Professional Documents

Culture Documents

Product Description Diesel Engine Fire Pump Controller FTA1100

Uploaded by

Gerardo Muñoz Urbina0 ratings0% found this document useful (0 votes)

85 views2 pagesOriginal Title

Tablero firetrol

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

85 views2 pagesProduct Description Diesel Engine Fire Pump Controller FTA1100

Uploaded by

Gerardo Muñoz UrbinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Product Description

Diesel Engine Fire Pump Controller • FTA1100

n Two manual crank push-buttons

n Two 10 Amp battery chargers with 4 stage charg-

ing cycle, selectable AC voltage (110 / 220), se-

lectable DC voltage (12 / 24), and selectable

battery type (Lead Acid, Ni-Cad 9/18 Cell, Ni-

Cad 10/20 Cell)

n Door mounted display/interface panel featuring

a 80 Character Vacuum Fluorescent Display,

Membrane Type User Control Push-buttons and

easy to read LED Indicators

n MAIN SWITCH IN AUTO LED

n ENGINE FAIL TO START LED

n CHARGER MALFUNCTION LED

n BATTERY #1 TROUBLE LED

n BATTERY #2 TROUBLE LED

n SYSTEM PRESSURE LOW LED

n ENGINE RUNNING LED

n ENGINE COOLANT TEMP HIGH LED

n ENGINE OIL PRESSURE LOW LED

Description – Firetrol® combined automatic and n ENGINE OVERSPEED LED

manual Mark II based diesel engine fire pump con- n LOW FUEL LEVEL LED

trollers are intended for starting and monitoring fire n Minimum Run Timer / Off Delay Timer

pump diesel engines. They are available for use n Daylight Savings Time Option

with 12 or 24 volt negative ground systems using n Weekly Test Timer

lead acid or Nickel-Cadmium batteries. The con- n Engine Run Time Meter

troller monitors, displays and records fire pump n Digital Pressure Display

system information. n 3.5” 1.44M Floppy Disk Drive (20,000 events)

n Data Log

Approvals – Firetrol fire pump controllers are listed n Event Log (3000 events)

by Underwriters’ Laboratories, Inc., in accordance n Simultaneous Display of Battery Voltages and

with UL218, Standard for Fire Pump Controllers, Charging Rates

CSA, Standard for Industrial Control Equipment n Disk Error Message

(cUL), and approved by Factory Mutual. They are n Disk Near Full Message

built to meet or exceed the requirements of the n Pressure Error Message

approving authorities as well as NEMA and the n Fail to Start Message

latest editions of NFPA 20, Installation of Centrifu- n Low Suction Pressure Message

gal Fire Pumps, and NFPA 70, National Electrical n Crank Cycle Status Indication (Displays Crank-

Code. ing Battery, Number of Starting Attempts and

Crank/Rest Time Remaining)

Standard Features – The following are included n 300 psi (20.7 bars) wet parts (pressure trans-

as standard with each controller: ducer, solenoid valve, plumbing) for fresh wa-

n Two pole AC line circuit breaker ter applications

n Manual-Off-Auto selector switch n High Speed Open Serial Communications Port

n Manual test push-button n NEMA Type 2 enclosure

Special Enclosures -AW Contacts for remote indication,

-T NEMA Type 3R (IEC IP14) reservoir low1

-E NEMA Type 4 (IEC IP 56) -AY Contacts for remote indication,

-F NEMA Type 4X (IEC IP56) #304 Stainless low suction pressure1

Steel -COM Visible low suction pressure alarm with

-G NEMA Type 12 (IEC IP52) manual reset push-button1

-CTS Built-in low suction pressure alarm

Mounting Legs panel (Includes selectable auto/

-N31 Standard 12” Mounting Legs manual reset, audible, visible and

-N32 Base Mounting Legs 6” remote alarms and mounted and

wired pressure switch)

Anti-Condensation Space Heaters -EE Additional contacts for remote indica-

-H 120 Volt Space Heater tion, engine trouble (common alarm) -

-J 120 Volt Space Heater with Thermostat 1 set provided as standard

-K 120 Volt Space Heater with Humidistat -EF Additional contacts for remote indica-

-L 240 Volt Space Heater tion, main switch mis-set (common

-M 240 Volt Space Heater with Thermostat alarm) - 1 set provided as standard

-N 240 Volt Space Heater with Humidistat -EH Contacts for remote indication,

relief valve discharge1

Pressure Transducers, Solenoid Valves, Plumbing -EJ Visible flow meter on alarm1

-B 0-600 psi (0-41.4 bars) wet parts for fresh -EK Contacts for remote indication,

water applications flow meter on1

-C 0-300 psi (0-21.1 bars) wet parts for sea -LC Contacts for remote indication,

water/foam or copper corrosive applica- high fuel level1

tions -LD Visible fuel spill alarm1

-D 0-600 psi (0-41.4 bars) wet parts for sea -LE Contacts for remote indication,

water/foam or copper corrosive applica- fuel spill1

tions -LG Contacts for remote indication,

reservoir high1

Alarms -PE Contacts for remote indication,

-AC Additional contacts for remote indica- low system pressure

tion, engine running - 2 sets provided

as standard Miscellaneous

-AJ Contacts for remote indication, -AZ Low pump room temperature switch,

engine overspeed mounted and wired

-AK Contacts for remote indication, -BA 220-240 Volt operation

low oil pressure -EL Series pumping, high zone controller

-AL Contacts for remote indication, -EM Series pumping, mid zone controller

high water temperature -EN Series pumping, low zone controller

-AM Contacts for remote indication, -S Tropicalization

engine failed to start -ZPA Customized, annual service display

-AN Contacts for remote indication, message (factory programmed)

battery / charger failure -ZPB High quality impact printer with auto-

-AP Contacts for remote indication, matic paper take-up mechanism

main switch in manual

-AR Contacts for remote indication, FTA1100-K1 Low fuel level switch2

main switch in off FTA1100-K21 380-480 volt operation (trans-

-AS Contacts for remote indication, former)2

main switch in auto Export packaging

-AT Contacts for remote indication,

pump room trouble (common alarm)1 1

- Initiating switches by others

-AV Contacts for remote indication, 2

- Shipped loose for installation by the cus-

low pump room temperature1 tomer

(919) 460-5200 • www.firetrol.com • Sales Office: Cary, NC 27512 USA

PD1100-20(A)

You might also like

- P - 4.2200 Manual Parts FiretrolDocument2 pagesP - 4.2200 Manual Parts Firetrolvenis padilla chanNo ratings yet

- FTA1100J Diesel Engine Fire Pump Controllers Product DescriptionDocument2 pagesFTA1100J Diesel Engine Fire Pump Controllers Product Descriptionrahu2260100% (1)

- A7.1.3 电动消防泵控制柜资料Document7 pagesA7.1.3 电动消防泵控制柜资料董鹏No ratings yet

- Single Phase - Online 2020Document6 pagesSingle Phase - Online 2020Techno AgeNo ratings yet

- FTA550F: Limited Option Jockeyxg Pump ControllerDocument8 pagesFTA550F: Limited Option Jockeyxg Pump ControllerMOHNISHKUMARJHANo ratings yet

- Tablero Controlador FIRETROL FTA1300Document2 pagesTablero Controlador FIRETROL FTA1300Accesorios y SistemasNo ratings yet

- PE2-User-Manual Fire PanelDocument15 pagesPE2-User-Manual Fire PanelsujiNo ratings yet

- Fire Alarm Control Panel: Product OverviewDocument3 pagesFire Alarm Control Panel: Product OverviewKarkare89No ratings yet

- Options & Modifications FTA1100J: M Diesel Engine Fire Pump ControllerDocument2 pagesOptions & Modifications FTA1100J: M Diesel Engine Fire Pump Controllerkiko523iNo ratings yet

- Three-Phase OnlineDocument6 pagesThree-Phase Onlinethreephase electricNo ratings yet

- Fire Alarm Control Panel: Product OverviewDocument3 pagesFire Alarm Control Panel: Product OverviewBharaneeNo ratings yet

- GPD SV E 1 SubmittalDocument10 pagesGPD SV E 1 Submittalandy bokepNo ratings yet

- EE Corporate CatalogDocument28 pagesEE Corporate CatalogudhayNo ratings yet

- MERCURY OUTBOARD MOTOR PCM DiagnosticsDocument20 pagesMERCURY OUTBOARD MOTOR PCM DiagnosticsKaivan Kalyaniwalla100% (2)

- Model: Diesel Engine Fire Pump Controller Relay Logic BasedDocument2 pagesModel: Diesel Engine Fire Pump Controller Relay Logic BasedGerardo Muñoz UrbinaNo ratings yet

- 1508333679MP 5200Document20 pages1508333679MP 5200engenhariahabNo ratings yet

- NRC12 VarlogiDocument2 pagesNRC12 VarlogiNima MahmoudpourNo ratings yet

- DKG-105 Automatic Mains Failure Unit: Description FeaturesDocument2 pagesDKG-105 Automatic Mains Failure Unit: Description FeaturesMostafa ShannaNo ratings yet

- Kea 071 AnlDocument12 pagesKea 071 Anlamin shirkhaniNo ratings yet

- Model IN042: ApplicationsDocument2 pagesModel IN042: ApplicationsAlmira GhaisaniNo ratings yet

- Re 2554Document4 pagesRe 2554Brian MirandaNo ratings yet

- T1611110 Red Lion Controls Datasheet 9636899Document3 pagesT1611110 Red Lion Controls Datasheet 9636899luis esquedaNo ratings yet

- Bravo Genset PRM26Document2 pagesBravo Genset PRM26gargmanishgargNo ratings yet

- HT SwitchgareDocument3 pagesHT Switchgarerana baruaNo ratings yet

- Ravel 25AR TDSDocument3 pagesRavel 25AR TDSHarshith KunjathurNo ratings yet

- FTA2000 Medium Voltage Electric Fire Pump ControllersDocument8 pagesFTA2000 Medium Voltage Electric Fire Pump ControllersOhaneje Uzoma50% (2)

- 2d Insulation Resistance Monitor 6Document6 pages2d Insulation Resistance Monitor 6john smithNo ratings yet

- Options & Modifications FTA1100J: M Diesel Engine Fire Pump ControllerDocument3 pagesOptions & Modifications FTA1100J: M Diesel Engine Fire Pump ControllersnonumNo ratings yet

- Led TV Service Manual: Model Name: STV-42LED11 Version NO: 1.0Document40 pagesLed TV Service Manual: Model Name: STV-42LED11 Version NO: 1.0Marcelo MoreiraNo ratings yet

- Check List Untuk TRFDocument10 pagesCheck List Untuk TRFmrubbyantoNo ratings yet

- 2100 2500 Cummins ENDocument2 pages2100 2500 Cummins ENMinn Thet NaingNo ratings yet

- Ontime THC AVC118 ManualDocument27 pagesOntime THC AVC118 ManualNawres ArifNo ratings yet

- LD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDocument38 pagesLD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsmejoralNo ratings yet

- LD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDocument38 pagesLD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsNafise AshrafiNo ratings yet

- Regulador LD1117 SeriesDocument38 pagesRegulador LD1117 Seriesprubassoftdigital2 softdigitalNo ratings yet

- R1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineDocument33 pagesR1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineajisardadiNo ratings yet

- PS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Document1 pagePS05805010K - B - JOCKEY Touch - Ver Jun 2015 - NS - 05-25-15Fernando KatayamaNo ratings yet

- PowerWizard Control SystemDocument54 pagesPowerWizard Control SystemErissonNo ratings yet

- Manual Multimetro Goldstar dm-332 - CalDocument13 pagesManual Multimetro Goldstar dm-332 - Calav100% (2)

- Liquid Level Controller - Water Level Controller - Level Controller - GIC IndiaDocument5 pagesLiquid Level Controller - Water Level Controller - Level Controller - GIC IndiaPrasadPurohitNo ratings yet

- GU320B Controller Brief Introduction Harsen Description: Panel ButtonsDocument3 pagesGU320B Controller Brief Introduction Harsen Description: Panel Buttonsjuan joseNo ratings yet

- PDF2Document1 pagePDF2Jesus BarriNo ratings yet

- JTL28D - Specs 070925Document1 pageJTL28D - Specs 070925Ewa IrlaNo ratings yet

- LT3932-3932-1-36V, 2A SynchronousDocument30 pagesLT3932-3932-1-36V, 2A Synchronousjustinvil1103No ratings yet

- D/E Remote Relay Panel User Guide: This Manual Should Remain With The UnitDocument8 pagesD/E Remote Relay Panel User Guide: This Manual Should Remain With The Unitroberto sanchezNo ratings yet

- Planos FTA1300 Submittal (Large HP) (Descargado Internet)Document10 pagesPlanos FTA1300 Submittal (Large HP) (Descargado Internet)Artemio Chata ChambiNo ratings yet

- Automatic Voltage Regulating Relay (Avr-03) : FeaturesDocument1 pageAutomatic Voltage Regulating Relay (Avr-03) : Featuresss subramanyamNo ratings yet

- TCD4281DNDDocument14 pagesTCD4281DNDPierina AstudilloNo ratings yet

- Automatic Voltage Regulating Relay EE 301-M: Instruction ManualDocument22 pagesAutomatic Voltage Regulating Relay EE 301-M: Instruction ManualnarendragahlotNo ratings yet

- PANEL RAVEL 2554 (4 Zonas)Document4 pagesPANEL RAVEL 2554 (4 Zonas)Alex JanampaNo ratings yet

- Generators Control Panel: Service ManualDocument34 pagesGenerators Control Panel: Service Manualtopsi kretsNo ratings yet

- Dynadrive: Information Manual SDFP (S) 1525-17Document15 pagesDynadrive: Information Manual SDFP (S) 1525-17Doug WilsonNo ratings yet

- 300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesDocument12 pages300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesPierpaolo GustinNo ratings yet

- GEH250-2 (3-Phase) : Diesel Generating SetDocument6 pagesGEH250-2 (3-Phase) : Diesel Generating SetДмитрийNo ratings yet

- Sanyo MDF-U4186S Service ManualDocument30 pagesSanyo MDF-U4186S Service ManualEmRe OflazNo ratings yet

- MC 10160102 9999Document5 pagesMC 10160102 9999ونس نصيراتNo ratings yet

- Panel Relay Remoto PDFDocument12 pagesPanel Relay Remoto PDFroberto sanchezNo ratings yet

- Kea 081 AnlDocument17 pagesKea 081 Anlamin shirkhaniNo ratings yet

- Wire and Cable Technical Information Handbook: $80.00 HARDBOUND $50.00 SOFTBOUNDDocument7 pagesWire and Cable Technical Information Handbook: $80.00 HARDBOUND $50.00 SOFTBOUNDGerardo Muñoz UrbinaNo ratings yet

- Installation and Testing: 8.1 Receiving, Handling and StorageDocument29 pagesInstallation and Testing: 8.1 Receiving, Handling and StorageGerardo Muñoz UrbinaNo ratings yet

- Electrical Characteristics: 7.1 DC Resistance of Plated Copper ConductorsDocument20 pagesElectrical Characteristics: 7.1 DC Resistance of Plated Copper ConductorsGerardo Muñoz UrbinaNo ratings yet

- Connectors, Lugs & TerminationsDocument15 pagesConnectors, Lugs & TerminationsGerardo Muñoz UrbinaNo ratings yet

- Cable Types and Selection Criteria: 6.1 Portable Power and ControlDocument26 pagesCable Types and Selection Criteria: 6.1 Portable Power and ControlGerardo Muñoz UrbinaNo ratings yet

- Conversion Tables: 12.1 Metric To English Conductor SizeDocument16 pagesConversion Tables: 12.1 Metric To English Conductor SizeGerardo Muñoz UrbinaNo ratings yet

- Packaging of Wire and Cable: 10.1 Reel SizeDocument12 pagesPackaging of Wire and Cable: 10.1 Reel SizeGerardo Muñoz UrbinaNo ratings yet

- Formulas and Constants: 13.1 Electrical Properties of CircuitsDocument7 pagesFormulas and Constants: 13.1 Electrical Properties of CircuitsGerardo Muñoz UrbinaNo ratings yet

- Standards and SpecificationsDocument42 pagesStandards and SpecificationsGerardo Muñoz UrbinaNo ratings yet

- WCH 14Document31 pagesWCH 14Gerardo Muñoz UrbinaNo ratings yet

- WCH 19Document28 pagesWCH 19Gerardo Muñoz UrbinaNo ratings yet

- Latin and South America: 16.1 Mexican StandardsDocument4 pagesLatin and South America: 16.1 Mexican StandardsGerardo Muñoz UrbinaNo ratings yet

- Asia and The Pacific Rim: 18.1 Australian StandardsDocument7 pagesAsia and The Pacific Rim: 18.1 Australian StandardsGerardo Muñoz UrbinaNo ratings yet

- Canada: 17.1 Standards OrganizationsDocument14 pagesCanada: 17.1 Standards OrganizationsGerardo Muñoz UrbinaNo ratings yet

- Latin and South America: 16.1 Mexican StandardsDocument4 pagesLatin and South America: 16.1 Mexican StandardsGerardo Muñoz UrbinaNo ratings yet

- CurveData CFP33-F10Document4 pagesCurveData CFP33-F10Gerardo Muñoz UrbinaNo ratings yet

- Model: Diesel Engine Fire Pump Controller Relay Logic BasedDocument2 pagesModel: Diesel Engine Fire Pump Controller Relay Logic BasedGerardo Muñoz UrbinaNo ratings yet

- EPA Tier 1 Emission Data Fire Pump NSPS Compliant: 15 PPM Diesel FuelDocument1 pageEPA Tier 1 Emission Data Fire Pump NSPS Compliant: 15 PPM Diesel FuelGerardo Muñoz UrbinaNo ratings yet

- United Kingdom: 15.1 Standards OrganizationsDocument10 pagesUnited Kingdom: 15.1 Standards OrganizationsGerardo Muñoz UrbinaNo ratings yet

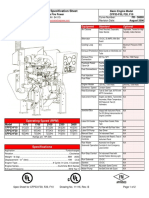

- Engine Specification Sheet: Depere, Wi 54115 Curve Number: Revision DateDocument2 pagesEngine Specification Sheet: Depere, Wi 54115 Curve Number: Revision DateGerardo Muñoz UrbinaNo ratings yet

- Wafer API 22 2 Paper For Mexico 2006 March 14 Rev AcceptedDocument28 pagesWafer API 22 2 Paper For Mexico 2006 March 14 Rev AcceptedGerardo Muñoz UrbinaNo ratings yet

- PDS Placas DANIEL DIC 17Document15 pagesPDS Placas DANIEL DIC 17Katia ArroyueloNo ratings yet

- LM2438 Monolithic Triple 13.5 Ns CRT Driver: General Description FeaturesDocument11 pagesLM2438 Monolithic Triple 13.5 Ns CRT Driver: General Description FeaturesAbel RodriguezNo ratings yet

- Eplan Software & Service GMBH & Co. KG: Ed Iec - Tpl001 Asus Date 2/4/2021Document13 pagesEplan Software & Service GMBH & Co. KG: Ed Iec - Tpl001 Asus Date 2/4/2021Tinto TenNo ratings yet

- Physics Class Xii Sample Paper 04 For 2019 20 1Document7 pagesPhysics Class Xii Sample Paper 04 For 2019 20 1jay danenjeyanNo ratings yet

- 6820 Accessory G4325A LAN Installation Guide G1176-90757Document16 pages6820 Accessory G4325A LAN Installation Guide G1176-90757Spyr TourNo ratings yet

- STNS01: Li-Ion Linear Battery Charger With LDODocument29 pagesSTNS01: Li-Ion Linear Battery Charger With LDO123No ratings yet

- Power Transformer: (Equipped With Static Shield, Magnetic Shieid)Document5 pagesPower Transformer: (Equipped With Static Shield, Magnetic Shieid)Leonardo MarraffiniNo ratings yet

- MTD Handmade Bass Wiring - For Professional/Expert Use: Pickups and ElectronicsDocument1 pageMTD Handmade Bass Wiring - For Professional/Expert Use: Pickups and ElectronicsRonald Cardenas AntayhuaNo ratings yet

- VSR PotterDocument5 pagesVSR PotterAhlan kpNo ratings yet

- Datasheet - Trimble DA2 GNSS Receiver - UK EnglishDocument2 pagesDatasheet - Trimble DA2 GNSS Receiver - UK EnglishJohnNo ratings yet

- Single Phase RectificationDocument13 pagesSingle Phase RectificationMariusNo ratings yet

- In Situ Construction of A Cs2SnI6 Perovskite Nanocrystal SnS2 NanosheetDocument8 pagesIn Situ Construction of A Cs2SnI6 Perovskite Nanocrystal SnS2 NanosheetdebmallyNo ratings yet

- Sco 106 Introduction To ElectronicsDocument3 pagesSco 106 Introduction To ElectronicsjustuskyalomusembiNo ratings yet

- M 95640-A125-A145 - EepromDocument44 pagesM 95640-A125-A145 - EepromTiago LeonhardtNo ratings yet

- HBS86H Hybrid Stepper Servo Drive ManualDocument22 pagesHBS86H Hybrid Stepper Servo Drive ManualPhúc Phan TiếnNo ratings yet

- HY5118164B, HY5116164B: DescriptionDocument8 pagesHY5118164B, HY5116164B: Descriptiontolomeo10No ratings yet

- TPCC8131 Datasheet en 20140217Document9 pagesTPCC8131 Datasheet en 20140217CarlosClarosNo ratings yet

- Apctest OutputDocument11 pagesApctest Outputgybmllpusaqyzwgovs nthrw.comNo ratings yet

- Nanotechnology PresentationDocument34 pagesNanotechnology PresentationFawzan Fahad MDNo ratings yet

- MT215DW01 V0Document24 pagesMT215DW01 V0ivanivz62No ratings yet

- Flyback Bias Winding and Transformer LeakageDocument10 pagesFlyback Bias Winding and Transformer LeakageThanhha NguyenNo ratings yet

- MM16USB Service ManualDocument29 pagesMM16USB Service ManualZoeloe_2No ratings yet

- Module 1 Notes - PSOCDocument23 pagesModule 1 Notes - PSOCpriya100% (1)

- Us MX5021 Sell Sheet PaDocument2 pagesUs MX5021 Sell Sheet PaIKon 's PirasiNo ratings yet

- Fanuc System 10 and Series 11 Master Board Alarm CodesDocument2 pagesFanuc System 10 and Series 11 Master Board Alarm CodesLeonardusNo ratings yet

- P14D TM en 3 PDFDocument690 pagesP14D TM en 3 PDFMeghavahinaNo ratings yet

- Physics 2 - Activity 1 - Physics ProblemsDocument6 pagesPhysics 2 - Activity 1 - Physics ProblemsChristian Paul A. AsicoNo ratings yet

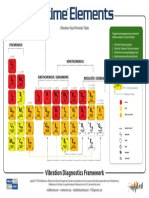

- Vibration Fault Periodic Table: E L M UDocument1 pageVibration Fault Periodic Table: E L M UHaitham Youssef100% (1)

- MAX44267 +15V Single-Supply, Dual Op Amp With 10V Output RangeDocument19 pagesMAX44267 +15V Single-Supply, Dual Op Amp With 10V Output RangegirimooliNo ratings yet

- Wireless PowerDocument31 pagesWireless Poweral_1989No ratings yet

- 7SR224 - Argus Complete Technical Manual (201-300)Document100 pages7SR224 - Argus Complete Technical Manual (201-300)Rosa MiñanoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)