Professional Documents

Culture Documents

Icaf Aislamiento y Proteccion Personal

Uploaded by

Miguel Martinez GuerreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Icaf Aislamiento y Proteccion Personal

Uploaded by

Miguel Martinez GuerreroCopyright:

Available Formats

1 2 3 4 5

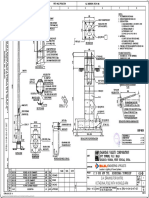

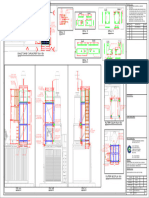

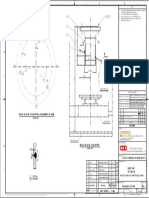

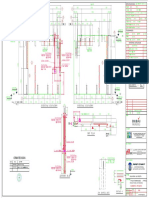

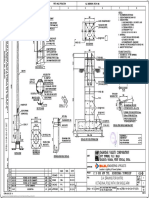

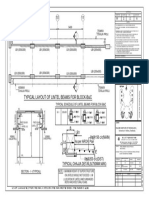

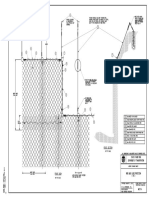

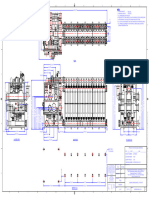

INSULATION NOTES:

FLOATING RING 1. HORIZONTAL VESSELS OVER 1500mm SHALL BE PROVIDED WITH AT LEAST TWO LONGITUDINAL SUPPORTS.

T.L.

T.L.

(TYP.)

25.4 mm SEPARATION 2. ALL DIMENSIONS ARE IN mm UNLESS NOTED UNIT.

BETWEEN DRIPPING 6.4

3. VESSEL SUPPLIER SHALL FURNISH AND INSTALL SUPPORTS AS REQUIRED.

RING AND COLLAR 4. ALL MATERIAL WELDED TO VESSEL TO BE THE SAME MATERIAL AS THE VESSEL. ALL OTHER MATERIAL TO BE

INSUL. THK + 25.4 mm

CARBON STEEL.

5. INSULATION ARE FURNISHED AND INSTALLED BY OTHERS

6. SPECIFICATIONS: NRF-034-PEMEX-2011, NOM-009-ENER-1995

FLANGE BOLT

LENGTH

EQUALLY SPACED SUPPORT 7. VESSEL SUPPLIER SHALL THOROUGHLY CLEAN ALL SURFACES TO REMOVE OIL, GREASE, LOOSE SCALE, DIRT

OF 3/8" THK. PLATE ETC. BEFORE ATTACHING SUPPORT PARTS.

(600 MAXIMUM)

TOE PLATE

8. DOUBLE LAYER INSULATION SHALL BE USED ONLY WHEN SPECIFIED

A DRIPPING RING OF 9. SELLER SHALL CONSIDER THE FOLLOWING ASPECTS OF INSULATION FOR PERSONNEL PROTECTION:

15.0000°

GRATE 9.53 THK. A. ALL PROTRUSION IN EQUIPMENT MUST BE ISOLATED AT LEAST AT A DISTANCE OF 4 TIMES THE THICKNESS

USED TO PREVENT BURNS TO PERSONNEL.

B. SELLER SHALL CONSIDER SHEET GAGE 12 OF STEEL STAINLESS TYPE 304 WITH PERFORATIONS

FOR DETAILS

25 SEE SECCTION "A-A" NO LARGER OF 12.7 mm (1/2 in) OF DIAMETER. SEE DETAIL "C" THE PERSONNEL PROTECTION SHOULD

METAL STRIP *

DRAWING ART-02-300-H-PL-0300 BE SEPARATED FROM THE SHELL AT LEAST 127mm (5 in). THE SEPARATION FINAL WILL BE

(TYP)

(SHEET 11 OF 15) SEAL SHEET METAL * PROVIDED DURING DETAIL ENGINEERING.

51

C. THE SUPPORTS MUST BE THE SAME MATERIAL EQUIPMENT JOINT BY WELDING. THE NUMBER

OF SUPPORTS SHOULD BE SUFFICIENT TO KEEP STEADY THE PERSONNEL PROTECTION, BUT MUST NOT

BE LESS OF THREE SUPPORTS AND SPACING BETWEEN SUPPORTS SHOULD NOT BE GREATER THAN

SHEET METAL * 600 mm (23.6221 in).

D. PERSONNEL PROTECTION MUST BE INSTALLED AT LEAST FROM 2150mm FINISHED FLOOR LEVEL

OR PLATFORM FLOOR.

E. EXTENT OF PERSONNEL PROTECTION SHALL BE SHOWN ON INDIVIDUAL EQUIPMENT PERSONNEL

PROTECTION DRAWING FOR SPECIFIC ITEM.

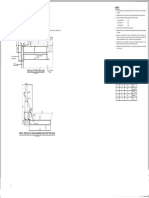

SEE DETAIL "A" SEE DETAIL "A" F. EXPANDED METAL SHALL BE PRE ROLLED OR FORMED WITH ALL EXPOSED EDGES CUT SUCH THAT

T.L.

FULL DIAMONDS FORM A CLEAN EDGE AND ALL SHARP EDGES ARE SMOOTH AND FREE OF BURRS.

50 G. ALL PARTS SHALL BE IDENTIFIED WITH A METAL TAG INDICATING ITEM NO., P.O. NO., AND PC.MK.

NO. INSTALLATION HARDWARE (INCLUDING STAND-OFFS) SHALL BE BOXED AND TAGGED AS ABOVE

(TYP.) WITH TEN PERCENT (10%) EXTRA TO ACCOUNT FOR LOSS OR DAMAGE.

IN VESSEL INSIDE DIAMETER GREATER DETAIL "B" 10 DIA. C.S. ROD H. FOR PERSONNEL PROTECTION AT LADDERS SERVING TOP HEAD PLATFORMS, EXPANDED METAL

IN VESSEL WITH INSIDE DIAMETER LESS OF 2500 mm,

OF 2500 mm BE SUBJET WITH STUD SELF WEDING FLOATING RING SHALL EXTEND TO THE TOP HEAD SEAM EXCEPT AS NOTED ON INDIVIDUAL EQUIPMENT

PLACE NUTS WELDED IN PARALLEL ROWS TO AXIS

VESSEL, WITH 610 mm SEPARATION. SIZE OF NUTS TYPE MS-1 IN AN SUFACE OF 8 TO 11 STUDS/m2 FABRICATOR SHALL TIE-OFF PERSONNEL PROTECTION DRAWING.

MUST BE OF 19 mm OR GREATER, BUT LESS 6mm THE STUDS MUST BE AN LENGTH OF 6 mm 10 DIA. ROD FOR SHIPMENT. I. WHEN TWO ISOLATED SECTIONS ARE SEPARATED BY A DISTANCE LESS THAN

THAT THE THICKNESS OF THE INSULATION

SIDE VIEW GREATER THAT THICKNESS INSULATION, AFTER 2500, PERSONNEL PROTECTION SHOULD BE CONTINUED.

PLACE THE INSULATION SHOULD BE CUT LESSER

B THAT INSULATION

* BY OTHERS

MIN.

TOP HEAD SEAM

SEE NOTE-H

EQUALLY SPACED

BTM. ROW OF STAND-OFF CLIPS

BOTTOM HEAD SEAM

TOP OF FIREPROOFING

SEE DETAIL "A" SPACER RODS

VERTICAL VESSEL OR HEAT EXCHANGER

460 APART INSUL. THK. (-) 13

PERSONNEL

PROTECTION

152 FIREPROOFING

SPACER ROD

C HORIZONTAL SUP'T.

& SPACER RODS

(REF)

ELEVATION

458

CL LADDER

(REF)

458

5

C HORIZONTAL SUP'T.

458

DETAIL "A"

& SPACER RODS

10 DIA. ROUND BAR

BOTTOM HEAD SEAM

PERSONNEL

PROTECTION SURFACE TEMPERATURE

SHALL NOT EXCEED 45°C.

C

915 2134 610 FOR NON-FIREPROOFED

45 SKIRTS

END VIEW 8

CL TOP RUNG TOP OF PLATFORM GRATING

OR CHECKERED PLATE

PLAN VIEW

EDGE OF PLATFORM DETAIL "C"

PERSONNEL

PROTECTION WITH WELDED NUT

BOLTS OR STUDS

TYPE 304 STAINLESS STEEL

MIN. GAGE 12 SHEET WITH

(TYP) PERFORATIONS NO LARGER

THAN 13 mm (1/2 in) IN DIAMETER

AREA OF EXPOSURE WASHER OF THE

SEE NOTE-E ELASTOMERIC

SAME MATERIAL

SEALING WASHER

AS THE BOLT

INSULATING MATERIAL 6

(PTFE, BAKELITE) WITH

SURFACE TEMPERATURE 3mm OF THK. OR MORE

SHALL NOT EXCEED 45°C. AREA OF EXPOSURE

SEE NOTE-E AND I

BOLTS OR STUDS DETAIL "D"

END VIEW

THREADED FASTENER

SIDE ELEVATION

MATERIAL STAINLESS STEEL PERSONNEL PROTECTION

D DETAIL "E" SUPPORT

HORIZONTAL VESSEL OR HEAT EXCHANGER Cr 500

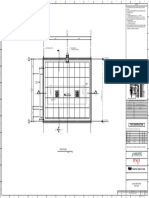

C.P. FECHA R E V I S I O N E S NUM. DIBUJOS DE REFERENCIA SUPERVISIÓN POR PTI-ID INICIALES

REV. D E S C R I P C I Ó N FECHA POR APR.

DIBUJÓ: ENRIQUE ANDRES

By LUIS ENRIQUE ANDRES JOAQUIN at 9:18 am, Feb 27, 2020

L.E.A.J. Suministro e Instalación de Módulos, Refinería Dos Bocas

A EPR - EMITIDO PARA REVISIÓN Y COMENTARIOS 27/FEB/2020 L.E.A.J. G.C.P. DISEÑÓ: MIGUEL NAVARRETE

INICIALES Planta de Alquilación

By Miguel Navarrete at 12:36 pm, Feb 27, 2020

M.A.N.H.

ESPECIALISTA TÉCNICO

REVISÓ: GABRIEL CASCANTE

By Gabriel Cascante Pérez at 1:18 pm, Feb 27, 2020

INICIALES

G.C.P.

DETALLES DE SOPORTES PARA AISLAMIENTO PARA SERVICIO

INICIALES DE ALTA TEMPERATURA Y PROTECCION CONTRA FUEGO 2

COORDINADOR DE ESPECIALIDAD APROBÓ: L. BECERRA / B. FRANCO LGBN / BDFD

By LUIS GERARDO BECERRA at 6:55 pm, Feb 27, 2020

"ESTE DOCUMENTO CONTIENE INFORMACIÓN CONFIDENCIAL Y PROPIETARIA, QUE NO

DEBE SER PUBLICADA A OTROS, REPRODUCIDA Y UTILIZADA PARA INICIALES

OTRO PROPÓSITO QUE NO SEA PARA EL CUAL FUE ELABORADO, SIN PERMISO AUTORIZÓ: PROYECTO No.: NÚMERO DE DIBUJO: REV.

PREVIO Y POR ESCRITO DE ICA FLUOR Y PTI-ID"

CONTRATO No.: PTI-ID-MOD-003-2019 DIBUJO ELABORADO EN: MÉXICO, CDMX FECHA: 27/FEB/2020 ESCALA: S / ESC. ACOT.: mm LUGAR: R2BP3-210-02-H-PL-00116 A

COORDINADOR DE INGENIERÍA PARAISO, TABASCO

NOMBRE DEL ARCHIVO: R2BP3-210-02-H-PL-00116_A.DWG

You might also like

- Unit Weight KG 0.2 2: RevisionsDocument1 pageUnit Weight KG 0.2 2: RevisionsANIL PLAMOOTTILNo ratings yet

- Electrical DesignDocument1 pageElectrical DesignTrikam PatelNo ratings yet

- 001 - Typical Detail of Floor Expansion Joint Ej-02 (PJC-6 PJCL-6)Document1 page001 - Typical Detail of Floor Expansion Joint Ej-02 (PJC-6 PJCL-6)Varunn VelNo ratings yet

- Detail Plan: Standard Dpwh-Deped One (1) Storey Unique Workshop BuildingDocument1 pageDetail Plan: Standard Dpwh-Deped One (1) Storey Unique Workshop Buildingglen raymundoNo ratings yet

- SP & SSPDocument2 pagesSP & SSPveerendrareddyNo ratings yet

- Elevation: NotesDocument1 pageElevation: NotesErika Faye GutierrezNo ratings yet

- Notes:: SWCC 24 FOC Depth XX MP # 0001 Additional Info Project NameDocument1 pageNotes:: SWCC 24 FOC Depth XX MP # 0001 Additional Info Project NameGousePeerzadeNo ratings yet

- Ground Floor: B RA-620717 001 B 961 G203Document1 pageGround Floor: B RA-620717 001 B 961 G203muthuvelaaNo ratings yet

- Foundation Notes:-: G.A. Drawing For 6 Mtrs. Octagonal Pole With 1M Single ArmDocument1 pageFoundation Notes:-: G.A. Drawing For 6 Mtrs. Octagonal Pole With 1M Single ArmP.MannaNo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 55Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 55waz ahmedNo ratings yet

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- 1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLDocument1 page1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLMANOJTRIVEDI100% (1)

- 2495 000 JSS 1684 51 - BDocument23 pages2495 000 JSS 1684 51 - BSinaNo ratings yet

- Filter: Saudi Arabian Oil CompanyDocument1 pageFilter: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Lok Heng Site Caged Ladder 15 DisDocument1 pageLok Heng Site Caged Ladder 15 DisJebat DerhakaNo ratings yet

- WH2 GaDocument5 pagesWH2 GaRaveendra Babu CherukuriNo ratings yet

- 10040 00 133 ES 0003 - rev01保温保冷手册指南 PDFDocument25 pages10040 00 133 ES 0003 - rev01保温保冷手册指南 PDFJimlemonNo ratings yet

- Plano Mecanico de Detalle - Py UtpDocument1 pagePlano Mecanico de Detalle - Py UtpnelsonNo ratings yet

- Válvula de Cilindro 69S411RDocument1 pageVálvula de Cilindro 69S411RHuber Pucuhuayla RojasNo ratings yet

- Brickell Key Ii - A2-03 - Sections and Details - V1Document1 pageBrickell Key Ii - A2-03 - Sections and Details - V1dianaNo ratings yet

- 13-11-2019 - FLOATING STAIR DETAILS-ModelDocument1 page13-11-2019 - FLOATING STAIR DETAILS-ModelkalpanaNo ratings yet

- TCS - MOD - 01 To 07-Dwg-HIGH EMBK PDFDocument1 pageTCS - MOD - 01 To 07-Dwg-HIGH EMBK PDFAnas KhanNo ratings yet

- Detail: Scale: NtsDocument1 pageDetail: Scale: NtsANIL PLAMOOTTILNo ratings yet

- DN Stream Side Up Stream Side: CL HighwayDocument1 pageDN Stream Side Up Stream Side: CL HighwayVikas SharmaNo ratings yet

- Iso View: All Process Connections Must Be Flexible and Have A Slope Greater Than 20° To Prevent Sanding OutDocument1 pageIso View: All Process Connections Must Be Flexible and Have A Slope Greater Than 20° To Prevent Sanding OutAntonio Segura FuentesNo ratings yet

- LIFT Layout1Document1 pageLIFT Layout1nikita chawlaNo ratings yet

- CRWN Revision: Internal Elevation External ElevationDocument1 pageCRWN Revision: Internal Elevation External ElevationMohammad YusufNo ratings yet

- Epbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalDocument1 pageEpbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalP.MannaNo ratings yet

- Epbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFDocument1 pageEpbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFP.MannaNo ratings yet

- CS Sta 0000 0006 PDFDocument1 pageCS Sta 0000 0006 PDFBALA kNo ratings yet

- NS2-VW00-P0UEW-173021 - FA Transfer Compressor Shelter - Ground Floor PlanDocument1 pageNS2-VW00-P0UEW-173021 - FA Transfer Compressor Shelter - Ground Floor PlanLê Quốc TínNo ratings yet

- Ns2-Vw00-p0uyq-174224 Vehicle Repair Shop Roof Plan Rev.0int1Document1 pageNs2-Vw00-p0uyq-174224 Vehicle Repair Shop Roof Plan Rev.0int1Doan Ngoc DucNo ratings yet

- Thread Draw CadDocument1 pageThread Draw CadJePongNo ratings yet

- B&C Lintel Details-Block-B&cDocument1 pageB&C Lintel Details-Block-B&cozu1ssasNo ratings yet

- Flow Control Chamber DdrawingDocument1 pageFlow Control Chamber DdrawingPranav KumarNo ratings yet

- PID Booklet As Built Without PFD Rev - Part75Document1 pagePID Booklet As Built Without PFD Rev - Part75megarezky235No ratings yet

- TCS - MOD - 01 To 07-Dwg-FILL-CUT PDFDocument1 pageTCS - MOD - 01 To 07-Dwg-FILL-CUT PDFAnas KhanNo ratings yet

- Structural 1Document9 pagesStructural 1manglicmotabigail11No ratings yet

- ABN-MTA90 - Rev ADocument2 pagesABN-MTA90 - Rev AkippcamNo ratings yet

- Anchor Foundation Detail On Standard: Anchor Locations Anchors Spaced Every 3.5M (Refer To TypicalDocument1 pageAnchor Foundation Detail On Standard: Anchor Locations Anchors Spaced Every 3.5M (Refer To TypicalJUAN RULFONo ratings yet

- Dn107-P01a-Qbs-Pw-7001 7003 Rev00 - (Woc)Document3 pagesDn107-P01a-Qbs-Pw-7001 7003 Rev00 - (Woc)moon arainNo ratings yet

- NEWS STUDIO BS-16 - 1 - 10243 - 2f88e925Document2 pagesNEWS STUDIO BS-16 - 1 - 10243 - 2f88e925Prajwal ShettyNo ratings yet

- TCS - MOD - 01 To 07-Dwg-YARD PDFDocument1 pageTCS - MOD - 01 To 07-Dwg-YARD PDFAnas KhanNo ratings yet

- Amphenol ZEUS High-Voltage ROV Connector SeriesDocument2 pagesAmphenol ZEUS High-Voltage ROV Connector SeriesVinicius PereiraNo ratings yet

- 2301 - Friction Slab - DD01Document1 page2301 - Friction Slab - DD01ShivamKumarNo ratings yet

- 03.08.16 Karama HC Plans - Revision 1-GF-RCP)Document1 page03.08.16 Karama HC Plans - Revision 1-GF-RCP)Ashiq NishmaNo ratings yet

- 16 Roof Plan For Flat RoofDocument1 page16 Roof Plan For Flat Roofmohammed amir aliNo ratings yet

- PDF Crop PDFDocument1 pagePDF Crop PDFAditiNo ratings yet

- Center Line: Specific Notes Approvals From Architects OfficeDocument1 pageCenter Line: Specific Notes Approvals From Architects OfficeSimran KaurNo ratings yet

- Project On Residential Building: Sunken Slab DetailDocument1 pageProject On Residential Building: Sunken Slab DetailPraveen G MNo ratings yet

- Uep00259 Ga 15 01 - 20230907TTDocument6 pagesUep00259 Ga 15 01 - 20230907TTEduardo ArrietaNo ratings yet

- Bus StopDocument1 pageBus Stopshurl88No ratings yet

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- Reinforcement Details of Pile, Pile Cap & Pier, Pier Cap.Document1 pageReinforcement Details of Pile, Pile Cap & Pier, Pier Cap.Birendra Kumar DhamiNo ratings yet

- Top View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningDocument2 pagesTop View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningPunky IrlanditoNo ratings yet

- 2+2 Jodi PlanDocument1 page2+2 Jodi Planshashank waghmareNo ratings yet

- TCS - MOD - 01 To 07-Dwg-CURVE PDFDocument1 pageTCS - MOD - 01 To 07-Dwg-CURVE PDFAnas KhanNo ratings yet

- 611.1-35-Sheet 1Document1 page611.1-35-Sheet 1RogersNo ratings yet

- Uecp-Sd-Cul - 12.1-R00Document3 pagesUecp-Sd-Cul - 12.1-R00Anuradha KoswaththaNo ratings yet

- Recubrimiento Especificacion 20072-O-201Document18 pagesRecubrimiento Especificacion 20072-O-201Miguel Martinez GuerreroNo ratings yet

- Tank Weights: Mechanical Engineering Tank Reference Manual Rev. Date: SECTION: 3.2 12-95Document6 pagesTank Weights: Mechanical Engineering Tank Reference Manual Rev. Date: SECTION: 3.2 12-95Miguel Martinez GuerreroNo ratings yet

- 4.2 Miscellaneous Data and Design in TanksDocument5 pages4.2 Miscellaneous Data and Design in TanksMiguel Martinez GuerreroNo ratings yet

- 4.5 External Pressure Design For Flat Bottom Cone Roof (RBCR) TanksDocument7 pages4.5 External Pressure Design For Flat Bottom Cone Roof (RBCR) TanksMiguel Martinez GuerreroNo ratings yet

- 4.3 Basic Design Awwa D100 & Api 650Document7 pages4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- II Tank Capacities: Mechanical Engineering Rev. Date Section 3.1 Tank Reference Manual PageDocument6 pagesII Tank Capacities: Mechanical Engineering Rev. Date Section 3.1 Tank Reference Manual PageMiguel Martinez GuerreroNo ratings yet

- Pipe & Mechanical InsulationDocument36 pagesPipe & Mechanical InsulationMiguel Martinez GuerreroNo ratings yet

- Tipos de Aletas para Tubos AletadosDocument8 pagesTipos de Aletas para Tubos AletadosMiguel Martinez GuerreroNo ratings yet

- Rti Brochure Astm Compliance Chart Na enDocument2 pagesRti Brochure Astm Compliance Chart Na enMiguel Martinez GuerreroNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- Insulation Materials Spec Chart Updated JULY 2016Document2 pagesInsulation Materials Spec Chart Updated JULY 2016instagram agnesNo ratings yet

- Tipos de Aletas para Tubos AletadosDocument8 pagesTipos de Aletas para Tubos AletadosMiguel Martinez GuerreroNo ratings yet

- Specification Compliance: and Reference GuideDocument12 pagesSpecification Compliance: and Reference GuideMiguel Martinez GuerreroNo ratings yet

- Especificacion de Ingenieria E-401 Requirement For Design and Fabircation of Destillation Tower Plates and InternalsDocument16 pagesEspecificacion de Ingenieria E-401 Requirement For Design and Fabircation of Destillation Tower Plates and InternalsMiguel Martinez GuerreroNo ratings yet

- 512-ET-08-REV-1-Atmopheric TanksDocument17 pages512-ET-08-REV-1-Atmopheric TanksMiguel Martinez GuerreroNo ratings yet

- Astm A182 PDFDocument17 pagesAstm A182 PDFJacarrero100% (1)

- What's Where On Earth Atlas - DKDocument162 pagesWhat's Where On Earth Atlas - DKMiguel Martinez Guerrero100% (2)

- Astm D2143 - 2005 PDFDocument3 pagesAstm D2143 - 2005 PDFMiguel Martinez GuerreroNo ratings yet

- ASME Interpretation VIII-1!16!85Document1 pageASME Interpretation VIII-1!16!85Miguel Martinez GuerreroNo ratings yet

- D 2239 - 03 - Rdiymzk - PDFDocument7 pagesD 2239 - 03 - Rdiymzk - PDFAndre CasteloNo ratings yet

- 11Document26 pages11Anonymous f5gNPeZDCNo ratings yet

- Astm e 165Document17 pagesAstm e 165adrianhhhh1984No ratings yet

- Bandlock™ 2: Quick Opening ClosureDocument4 pagesBandlock™ 2: Quick Opening ClosureRraffrizal ChandsNo ratings yet

- Astm e 84Document19 pagesAstm e 84Miguel Martinez GuerreroNo ratings yet

- IMOA Shop Sheet 101Document2 pagesIMOA Shop Sheet 101zhiqianxuNo ratings yet

- (UNS N08904) : NAS High Corrosion Resistant Stainless SteelDocument4 pages(UNS N08904) : NAS High Corrosion Resistant Stainless SteelMiguel Martinez GuerreroNo ratings yet

- MarineAnodes PDFDocument4 pagesMarineAnodes PDFAan Wasis MardianaNo ratings yet

- Specifications/Grades: Key BenefitsDocument2 pagesSpecifications/Grades: Key BenefitsMiguel Martinez GuerreroNo ratings yet

- Chemax Tracit Heat Transfer CompoundDocument1 pageChemax Tracit Heat Transfer CompoundMiguel Martinez GuerreroNo ratings yet

- Parts KCG 950GDocument4 pagesParts KCG 950GJanina Cseko100% (1)

- Duodanmill PDFDocument4 pagesDuodanmill PDFidontlikeebooksNo ratings yet

- Mech ValvulasDocument92 pagesMech ValvulasmoloNo ratings yet

- Plate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Document16 pagesPlate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Jacob PhilipNo ratings yet

- Constant Flow Valves: Installation, Operation and Maintenance ManualDocument16 pagesConstant Flow Valves: Installation, Operation and Maintenance ManualQuỳnh GermanNo ratings yet

- 32 Samss 022Document11 pages32 Samss 022naruto256No ratings yet

- Ball Valve KnowledgeDocument40 pagesBall Valve KnowledgeMeanRat100% (1)

- Stihl FS350 Service Manual PDFDocument63 pagesStihl FS350 Service Manual PDFMarko ZgNo ratings yet

- Electrical StandardDocument29 pagesElectrical Standardmohan babuNo ratings yet

- 134-05 EsDocument2 pages134-05 EsFreddy Ibañez PeñaNo ratings yet

- ProposedTIA1054NFPA13 - ProposedTIA1054NFPA13Document7 pagesProposedTIA1054NFPA13 - ProposedTIA1054NFPA13daniela hritucNo ratings yet

- ABB Flow MeterDocument48 pagesABB Flow MeterEMS GlobalNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- Saes L 125Document22 pagesSaes L 125Shawn LeoNo ratings yet

- Installation and Operating Manual: For Study Material and Latest Questions Join Us On Telegram @mmdmeoclass4 Saheem KhanDocument22 pagesInstallation and Operating Manual: For Study Material and Latest Questions Join Us On Telegram @mmdmeoclass4 Saheem KhanAravindNo ratings yet

- SU 846 - Parts - 2007Document58 pagesSU 846 - Parts - 2007Centrifugal SeparatorNo ratings yet

- Spec 17037-P4-P-0a1g-Sz-00006 - 5 PDFDocument50 pagesSpec 17037-P4-P-0a1g-Sz-00006 - 5 PDFiman sihotangNo ratings yet

- Steel Interchange: Steel's Monthly Steel Interchange Is For You! Send YourDocument2 pagesSteel Interchange: Steel's Monthly Steel Interchange Is For You! Send Yourgv Sathishkumar KumarNo ratings yet

- Bolt Tightening Sequence Recommendations and Restrictions - Hex TechnologyDocument13 pagesBolt Tightening Sequence Recommendations and Restrictions - Hex TechnologySavoire FaireNo ratings yet

- Positive Material Identification: ScopeDocument15 pagesPositive Material Identification: Scopebenedicto soto mestanzaNo ratings yet

- Pressure Gauge TeklandDocument11 pagesPressure Gauge Teklandพสธร สอนทองNo ratings yet

- 2Document17 pages2WormInchNo ratings yet

- Cad Worx Plant Tutorial 2018Document65 pagesCad Worx Plant Tutorial 2018Razvan Nicusor Stefan100% (2)

- Blowout Resistance of Room-Temperature Vulcanized ElastomersDocument5 pagesBlowout Resistance of Room-Temperature Vulcanized ElastomersAMUL VEKARIANo ratings yet

- PPP WHADocument3 pagesPPP WHAMartin Roberto GarciaNo ratings yet

- NEWCO Cast Steel Bolted Bonnet Globe ValvesDocument7 pagesNEWCO Cast Steel Bolted Bonnet Globe ValvesLuis Daniel ContrerasNo ratings yet

- Man Propeller Vbs 1460Document30 pagesMan Propeller Vbs 1460ANGEL VALHONDONo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- 400e 1M PDFDocument4 pages400e 1M PDFLuis RolaNo ratings yet

- Trunnion Ball Valve - Class 150#Document6 pagesTrunnion Ball Valve - Class 150#adrianioantomaNo ratings yet