Professional Documents

Culture Documents

Read Me

Uploaded by

kachkach zakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Read Me

Uploaded by

kachkach zakCopyright:

Available Formats

Visual Management

Tim Hirsch – Kaizen Specialist, Premera Blue Cross

Christina Webber – Kaizen Specialist, Premera Blue Cross

October 24th, 2012

*Contents included in the presentation are informed by our study of the Toyota Production System

*Images are from Microsoft Office and are trademarks or registered trademarks of Microsoft Corporation in the United States and/or other countries.

Copyright © 2012 Premera Blue Cross

An Independent Licensee of the Blue Cross Blue Shield Association

Workshop Definition

• How do you solve a problem if you can’t see it?

• How do you build a culture where people doing the

work feel safe surfacing problems and tap into their

creativity in coming up with solution?

Visual Management is a foundational Lean concept

focused on making goals and actual results visible so

that they can be solved.

Copyright © 2012 Premera Blue Cross

Visual Management: Agenda

• Why is it important?

• What is it?

• How do I apply it?

Copyright © 2012 Premera Blue Cross

Visual Management

What is actually happening

VS

What should be happening

Copyright © 2012 Premera Blue Cross

Visual Controls in Everyday Life

Actionable

Simple Intuitive

In the right place

Copyright © 2012 Premera Blue Cross

Visual Controls

You have to see it to improve it!

• Simple & Intuitive

• Easy to understand

• Visibility to problems

Copyright © 2012 Premera Blue Cross

Visual Control: Let the Pictures Do the Talking

Copyright © 2012 Premera Blue Cross

Visual Controls: Simple and Intuitive

Copyright © 2012 Premera Blue Cross

Visual Controls: What is Happening?

Copyright © 2012 Premera Blue Cross

Visual Controls: What should be happening

Copyright © 2012 Premera Blue Cross

Visual Control Board: Status at a Glance

Copyright © 2012 Premera Blue Cross

Andon

• Alert to problems

• A call for help

• Stop the line

• A plan for action

Copyright © 2012 Premera Blue Cross

Andons Alert Everyone to Problems

Copyright © 2012 Premera Blue Cross

Andon: A Call for Response and a Plan for Action

Copyright © 2012 Premera Blue Cross

5S: A Series of Steps to Eliminate Waste

• Sort

• Simplify

• Sweep

• Standardize

• Self-Discipline

Copyright © 2012 Premera Blue Cross

Why 5S?

Cuts Costs Fosters

Teamwork

Improves Promotes

Productivity Safety

5S

Copyright © 2012 Premera Blue Cross

5S - Sort: Separate Necessary from Unnecessary

BEFORE AFTER

Copyright © 2012 Premera Blue Cross

5S - Simplify: A Place for Everything

BEFORE AFTER

Copyright © 2012 Premera Blue Cross

5S - Sweep: Make it Clean and Safe

BEFORE AFTER

Copyright © 2012 Premera Blue Cross

5S - Standardize: Make it Easy to Maintain

BEFORE AFTER

Copyright © 2012 Premera Blue Cross

5S - Self-Discipline: Maintain and Improve

BEFORE AFTER

Copyright © 2012 Premera Blue Cross

5S: Foundational to Continuous Improvement

Sort

Self-

Discipline Simplify

Standardize Sweep

Copyright © 2012 Premera Blue Cross

Summary…….

Visual Controls Lead to Visual Management!

• Make it Visible

• Actual vs Expected

• Take Action

Copyright © 2012 Premera Blue Cross

Visual Management: Seeing Leads to Solving

Copyright © 2012 Premera Blue Cross

24

Celebrate Problems as Opportunities!

Recognize associates who make problems visible!

Copyright © 2012 Premera Blue Cross

Questions

Copyright © 2012 Premera Blue Cross

You might also like

- Heat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFDocument46 pagesHeat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFAnaQatarina50% (4)

- CNAF NAE GB Student Book (Ver 1070)Document190 pagesCNAF NAE GB Student Book (Ver 1070)Joshua StuartNo ratings yet

- Training: 7 Waste: Insert Image HereDocument11 pagesTraining: 7 Waste: Insert Image HereukavathekarNo ratings yet

- Session 03. Designing Quality As An Inclusive Business System (Watson, 2020)Document66 pagesSession 03. Designing Quality As An Inclusive Business System (Watson, 2020)taghavi1347No ratings yet

- Webinar-3. Exercising Management Roles of Front-Line Leadership (Watson, 2021)Document47 pagesWebinar-3. Exercising Management Roles of Front-Line Leadership (Watson, 2021)taghavi1347No ratings yet

- Session 14. Quality As An Economic Imperative (Watson, 2021)Document32 pagesSession 14. Quality As An Economic Imperative (Watson, 2021)taghavi1347No ratings yet

- Module 51. Improve TollgateDocument45 pagesModule 51. Improve Tollgatetaghavi1347No ratings yet

- NCR FormatDocument5 pagesNCR FormatSakib KhanNo ratings yet

- CI School TrainingDocument300 pagesCI School TrainingJessa Palamara100% (1)

- Productivity Improvement Strategy:: "Visual Management"Document14 pagesProductivity Improvement Strategy:: "Visual Management"Tito Setiawan NugrohoNo ratings yet

- 5S Workplace ImprovementDocument82 pages5S Workplace ImprovementSenyum Sehat100% (1)

- Session 11. Defining Quality To Apply To Everyone, Everywhere (Watson, 2020)Document49 pagesSession 11. Defining Quality To Apply To Everyone, Everywhere (Watson, 2020)taghavi1347No ratings yet

- Session 06. Organizational Learning - Triple-Loop Experience (Watson, 2020)Document52 pagesSession 06. Organizational Learning - Triple-Loop Experience (Watson, 2020)taghavi1347No ratings yet

- 09 Process Capability PDFDocument41 pages09 Process Capability PDFMukesh Krishna RNo ratings yet

- 3.10.5 Shop Floor (Gemba) Examples of Walk Around and Dialogue ActivitiesDocument12 pages3.10.5 Shop Floor (Gemba) Examples of Walk Around and Dialogue ActivitieskearnjNo ratings yet

- Module 14. Define TollgateDocument17 pagesModule 14. Define Tollgatetaghavi1347No ratings yet

- Module 38. Analyze TollgateDocument36 pagesModule 38. Analyze Tollgatetaghavi1347No ratings yet

- Session 15. Quality As A Social Responsibility (Watson, 2021)Document42 pagesSession 15. Quality As A Social Responsibility (Watson, 2021)taghavi1347No ratings yet

- Histogram Box Plot Statistics AdaptiveBMSDocument13 pagesHistogram Box Plot Statistics AdaptiveBMSashutoshrvNo ratings yet

- QC Story BlankDocument22 pagesQC Story BlankSenthil KumarNo ratings yet

- FMEA Guide for Process ImprovementDocument20 pagesFMEA Guide for Process ImprovementViswanathan SrkNo ratings yet

- Session 16. Quality As A Human Right (Watson, 2021)Document45 pagesSession 16. Quality As A Human Right (Watson, 2021)taghavi1347No ratings yet

- Total Service Management 5S CampaignDocument18 pagesTotal Service Management 5S CampaigntimazaNo ratings yet

- Lean Manufacturing 1Document70 pagesLean Manufacturing 1AbhiNo ratings yet

- QRG 5S Color Code (5scolor)Document2 pagesQRG 5S Color Code (5scolor)josé_filipe_35No ratings yet

- Session 07. Managerial Engineering - Designing Future Firms (Watson, 2020)Document70 pagesSession 07. Managerial Engineering - Designing Future Firms (Watson, 2020)taghavi1347No ratings yet

- JH - Kaizen Training ModuleDocument19 pagesJH - Kaizen Training Moduleshariq warsiNo ratings yet

- Poka Yoke Best Presentation.....Document39 pagesPoka Yoke Best Presentation.....DebashishDolonNo ratings yet

- Standard Operating Procedure for Drawing Letters M and WDocument126 pagesStandard Operating Procedure for Drawing Letters M and WIb JensenNo ratings yet

- Session 13. Quality As An Environmental Mandate (Watson, 2020)Document40 pagesSession 13. Quality As An Environmental Mandate (Watson, 2020)taghavi1347No ratings yet

- PCPA Report-Large Roof Lamp With LEDDocument3 pagesPCPA Report-Large Roof Lamp With LEDawdhut kulkarniNo ratings yet

- World Class Manufacturing: SR - No Description Option1 Option2 Option3 Option4 ADocument11 pagesWorld Class Manufacturing: SR - No Description Option1 Option2 Option3 Option4 AKrish KrishNo ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- PM Kaizen SHEETDocument3 pagesPM Kaizen SHEETKrishna JoshiNo ratings yet

- 2.4 VSM Current State GB V 1Document18 pages2.4 VSM Current State GB V 1haidar khadourNo ratings yet

- JH PPT 18.12.20Document46 pagesJH PPT 18.12.20MAngesh Gade0% (1)

- 5S Visual Management Jun-20Document73 pages5S Visual Management Jun-20Vipul JhaNo ratings yet

- MTBF - MTTRDocument11 pagesMTBF - MTTRYogesh BadheNo ratings yet

- J I D O K A - RevisitedDocument45 pagesJ I D O K A - RevisitedmagudeeshNo ratings yet

- A3 Report Writing: Toyota's Preferred Method of Written CommunicationDocument63 pagesA3 Report Writing: Toyota's Preferred Method of Written Communicationsudar1477No ratings yet

- Mistake Proofing & Poka-Yoke: A Strategy For Performance ExcellenceDocument73 pagesMistake Proofing & Poka-Yoke: A Strategy For Performance Excellencekumarkk1969No ratings yet

- National Guard Black Belt Training: Intro To MinitabDocument90 pagesNational Guard Black Belt Training: Intro To MinitabUday SharmaNo ratings yet

- 3-2 Introduction To ImproveDocument11 pages3-2 Introduction To Improveanjo0225No ratings yet

- E.C.R.S.: Problem Solving ToolsDocument10 pagesE.C.R.S.: Problem Solving ToolsRahul RawatNo ratings yet

- Visual Management: Using Visual Elements To Control Work and Monitor StatusDocument9 pagesVisual Management: Using Visual Elements To Control Work and Monitor StatusFran JimenezNo ratings yet

- Workplace Safety Signs ExplainedDocument3 pagesWorkplace Safety Signs ExplainedBaharudin HelmyNo ratings yet

- VSM Template (LEan Six Sigma)Document8 pagesVSM Template (LEan Six Sigma)DearRed FrankNo ratings yet

- Environment EventDocument90 pagesEnvironment EventRonald Abadi TariganNo ratings yet

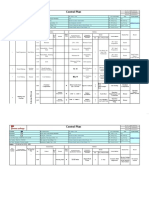

- Control Plan for Flywheel Assembly CastingDocument24 pagesControl Plan for Flywheel Assembly CastingSuraj RawatNo ratings yet

- Webinar-1. Understanding Japanese Management - A Tale of Three Gemba (Watson, 2021)Document59 pagesWebinar-1. Understanding Japanese Management - A Tale of Three Gemba (Watson, 2021)taghavi1347No ratings yet

- Poka Yoke: NH Ag NH CeDocument33 pagesPoka Yoke: NH Ag NH CevictorNo ratings yet

- Cost of Quality: Understanding Prevention & Failure CostsDocument4 pagesCost of Quality: Understanding Prevention & Failure CostsnowsheenbdNo ratings yet

- LSS Tools 2020Document6 pagesLSS Tools 2020Varun KumarNo ratings yet

- Introduction To Six SigmaDocument41 pagesIntroduction To Six SigmaSandovalHumbertoNo ratings yet

- SPC Training Material - 18!04!2018Document34 pagesSPC Training Material - 18!04!2018Rajesh KumarNo ratings yet

- Module 13. Voice of The Customer (VOC)Document47 pagesModule 13. Voice of The Customer (VOC)taghavi1347No ratings yet

- Operator Skill MatrixDocument11 pagesOperator Skill MatrixNikhil SirNo ratings yet

- Session 04. Conducing Executive Inquiry & Formulating Strategy (Watson, 2020)Document26 pagesSession 04. Conducing Executive Inquiry & Formulating Strategy (Watson, 2020)taghavi1347No ratings yet

- Measurement System AnalysisDocument2 pagesMeasurement System AnalysispsathishthevanNo ratings yet

- Kano model customer satisfaction categoriesDocument1 pageKano model customer satisfaction categoriessrinivas rao rayuduNo ratings yet

- Blueprint 10 Career Crushers SlidesDocument58 pagesBlueprint 10 Career Crushers Slidesnoosi nchobaNo ratings yet

- Education Tutoring Flyer TemplateDocument1 pageEducation Tutoring Flyer Templatekachkach zakNo ratings yet

- 5s (Workplace Organization) Implementation: Confidential and Proprietary - © 2008 Kellogg Na CompanyDocument33 pages5s (Workplace Organization) Implementation: Confidential and Proprietary - © 2008 Kellogg Na CompanyAko Lang PohNo ratings yet

- House RulesDocument1 pageHouse Ruleskachkach zakNo ratings yet

- Product Available at Arafa FarmDocument1 pageProduct Available at Arafa Farmkachkach zakNo ratings yet

- Read Me 1Document12 pagesRead Me 1kachkach zakNo ratings yet

- Six Sigma Green Belt 1. DEFINE (IASSC)Document114 pagesSix Sigma Green Belt 1. DEFINE (IASSC)kachkach zak100% (2)

- Six Sigma Green Belt 3.ANALYSE (IASSC)Document99 pagesSix Sigma Green Belt 3.ANALYSE (IASSC)kachkach zak100% (1)

- Six Sigma Green Belt 2. MEASURE (IASSC)Document125 pagesSix Sigma Green Belt 2. MEASURE (IASSC)kachkach zak100% (1)

- Y12 - Hand - Book - 2019 2Document22 pagesY12 - Hand - Book - 2019 2tiagoNo ratings yet

- Lesson 2.1Document16 pagesLesson 2.1Jeremie Manimbao OrdinarioNo ratings yet

- About InvestopediaDocument10 pagesAbout InvestopediaMuhammad SalmanNo ratings yet

- Mitigating Contractor's Claim On Loss and Expense Due To The Extension of Time in Public Projects: An Exploratory SurveyDocument12 pagesMitigating Contractor's Claim On Loss and Expense Due To The Extension of Time in Public Projects: An Exploratory SurveyWeei Zhee70No ratings yet

- xg01 Koso Kent Introl PDFDocument22 pagesxg01 Koso Kent Introl PDFhaidinuNo ratings yet

- Student Report Card ManagementDocument38 pagesStudent Report Card ManagementKannan Thangaraju41% (17)

- Mainf 517-527Document11 pagesMainf 517-527Upeksha PereraNo ratings yet

- Finite Element and Analytical Modelling of PVC-confined Concrete Columns Under Axial CompressionDocument23 pagesFinite Element and Analytical Modelling of PVC-confined Concrete Columns Under Axial CompressionShaker QaidiNo ratings yet

- International ArbitrageDocument24 pagesInternational Arbitrageaadis191No ratings yet

- Donor Selections..Document17 pagesDonor Selections..OmamaNo ratings yet

- Plates of The Dinosaur Stegosaurus - Forced Convection Heat Loos FinsDocument3 pagesPlates of The Dinosaur Stegosaurus - Forced Convection Heat Loos FinsJuan Fernando Cano LarrotaNo ratings yet

- Adrenergic SystemDocument6 pagesAdrenergic SystemdocsNo ratings yet

- Isla, Julie Anne - Midterm Exam - RM (25 April 2021)Document7 pagesIsla, Julie Anne - Midterm Exam - RM (25 April 2021)Julie anne IslaNo ratings yet

- Dryspell+ ManualDocument71 pagesDryspell+ ManualAldo D'AndreaNo ratings yet

- HAM Processing Technique for Ocular Surface ReconstructionDocument4 pagesHAM Processing Technique for Ocular Surface ReconstructionJoel JohnsonNo ratings yet

- Library ClassificationDocument10 pagesLibrary ClassificationKakeembo NasiifuNo ratings yet

- L05 - Selection of Indicators (ENG)Document9 pagesL05 - Selection of Indicators (ENG)killerkissNo ratings yet

- Collateral Asset DefinitionsDocument116 pagesCollateral Asset Definitionsapi-3748391100% (2)

- Codex AlexandrinusDocument294 pagesCodex AlexandrinusHevel Cava100% (2)

- Campus Event ReflectionDocument2 pagesCampus Event ReflectiondntbenfordNo ratings yet

- "Disaster Readiness and Risk Reduction": Test 2 True or FalseDocument2 pages"Disaster Readiness and Risk Reduction": Test 2 True or FalseMiki AntonNo ratings yet

- PTE Academic Lesson Plan Ideas: Test Taking Strategies: Vikki Weston, Vessela GasperDocument2 pagesPTE Academic Lesson Plan Ideas: Test Taking Strategies: Vikki Weston, Vessela GasperStanley AlexNo ratings yet

- Lovacka Kamera UputstvoDocument24 pagesLovacka Kamera UputstvoEmir MusijaNo ratings yet

- Roll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHDocument3 pagesRoll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHBeenish MirzaNo ratings yet

- Módulo Dcp-Frcma-I (Frcme-M+sci)Document2 pagesMódulo Dcp-Frcma-I (Frcme-M+sci)alexropaNo ratings yet

- Lead Creation v. Schedule A - 1st Amended ComplaintDocument16 pagesLead Creation v. Schedule A - 1st Amended ComplaintSarah BursteinNo ratings yet

- 4 Ways to Improve Your Strategic ThinkingDocument3 pages4 Ways to Improve Your Strategic ThinkingJyothi MallyaNo ratings yet

- GCC Lab ManualDocument61 pagesGCC Lab ManualMadhu BalaNo ratings yet

- Incremental Analysis Decision MakingDocument4 pagesIncremental Analysis Decision MakingMa Teresa B. CerezoNo ratings yet