Professional Documents

Culture Documents

General Information Chassis

Uploaded by

Kada Ben youcefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Information Chassis

Uploaded by

Kada Ben youcefCopyright:

Available Formats

CHASSIS GENERAL INFORMATION

0000-00

CHASSIS GENERAL INFORMATION

MAJOR COMPONENTS SPECIAL TOOLS AND EQUIPMENT

cardiagn.com

1. MOUNTING LOCATIONS (CHASSIS)..... 2 1. NEW SPECIAL TOOLS.......................... 22

2. CHASSIS COMPONENT LAYOUT......... 4 2. NORMAL EQUIPMENTS........................ 23

3. SUB FRAME AND STEERING

GEAR BOX LAYOUT.............................. 6

4. FRONT SUSPENSION COMPONENT

LAYOUT................................................. 8

5. REAR SUSPENSION COMPONENT

LAYOUT................................................. 10

6. BRAKE SYSTEM AND ESP SYSTEM

LAYOUT................................................. 12

7. STEERING SYSTEM LAYOUT.............. 14

DURING SERVICE WORK

1. GUIDELINES FOR SERVICE WORK

SAFETY................................................. 16

2. JACK-UP POINTS.................................. 20

3. STANDARD BOLTS SPECIFICATIONS.. 21

01-2 0000-00

1. MOUNTING LOCATIONS (CHASSIS)

HECU (Hydraulic & Electronic Control Unit)

HECU for ABS HECU for EPS

Motor Motor

HU ECU HU

(Hydraulic (Electronic (Hydraulic ECU (Electronic

Unit) Control Unit) Unit) Control Unit)

The HECU (Hydraulic & Electronic Control Unit) determines the slip conditions of vehicle

wheels by calculating each wheel's speed and the increment/decrement of speed based on the

information detected by the sensors, and controls the pumping and boosting/reducing/keeping

cardiagn.com

pressure by operating the valve and motor of HECU.

EPS unit

Motor angle Connector to vehicle (8P)

(8P) Battery (2P)

Torque angle

sensor (8P)

Motor power (3P)

The ECU controls the electric power

steering system depending on the driving

conditions, based on the signals from the

torque and angle sensor.

Fuse for vehicle with EPS

Steering wheel angle sensor (SWAS)

The steering wheel angle

sensor is mounted between

the steering column and the

steering column shaft. It is

commonly used by the ESP

(Electronic Stability Program)

system. And it receives

signals of the steering wheel

The vehicle with EPS has EPS fuse (80A) angle sensor from the ESP

mounted to the positive (+) terminal of the HECU (Hydraulic & Electronic

battery not in the fuse box. Control Unit).

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-3

Sensor cluster TGS Lever assembly

The TGS communicates with

TCU (Transmission Control

Unit), ECU, ESP HECU and

instrument cluster to let the

driver select the desired

transmission gear and to

maintain the desired driving

condition. Also, the tip switch is

The sensor cluster is linked installed on the lever knob and

to the sensors on the unit the steering wheel so that the

board and CAN interface. driver select the gear manually

And they are housed in one when the shift lever is in "M".

case and mounted to the

body.

G-sensor

cardiagn.com

For the vehicle with the ABS, a speed difference

between the wheels is not noticeable as all the

wheels are slipping during abrupt braking.

Therefore, the vehicle needs the speed information

from other sensors other than the wheel speed

sensor. The longitudinal acceleration sensor (G-

sensor) is used for this case. It controls the ABS by

using the signals from the sensor during abrupt

braking and acceleration.

TCU unit

E-coupling unit

The transmission control unit (TCU) is

installed under the driver seat, and controls

The E-coupling unit is a control unit which the transmission.

determines the magnetic force by considering The TCU is operated by the ignition power

CAN signals (wheel speed, engine torque, supply and receives and processes the

pedal opening, ABS/ESP CAN signals, etc.) following information from the inner sensors

from other ECUs. through CAN buses.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-4 0000-00

2. CHASSIS COMPONENT LAYOUT

1) 4WD Vehicle With Automatic Transmission

M11 6-speed A/T assembly

Inhibitor

switch

Oil pan

Torque converter

M11 6-speed automatic transmission is available

as 4WD- and 2WD-type, and provides 6 speeds

for forward travel and 1 reverse travel. It is also

equipped with the torque converter with inner Propeller

cardiagn.com

lock-up clutch and electronically controlled shaft

solenoid which controls all hydraulic functions.

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle

through propeller shaft and E-coupling by

changing the power flow direction by 90° in Rear axle assembly

the front wheel drive type 4WD vehicle.

E-coupling control unit (E-Coupling ECU)

E-coupling side Rear axle side

The rear axle installed in this car is a

removable axle, called IRDA (Independent

Rear Differential Axle). The rear differential

The E-coupling unit is a control unit which carrier is installed directly on the sub frame,

determines the magnetic force by considering and there is an independent suspension that

CAN signals (wheel speed, engine torque, pedal allows each wheel on the same axle to move

opening, ABS/ESP CAN signals, etc.) from other vertically independently of each other with the

ECUs. universal joint and the slip joint.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-5

2) 2WD Vehicle With Manual Transmission

The 2WD vehicle with manual transmission is a front wheel drive type vehicle that doesn't have

PTU, propeller shaft, E-coupling and rear axle which are applied to 4WD vehicle. Its under

structure is very simple.

M6LF1 manual transmission

Transmission side Control shaft assembly

cardiagn.com

Transaxle side Concentric slave assembly

M6LF1 manual transmission is a model modified from

the one that used in other vehicle so that it can be

applied to FF (Front engine-Front wheel driving) type

vehicle, and has an axle in one piece. The engine

torque and gear ratio of this transmission have been

optimized to maximize driving performance. It provides

6 speeds for forward travel and 1 reverse travel.

Clutch assembly

Clutch disc Pressure plate

Manual gear selector lever

M6LF1 manual transmission is a model modified from

the one that used in other vehicle so that it can be

applied to FF (Front engine-Front wheel driving) type

vehicle, and has an axle in one piece. The engine

torque and gear ratio of this transmission have been

optimized to maximize driving performance. It provides

6 speeds for forward travel and 1 reverse travel.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-6 0000-00

3. SUB FRAME AND STEERING GEAR BOX LAYOUT

Front sub frame with HPS type steering gear box assembly

Rear side HPS type steering

gear box assembly

cardiagn.com

Front sub frame

Front side assembly

The front sub frame consists of 4 body bush mountings and 2

transmission bush mountings which reduce the vibration from the

powertrain and road, and also control the torque. And the frame is

equipped with hydraulic pressure pipe of the HPS type steering gear

box.

Front sub frame with EPS type steering gear box assembly

Rear side EPS type steering

gear box assembly

Front sub frame

Front side assembly

This kind of front sub frame system has the same mounting structure

with the frame with HPS. But the EPS type steering gear box has no

hydraulic pressure pipe since it is driven by the electric motor.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-7

Rear sub frame assembly for 4WD

Rear side

Body mounting Body mounting

Axle mounting

cardiagn.com

Body mounting Body mounting

Front side

The rear sub frame for 4WD vehicle consists of 4 body (bush)

mountings and 2 axle (direct) mountings which reduce the

vibration from the powertrain and road, and also control the

torque.

Rear sub frame assembly for 2WD

Body mounting Rear side Body mounting

Body mounting Body mounting

Front side

The rear sub frame for 2WD vehicle functions in the same way as

the one for 4WD vehicle, but the structure is different from the one

for 4WD. It consists of 4 body (bush) mountings.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-8 0000-00

4. FRONT SUSPENSION COMPONENT LAYOUT

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this

type of suspension, the steering linkage tie rod is mounted on the knuckle. The Macpherson

Strut suspension is an independent suspension which has a spring on the strut with a built-in

shock absorber. The lower arm is installed on sub frame and large strut damper is installed on

the knuckle to support the tire.

Stabilizer bar assembly

Stabilizer bar

Bushing

Clamp

cardiagn.com

Link

The stabilizer bar assembly is not activated if the

left/right wheels move up/down simultaneously, but if

both wheels move up/down differently it is activated

with frame to minimize the tilting of the body.

Lower arm assembly

The lower arm assembly connects the frame and

knuckle. It supports the load transferred to the tire

knuckle, relieves the impact from the vehicle and

ground conditions, and ensures driving stability.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-9

cardiagn.com

Front coil spring assembly

Coil spring

Shock absorber

assembly

The coil spring is made by winding solid steel rod to

form the coil shape. Its energy absorption rate per

weight is higher than that of the leaf spring and it

allows to absorb small vibration properly resulted in

keeping the ride comforts. Therefore, it's difficult to

make an effect on vibration damping because there

is not any friction between coils.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-10 0000-00

5. REAR SUSPENSION COMPONENT LAYOUT

Multi-link type suspension is the independent suspension. It provides good ride comfort and

drivability by reducing the coil spring weight. Also, it increases the space for passenger

compartment by lowering the floor.

This type of suspension consists of multiple links such as trailing arm, upper arm, lower arm

and track rod.

Shock absorber assembly

This vehicle uses the gas

shock absorber. This

relieves the vertical

vibrations of vehicle to

provide ride comforts,

prevents the spring

cardiagn.com

break, enhances

drivability, and extends

the life span of steering

components.

Upper arm assembly

Upper arm is installed between knuckle and

sub frame and controls the lateral load and

vehicle height.

Trailing arm assembly

Track rod assembly

Trailing arm is installed between knuckle Track rod is installed between knuckle and

and vehicle body and controls the front and rear sub frame and controls and

rear load. compensates the lateral load.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-11

Stabilizer bar assembly

Stabilizer bar

Bushing

Clamp

Link

The stabilizer bar assembly is not activated if the

cardiagn.com

left/right wheels move up/down simultaneously,

but if both wheels move up/down differently it is

activated with frame to minimize the tilting of the

body.

Coil spring

Coil spring is installed between

the coil spring link and body

frame. It relieves the vibrations

and impacts from wheels to

vehicle body.

Lower arm assembly

The lower arm is installed between knuckle and

rear sub frame and relieves the load to coil

spring from wheel. In other word, it controls the

longitudinal load.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-12 0000-00

6. BRAKE SYSTEM AND ESP SYSTEM LAYOUT

A. Indicators on instrument cluster

Parking brake ESP indicator

warning light

ABS warning lamp

B. Master cylinder assembly

cardiagn.com

Description for master cylinder in this chapter

is based on ABS/ESP equipped vehicle. For

CBS, there is an extra pressure valve

mounted to the master cylinder.

C. HECU assembly D. Front brake assembly

Caliper Disc

The HECU assemblies for ABS and ESP The disc brake for 4WD vehicle is the same

have similar appearance but they have with the one for 2WD vehicle.

different inner structure and connector

connections from each other.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-13

G. Brake pedal

H. Parking brake

4WD and 2WD 2WD Rear side

Front side

cardiagn.com

The wheel speed sensor for 4WD has the same

structure and mounting location with the one for

2WD vehicle. But the rear side wheel speed

sensor for 2WD vehicle has different sensor

appearance and mounting status because the

knuckle shape is different from the 4WD vehicle.

E. Rear brake assembly H. Parking brake

Caliper

Disc

The parking brake is the mechanical device

to hold the vehicle. When pulling up the lever,

The disc brake for 4WD vehicle has the same the parking brake cable between the lever

structure with the one for 2WD vehicle, but and the rear drum brake trailing shoe pulls

the appearance and knuckle shape is the parking brake lining to contact to drum.

different from each other.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-14 0000-00

7. STEERING SYSTEM LAYOUT

1) HPS (Hydraulic Power Steering)

The hydraulic pump is a The oil reservoir sends the There is a shock absorber

vane type pump and oil to the power steering which is folded in the axial

consists of the flow control pump and receives the oil direction when the vehicle is

valve and pressure relief from the power steering crashed and a ignition switch

valve. gear. assembly on the column

shaft.

cardiagn.com

Steering wheel Column shaft

assembly

Lower shaft

Hydraulic pipe & hose

The lower shaft minimizes the

torque change using a CV

joint which has constant

angular speed.

The steering gear box assembly consists of power cylinder and control valve. The power

cylinder has a cylinder, piston and piston rod. The control valve directs the oil to one end face

of the piston to enhance the steering force. There is a safety check valve which lets the driver

steer manually when there is a malfunction in the hydraulic circuit.

Hydraulic pipe Gear box

Steering cylinder

Tie rod end

Tie rod end

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-15

2) EPS (Electric Power Steering)

The ECU controls the The vehicle with EPS has The column shaft assembly

electric power steering EPS fuse (80A) mounted consists of BLAC motor, ECU,

system depending on the to the positive (+) terminal torque and angle sensors. The

driving conditions, based of the battery, and this fuse electric power steering (EPS)

on the signals from the supplies power to the EPS system uses the electric motor to

torque and angle sensor. unit directly. assist the steering force. It

functions independently

regardless of whether the engine

is running or not, unlike the

existing hydraulic power steering.

The lower shafts functions in the

same way as the hydraulic type.

cardiagn.com

Column

Steering wheel assembly shaft

BLACK motor ECU

Lower

shaft

When the driver turns the steering wheel, a torque is generated and the torque sensor and the

steering angle sensor in the EPS system detect the rotation of the steering column to run the

electric motor. At this time, the worm gear connected to the motor drives the helical gear

mounted to the steering column to generate the assist torque for the steering column. This

allows the driver to operate the steering wheel easier.

Gear box

Tie rod end Steering cylinder Tie rod end

CHASSIS GENERAL INFORMATION

korando 2010.10

01-16 0000-00

1. GUIDELINES FOR SERVICE WORK SAFETY

1) For Safety

To maintain and operate the vehicle under optimum state by performing safe service works, the

service works should be done by following correct methods and procedures.

Accordingly, the purpose of this manual is to prevent differences that can be caused by

personal working method, skill, ways and service procedures and to allow prompt/correct

service works.

While using this manual, there are a lot of Note or Notice having below meaning.

Note means detailed description of supplementary information on work procedure or skill.

cardiagn.com

Notice means precautions on tool/device or part damages or personal injuries that can

occur during service works.

However, above references and cautions cannot be inclusive measures, so should have habits

of taking concerns and cautions based on common senses.

2) Equipment

- Korando C is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system

are integrated into the engine compartment. Thus 2-post lift and general equipment are

needed when working on the engine and transmission.

- Major dedicated equipment: Engine and transmission jack (use the one for Chairman W),

Engine stand, Engine crane, transmission jack, Engine hanger

Engine crane

Engine stand Transmission jack

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-17

Lower the engine and transmission (transaxle) at the same time.

- Manual transmission: Can be removed and installed after lowering with the engine and sub

frame at the same time.

- Automatic transmission: Only transmission can be removed and installed after removing the

sub frame.

3) During Service Work

(1) Before lifting up the vehicle with lift, correctly support the lifting points and lift up.

(2) When using a jack, park the vehicle on the level ground and place wheel chocks

underneath the tires. Position the jack under the frame and lift up the vehicle and then

support with chassis stand before service work.

(3) Before service work, be sure to disconnect battery negative (-) terminal to prevent

damages by bad wire and short.

(4) If service from interior of the vehicle, use protection cover to prevent damage and

cardiagn.com

contamination of seat and floor.

(5) Brake fluid and anti-freeze can damage painted surface of body. So carefully handle them

during service work.

(6) Use recommended and specified tools to increase efficiency of service work.

(7) Use only genuine spare parts.

(8) Never reuse cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut.

Replace them with new.

(9) If reused, normal functions cannot be maintained.

(10) Align the disassembled parts in clean according to disassembling order and group for easy

assembling.

(11) According to installing positions, the bolts and nuts have different hardness and design.

So be careful not to mix removed bolts and nuts each other and align them according

installing positions.

(12) To inspect and assemble, clean the parts. Securely clean the parts that related with oil not

to be affected by viscosity of oil.

(13) Coat oil or grease on the driving and sliding surfaces before installing parts. Use sealer or

gasket to prevent leakage if necessary.

(14) Tighten every bolt and nut with specified torque.

(15) When service work is completed, check finally whether the work is performed properly or

the problem is solved.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-18 0000-00

4) Basic Inspection

(1) Horn operation

- Listen for horn sound by operating the horn.

(2) Brake operation

- Check if there is any abnormal noise, braking distance is increased or the braking force is

applied to the only one wheel. If the brake warning lamp is not turned off or flashing, recheck

the brake system because there is a fault in the brake system.

- Check the brake pipes and hoses for connection, oil leak, crack or interference after

changing tire location. When replacing tires check the brake disc for surface condition and

wear, too.

- Check the parking brake cable and brake operation. Inspect the brakes more often if habit

or conditions result in frequent braking.

cardiagn.com

(3) Exhaust system

- Be alert to any changes in the sound of the system or the smell of the fumes. These are

signs that the system may be leaking or overheating. Have the system inspected and

repaired immediately.

- Inspect the complete system (including the catalytic converter if equipped). Inspect the body

near the exhaust system. Look for broken, damaged, missing, or out-of position parts as

well as open seams, holes, loose connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep into the trunk or passenger

compartment.

(4) Tires

- Be alert to any vibration of the steering wheel or the seats at normal highway speeds. This

may mean a wheel needs to be balanced. Also, a pull right or left on a straight, level road

may show the need for a tire pressure adjustment or a wheel alignment.

(5) Steering and suspension system

- Inspect the front and rear suspension and the steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. Clean and inspect the drive axle boot and

seals for damage, tears or leakage. Replace the seals if necessary.

(6) Engine oil

- Check the oil level and add oil if necessary. The best time to check the engine oil level is

when the oil is warm.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-19

(7) Coolant

- Check the coolant level in the coolant reservoir and coolant condition (contamination, foreign

material), coolant hose damage or leakage. Replace or add Ssangyong genuine coolant, if

needed.

(8) Engine drive belt

- Check all drive belts of the engine for wear, crack, looseness, tension. Retighten or replace

the belt, if needed.

cardiagn.com

CHASSIS GENERAL INFORMATION

korando 2010.10

01-20 0000-00

2. JACK-UP POINTS

▶ Stand jack-up points and installation status (front side)

Stand jack-up points and installation

status (front side)

Mounting status

cardiagn.com

Jack-up points Jack-up points

for 2-post lift for 2-post lift

Stand jack-up points and installation

status (rear side)

Mounting status

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-21

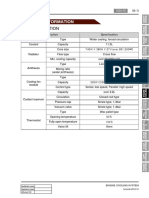

3. STANDARD BOLTS SPECIFICATIONS

cardiagn.com

1) Metric bolt strength is embossed on the head of each bolt. The strength of bolt can be

classified as 4T, 7T, 8.8T, 10.9T, 11T and 12.9T in general.

2) Observe standard tightening torque during bolt tightening works and can adjust torque to be

proper within 15 % if necessary. Try not to over max. allowable tightening torque if not

required to do so.

3) Determine extra proper tightening torque if tightens with washer or packing.

4) If tightens bolts on the below materials, be sure to determine the proper torque.

- Aluminum alloy: Tighten to 80 % of above torque table.

- Plastics: Tighten to 20 % of above torque table.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-22 0000-00

1. NEW SPECIAL TOOL

To repair Korando C, new special tools which are developed for new engine and systems,

normal equipments and conventional tools are used.

Name and Part Number Special tool Use

Part number: T99300010A

Name: Centering pin for

installing clutch

Use:

Used when installing clutch

disc and pressure plate to

engine.

cardiagn.com

Part number: T99410010A

Name: Rear knuckle bushing

adapter

Use:

Used when removing and

installing rear knuckle

bushing

Part number: T99420010A A dedicated tool for

Name: Differential gear oil

transmission

seal installer

Use:

Used when installing

differential side gear side

(inner) oil seal with a

dedicated tool for

transmission.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-23

2. NORMAL EQUIPMENTS

1) Engine Assembly Removal & Installation Equipments

Name and Part Number Tool Use

Name: Engine and

transmission jack

Use:

High load jack dedicated for

Chairman W,

but can be used for Korando

C to support module when

lowering engine and

transmission mounted to sub

frame at the same time

cardiagn.com

(replacing manual

transmission).

Name: Engine stand

(1 tone or more)

Use:

Used to fix the removed

engine or engine and

transmission (transaxle) and

can support at least 1 tone.

Name: Engine crane

(1 tone or more)

Use:

Used to move engine module

(including transaxle) to

working space or engine

stand, and can support at

least 1 tonne.

CHASSIS GENERAL INFORMATION

korando 2010.10

01-24 0000-00

2) Tool Only For Manual Transmission

Name and Part Number Tool Use

Tool only for manual

transmission

Used when assembling

manual transmission after

disassembling. It consists of

14 components.

cardiagn.com

Name:

1. Differential carrier taper

roller bearing installer

Use:

Used when installing taper

roller bearing of differential

carrier.

Name:

2. Differential carrier taper

roller bearing installer

Use:

Used when installing taper

roller bearing of differential

carrier.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-25

Name and Part Number Tool Use

Name:

3. Clutch housing oil seal

installer

Use:

Used as a connecting rod

(13) when installing clutch

Connecting rod

housing oil seal.

Name:

4. Transmission housing oil

seal installer

cardiagn.com

Use:

Used as a connecting rod

(13) when installing clutch

housing oil seal.

Connecting rod

Name:

5. Differential carrier front

bearing outer race installer

Use:

Used as a connecting rod

(13) when installing

differential carrier front

bearing outer race of clutch

housing (outer diameter: 89

mm). Connecting rod

Name:

6. Primary output shaft

bearing race installer

Use:

Used as a connecting rod

(13) when installing bearing

outer race of primary output

shaft (outer diameter: 79 Connecting rod

mm).

CHASSIS GENERAL INFORMATION

korando 2010.10

01-26 0000-00

Name and Part Number Tool Use

Name:

7. Bearing support installer

Use:

Used to support bottom of

shaft when installing gears

and hubs to output shafts.

Name:

8. Output shaft bearing

installer

cardiagn.com

Use:

Used as a bearing support

installer (7) when installing

Bearing

taper roller bearing to output

shafts. support

installer

Name:

9. Bearing outer race

installer

Use:

Used as a connecting rod

(13) when installing

differential carrier bearing

outer race of transmission

housing (outer diameter: Connecting rod

75.5 mm).

Name:

10. Control shaft oil seal

installer

Use:

Used when installing control

shaft oil seal.

CHASSIS GENERAL INFORMATION

korando 2010.10

0000-00 01-27

Name and Part Number Tool Use

Name:

11. Bearing outer race Secondary

installer output shaft

Use:

Used as a connecting rod

(13) when installing

transmission housing input

shaft and secondary output Input shaft

shaft bearing.

(Outer diameter: 70.5 mm)

Name:

12. Bearing outer race

cardiagn.com

installer

Use:

Used as a connecting rod

(13) when installing clutch

housing input shaft bearing

outer race.

(Outer diameter: 64.5 mm) Connecting rod

Name:

14. Synchro hub installer

Use:

Used as a bearing support

installer (7) when installing

gear and hub to output

shafts.

CHASSIS GENERAL INFORMATION

korando 2010.10

cardiagn.com

You might also like

- 2001 F250 Wiring DiagramsDocument107 pages2001 F250 Wiring Diagramsmike60% (5)

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Meritor ABS TrainingDocument108 pagesMeritor ABS Trainingford62b100% (3)

- Bendix ® Gen 4 TM and Gen 5 TMDocument48 pagesBendix ® Gen 4 TM and Gen 5 TMMarcialCastroLeonidasNo ratings yet

- MM 36Document23 pagesMM 36renganathan21051990No ratings yet

- Electronically Controlled Air Suspension (ECAS) For Buses and Trucks With CAN II (SAE 1939) Maintenance 0Document27 pagesElectronically Controlled Air Suspension (ECAS) For Buses and Trucks With CAN II (SAE 1939) Maintenance 0Miller Andres Aroca100% (1)

- Fdocuments - in Wabco Tebs eDocument225 pagesFdocuments - in Wabco Tebs etikiNo ratings yet

- Electronic Control of Automobiles: K.Niharika V.SindhuDocument61 pagesElectronic Control of Automobiles: K.Niharika V.SindhuNiharika KolliNo ratings yet

- How To Use KTAG Programmer To Read Detroit DD15 ACM2 Data - Auto Repair Technician HomeDocument1 pageHow To Use KTAG Programmer To Read Detroit DD15 ACM2 Data - Auto Repair Technician HomeSergiiNo ratings yet

- Proton Preve CFE Spare Part ListDocument30 pagesProton Preve CFE Spare Part ListYong Siang50% (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Anti Lock Brake System Tata Motors Information PDFDocument16 pagesAnti Lock Brake System Tata Motors Information PDFValBMSNo ratings yet

- Abs EdgeDocument39 pagesAbs Edgecorporacion corprosinfro100% (3)

- BMW Coding Parameters - I01 - For I3 SeriesDocument5 pagesBMW Coding Parameters - I01 - For I3 SeriesJB100% (1)

- MM36 ECAS Maintenance Manual For TrucksDocument22 pagesMM36 ECAS Maintenance Manual For Trucksvo phuong100% (5)

- Alfa Romeo, 2011 Alfa 159 - Alfa 159 SportwagonDocument21 pagesAlfa Romeo, 2011 Alfa 159 - Alfa 159 SportwagonJason TaitNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Lateral Acceleration SensorDocument4 pagesLateral Acceleration SensorMohamad AfiqNo ratings yet

- EPS: Electric Power Steering Components & ModesDocument9 pagesEPS: Electric Power Steering Components & ModesTilahun Worku100% (1)

- TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417C Electrical Schematic 31200832 TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417CDocument15 pagesTH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417C Electrical Schematic 31200832 TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417CEduardo67% (3)

- Registration Certificate for Vehicle KA50N2994Document1 pageRegistration Certificate for Vehicle KA50N2994Sudhir ENo ratings yet

- 722.6 AtraDocument10 pages722.6 AtraTransmisiones Guero100% (7)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument73 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SENilson BarbosaNo ratings yet

- Parts Manual Reach Stacker Rs 45 31 CH (C222e) H PM Uk en (08 2014)Document826 pagesParts Manual Reach Stacker Rs 45 31 CH (C222e) H PM Uk en (08 2014)Thawan100% (2)

- Miata Alignment SpecsDocument3 pagesMiata Alignment SpecsKevin OP100% (1)

- Kubota B2650 - B3350 - B3350SU Tractor Operators ManualDocument110 pagesKubota B2650 - B3350 - B3350SU Tractor Operators ManualСвятослав ВороновNo ratings yet

- 06 - E60 Active Front SteeringDocument19 pages06 - E60 Active Front Steeringbernacki100% (1)

- D20Dtf Engine: 1. SpecificationDocument26 pagesD20Dtf Engine: 1. SpecificationKada Ben youcefNo ratings yet

- Common Rail Diesel Systems GuideDocument24 pagesCommon Rail Diesel Systems GuideBer HonzaNo ratings yet

- Insurance Summary for BARUAH AUTOMOBILES PVT. LTDDocument2 pagesInsurance Summary for BARUAH AUTOMOBILES PVT. LTDVinayNo ratings yet

- Anti Lock Brake System (Tata Motors Information)Document16 pagesAnti Lock Brake System (Tata Motors Information)Tapas Banerjee100% (3)

- Daewoo Korando Service ManualDocument1,462 pagesDaewoo Korando Service Manualzambila4088% (17)

- Almdv Service Manual: EDC System For Hino BS III EnginesDocument47 pagesAlmdv Service Manual: EDC System For Hino BS III EnginesMohan Charanchath100% (4)

- SSP 204 EspDocument64 pagesSSP 204 Espภูเก็ต เป็นเกาะNo ratings yet

- 8150100273t2 PDFDocument34 pages8150100273t2 PDFAnonymous 6sZbadO2100% (2)

- C200 - Charge SystemDocument10 pagesC200 - Charge SystemKada Ben youcefNo ratings yet

- 2007 RobertBosch ESPDocument8 pages2007 RobertBosch ESPmovebe6870No ratings yet

- Guide to an Electric Power Steering SystemDocument45 pagesGuide to an Electric Power Steering SystemShifat UllahNo ratings yet

- General Removal and InstallationDocument54 pagesGeneral Removal and InstallationKelvis RojasNo ratings yet

- This Content Downloaded From 85.201.166.128 On Sun, 03 Oct 2021 00:03:52 UTCDocument11 pagesThis Content Downloaded From 85.201.166.128 On Sun, 03 Oct 2021 00:03:52 UTCNguyễn Trường GiangNo ratings yet

- Viewfile 8 C 75Document39 pagesViewfile 8 C 75Memo VelascoNo ratings yet

- Pruebas ABS C2777Document58 pagesPruebas ABS C2777Alirio VilchezNo ratings yet

- Active Front SteeringDocument19 pagesActive Front SteeringENIC-AITCG100% (2)

- Air Suspension System OperationDocument2 pagesAir Suspension System Operationbob loblawNo ratings yet

- Specification: Unit Description Specification ABS ESP HecuDocument22 pagesSpecification: Unit Description Specification ABS ESP HecuKada Ben youcefNo ratings yet

- Antilock Braking System (Abs)Document7 pagesAntilock Braking System (Abs)Rushikesh WakodeNo ratings yet

- Mid 150Document51 pagesMid 150Julio Jara AguileraNo ratings yet

- Sensors Used in Electric CarsDocument5 pagesSensors Used in Electric CarsAbhinav AbhiNo ratings yet

- SUJITNAYAKDocument14 pagesSUJITNAYAKShahzad AlamNo ratings yet

- Electronic Power Assist Steering (EPAS) SystemDocument21 pagesElectronic Power Assist Steering (EPAS) SystemCamilo RamosNo ratings yet

- Abs ProgressDocument9 pagesAbs Progresseyasu mulugetaNo ratings yet

- BMW E70 Lateral Dynamics SystemsDocument29 pagesBMW E70 Lateral Dynamics SystemsmindaugasxxxxNo ratings yet

- System Description - Lane Change Assist (Audi Side Assist)Document10 pagesSystem Description - Lane Change Assist (Audi Side Assist)ergdegNo ratings yet

- Fabrication and Analysis of Intelligent Braking SystemDocument19 pagesFabrication and Analysis of Intelligent Braking SystemVishal LabdeNo ratings yet

- Project Report Nano ElectronicsDocument37 pagesProject Report Nano Electronics22L149 - SUBASH KARTHICK VNo ratings yet

- 35C Traction Control, Active Stability Control SystemDocument23 pages35C Traction Control, Active Stability Control Systemmanh100% (1)

- 16 Ignition SystemsDocument24 pages16 Ignition Systemsapinya doungsoilNo ratings yet

- P38 SYSTEM _ABS,SRS,HEVAC,GEARBOX,HELLA CCDocument16 pagesP38 SYSTEM _ABS,SRS,HEVAC,GEARBOX,HELLA CCandrianjaka27No ratings yet

- AMK chp4Document7 pagesAMK chp4atifkhot8No ratings yet

- Sensotronic Brake Control and Brake Wear Sensor: Related PapersDocument4 pagesSensotronic Brake Control and Brake Wear Sensor: Related PapersChandan C RNo ratings yet

- Ijfeat: Review Paper On Magic Body Control SuspensionDocument4 pagesIjfeat: Review Paper On Magic Body Control SuspensionTech DudeNo ratings yet

- System Description - Lane Departure Warning (Audi Lane Assist)Document13 pagesSystem Description - Lane Departure Warning (Audi Lane Assist)ergdegNo ratings yet

- Automotive Sensors and Their FunctionsDocument13 pagesAutomotive Sensors and Their Functionsمحمد أمير الهادي عزميNo ratings yet

- Advanced Chassis and Body Control Systems-Part1Document8 pagesAdvanced Chassis and Body Control Systems-Part1aliNo ratings yet

- AUTOTRONICSDocument20 pagesAUTOTRONICSAzeez Mc0% (1)

- Lane Keeping Assist System For Passenger CarsDocument8 pagesLane Keeping Assist System For Passenger CarsEnkhbaatar TumenjargalNo ratings yet

- C4-Brake ABS TrainingDocument8 pagesC4-Brake ABS TrainingcasvbNo ratings yet

- DF Series 150 and 250 Electron Control System Ser. Man. Pn-Yz103052Document29 pagesDF Series 150 and 250 Electron Control System Ser. Man. Pn-Yz103052Nerfs MendizabalNo ratings yet

- EDC 17 For H-Series BSIII and BSIV EnginesDocument69 pagesEDC 17 For H-Series BSIII and BSIV Enginestejpratappandey597No ratings yet

- BMW X5 Dynamic Stability ControlDocument34 pagesBMW X5 Dynamic Stability Controlashish_j100% (4)

- Abuki Anti Lock Braking SystemDocument20 pagesAbuki Anti Lock Braking SystemAbubaker MuzayinNo ratings yet

- Ijeit1412201203 04Document3 pagesIjeit1412201203 04Edy KurniawanNo ratings yet

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveFrom EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNo ratings yet

- CamScanner Document ScansDocument78 pagesCamScanner Document ScansKada Ben youcefNo ratings yet

- 10 Diagnostic Et Traitement Des Diarrhees Aigues de L'adulteDocument64 pages10 Diagnostic Et Traitement Des Diarrhees Aigues de L'adulteKada Ben youcefNo ratings yet

- 20 Cat Devant Des Douleurs Abdominales de L'enfantDocument51 pages20 Cat Devant Des Douleurs Abdominales de L'enfantKada Ben youcefNo ratings yet

- 22809419Document1 page22809419Kada Ben youcefNo ratings yet

- 19 Cat Devant Des Vomissements de L'enfantDocument45 pages19 Cat Devant Des Vomissements de L'enfantKada Ben youcefNo ratings yet

- 01 FcuDocument35 pages01 FcuKada Ben youcefNo ratings yet

- 11 Diagnostic Et Traitement Du Rgo de L'adulteDocument56 pages11 Diagnostic Et Traitement Du Rgo de L'adulteKada Ben youcefNo ratings yet

- 12 Cat Devant Une Creatinine EleveeDocument13 pages12 Cat Devant Une Creatinine EleveeKada Ben youcefNo ratings yet

- C200 - Fuel SystemDocument27 pagesC200 - Fuel SystemKada Ben youcefNo ratings yet

- 02 InflammationDocument65 pages02 InflammationKada Ben youcefNo ratings yet

- Component Item SpecificationDocument22 pagesComponent Item SpecificationKada Ben youcefNo ratings yet

- C200 - Intake SystemDocument9 pagesC200 - Intake SystemKada Ben youcefNo ratings yet

- C200 - Pre-Heating SystemDocument7 pagesC200 - Pre-Heating SystemKada Ben youcefNo ratings yet

- C200 - Starting SystemDocument5 pagesC200 - Starting SystemKada Ben youcefNo ratings yet

- C200 - Lubrication SystemDocument5 pagesC200 - Lubrication SystemKada Ben youcefNo ratings yet

- Engine Data ListDocument45 pagesEngine Data ListKada Ben youcefNo ratings yet

- Suspension SystemDocument13 pagesSuspension SystemKada Ben youcefNo ratings yet

- C200 - CDPF SystemDocument12 pagesC200 - CDPF SystemKada Ben youcefNo ratings yet

- Troubleshooting: 1) Work FlowDocument4 pagesTroubleshooting: 1) Work FlowKada Ben youcefNo ratings yet

- C200 - Engine GeneralDocument16 pagesC200 - Engine GeneralKada Ben youcefNo ratings yet

- C200 - Cruise Control SystemDocument12 pagesC200 - Cruise Control SystemKada Ben youcefNo ratings yet

- Cooling System SpecificationDocument11 pagesCooling System SpecificationKada Ben youcefNo ratings yet

- Specification: Unit ConstructionDocument7 pagesSpecification: Unit ConstructionKada Ben youcefNo ratings yet

- E-EGR System Specification and OperationDocument9 pagesE-EGR System Specification and OperationKada Ben youcefNo ratings yet

- Specification: 1) Appearance of WheelsDocument6 pagesSpecification: 1) Appearance of WheelsKada Ben youcefNo ratings yet

- Propeller Shaft (4Wd Only) : 1. SpecificationDocument3 pagesPropeller Shaft (4Wd Only) : 1. SpecificationKada Ben youcefNo ratings yet

- Power Steering SystemDocument5 pagesPower Steering SystemKada Ben youcefNo ratings yet

- Part Maintenance D375-5 Dan D375-6RDocument4 pagesPart Maintenance D375-5 Dan D375-6RAdi MNo ratings yet

- Código de existencia de refaccionesDocument33 pagesCódigo de existencia de refaccionesfranklin guerraNo ratings yet

- 1500 Series Simplified Front End Accessory Drive - 03022016Document3 pages1500 Series Simplified Front End Accessory Drive - 03022016M. ShaatNo ratings yet

- Hidro Driver ZTR 5900681Document72 pagesHidro Driver ZTR 5900681JoeNo ratings yet

- E Mobility Sales Review q3Document24 pagesE Mobility Sales Review q3Sylvie PerronNo ratings yet

- Alto Diesel Performance 18302 CatDocument4 pagesAlto Diesel Performance 18302 CatGustampa TampaNo ratings yet

- SpicerDocument3 pagesSpicerBrayan Mejia AlvarezNo ratings yet

- Caja Eléctrica Central (CJB) - RHD 4WDRHD RWD PDFDocument2 pagesCaja Eléctrica Central (CJB) - RHD 4WDRHD RWD PDFSamuel SouzaNo ratings yet

- Workshop Manual Transporter 2016 26-29Document524 pagesWorkshop Manual Transporter 2016 26-29samueleNo ratings yet

- Safety Assists Technologies ExplainedDocument10 pagesSafety Assists Technologies ExplainedLorenz BanadaNo ratings yet

- Pct-00048-Bolero RHD SC FB Diesel Mdi Bs2 Bs3 Micro Hybrid 2wd Ps Version 3 Sept - 2010Document130 pagesPct-00048-Bolero RHD SC FB Diesel Mdi Bs2 Bs3 Micro Hybrid 2wd Ps Version 3 Sept - 2010Bhawani CopyNo ratings yet

- C06135F Performance Curve (NM6-135)Document1 pageC06135F Performance Curve (NM6-135)Rodrigo LimaNo ratings yet

- BMW LubrikantiDocument3 pagesBMW LubrikantiNikola PorkiNo ratings yet

- Changan 1Document10 pagesChangan 1ahmedNo ratings yet

- Electronic Brake Force DistributionDocument17 pagesElectronic Brake Force Distributionvikas suryawanshi67% (3)

- Bentley Continental GT 2007 Misc Documents-BrochureDocument19 pagesBentley Continental GT 2007 Misc Documents-BrochureMusaHamzic100% (1)

- KTM Duke 125Document1 pageKTM Duke 125Zamir YusofNo ratings yet