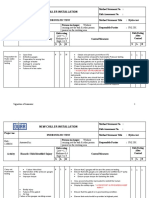

Mobile Crane Permit, Lifting Plan Method & Risk Assessment

(For regulation covering issue of this permit, Refer to Labour Law For The Private Sector, 1977 and Legislation Relating Thereto GS/ILO Regulations and BS

7121

Project Name Date

Site / Location Revision Issued By

Permit Number From To

Contact Phone

Site Contact Phone

Description of lift:

Details of Loads

Weight Date of lift:

Dimension Time of lift

Position of Cof G Monetary value of load

Height of lift (worst case only) Max. radius (Worst case only)

Details of Cranes

Make & model Max. ground bearing capacity

Capacity Counterweight

Jib length Weight of crane

Outrigger spread Outrigger load

Ground Conditions (Visual assessment)

Access/Egress for crane &

transport

Lifting position:

Identification of Hazards

Proximity Hazard Present? Proximity Hazard (cont) Present?

Overhead power lines Building

Other overhead obstacles Other hazards identified

Underground services

Excavations

Unstable / Soft ground Load Hazard Present?

Hazardous chemicals/ materials Slinging difficulties

Confined working area Top heavy

Restricted access - width Other hazards identified

Other vehicles

Complete checklist below to ensure a safe lift is planned

The load weight is confirmed known.

The load hook is directly over the load center of gravity.

Boom angle, boom length, lift radius, and the crane capacity are known.

Outrigger pads are fully extended and blocking is sufficient for the load.

PLT-C1-007-009-R00

Rev:00 (18/02/2018) Page 1 of 3

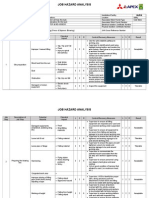

�Complete checklist below to ensure a safe lift is planned

Tires are clear of the ground and the crane is level.

Ground, soil, and/or pavement is confirmed to have capacity for the imposed load.

Rigging equipment has been inspected and in safe working condition.

All obstacles and obstructions have been identified.

A final check will determine the wind speed is within approved limits for this lift.

A signal method of communication has been determined between the crane operator and the signalman.

An individual has been designated to observe for obstructions and unauthorized personnel.

The crane operator meets MOL qualifications requirements to operate the crane.

Verify a "competent person" is to inspect prior to use and during use, all slings, fastenings, and attachments for damage or defects. Damaged or

defective equipment shall be immediately removed from service.

Verify a "competent person" is to inspect all crane equipment and machinery prior to use and during use to ensure it is in safe operating condition.

Any deficiencies shall be repaired prior to continued use.

Assessment of Risk

Hazard Present Risk Action to Avoid or Reduce Risk

Personnel Protective Equipment (PPE)

Steel-toed shoes Required for all personnel involved with lift activity to protect from crushing of feet/toes.

Gloves Required when handling materials or guiding a load.

Required for all personnel under the bridge of a moving bridge crane and whenever the potential

Hard hat

For head injury exists (e.g. Working near a load where the head could contact load).

Required when potential exists for objects to fall into eyes (e.g.. Working under bridge of crane and

Safety glasses

looking up).

Hi Vis

Other (specify)

Sketch intended to assist in clarification of crane set-up in relation to load, surrounding structures, rigging, and lay-down location. To

be completed at the discretion of the Lift Planner.

PLT-C1-007-009-

Rev:00 Page 2 of 3

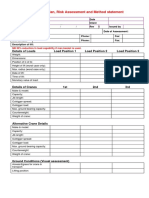

� Appointed Person's Acceptance of Responsibilities

I confirm that the lifts have been planned and will be carried out in accordance Signed Date Time

with current legislation (Order No. 14/1977 SHE-SM 25/24) and British Standard

7121 and that I accept responsibility for the preparation of this Risk Assessment

and Method Statement.

Cranes Supervisor's Acceptance of Duties

Signed Date Time

Issuing Authority

Signed Date Time

I have discussed the terms of this permit with the person responsible for the

work and now issue it

Issuing Authority

Signed Date Time

I am satisfied this permit can be cancelled.

Permit to be kept at work site. Permit must be returned to the issuing authority when job is completed or stopped.

Reset Print

PLT-C1-007-009-

Rev:00 Page 3 of 3