Professional Documents

Culture Documents

P - 4.2200 Manual Parts Firetrol

Uploaded by

venis padilla chan0 ratings0% found this document useful (0 votes)

102 views2 pagesFiretrol

Original Title

P_4.2200 Manual Parts Firetrol

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFiretrol

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

102 views2 pagesP - 4.2200 Manual Parts Firetrol

Uploaded by

venis padilla chanFiretrol

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Product Description

Diesel Engine Fire Pump Controller • FTA1100

Two manual crank push-buttons

Two 10 Amp battery chargers with 4 stage charg-

ing cycle, selectable AC voltage (110 / 220),

selectable DC voltage (12 / 24), and selectable

battery type (Lead Acid, Ni-Cad 9/18 Cell, Ni-

Cad 10/20 Cell)

Door mounted display/interface panel featuring

a 80 Character Vacuum Fluorescent Display,

Membrane Type User Control Push-buttons and

easy to read LED Indicators

MAIN SWITCH IN AUTO LED

ENGINE FAIL TO START LED

CHARGER MALFUNCTION LED

BATTERY #1 TROUBLE LED

BATTERY #2 TROUBLE LED

SYSTEM PRESSURE LOW LED

ENGINE RUNNING LED

ENGINE COOLANT TEMP HIGH LED

ENGINE OIL PRESSURE LOW LED

Description – Firetrol® combined automatic and ENGINE OVERSPEED LED

manual Mark II based diesel engine fire pump LOW FUEL LEVEL LED

controllers are intended for starting and monitoring Minimum Run Timer / Off Delay Timer

fire pump diesel engines. They are available for Daylight Savings Time Option

use with 12 or 24 volt negative ground systems Weekly Test Timer

using lead acid or Nickel-Cadmium batteries. The Engine Run Time Meter

controller monitors, displays and records fire pump Digital Pressure Display

system information. USB Host Controller and Port

Solid State Pressure Transducer

Approvals – Firetrol fire pump controllers are listed Data Log

by Underwriters’ Laboratories, Inc., in accordance Event Log (3000 events)

with UL218, Standard for Fire Pump Controllers, Simultaneous Display of Battery Voltages and

CSA, Standard for Industrial Control Equipment Charging Rates

(cUL), and approved by Factory Mutual. They are Disk Error Message

built to meet or exceed the requirements of the ap- Disk Near Full Message

proving authorities as well as NEMA and the latest Pressure Error Message

editions of NFPA 20, Installation of Centrifugal Fire Fail to Start Message

Pumps, and NFPA 70, National Electrical Code. Low Suction Pressure Message

Crank Cycle Status Indication (Displays Crank-

Standard Features – The following are included ing Battery, Number of Starting Attempts and

as standard with each controller: Crank/Rest Time Remaining)

Two pole AC line circuit breaker 300 psi (20.7 bars) wet parts (solid state pres-

Manual-Off-Auto selector switch sure transducer, solenoid valve, plumbing) for

Manual test push-button fresh water applications

High Speed Open Serial Communications Port

NEMA Type 2 enclosure

Special Enclosures -CPL Contacts for remote indication, system 115%

-T NEMA Type 3R (IEC IP14), Painted Steel over pressure (for use with PLD engines only)

-E NEMA Type 4 (IEC IP56), Painted Steel -CTS Built-in low suction pressure alarm panel (In-

-F NEMA Type 4X (IEC IP56), #304 Stainless Steel, cludes selectable auto/manual reset, audible,

Unfinished** visible and remote alarms and mounted and

-FXP NEMA Type 4X (IEC IP56), #304 Stainless Steel, wired pressure switch)

Painted Finish -EE Additional contacts for remote indication, engine

-FD NEMA Type 4X (IEC IP56), #316 Stainless Steel, trouble (common alarm) - 1 set provided as

Unfinished** standard

-FDB NEMA Type 4X (IEC IP56), 12 Gauge, Seam -EF Additional contacts for remote indication, main

Welded, #316 Stainless Steel, Polished and switch mis-set (common alarm) - 1 set provided

Brushed Finish as standard

-FDP NEMA Type 4X (IEC IP56), #316 Stainless Steel -EH Contacts for remote indication,

Painted Finish relief valve discharge1

-G NEMA Type 12 (IEC IP52), Painted Steel -EJ Visible flow meter on alarm1

** Unfinished (Not painted, polished or brushed). -EK Contacts for remote indication,

flow meter on1

Mounting Legs -JR Visible jockey pump running indication

-N31 Standard 12” Mounting Legs -JT Audible and Visible jockey pump trouble indica-

-N32 Base Mounting Legs 6” tion

-KH Contacts for remote indication, common output

Anti-Condensation Space Heaters for any alarm

-H 120 Volt Space Heater -LC Contacts for remote indication,

-J 120 Volt Space Heater with Thermostat high fuel level1

-K 120 Volt Space Heater with Humidistat -LD Visible fuel spill alarm1

-L 240 Volt Space Heater -LE Contacts for remote indication,

-M 240 Volt Space Heater with Thermostat fuel spill1

-N 240 Volt Space Heater with Humidistat -LG Contacts for remote indication,

reservoir high1

Pressure Transducers, Solenoid Valves, Plumbing -PE Contacts for remote indication,

-B 0-600 psi (0-41.4 bars) wet parts for fresh water low system pressure

applications

-C 0-300 psi (0-21.1 bars) wet parts for sea water/

foam or copper corrosive applications Miscellaneous

-D 0-600 psi (0-41.4 bars) wet parts for sea water/ -AZ Low pump room temperature switch, mounted

foam or copper corrosive applications and wired

-BA 220-240 Volt operation

Alarms -EL Series pumping, high zone controller

-AC Additional contacts for remote indication, en- -EM Series pumping, mid zone controller

gine running - 2 sets provided as standard -EN Series pumping, low zone controller

-AJ Contacts for remote indication, -S Tropicalization

engine overspeed -ZPA Customized, annual service display message

-AK Contacts for remote indication, (factory programmed)

low oil pressure -ZPN 5150 Ethernet Connectivity Module (Allows

-AL Contacts for remote indication, users to monitor limited controller status via a

high water temperature single computer or over a computer network)

-AM Contacts for remote indication, -ZPM Serial Modbus RTU Communications Protocol

engine failed to start (Allows users to monitor all aspects of the con-

-AN Contacts for remote indication, troller status via a RS485 communications net-

battery / charger failure work (system integration required). (Includes

-AP Contacts for remote indication, RS485 to twisted pair breakout module, optical

main switch in manual isolation module (4000 ft. range) and customer

-AR Contacts for remote indication, connection terminal blocks).

main switch in off

-AS Contacts for remote indication, FTA1100-K1 Low fuel level switch, 16” Max. Length2

main switch in auto FTA1100-K1-X High/Low fuel level switch - specify lev-

-AT Contacts for remote indication, els/tank dimensions2

pump room trouble (common alarm)1 FTA1100-K2 Low fuel level switch, 25” Max. Length2

-AV Contacts for remote indication, FTA1100-K21 380-480 volt operation (transformer)2

low pump room temperature1 Export packaging (Wooden crating to conform to IPPC

-AW Contacts for remote indication, reservoir low1 standards)

-AY Contacts for remote indication, low suction

1

pressure1 - Initiating switches by others

2

-COM Low suction pressure alarm, (Includes - Shipped loose for installation by the customer

selectable auto/manual reset, audible, visible

and remote alarms, initiating pressure switch not

included)

(919) 460-5200 • www.firetrol.com • Sales Office: Cary, NC 27512 USA

PD1100-20 (06-11-07)

You might also like

- Product Description Diesel Engine Fire Pump Controller FTA1100Document2 pagesProduct Description Diesel Engine Fire Pump Controller FTA1100Gerardo Muñoz UrbinaNo ratings yet

- FTA1100J Diesel Engine Fire Pump Controllers Product DescriptionDocument2 pagesFTA1100J Diesel Engine Fire Pump Controllers Product Descriptionrahu2260100% (1)

- A7.1.3 电动消防泵控制柜资料Document7 pagesA7.1.3 电动消防泵控制柜资料董鹏No ratings yet

- GPD SV E 1 SubmittalDocument10 pagesGPD SV E 1 Submittalandy bokepNo ratings yet

- Tablero Controlador FIRETROL FTA1300Document2 pagesTablero Controlador FIRETROL FTA1300Accesorios y SistemasNo ratings yet

- FTA550F: Limited Option Jockeyxg Pump ControllerDocument8 pagesFTA550F: Limited Option Jockeyxg Pump ControllerMOHNISHKUMARJHANo ratings yet

- Options & Modifications FTA1100J: M Diesel Engine Fire Pump ControllerDocument2 pagesOptions & Modifications FTA1100J: M Diesel Engine Fire Pump Controllerkiko523iNo ratings yet

- PE2-User-Manual Fire PanelDocument15 pagesPE2-User-Manual Fire PanelsujiNo ratings yet

- Options & Modifications FTA1100J: M Diesel Engine Fire Pump ControllerDocument3 pagesOptions & Modifications FTA1100J: M Diesel Engine Fire Pump ControllersnonumNo ratings yet

- Fire Alarm Control Panel: Product OverviewDocument3 pagesFire Alarm Control Panel: Product OverviewKarkare89No ratings yet

- Model IN042: ApplicationsDocument2 pagesModel IN042: ApplicationsAlmira GhaisaniNo ratings yet

- PS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Document1 pagePS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Fernando KatayamaNo ratings yet

- Service Manual for Ultra-low Temperature Freezer MDF-U4186SDocument30 pagesService Manual for Ultra-low Temperature Freezer MDF-U4186SEmRe OflazNo ratings yet

- Product Description: Mark II Electric Fire Pump ControllersDocument2 pagesProduct Description: Mark II Electric Fire Pump ControllersBill Kerwin Nava JimenezNo ratings yet

- HT SwitchgareDocument3 pagesHT Switchgarerana baruaNo ratings yet

- Asc FPC Ds pd1000 50f PDFDocument2 pagesAsc FPC Ds pd1000 50f PDFandres fernandoNo ratings yet

- RE-104 Fire Alarm Control Panel Product OverviewDocument3 pagesRE-104 Fire Alarm Control Panel Product OverviewBharaneeNo ratings yet

- Wizard LEXF4910 03Document2 pagesWizard LEXF4910 03Rolando ChanisNo ratings yet

- EE Corporate CatalogDocument28 pagesEE Corporate CatalogudhayNo ratings yet

- PVD200 Proportional Valve Driver: Technical Data General Features PVD200Document3 pagesPVD200 Proportional Valve Driver: Technical Data General Features PVD200Sitt Nyein SoeNo ratings yet

- GTR-205 Generator Controller Manual: Web SiteDocument24 pagesGTR-205 Generator Controller Manual: Web SiterianartoNo ratings yet

- FlumenfireDocument16 pagesFlumenfiresato.cryptoniteNo ratings yet

- GEH250-2 (3-Phase) : Diesel Generating SetDocument6 pagesGEH250-2 (3-Phase) : Diesel Generating SetДмитрийNo ratings yet

- Model: Diesel Engine Fire Pump Controller Relay Logic BasedDocument2 pagesModel: Diesel Engine Fire Pump Controller Relay Logic BasedGerardo Muñoz UrbinaNo ratings yet

- FG Wilson Power Wizard 1.0Document2 pagesFG Wilson Power Wizard 1.0presertec83% (46)

- GEP150 (3-Phase) : Diesel Generating SetDocument6 pagesGEP150 (3-Phase) : Diesel Generating SetJulio Ricardo EspinozaNo ratings yet

- Product Description Diesel Engine Fire Pump Controller FTA1100Document1 pageProduct Description Diesel Engine Fire Pump Controller FTA1100Amira ElbarbaryNo ratings yet

- D/E Remote Relay Panel User Guide: This Manual Should Remain With The UnitDocument8 pagesD/E Remote Relay Panel User Guide: This Manual Should Remain With The Unitroberto sanchezNo ratings yet

- hlsr-p_seriesDocument13 pageshlsr-p_seriesGerson David Reto PeñaNo ratings yet

- Room RH TransmitterDocument4 pagesRoom RH TransmitterIrpan NugrahaNo ratings yet

- FR100 Series User Manual EN V1.320150325Document121 pagesFR100 Series User Manual EN V1.320150325MD SHAHIN MIANo ratings yet

- Available Fully Networked To NMEA 2000: EDT EDTDocument2 pagesAvailable Fully Networked To NMEA 2000: EDT EDTAngel AlvarezNo ratings yet

- Fire Data Sheet - Analogue SensorsDocument2 pagesFire Data Sheet - Analogue SensorsvimalNo ratings yet

- Led TV Service Manual: Model Name: STV-42LED11 Version NO: 1.0Document40 pagesLed TV Service Manual: Model Name: STV-42LED11 Version NO: 1.0Marcelo MoreiraNo ratings yet

- PowerWizard Control SystemDocument54 pagesPowerWizard Control SystemErissonNo ratings yet

- LM 3481Document41 pagesLM 3481abdelrhaffar LE HAMDI ALAOUINo ratings yet

- Zeta Alarm System EX-Pro-BrochureDocument6 pagesZeta Alarm System EX-Pro-BrochureSarah NtimNo ratings yet

- MERCURY OUTBOARD MOTOR PCM DiagnosticsDocument20 pagesMERCURY OUTBOARD MOTOR PCM DiagnosticsKaivan Kalyaniwalla100% (2)

- Reliable Generator Design SpecificationsDocument2 pagesReliable Generator Design SpecificationsgargmanishgargNo ratings yet

- Kohler APM402Document4 pagesKohler APM402Marc D. Fisher100% (2)

- Modern EX Pro Fire Control PanelDocument2 pagesModern EX Pro Fire Control PanelmotaNo ratings yet

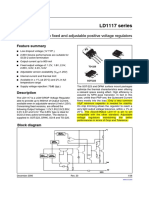

- LD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDocument38 pagesLD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsNafise AshrafiNo ratings yet

- LD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDocument38 pagesLD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsmejoralNo ratings yet

- Regulador LD1117 SeriesDocument38 pagesRegulador LD1117 Seriesprubassoftdigital2 softdigitalNo ratings yet

- Manual Olympian Gep220-2Document6 pagesManual Olympian Gep220-2Javier Moronta100% (1)

- LM3481 / - Q1 High-Efficiency Controller For Boost, SEPIC and Flyback DC-DC ConvertersDocument38 pagesLM3481 / - Q1 High-Efficiency Controller For Boost, SEPIC and Flyback DC-DC ConvertersPLSNo ratings yet

- Gep165 PDFDocument6 pagesGep165 PDFMontaser0% (1)

- TS19503CB10H: Taiwan SemiconductorDocument13 pagesTS19503CB10H: Taiwan Semiconductorn tanevarNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- Service Manual MDF-594 MDF-594AT MDF-593 (N) : Ultra-Low Temperature FreezerDocument29 pagesService Manual MDF-594 MDF-594AT MDF-593 (N) : Ultra-Low Temperature FreezerАНДРЕЙNo ratings yet

- Additive Foam Pump ControllerDocument12 pagesAdditive Foam Pump ControllerAdeel AslamNo ratings yet

- Ap7361ea PDFDocument24 pagesAp7361ea PDFAlejandro DemitiNo ratings yet

- MDFU443 Service ManualDocument81 pagesMDFU443 Service ManualtonyNo ratings yet

- PowerWizard 1 (GB) (0208) PDFDocument2 pagesPowerWizard 1 (GB) (0208) PDFايمن الهدام100% (1)

- FMU Filter Indicators FDHB500UKv2.0 1306Document7 pagesFMU Filter Indicators FDHB500UKv2.0 1306Чингис ЭрдынеевNo ratings yet

- Main Specifications of Generator SetsDocument4 pagesMain Specifications of Generator SetswondNo ratings yet

- 86 Broch 1Document3 pages86 Broch 1electromecanicosNo ratings yet

- Lehe4013 2Document2 pagesLehe4013 2Nour MahmoudNo ratings yet

- PBL3 Combination Push Buttons and Pilot LightsDocument2 pagesPBL3 Combination Push Buttons and Pilot LightsNopNo ratings yet

- Tuberculin Skin Test: Facilitator GuideDocument31 pagesTuberculin Skin Test: Facilitator GuideTiwi NaloleNo ratings yet

- Tirfor: Lifting and Pulling Machines With Unlimited Wire RopeDocument26 pagesTirfor: Lifting and Pulling Machines With Unlimited Wire RopeGreg ArabazNo ratings yet

- The Mars ForceDocument249 pagesThe Mars Forceridikitty100% (2)

- Delhi (The Capital of India) : Ebook by Ssac InstituteDocument27 pagesDelhi (The Capital of India) : Ebook by Ssac InstituteAnanjay ChawlaNo ratings yet

- Political Engineering and Party Politics in Conflict-Prone SocietiesDocument18 pagesPolitical Engineering and Party Politics in Conflict-Prone SocietiesNashiba Dida-AgunNo ratings yet

- Solutions: Spheres, Cones and CylindersDocument13 pagesSolutions: Spheres, Cones and CylindersKeri-ann MillarNo ratings yet

- Advanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityDocument15 pagesAdvanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityGilbert TamayoNo ratings yet

- Fjords Blue Web ENG PDFDocument20 pagesFjords Blue Web ENG PDFMoldovan MirceaNo ratings yet

- Multivariate Analysis Homework QuestionsDocument2 pagesMultivariate Analysis Homework Questions歐怡君No ratings yet

- Document-SAP EWM For Fashion 1.0: 1.general IntroductionDocument3 pagesDocument-SAP EWM For Fashion 1.0: 1.general IntroductionAnonymous u3PhTjWZRNo ratings yet

- MECHANICAL PROPERTIES OF SOLIDSDocument39 pagesMECHANICAL PROPERTIES OF SOLIDSAbdul Musavir100% (1)

- How Do I Prepare For Public Administration For IAS by Myself Without Any Coaching? Which Books Should I Follow?Document3 pagesHow Do I Prepare For Public Administration For IAS by Myself Without Any Coaching? Which Books Should I Follow?saiviswanath0990100% (1)

- Variables in Language Teaching - The Role of The TeacherDocument34 pagesVariables in Language Teaching - The Role of The TeacherFatin AqilahNo ratings yet

- Design ThinkingDocument16 pagesDesign ThinkingbhattanitanNo ratings yet

- Millennium Separation ReportDocument3 pagesMillennium Separation ReportAlexandra AkeNo ratings yet

- Banu Maaruf of The LevantDocument6 pagesBanu Maaruf of The LevantMotiwala AbbasNo ratings yet

- INVENTORY MANAGEMENT TechniquesDocument24 pagesINVENTORY MANAGEMENT TechniquesWessal100% (1)

- EST I - Literacy Test I (Language)Document20 pagesEST I - Literacy Test I (Language)Mohammed Abdallah100% (1)

- Flexible Ductwork Report - November 2011v2Document69 pagesFlexible Ductwork Report - November 2011v2bommobNo ratings yet

- Project Report Software and Web Development Company: WWW - Dparksolutions.inDocument12 pagesProject Report Software and Web Development Company: WWW - Dparksolutions.inRavi Kiran Rajbhure100% (1)

- Inventory Storage and Retrieval System PatentDocument15 pagesInventory Storage and Retrieval System PatentdevanasokaNo ratings yet

- Simulia Abaqus Standard DatasheetDocument3 pagesSimulia Abaqus Standard Datasheetuser923019231831No ratings yet

- Request For Proposal Construction & Phase 1 OperationDocument116 pagesRequest For Proposal Construction & Phase 1 Operationsobhi100% (2)

- Common Pesticides in AgricultureDocument6 pagesCommon Pesticides in AgricultureBMohdIshaqNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Winkens Et Al 2009Document8 pagesWinkens Et Al 2009Marta SanchezNo ratings yet

- Angelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannDocument374 pagesAngelomorphic Christology and The Book of Revelation - Matthias Reinhard HoffmannEusebius325100% (2)

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- Hajj A Practical Guide-Imam TahirDocument86 pagesHajj A Practical Guide-Imam TahirMateen YousufNo ratings yet

- Biamp Vocia Catalog Apr2020Document24 pagesBiamp Vocia Catalog Apr2020Mahavir Shantilal DhokaNo ratings yet