Professional Documents

Culture Documents

Hvi Sow101320 VLF Ieee Web

Uploaded by

CLAVOTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hvi Sow101320 VLF Ieee Web

Uploaded by

CLAVOTCopyright:

Available Formats

VLF AC WITHSTAND TESTING OF CABLE

Voltage Levels & Time Durations of Test

Advance Test Equipment for High Voltage Proof and Preventice Maintenance Testing of Electrial Apparatus hvinc.com

When performing a VLF Withstand test on shielded power cable, HVI recommends following the guidelines as set forth by the

IEEE 400.2-2013 standard. The test voltage and time duration are critical for each test described within the standard and are the

result of many years of VLF field use and 3rd party research. A VLF Withstand test performed as per IEEE 400.2-2013 will trigger a

partial discharge event within any defect large enough to be excited by the test voltage applied and drive this defect toward failure

during the test. If the test duration is not long enough, the test may only severely weaken the defect resulting in an in-service failure

sometime after the now insulation compromised cable has been put back into service. Lesser defects are not affected, as they are

not large enough to be excited into PD by the applied test voltage. They remain dormant and are not aggravated by the test voltage

since it is below the PD inception voltage level of the defect.

The information and data that follows is taken directly from the IEEE 400.2-2013 Standard.

IEEE Std. 400.2-2013

IEEE Guide for Field Testing of Shielded Power Cable Systems Using Very Low Frequency (VLF) (less than 1 Hz)

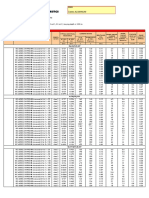

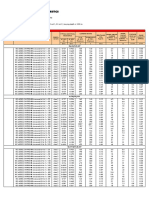

Table 3 - VLF withstand test voltages for sinusoidal and cosine-rectangular waveforms (see note 1)

Cable System Testing Maintenance2

Installation Acceptance

Waveform (phase to phase) (phase to ground)

(phase to ground) (phase to ground)

kV See Note 2

kV rms kV peak kV rms kV peak kV rms kV peak

Sinusoidal 5 9 13 10 14 7 10

8 11 16 13 18 10 14

15 19 27 21 30 16 22

25 34

20 26 37 20 28

(Note 3) (Note 3)

29 41 24 34

25 32 45

(Note 3) (Note 3) (Note 3) (Note 3)

36 51

28 32 45 27 38

(Note 3) (Note 3

29 41

30 34 48 38 54

(Note 3) (Note 3)

35 39 55 44 62 33 47

46 51 72 57 81 43 61

69 75 106 84 119 63 89

NOTE 1 - If the operating voltage is a voltage class lower than the rated voltage of the cable, it is recommended that the

maintenance test voltages should be those corresponding to the operating voltage class.

NOTE 2 - The maintenance voltage is about 75% of the acceptance test voltage magnitude.

NOTE 3 - Some existing test sets have a maximum voltage that is up to 5% below the values listed in the table. These test sets are

acceptable to be used. However, there is a risk that the cable may be “undertested” due to a combination of lower test voltage and

allowed uncertainty of the measuring circuit.

VLF ac voltage testing methods utilize ac signals at frequencies in the range of 0.01 Hz to 1 Hz. The most commonly used,

commercially available VLF ac voltage test frequency is 0.1 Hz. VLF ac test voltages with cosine-rectangular and the sinusoidal wave

shapes are most commonly used.

HIGH VOLTAGE, INC. 31 County Route 7A • Copake, NY 12516

hvinc.com • sales@hvinc.com • f. 518.329.3271 • p. 518.329.3275

VLF AC Withstand Testing of Cable

5.1 General VLF ac withstand voltage testing

5.1.1 VLF ac withstand voltage test parameters

The purpose of a withstand test is to verify the integrity of the cable under test. If the test cable has a defect severe enough at the

withstand test voltage, an electrical tree will initiate and grow in the insulation. Inception of an electrical tree and channel growth

time are functions of several factors including test voltage, source frequency and amplitude, and the geometry of the defect. For an

electrical tree from the tip of a needle in PE insulation in laboratory conditions to completely penetrate the insulation during the test

duration, VLF ac voltage test levels and testing time durations have been established for the two most commonly used test voltage

sources, the cosine-rectangular and the sinusoidal wave shapes. However, the time to failure will vary according to the type of

insulation such as PE, paper, and rubber. Thus the electrical tree growth rate is not the same for all materials and defects.

The voltage levels (installation and acceptance) are based on the most used, worldwide practices of from less than 2 U0 to 3U0,

where U0 is the rated rms phase to ground voltage, for cables rated between 5 kV and 69 kV. The maintenance test level is about

75% of the acceptance test level. One can reduce the test voltage by another 20% if the voltage is applied for longer times (Bach

[B2]; Baur, Mohaupt, and Schlick, [B6]; Krefter [B27]). Evidence (Hernandez-Mejía, et al. [B21]) indicates that increasing the voltage

above 3U0 to compensate for reduced test cycles (time) does not replicate performance either on test or in service as compared to

the lower voltage, longer time tests.

Table 3 lists voltage levels for VLF withstand testing of shielded power cable systems using cosine-rectangular and sinusoidal

waveforms (Bach [B2]; Eager, et al. [B9]; Krefter [B27]; Moh [B28]). For a sinusoidal waveform the rms is 0.707 of the peak value,

assuming less than 5% harmonic distortion. The rms and peak values of the cosine-rectangular waveform are assumed to be equal.

It should be noted that terminations may need to be added to avoid flashover for installation tests on cables rated above 35 kV.

The recommended minimum testing time for a simple withstand test on aged cable circuits is 30 min at 0.1 Hz (Goodwin, Oetjen, and

Peschel [B13]). If a circuit is considered as important, e.g., feeder circuits, then consideration should be given to extending the testing

time to 60 min at 0.1 Hz (Hampton, et al. [B19].

The recommended minimum testing time for an installation and/or acceptance withstand test on new cable circuits is 60 minutes.

A test time within the range 15–30 min may be considered if the monitored characteristic remains stable for at least 15 min and no

failure occurs. It should be noted that the recommended test time for a withstand test is 30 min.

If the circuit fails during the test, it should be repaired or replaced and then retested using a complete 30-minute test, preferably a

monitored withstand test. It is recommended to retest each section with VLF-TD, VLF-DTD, VLF-TDTS, or VLF-PD before the repair

to get an assessment of the cable before repair. It is also recommended to retest with VLF-TD, VLF-DTD, VLF-TDTS, or VLF-PD after

repair to assess the workmanship of the repair. Monitoring cannot be used to reduce the tests as the cable system has already been

shown to be potentially weak by the prior failure. End of IEEE reference.

Summary

The above information describes VLF Withstand testing, where the intent of the test is to apply a sufficient test voltage for a long

enough time to permit any severe defects driven into partial discharge to fail within the test duration. If a defect can’t withstand the

test voltage, let it fail and make the repair or replacement. If the cable holds, the operator has a high assurance that the cable should

not fail in service for many years.

If a pass/fail AC Withstand test is not desired, there are several qualitative Diagnostic Tests available. Using the VLF as the over

voltage source, Tangent Delta (δ) measurements and Partial Discharge detection and location tests can be performed with

accessories added; available from HVI.

HIGH VOLTAGE, INC. 31 County Route 7A • Copake, NY 12516

hvinc.com • sales@hvinc.com • f. 518.329.3271 • p. 518.329.3275

VLF-IEEE-SS-V2-03/2020-TC

You might also like

- VLF Cable Test Voltages Per IEEE 400.2 1Document2 pagesVLF Cable Test Voltages Per IEEE 400.2 1Hamdan Hasian RitongaNo ratings yet

- VLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVDocument1 pageVLF-6022CM (F) : VLF Cable Testing For Cables Rated To 35kVSelk CLNo ratings yet

- VLF-65E: VLF Cable Testing For Cables Rated To 35kVDocument1 pageVLF-65E: VLF Cable Testing For Cables Rated To 35kVMarcos Willian RodriguesNo ratings yet

- Baterias 6FTJ-100BDocument2 pagesBaterias 6FTJ-100Bpaolo gonzalo padilla gonzalesNo ratings yet

- 2nd Period LabDocument4 pages2nd Period Labapi-458764744No ratings yet

- Table 4d5Document1 pageTable 4d5Eddie TweNo ratings yet

- Field Devices - Traditional: Product SpecificationsDocument6 pagesField Devices - Traditional: Product SpecificationsGolconda MitraNo ratings yet

- 7RE28x ManualDocument10 pages7RE28x ManualĐỗ Xuân BằngNo ratings yet

- DC test verifies vacuum integrity in MV switchgearDocument4 pagesDC test verifies vacuum integrity in MV switchgearnassarkiNo ratings yet

- HVT 250 Edr5219 PDFDocument8 pagesHVT 250 Edr5219 PDFMax FerreNo ratings yet

- 2.1 Protection Development Branch: Industrial Training ReportDocument11 pages2.1 Protection Development Branch: Industrial Training ReportIsuru Pasan DasanayakeNo ratings yet

- MES2 Humidifier O&MDocument54 pagesMES2 Humidifier O&MpabloabelgilsotoNo ratings yet

- Philips ApplicationBook IndustrialTriacsApplications 1975-02Document144 pagesPhilips ApplicationBook IndustrialTriacsApplications 1975-02hidalgobNo ratings yet

- Art1k6fh 1K6FHS 1K6FHGDocument17 pagesArt1k6fh 1K6FHS 1K6FHGWagner AngenendtNo ratings yet

- Fusing Equipment: Oil Immersed Current Sensing Weak Link CartridgeDocument4 pagesFusing Equipment: Oil Immersed Current Sensing Weak Link Cartridgeheri fauziNo ratings yet

- Art2k0fe 2k0fes 2k0fegDocument18 pagesArt2k0fe 2k0fes 2k0fegjavier mauricio gomezNo ratings yet

- CVM 2Document23 pagesCVM 2Mantenimiento RibagorzaNo ratings yet

- Test 2 Semester 2Document4 pagesTest 2 Semester 2smisosphamandla30No ratings yet

- The Role of AC & DC Hipot Testing in Stator Winding AgeingDocument4 pagesThe Role of AC & DC Hipot Testing in Stator Winding AgeingGonzalo GómezNo ratings yet

- How To Determine Cable Size With Exampe-1Document8 pagesHow To Determine Cable Size With Exampe-1Charles Ekpima100% (1)

- Summary Results of North Arm Bridge Cable Model AnalysisDocument7 pagesSummary Results of North Arm Bridge Cable Model Analysisbcdavid100% (1)

- STP 4 N 150Document23 pagesSTP 4 N 150Калин КалиновNo ratings yet

- Panasonic Tc-21fg20p Gp31 Service ManualDocument30 pagesPanasonic Tc-21fg20p Gp31 Service ManualAlfatah Dan AryaNo ratings yet

- Ehsan (3050) Lab 02Document6 pagesEhsan (3050) Lab 02Antenna /// Power ElectronicsNo ratings yet

- A Study For Electric Environment Characteristics in 154kV AC / 80kV DC Hybrid Transmission LineDocument8 pagesA Study For Electric Environment Characteristics in 154kV AC / 80kV DC Hybrid Transmission LineHugh EdwardsNo ratings yet

- LSA 42.2 Alternator Technical Data SheetDocument7 pagesLSA 42.2 Alternator Technical Data SheetParinyaNo ratings yet

- 4.3 Transfer of The AFRL 0.14Document4 pages4.3 Transfer of The AFRL 0.14475976550No ratings yet

- Questions and ProblemsDocument7 pagesQuestions and ProblemsMarife CompraNo ratings yet

- EMC Data Sheet Variable Speed DriveDocument24 pagesEMC Data Sheet Variable Speed Drivehafid ganeshaNo ratings yet

- Engineering Utilities: Lecture 1: Lighting, Outlets, Laundry, RangeDocument24 pagesEngineering Utilities: Lecture 1: Lighting, Outlets, Laundry, RangeChelsiemea VargasNo ratings yet

- Sattcon Op (V4) : Maintenance ManualDocument43 pagesSattcon Op (V4) : Maintenance Manualgrant muirNo ratings yet

- Relay and HV Lab-ManualDocument38 pagesRelay and HV Lab-ManualBhavik PrajapatiNo ratings yet

- Multi Function Meter: 2 X 7 MW Ende Coal Fired Power Plant 70Kv Switchyard Field Test ReportDocument18 pagesMulti Function Meter: 2 X 7 MW Ende Coal Fired Power Plant 70Kv Switchyard Field Test ReportAnto DamanikNo ratings yet

- Quality Protection Commissioning ProceduresDocument43 pagesQuality Protection Commissioning Proceduressheik hussain100% (1)

- FT Series: FTA12-200 12V200Ah FTA12-200 12V200AhDocument2 pagesFT Series: FTA12-200 12V200Ah FTA12-200 12V200AhALEX ALEXNo ratings yet

- VII.4 Test Method of Trap Performance For Induced SiphonageDocument13 pagesVII.4 Test Method of Trap Performance For Induced SiphonageAl FauzanNo ratings yet

- Chapter 8.2-A Commissioning of The Micom P220 RelayDocument22 pagesChapter 8.2-A Commissioning of The Micom P220 RelayGaurang PatelNo ratings yet

- TPS7A4700EVM-094 Evaluation Module: User's GuideDocument14 pagesTPS7A4700EVM-094 Evaluation Module: User's GuideJaroslav BiresNo ratings yet

- Transformer Failure Analysis Case Study Weidmann Electrical Technology AGDocument5 pagesTransformer Failure Analysis Case Study Weidmann Electrical Technology AGHanumantha Kumar100% (1)

- Electrical Switchboard Test and Commissioning ProcedureDocument4 pagesElectrical Switchboard Test and Commissioning ProcedureAodman4u100% (2)

- KX Tga270lxsDocument64 pagesKX Tga270lxsAnonymous Lfgk6vygNo ratings yet

- Commander S100 EMC Datasheet Issue 1 - 1Document33 pagesCommander S100 EMC Datasheet Issue 1 - 1Hugo CepedaNo ratings yet

- Selection of Station Surge Arresters For Control of Slow-Front Overvoltages On Compact LinesDocument15 pagesSelection of Station Surge Arresters For Control of Slow-Front Overvoltages On Compact LinesGreen BeretNo ratings yet

- Voltage Detecting Protecting Relay: ApplicationDocument7 pagesVoltage Detecting Protecting Relay: ApplicationNelson P. ColoNo ratings yet

- Transformer Routine TestDocument22 pagesTransformer Routine TestFarekhNo ratings yet

- Dokumen - Tips - Dewa Testing Procedure 1Document27 pagesDokumen - Tips - Dewa Testing Procedure 1aksamiNo ratings yet

- ART700FH: 1. Product ProfileDocument16 pagesART700FH: 1. Product ProfileFahry PramoddyaNo ratings yet

- Alternator LSA42.3j enDocument12 pagesAlternator LSA42.3j enArdi Wiranata PermadiNo ratings yet

- Abdullah Al MahiDocument8 pagesAbdullah Al Mahianisruhan6No ratings yet

- RCM 601buz 45Document2 pagesRCM 601buz 45Raymond CruzinNo ratings yet

- Arc Flash: Technical PerspectiveDocument29 pagesArc Flash: Technical Perspective최형식No ratings yet

- Ex5 (Ra2111003010611)Document15 pagesEx5 (Ra2111003010611)shubhamNo ratings yet

- 5.2.3.1equipment For High Voltage Spark TestingDocument5 pages5.2.3.1equipment For High Voltage Spark TestingManriquez AndresNo ratings yet

- MVGC Operating ManualDocument46 pagesMVGC Operating ManualMartin ManuelNo ratings yet

- BGR ProjectDocument37 pagesBGR ProjectAnonymous TPVfFif6TONo ratings yet

- EMD Power Utilities Termination Whitepaper - USDocument12 pagesEMD Power Utilities Termination Whitepaper - USfaisalardy20No ratings yet

- BLF888A BLF888AS: 1. Product ProfileDocument17 pagesBLF888A BLF888AS: 1. Product ProfileCordell JonesNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Practical Power System and Protective Relays CommissioningFrom EverandPractical Power System and Protective Relays CommissioningRating: 4.5 out of 5 stars4.5/5 (10)

- Gis - Elk-04 - 170 - 1HC0130351 - Ag21 - enDocument16 pagesGis - Elk-04 - 170 - 1HC0130351 - Ag21 - enCLAVOTNo ratings yet

- BA 3AE Vakuum Leistungsschalter SION EN 201409231052218953 PDFDocument72 pagesBA 3AE Vakuum Leistungsschalter SION EN 201409231052218953 PDFSales PowertransmisiNo ratings yet

- Power & Control Cables: U /U 0.6/1 KV - IEC 60502-1Document72 pagesPower & Control Cables: U /U 0.6/1 KV - IEC 60502-1Amar JabarNo ratings yet

- Operating InstructionsDocument72 pagesOperating InstructionsCLAVOTNo ratings yet

- 45IECMC D-Line F Line ContactorsDocument33 pages45IECMC D-Line F Line ContactorsCLAVOTNo ratings yet

- KYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearDocument1 pageKYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearCLAVOTNo ratings yet

- KYN61-40.5 (Z) KYN61-40.5 (Z) : Metalclad AC Enclosed Switchgear Metalclad AC Enclosed SwitchgearDocument5 pagesKYN61-40.5 (Z) KYN61-40.5 (Z) : Metalclad AC Enclosed Switchgear Metalclad AC Enclosed SwitchgearCLAVOTNo ratings yet

- File 2697 BGDocument64 pagesFile 2697 BGCLAVOTNo ratings yet

- KYN61-40.5 Metal-Claded Withdrawable Type AC Metal-Enclosed SwitchgearDocument4 pagesKYN61-40.5 Metal-Claded Withdrawable Type AC Metal-Enclosed SwitchgearCLAVOTNo ratings yet

- Visual Inspection of TransformersDocument1 pageVisual Inspection of TransformersCLAVOTNo ratings yet

- Verification of camera system functionality and image qualityDocument5 pagesVerification of camera system functionality and image qualityCLAVOTNo ratings yet

- Operating Instructions: GeneralDocument2 pagesOperating Instructions: GeneralCLAVOTNo ratings yet

- Kubikel ListrikDocument120 pagesKubikel Listrikqodir_jaelaniNo ratings yet

- 7ss52 CatalogDocument16 pages7ss52 CatalogParichay GuptoNo ratings yet

- Power & Control Cables: U /U 0.6/1 KV - IEC 60502-1Document72 pagesPower & Control Cables: U /U 0.6/1 KV - IEC 60502-1Amar JabarNo ratings yet

- Fist3 30Document87 pagesFist3 30flegias100% (1)

- Intelilite mrs16Document632 pagesIntelilite mrs16CLAVOTNo ratings yet

- C NRJED315663EN 030418Document72 pagesC NRJED315663EN 030418bakien-canNo ratings yet

- Intelilite mrs16Document632 pagesIntelilite mrs16CLAVOTNo ratings yet

- Installation Operation Maintenance Technical Manual: Medium Voltage DistributionDocument76 pagesInstallation Operation Maintenance Technical Manual: Medium Voltage DistributionAurel DeduNo ratings yet

- MI GentleSpace 202012Document9 pagesMI GentleSpace 202012CLAVOTNo ratings yet

- Visual Inspection of TransformersDocument1 pageVisual Inspection of TransformersCLAVOTNo ratings yet

- Electrical Characteirstics IEC60502 2 Hypron Armoured SWAx ALUMINIUMDocument2 pagesElectrical Characteirstics IEC60502 2 Hypron Armoured SWAx ALUMINIUMCLAVOTNo ratings yet

- Utx/Mtx: Medium-Voltage SwitchgearDocument36 pagesUtx/Mtx: Medium-Voltage SwitchgearCLAVOT100% (1)

- C NRJED315663EN 030418Document72 pagesC NRJED315663EN 030418bakien-canNo ratings yet

- Electrical Characteirstics IEC60502 2 Hypron Armoured SWAxDocument2 pagesElectrical Characteirstics IEC60502 2 Hypron Armoured SWAxCLAVOTNo ratings yet

- Dept. EEE-2Document118 pagesDept. EEE-2RENGANATHAN PNo ratings yet

- Matlab & SimulinkDocument63 pagesMatlab & Simulinkabdullah86100% (1)

- (Ebook) - Electronics - Direct Current Electrical Motor PDFDocument1 page(Ebook) - Electronics - Direct Current Electrical Motor PDFCLAVOTNo ratings yet

- LST Gext3gcell - 071019Document3 pagesLST Gext3gcell - 071019Fred SiriuraoNo ratings yet

- TIA-862-B Draft 3 Due 2014-12-29Document43 pagesTIA-862-B Draft 3 Due 2014-12-29pabloabelgilsotoNo ratings yet

- The Electromagnetic Spectrum: Multiple ChoiceDocument10 pagesThe Electromagnetic Spectrum: Multiple ChoiceVannie MonderoNo ratings yet

- WCDMA HSPA optimization report metricsDocument19 pagesWCDMA HSPA optimization report metricsnorakNo ratings yet

- f1 Part 2Document25 pagesf1 Part 2ocean trotter worldwide100% (1)

- HW5e Upp Int TG Unit 05Document12 pagesHW5e Upp Int TG Unit 05summercourses.skylineNo ratings yet

- Electrical System - Body Radio Model 140Document3 pagesElectrical System - Body Radio Model 140Adrian FacaletNo ratings yet

- MCQ in Electronics - Principles of CommunicationsDocument9 pagesMCQ in Electronics - Principles of CommunicationsJhade Alcaraz89% (9)

- SAILOR RT2048 VHF Radio ManualDocument12 pagesSAILOR RT2048 VHF Radio ManualAkin OnalNo ratings yet

- DSTV Decoder - FREE Christian and Other ChannelsDocument1 pageDSTV Decoder - FREE Christian and Other Channelsbennieharmse0% (3)

- Mercedes Benz Audio 10 Owner's ManualDocument23 pagesMercedes Benz Audio 10 Owner's Manualmugavana71% (7)

- Characteristics of fading channels: Types of fading and their effectsDocument3 pagesCharacteristics of fading channels: Types of fading and their effectsAzim War100% (1)

- ONE-E-WAY INC v. Apple Patent InfringementDocument17 pagesONE-E-WAY INC v. Apple Patent InfringementJack PurcherNo ratings yet

- Samsung Troca de TelaDocument90 pagesSamsung Troca de Telarogerio pessanha dos santosNo ratings yet

- Comunicador DSC NeoDocument6 pagesComunicador DSC NeoIsmael molineroNo ratings yet

- Itu R Rec P.530 15Document53 pagesItu R Rec P.530 15Luc HenrykNo ratings yet

- Keysight Chart 5991-4907ENDocument1 pageKeysight Chart 5991-4907ENamitk guptaNo ratings yet

- SA858 Datasheet V1.5Document16 pagesSA858 Datasheet V1.5Himanshu SanadhyaNo ratings yet

- LTE1203 - Load Based Power Saving With TX Path Switching OffDocument85 pagesLTE1203 - Load Based Power Saving With TX Path Switching OffAdil MuradNo ratings yet

- STM-STM8-STM8S208MB-Learning Centre MCU-Application Notes-STMicroelectronics - Application - Notes - 17Document24 pagesSTM-STM8-STM8S208MB-Learning Centre MCU-Application Notes-STMicroelectronics - Application - Notes - 17Ahmet AkdoganNo ratings yet

- FS-T4A - Manual (HK - T4A) - Rádio PDFDocument15 pagesFS-T4A - Manual (HK - T4A) - Rádio PDFMarckos FrancoNo ratings yet

- Audio Equipments Final PDFDocument83 pagesAudio Equipments Final PDFparamveer singhNo ratings yet

- LTE Most Innovative Technology in Wireless WorldDocument7 pagesLTE Most Innovative Technology in Wireless WorldRAGHVENDRA BAJPAI EPGDIB 2017-19No ratings yet

- Apxvllll15b 43 C I20Document5 pagesApxvllll15b 43 C I20FernandoNo ratings yet

- The History of Bbc. Radio in Britain.: Televi - Sion andDocument1 pageThe History of Bbc. Radio in Britain.: Televi - Sion andMiranda AsunciónNo ratings yet

- First Steps & 1G: Archaic Mobile Communication" Electronic Communications: Fixed Networks"Document16 pagesFirst Steps & 1G: Archaic Mobile Communication" Electronic Communications: Fixed Networks"Bassem AbouamerNo ratings yet

- Activity No. 4 Street Lighting SurveyDocument19 pagesActivity No. 4 Street Lighting SurveyAlexis AguillonNo ratings yet

- Campus IoT 2020Document9 pagesCampus IoT 2020lucas ferreiraNo ratings yet

- Introduction to Broadcasting Systems and StandardsDocument8 pagesIntroduction to Broadcasting Systems and Standardsanon_534926606No ratings yet

- by Praveen SharmaDocument21 pagesby Praveen Sharmapsharma_950518No ratings yet