Professional Documents

Culture Documents

New Fan Anti Surge Control - Standard Data Sheet

New Fan Anti Surge Control - Standard Data Sheet

Uploaded by

PRASHANT GOUROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Fan Anti Surge Control - Standard Data Sheet

New Fan Anti Surge Control - Standard Data Sheet

Uploaded by

PRASHANT GOURCopyright:

Available Formats

FAN ANTI SURGE CONTROL

FAN ANTI SURGE CONTROL

When a fan system is delivering air into a large silo the pressure in that silo will

increase slowly and the flow of air to the silo will decrease.

At a certain moment the fan will not be able to deliver the required pressure to

transport more air into the silo; in fact the fan will surge and the air flow direction

will reverse.

The silo pressure will decrease until the fan recovers and the process will start

all over again. This phenomenon is called surging.

SPECIFICATIONS

SURGING SYMPTOMS

Surging does interrupt your process e.g. drying, heating, cooling or transporting.

Surging will cause a dramatic increase in noise and vibration. This will, in time, result in structural fatigue damage

to your fan.

Life of bearing, main shaft, hub, impeller, coupling and motor will be dramatically reduced and your fan process

will be interrupted.

HOW DOES IT WORK:

Air flow, pressure and temperature are measured, these conditions are converted to standard conditions and compared

to the surge characteristics of the fan by an advanced algorithm.

Then the flow through the fan starts to reduce and reaches a critical surge point the Anti Surge Controller will open a

bypass or blow-off valve to ensure the minimum required flow. The fan is now protected and the process is not

interrupted.

The PLC control algorithm not only calculates with the mentioned flow, pressures and temperatures but also takes

the molecular weight and polytrophic exponent of the gas into account. The fan characteristics are also entered.

All measured and calculated data is presented on the colour display.

SUITABLE FANS

The ASC is suitable for backward curved centrifugal fans or blowers with 1, 2 or 3 compression stages.

STANDALONE OPERATIONS

The ASC panel works as a standalone unit. Connection to a DCS is not required.

AVAILABLE OPTIONS

• CIP equipment for both chambers

• Suitable for ATEX zone 2

• Glass connection to the Distributed control system

• Remote controlling

• Flow transmitters

• Pressure transmitters

• Temperature transmitters

• Control valves

• Condition monitoring of bearings

VTK SiccaDania

Gooiland 8 www.vtk.nl

1948 RC Beverwijk sales@vtk.nl

The Netherlands P: +31 251 279900

You might also like

- Soundcloud - Abhisek Jena PDFDocument6 pagesSoundcloud - Abhisek Jena PDFAbhisek JenaNo ratings yet

- CRJ 700 - 900 Air Conditioning MX FamDocument90 pagesCRJ 700 - 900 Air Conditioning MX FamDarby Morgan100% (1)

- Electric Schematic: D110S-5, D130S-5, D160S-5Document11 pagesElectric Schematic: D110S-5, D130S-5, D160S-5Akbar FadhilNo ratings yet

- Sabre 25HE CombiDocument44 pagesSabre 25HE CombiRon Lester0% (1)

- Service Manual Sap-Krv93ehfp Sap-Crv93ehfp Sap-Krv123ehfp SDocument73 pagesService Manual Sap-Krv93ehfp Sap-Crv93ehfp Sap-Krv123ehfp SIan McPakeNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Netscapes Work CultureDocument10 pagesNetscapes Work CultureNidaNo ratings yet

- Furnace Replace Carrier 302075 304 Board Ig LIAF044 1Document2 pagesFurnace Replace Carrier 302075 304 Board Ig LIAF044 1topogigio240No ratings yet

- Pressure Switch (Refrigerant) : Systems OperationDocument3 pagesPressure Switch (Refrigerant) : Systems OperationMbahdiro KolenxNo ratings yet

- York Cat LC 2012 enDocument148 pagesYork Cat LC 2012 enMary Andrews100% (1)

- 2.5 GSHP CiatesaDocument20 pages2.5 GSHP CiatesaFPrueba1No ratings yet

- Stulz Cyber Air 2 - Whats New V1 (2) LEWISDocument21 pagesStulz Cyber Air 2 - Whats New V1 (2) LEWISVu Minh TuanNo ratings yet

- Chiller Selection Building A+j Cooling Only Rev 2Document7 pagesChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedNo ratings yet

- Yca PDFDocument44 pagesYca PDFsugirin100% (2)

- Technical Ycre YcseDocument18 pagesTechnical Ycre Ycsenairam2003No ratings yet

- Condenserless Liquid ChillersDocument12 pagesCondenserless Liquid ChillersBader ShrbajiNo ratings yet

- 30HXC CNDocument12 pages30HXC CNtechnokakiNo ratings yet

- Pressure Switch (Refrigerant) : Systems OperationDocument3 pagesPressure Switch (Refrigerant) : Systems OperationEshop ManualNo ratings yet

- TECS Water Cooled ChillerDocument8 pagesTECS Water Cooled Chillerntt_121987No ratings yet

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Document15 pagesFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987No ratings yet

- SCOH-K Tech Guide 0705Document48 pagesSCOH-K Tech Guide 0705Emir OmerdicNo ratings yet

- Multipower Cha K 726-P÷36012-P CLB 41.7Document40 pagesMultipower Cha K 726-P÷36012-P CLB 41.7Xavi Tendre100% (1)

- Ac Thermostat Specification PDFDocument4 pagesAc Thermostat Specification PDFMuhammad IbrahimNo ratings yet

- Air-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDocument12 pagesAir-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnappuertoparaisoNo ratings yet

- Skymark Vac8 25t Engineering Guide PDFDocument16 pagesSkymark Vac8 25t Engineering Guide PDFBraulio Ramón PeñaNo ratings yet

- Automatic Boiler ControlDocument16 pagesAutomatic Boiler ControlbadpplNo ratings yet

- GasCube PresentationDocument31 pagesGasCube PresentationJose AguilarNo ratings yet

- Water-Cooled Screw Chiller: Nominal Cooling Capacity: 335 1392kWDocument12 pagesWater-Cooled Screw Chiller: Nominal Cooling Capacity: 335 1392kWمحمد مرسيNo ratings yet

- Controlador Dixell Serie IC200LDocument35 pagesControlador Dixell Serie IC200LColossusNo ratings yet

- Technical YLAEDocument16 pagesTechnical YLAEnairam2003No ratings yet

- Aer 534 QCDocument48 pagesAer 534 QCsunny_nsecNo ratings yet

- 30GXDocument12 pages30GXAdolfo Riquelme Novoa0% (1)

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- Clint Cha k726p 36012p Brochure 0325 enDocument2 pagesClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- WHZ 2005 PDFDocument8 pagesWHZ 2005 PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- 38hdt PDDocument12 pages38hdt PDDoan Tien Do100% (1)

- Installation & Servicing Instructions: These Instructions To Be Retained by UserDocument44 pagesInstallation & Servicing Instructions: These Instructions To Be Retained by UserErwin De HeusNo ratings yet

- 741 VLB BrochureDocument4 pages741 VLB BrochureMohammad Ali ZamanNo ratings yet

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersvickersNo ratings yet

- HVAC en CatalogueDocument64 pagesHVAC en CataloguesafinditNo ratings yet

- WestinghouseDocument4 pagesWestinghouseJulio Fermin100% (2)

- 74 HC 191Document10 pages74 HC 191Ravi RathodNo ratings yet

- MANUAL Electronic Controls and Valves (RWR462)Document19 pagesMANUAL Electronic Controls and Valves (RWR462)Cezary50% (2)

- Digicold Digicold Digicold Digicold: SeriesDocument4 pagesDigicold Digicold Digicold Digicold: SeriesdbricchiNo ratings yet

- 1.0 Chiller UnitDocument12 pages1.0 Chiller UnitfebousNo ratings yet

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Ewaq Ewyq DaynDocument96 pagesEwaq Ewyq DaynValentin MalihinNo ratings yet

- Clivet Toplotne PumpeDocument15 pagesClivet Toplotne PumpeSean ThomasNo ratings yet

- KRV93-123EHN XDocument51 pagesKRV93-123EHN Xprr69No ratings yet

- KNX Fancoil Controller PDFDocument58 pagesKNX Fancoil Controller PDFlfrn20044593No ratings yet

- 30RB - RQ - Carrier - ManualzzDocument19 pages30RB - RQ - Carrier - ManualzzmelodyNo ratings yet

- Chapter 18 - Air Conditioning: Service ManualDocument48 pagesChapter 18 - Air Conditioning: Service Manualjacklyn ade putra100% (1)

- HP HeaterDocument29 pagesHP HeaterRajneesh Vachaspati100% (1)

- Daikin Cennik VRV 2014Document46 pagesDaikin Cennik VRV 2014LidijaSpaseskaNo ratings yet

- IMI CD3 MCU Tech Manual PDFDocument48 pagesIMI CD3 MCU Tech Manual PDFJoe BloggsNo ratings yet

- 2 Aire Acondicionado COMPAC I y IIDocument12 pages2 Aire Acondicionado COMPAC I y IILuis Enrique GarzonNo ratings yet

- XCC 638Document32 pagesXCC 638Nico NicoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Field CSI ChecklistDocument14 pagesField CSI Checklistfazlullah fazilNo ratings yet

- Super Capacitor - Seminar Report, PPT, PDF For ECE StudentsDocument3 pagesSuper Capacitor - Seminar Report, PPT, PDF For ECE StudentsvvkrkzNo ratings yet

- Revised - List of 373 Institutions For EoA in 2019-20Document41 pagesRevised - List of 373 Institutions For EoA in 2019-20AishaNo ratings yet

- CS10-1L Computer Fundamentals and Programming Laboratory: Practical Exam PE1 For Batch 2 (C++) Date Name CS10-1LDocument5 pagesCS10-1L Computer Fundamentals and Programming Laboratory: Practical Exam PE1 For Batch 2 (C++) Date Name CS10-1LRussell ViadoNo ratings yet

- Manual Walther CP99 Compact 2252206 2252208 2252216 04R14Document36 pagesManual Walther CP99 Compact 2252206 2252208 2252216 04R14Jefferson David VilladaNo ratings yet

- SKB La d704pDocument60 pagesSKB La d704pamitintime4uNo ratings yet

- 65 B 8 Ecd 1207151706574865Document21 pages65 B 8 Ecd 1207151706574865foracoy703No ratings yet

- 16 Popular Online Car Classifieds in IndonesiaDocument15 pages16 Popular Online Car Classifieds in IndonesiaKalenNo ratings yet

- Manual Diesel Test BenchDocument18 pagesManual Diesel Test BenchMelchor EstradaNo ratings yet

- Ecoinvent V.3.3 in OpenlcaDocument20 pagesEcoinvent V.3.3 in OpenlcayesinoeNo ratings yet

- The Reliable Hub-And-Spoke Design Problem - Models and AlgorithmsDocument20 pagesThe Reliable Hub-And-Spoke Design Problem - Models and AlgorithmsRuxandra PopaNo ratings yet

- Load Schedule: Proposed Two-Storey ResidenceDocument1 pageLoad Schedule: Proposed Two-Storey Residencear.christdelvivar.uapNo ratings yet

- Python Tutorials - Data To FishDocument4 pagesPython Tutorials - Data To FishWanly SanesulNo ratings yet

- Openstack Install Guide Apt Debian TrunkDocument143 pagesOpenstack Install Guide Apt Debian TrunkAdemir PajevicNo ratings yet

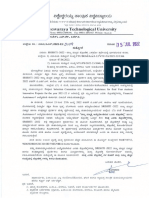

- VTU Shristi State Level Project ExpoDocument3 pagesVTU Shristi State Level Project ExpoHEMANTH KUMAR CNo ratings yet

- TF in SAPDocument21 pagesTF in SAPChandan MukherjeeNo ratings yet

- HTR900 Inspection, Maintenance, and TestingDocument27 pagesHTR900 Inspection, Maintenance, and TestingVicente Regulez FernandezNo ratings yet

- Refsheet 2nd Namhae Bridge CH enDocument1 pageRefsheet 2nd Namhae Bridge CH en王小波No ratings yet

- Technical Workshop On Wind & EqDocument113 pagesTechnical Workshop On Wind & Eqengr. abet hilarioNo ratings yet

- Unit Iv & VDocument41 pagesUnit Iv & Vvijay anandhNo ratings yet

- Ost PracDocument29 pagesOst PracPranav PasteNo ratings yet

- Task Performance Pre Final STSDocument5 pagesTask Performance Pre Final STSAshley Mae SarmientoNo ratings yet

- SUSPENSION SYSTEMS - LectureDocument84 pagesSUSPENSION SYSTEMS - LectureEbrahem Ahmed HafezNo ratings yet

- Accounting Information Systems 14th Edition Romney Test Bank Full Chapter PDFDocument53 pagesAccounting Information Systems 14th Edition Romney Test Bank Full Chapter PDFStephenBowenbxtm100% (16)

- COA M2022-003 Signed COA Style Guide PDFDocument31 pagesCOA M2022-003 Signed COA Style Guide PDFCharlie MaineNo ratings yet

- Development of Surveying InstrumentsDocument31 pagesDevelopment of Surveying InstrumentsMa. Jeza TrellasNo ratings yet

- Technical Detail - EHRW + SHRWDocument10 pagesTechnical Detail - EHRW + SHRWBalaji JenarthananNo ratings yet