Is repair and maintenance job of vehicles done at safe

20.8

place

Are parking brakes, wheel choke always used to prevent

20.9

unwanted roll over of vehicles?

Are vehicle drivers kept in a safe place away from the

20.10

vehicle while loading / unloading is carried out?

Are Hazards in the loading /unloading area displayed with

20.11

Dos and Don’ts at critical points

Are parking brakes, wheel choke always used to prevent

20.12

unwanted roll over of vehicles?

Blind spot from the vehicles has been removed by placing

20.13

camera and other mirrors

Is the vehicle being parked at the designated parking and

20.14

facing outwards?

Assessment Team:

1.

2.

3.

4.

5.

6.

Disclaimer:

This assessment report is based on sample audit conducted for the selected standards and locations.

Auditors had drawn conclusions on the compliance status of the facility based on conditions observed and information provided during the period of

time the auditors are on site.

Although professional care had been taken in picking a valid sample and effort had made to ensure the accuracy of this report, but still there is a

possibility of missing the non-compliance or showing compliance against the criteria exist, which may not represent the true picture of department.

Department should revisit all the findings including the compliance part and shall perform internal assessment to validate the same. If any such

Page 12 of 12