Professional Documents

Culture Documents

Bicycle Track Coating System

Uploaded by

jovindhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bicycle Track Coating System

Uploaded by

jovindhaCopyright:

Available Formats

BICYCLE TRACK COATING SYSTEM

GENERAL DESCRIPTION

The bicycle track coating system shall be a highly specialized, high performance

coating material from a reputable manufacturer and specifically designed for

application onto hot mix asphalt (HMA) to demarcate bicycle lanes.

The bicycle track coating shall be scientifically formulated to provide the optimal

balance of performance properties for a durable, long lasting color and texture to

HMA pavement surfaces. Some of the key performance properties include wear and

crack resistance, color retention, adhesion, minimal water absorption and increased

friction properties.

The bicycle track coating performance shall be tested and verified by an

independent recognized testing laboratory. A test report confirming the

performance test results shall be provided by the coating manufacturer.

A variety of colors shall be available including, but not limited to, green, blue, red

and yellow. To ensure a quality installation, the applicator shall be

accredited/certified by the coating system manufacturer.

REFERENCE STANDARDS

The performance properties described above are with reference to the following

standards, or equivalent.

ASTM D-4541 Standard Test Method for Pull-Off Strength of Coatings Using

Portable Adhesion Tester.

ASTM D-4060 Test Method for Abrasion Resistance of Organic Coatings by the

Taber Abrasion.

ASTM D522-93A Standard Test Method for Mandrel Bend Test of Attached Organic

Coatings.

ASTM G-155 QUV Accelerated Weathering Environment. Standard Practice for

Operating Xenon Arc Light Apparatus for UV Exposure of Nonmetallic Materials.

ASTM D-2486 MEK rub test for chemical resistance.

ASTM D-570 Standard Test Method for water absorption of plastics.

ASTM E-303 British Pendulum test for friction.

EPA 24, ASTM D3960-05 Volatile Organic Compounds.

MATERIALS

Materials used for the bicycle track coating of HMA pavements shall consist of an

epoxy-modified, acrylic, waterborne coating (or equivalent) specifically designed for

application on HMA pavements and shall be formulated to provide a safe, durable,

long lasting color and texture to the pavement surface. The coating shall be

environmentally safe and meet US EPA requirements for Volatile Organic

Compounds (VOC). The colorant shall be a highly concentrated, high quality, UV

stable, mineral oxide-based pigment blend designed to provide color to the coating.

The primer, if required by the coating manufacturer, shall be formulated to enhance

the adhesion of coating to new pavement, pre-existing pavement and/or previously

coated pavements.

PERFORMANCE PROPERTIES

The bicycle track coating system shall comply with the following performance

properties (or equivalent) and be backed up by test certificates from an

independent qualified testing laboratory.

Property Test Method Value

Durability: Taber ASTM D-4060 (1 day cure, H-10 <1.5 g/1000

Abrasion resistance wheel: cycles)-dry

Water sensitivity ASTM D570 (Water absorption <10%

after 9 days: Remaining absorption

after 1 hour of recovery:) < 1.0%

Color stability No significant fading

ASTM G-155

when compared to a

QUV 2,000 hours

control sample

Flexibility: 0.5mm thick sample

Mandrel Bend ASTM D522-93A Flexibility as passes 10 mm at 21°C

measured by Mandrel bend 0.5mm thick sample

passes 125mm at -18°C

Chemical ASTM D-2486 Modified MEK scrubs

resistance 400 microns, number of scrubs >5000

until 50% substrate exposed

Adhesion to

Asphalt ASTM D-4541 Substrate Failure

Friction Wet ASTM E-303 British Pendulum

>55

Tester

Environmental EPA 24, ASTM D3960-05

VOC < 150

Sensitivity Volatile Organic Compounds

APPLICATION

Ambient weather conditions, substrate preparation, application, re-coating

intervals, curing duration prior to use, etc. shall be strictly according to the coating

manufacturer’s requirements and recommended methods, procedures and

equipment.

The coating shall be applied in a minimum number of 3 coats (excluding any

primer/resurfacer) to achieve the minimum total dry film thickness of 800 microns

(plus thickness of primer/resurfacer) for the bicycle track or any associated

pedestrian areas. Lane marking paint, if required, shall be from the same

manufacturer as the bicycle coating system manufacturer. If other type of lane

marking paint is used it shall be compatible with the bicycle track coating and be

endorsed by its manufacturer.

WARRANTY

The bicycle track coating system shall have a 10-year performance warranty from

the manufacturer/supplier. Any defects in the applied coating system, beyond

normal wear and tear, shall be repaired by the manufacturer/supplier at no cost to

the Department.

You might also like

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Basf Masterprotect 300 SpecDocument2 pagesBasf Masterprotect 300 SpecWilfredoEnghoyNo ratings yet

- Xtreme 10 Mil Vapor Barrier Submittal - 06JUN13Document6 pagesXtreme 10 Mil Vapor Barrier Submittal - 06JUN13Binhscbm BinhscbmNo ratings yet

- CIM 800 Waterproof Coating for Roofs & DecksDocument4 pagesCIM 800 Waterproof Coating for Roofs & DecksIng Ramon GonzalezNo ratings yet

- ITEM 594.14010011 - Molded Rubber Fender Panel SystemDocument7 pagesITEM 594.14010011 - Molded Rubber Fender Panel Systemphd.meethaqNo ratings yet

- SEAL KRETE Epoxy Shell 1000 SpecificationDocument7 pagesSEAL KRETE Epoxy Shell 1000 SpecificationWalterEscalanteNo ratings yet

- 2603 2604 2605 - Comparisons - 4 6 11 PDFDocument1 page2603 2604 2605 - Comparisons - 4 6 11 PDFuocmogiandi_a100% (1)

- TDS 0038 DisboPOX-230-SF 201908Document7 pagesTDS 0038 DisboPOX-230-SF 201908Insafians PowerNo ratings yet

- SECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Document2 pagesSECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Eng CivilNo ratings yet

- Rubber Wheelstop or Parking Curb SpecificationsDocument5 pagesRubber Wheelstop or Parking Curb Specificationstlctrafficsafety100% (2)

- 13-Spec-Corrosion Protection System For Marine STRDocument3 pages13-Spec-Corrosion Protection System For Marine STRsunilbauchkarNo ratings yet

- Specification System Iii Icf WaterproofingDocument8 pagesSpecification System Iii Icf WaterproofingBaugh Graphic DesignNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Dymonic 100 Data SheetDocument2 pagesDymonic 100 Data SheetDavid LuongNo ratings yet

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- ALUBOND SpecificationsDocument2 pagesALUBOND SpecificationssoosanantonyNo ratings yet

- Specifications Dampproofing (Ecodamp)Document7 pagesSpecifications Dampproofing (Ecodamp)Baugh Graphic DesignNo ratings yet

- Specification: Concrete Deck/Green Roof (Reinforced)Document7 pagesSpecification: Concrete Deck/Green Roof (Reinforced)Baugh Graphic DesignNo ratings yet

- Polyurea 1044 Standard Pure TDS ENDocument4 pagesPolyurea 1044 Standard Pure TDS ENnsh.gnkinfraNo ratings yet

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Specifications Concrete Deck/Thin Set Tile OverlaymentDocument8 pagesSpecifications Concrete Deck/Thin Set Tile OverlaymentBaugh Graphic DesignNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- PDS Polyken Ygiii Oct13 V2 Aarps 0591Document2 pagesPDS Polyken Ygiii Oct13 V2 Aarps 0591Senthilkumar NarayananNo ratings yet

- DacrometDocument6 pagesDacrometPeter MangalukiNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- C 509 - 94 R99 - Qzuwos1sruqDocument6 pagesC 509 - 94 R99 - Qzuwos1sruqGustavo Adolfo Vargas MorantesNo ratings yet

- Whitechem Polyurea Pa 1005-EnDocument4 pagesWhitechem Polyurea Pa 1005-EnBien PangilinanNo ratings yet

- Kuat TarikDocument1 pageKuat TarikSeptian Ega PrasetyoNo ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- EpdmDocument2 pagesEpdmhappale2002No ratings yet

- Cerakote Brochure 2014 WebDocument2 pagesCerakote Brochure 2014 WebImaful HansaNo ratings yet

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDocument7 pagesMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- Cssbi S8 2018Document3 pagesCssbi S8 2018bpengineerNo ratings yet

- Pds Psx700 Jan 2008Document3 pagesPds Psx700 Jan 2008mjayhawk28No ratings yet

- Source Approval Kataline Part 2Document13 pagesSource Approval Kataline Part 2Arun KumarNo ratings yet

- Imact Protection From GoogleDocument4 pagesImact Protection From Googlemohammad noufalNo ratings yet

- 3M InfnDocument32 pages3M InfnAkash AkuNo ratings yet

- Offshore coating repair durability testing of pre-treatment quality and coating layersDocument17 pagesOffshore coating repair durability testing of pre-treatment quality and coating layersANIBALLOPEZVEGA100% (1)

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- Duct Liner PM: Air Handling SystemsDocument2 pagesDuct Liner PM: Air Handling SystemsEmiliuss HernandezNo ratings yet

- Specification - GeotextileDocument5 pagesSpecification - GeotextilechialunNo ratings yet

- Inter Shield 300 PICDocument2 pagesInter Shield 300 PICRifqi Fajri PrayudiNo ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Aama 2604 Color Card120 - RalDocument2 pagesAama 2604 Color Card120 - RalDee DeeNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Technical Specification WaterproofingDocument19 pagesTechnical Specification WaterproofingCee JayNo ratings yet

- MSDS-002 Sureflow 100Document45 pagesMSDS-002 Sureflow 100joker batmanNo ratings yet

- Specifications Waterproofing Tunnels/Underground StructuresDocument14 pagesSpecifications Waterproofing Tunnels/Underground StructuresBaugh Graphic DesignNo ratings yet

- Specification Concrete and Cmu Walls With BentoniteDocument8 pagesSpecification Concrete and Cmu Walls With BentoniteBaugh Graphic DesignNo ratings yet

- Fabrication of Large GRP Storage TanksDocument60 pagesFabrication of Large GRP Storage TanksjoekaledaNo ratings yet

- HIGH STRENGTH SILICONE SEALANTDocument1 pageHIGH STRENGTH SILICONE SEALANTEstevan huertasNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Traffic GuardDocument3 pagesTraffic GuardSyed HassaanNo ratings yet

- Suggested Specifications For X-PLUG-GreenstreakDocument3 pagesSuggested Specifications For X-PLUG-GreenstreakAlsayed DiabNo ratings yet

- Specifications Vapor Barrier/Dampproofing (Ecodamp)Document6 pagesSpecifications Vapor Barrier/Dampproofing (Ecodamp)Baugh Graphic DesignNo ratings yet

- Mobil SHC PM SeriesDocument3 pagesMobil SHC PM SeriesVictor ZhicayNo ratings yet

- 07 31.10.2022 - October 2022 Commission Monthly Progress Report (63) UpdatedDocument2 pages07 31.10.2022 - October 2022 Commission Monthly Progress Report (63) UpdatedjovindhaNo ratings yet

- Inspection-Certificate 2Document1 pageInspection-Certificate 2jovindhaNo ratings yet

- LHC Congress 2003 FinalDocument13 pagesLHC Congress 2003 FinaljovindhaNo ratings yet

- Vehicle License DetailsDocument1 pageVehicle License DetailsjovindhaNo ratings yet

- EIS Meadows Fee Policy For The Year 2021 2022Document2 pagesEIS Meadows Fee Policy For The Year 2021 2022jovindhaNo ratings yet

- Flexible Sheets For Waterproofing Ð Determination of Resistance To Tearing (Nail Shank) ÐDocument10 pagesFlexible Sheets For Waterproofing Ð Determination of Resistance To Tearing (Nail Shank) ÐjovindhaNo ratings yet

- Health CertificateDocument1 pageHealth CertificatejovindhaNo ratings yet

- Asphalt Mix Design Submittal: Project DescriptionDocument11 pagesAsphalt Mix Design Submittal: Project DescriptionjovindhaNo ratings yet

- Failures in Wearing Course For The Cycle Track1Document1 pageFailures in Wearing Course For The Cycle Track1jovindhaNo ratings yet

- Page 5 From BS EN 1344Document1 pagePage 5 From BS EN 1344jovindhaNo ratings yet

- Project: Subject: Reply Date: Product ADM COMMENTS (Application No: 202200286578)Document6 pagesProject: Subject: Reply Date: Product ADM COMMENTS (Application No: 202200286578)jovindhaNo ratings yet

- Failures in Wearing Course For The Cycle TrackDocument4 pagesFailures in Wearing Course For The Cycle TrackjovindhaNo ratings yet

- TT S 00227eDocument25 pagesTT S 00227eJesse JamesNo ratings yet

- Asjad CVDocument2 pagesAsjad CVjovindhaNo ratings yet

- 16.consultant Technical Evalution ReportsDocument1 page16.consultant Technical Evalution ReportsjovindhaNo ratings yet

- DSF-CRS-0952-02 Technical Submittal For Cement Lining of CS Pipes FittingsDocument3 pagesDSF-CRS-0952-02 Technical Submittal For Cement Lining of CS Pipes FittingsjovindhaNo ratings yet

- MAT-0010-Precast Concrete Kerbs - ADM Comments - RejectedDocument1 pageMAT-0010-Precast Concrete Kerbs - ADM Comments - RejectedjovindhaNo ratings yet

- Text For UplodingDocument1 pageText For UplodingjovindhaNo ratings yet

- Development of Roads Network at Mina Zayed Phase 1 Main TunnelDocument3 pagesDevelopment of Roads Network at Mina Zayed Phase 1 Main TunneljovindhaNo ratings yet

- Sandeep Singh: Contact No.: +971-508637292/ +91-9417177292Document2 pagesSandeep Singh: Contact No.: +971-508637292/ +91-9417177292jovindhaNo ratings yet

- MAT-MEP-0827 FIRE WATER TANK - ADM Comments - Returned For ModificationDocument1 pageMAT-MEP-0827 FIRE WATER TANK - ADM Comments - Returned For ModificationjovindhaNo ratings yet

- Rev. 00Document1 pageRev. 00jovindhaNo ratings yet

- Pitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemDocument9 pagesPitchmastic PMB LTD: Pitchmastic Bridge Deck Waterproofing System PMB Bridge Deck Waterproofing SystemjovindhaNo ratings yet

- Soil Analysis Services: World Class Geotechnical TestingDocument10 pagesSoil Analysis Services: World Class Geotechnical TestingjovindhaNo ratings yet

- IRI CommentsDocument1 pageIRI CommentsjovindhaNo ratings yet

- Action Plan For Close Out - 19122020Document5 pagesAction Plan For Close Out - 19122020jovindhaNo ratings yet

- CICONDocument1 pageCICONjovindhaNo ratings yet

- ASTM PageDocument1 pageASTM PagejovindhaNo ratings yet

- CICON - AUH Commercial License 2015Document1 pageCICON - AUH Commercial License 2015jovindhaNo ratings yet

- Honeybee Corpses As An Available Source of ChitinDocument8 pagesHoneybee Corpses As An Available Source of Chitinيحيى بورغدةNo ratings yet

- Unacademy NotesDocument52 pagesUnacademy NotesSoumyadeep DasNo ratings yet

- Heterocyclic Compounds: Lecture Note-3 Organic Chemistry CHE 502Document70 pagesHeterocyclic Compounds: Lecture Note-3 Organic Chemistry CHE 502Asif Khan100% (1)

- Honey-Profiling 2.0: Innovation With IntegrityDocument4 pagesHoney-Profiling 2.0: Innovation With IntegritySergio PérezNo ratings yet

- Rate of Reaction Lab - ProcedureDocument7 pagesRate of Reaction Lab - ProcedureSara Alexander100% (3)

- D1921-18 Standard Test Methods For Particle Size (Sieve Analysis) of Plastic MaterialsDocument4 pagesD1921-18 Standard Test Methods For Particle Size (Sieve Analysis) of Plastic MaterialsMarthaAlbaGuevara50% (2)

- Tantangan National High School: ?V SizxrscxbloDocument5 pagesTantangan National High School: ?V SizxrscxbloNelsonCatipayNo ratings yet

- Botanical Rust Remover From Macopa Fruit Extracts and Vinegar - Chapter 1Document8 pagesBotanical Rust Remover From Macopa Fruit Extracts and Vinegar - Chapter 1Samuel VillajuanNo ratings yet

- BT-303 Lab ManualDocument21 pagesBT-303 Lab ManualZakaullah Akhtar50% (2)

- TiO2 NPs - Daun Jarak PagarDocument4 pagesTiO2 NPs - Daun Jarak PagarselviraNo ratings yet

- Consumibles de CromatografiaDocument4 pagesConsumibles de CromatografiaRoberto Celso ChuquimayoNo ratings yet

- Polymer Testing: Material BehaviourDocument9 pagesPolymer Testing: Material BehaviourSiddharthBhasneyNo ratings yet

- SolutionsDocument51 pagesSolutionsSaad MazharNo ratings yet

- SPF HIS Oven Cleaner Gel CL-9221 ENDocument2 pagesSPF HIS Oven Cleaner Gel CL-9221 ENrezaNo ratings yet

- Compd Data Sheet 5060G ISO Ver 150106Document1 pageCompd Data Sheet 5060G ISO Ver 150106nimonhNo ratings yet

- 2022-Synoxyl® AZ BrochureDocument12 pages2022-Synoxyl® AZ BrochureMihaela Simona IsacNo ratings yet

- (B) Van Der Waals Equation of StateDocument3 pages(B) Van Der Waals Equation of StateOmkar NathNo ratings yet

- Process Modelling and SimulationDocument20 pagesProcess Modelling and SimulationSaurabh GuptaNo ratings yet

- All NDE ProcedureDocument35 pagesAll NDE ProcedureArun Karthikeyan100% (2)

- Chem 14 (2nd) PDFDocument44 pagesChem 14 (2nd) PDFRyanNo ratings yet

- QP Spec For Pre-Commissioning and New Commissioning of New Pipelines (QP-SPC-L-012-R1)Document29 pagesQP Spec For Pre-Commissioning and New Commissioning of New Pipelines (QP-SPC-L-012-R1)RajeshwariNo ratings yet

- One Pager TextileCoatings WB CrosslinkerDocument4 pagesOne Pager TextileCoatings WB CrosslinkerahmetNo ratings yet

- Quantitative Determination of DissolvedDocument5 pagesQuantitative Determination of DissolvedDam Yeo WoolNo ratings yet

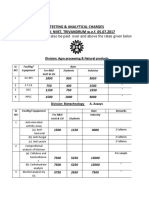

- New Testing ChargesDocument11 pagesNew Testing ChargesRay MrinalNo ratings yet

- PDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressDocument40 pagesPDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressVũ Văn QuangNo ratings yet

- CMP2015 - Nanoparticle Flotation Aids For Pentlandite FinesDocument13 pagesCMP2015 - Nanoparticle Flotation Aids For Pentlandite FinesrodrigoNo ratings yet

- Forensic Science UGC NET Examination Question Paper 2 2018 JulyDocument40 pagesForensic Science UGC NET Examination Question Paper 2 2018 JulyKuldeep SinghNo ratings yet

- Periodic Classification AakashDocument31 pagesPeriodic Classification AakashAsmitNo ratings yet

- Tapered Roller Bearing: Schaeffler IDDocument2 pagesTapered Roller Bearing: Schaeffler IDFlorian GhioculescuNo ratings yet

- 2021 JCE Chemistry LoyolaDocument10 pages2021 JCE Chemistry LoyolaMalack ChagwaNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- How to Write Construction Programmes & SchedulesFrom EverandHow to Write Construction Programmes & SchedulesRating: 4 out of 5 stars4/5 (9)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)