Professional Documents

Culture Documents

S60370 Nur Ain Farhani Binti Mohamad Yazid

Uploaded by

Ain frhnniii0 ratings0% found this document useful (0 votes)

18 views3 pagesOriginal Title

S60370 TEST GANTIAN

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views3 pagesS60370 Nur Ain Farhani Binti Mohamad Yazid

Uploaded by

Ain frhnniiiCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

S60370 NUR AIN FARHANI BINTI MOHAMAD YAZID

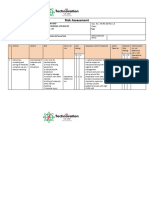

HIRARC Form (Hazard Identification at Port)

1. Hazard identification 2. Risk analysis 3. Risk Control

No Work Hazard Which can Existing risk Likelihood Severit Risk Recommended Control Measures

. activity cause/effect control y

(if any)

1. Moving Hit and being run over, appropriate 4 4 16 Ensuring that all operational areas and

Vehicles and accident crushed, or road signs access routes are sufficiently lit,

Equipment falling from a and markings especially at night or in reduced

moving vehicle visibility conditions.

2. Lifting and Lifting serious fatal Assigning a 4 5 20 Avoiding lifts over areas where people

unloading equipment injuries or being competent are likely to be working or passing and

failure and hit by falling or person to regularly inspecting and examining all

falling moving objects plan the lift lifting equipment and accessories

loads

3. Working Fall from Drowning and Guardrails 3 4 12 Ensuring that edge protection is in place

around height death and mobile on all open edges where there is a risk

unfenced elevating of falling from height

dock edges working

and wharves platform

being

installed.

4. Lifting, Repetitive back pain, workers 4 3 12 Using mechanical handling equipment,

carrying, and movement strains, sprains adopt safe such as vehicle-mounted hydraulic

maneuvering and and muscle lifting hoists, portable roller conveyors, and

loads, lifting excessive injuries. techniques pallet trucks

gear, and force

attachments

5. Badly Slips and minor injury proper 3 3 9 Ensuring that all access and emergency

stowed trips and concussion housekeeping routes are kept free of obstructions and

ropes, to broken or to keep all selecting suitable footwear for the task.

cables, dislocated parts of the

lashing gear, bones. port clean

and

equipment

6. Mooring Back lash Serious injury Stand clear of 3 5 15 Advise on never put their feet in bights

activity and being or death lines being or eyes of mooring lines or step over a

caught in thrown mooring line under tension.

the ropes

or

winches

on board

7. Handling Exposure Respiratory Hazardous 4 4 16 Both doors of the container should be

hazardous to toxic, problem or placard being opened to maximize natural ventilation

cargo poisonous death installed during cleaning operations, and any

or other necessary precautions should be

corrosive taken before entry

cargoes

8. Equipment Excessive Hearing damage Worker are 4 3 12 Sound-proofed safety cabs should be

and engines noise using ears fitted, which may also serve as a ROPS

operation productio defenders

n

9. Ship tank Toxic Respiratory permission 3 4 12 appropriate training and equipment

cleaning fumes and problem or sought from should be compulsory for the employee

substances death the master or

in the deck

confined officer in

spaces charge before

entering any

confined

space.

10. Electrical Electric Physical injury, Limiting 2 4 8 Daily inspections to ensure the electric

equipment shock burn and death electrical equipment are not exposed to water and

exposed to equipment only use safe working space when

the water or handling electrical equipment.

dirt

You might also like

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- 11 Nov 2Document13 pages11 Nov 2charlson p.cNo ratings yet

- New Job Hazard Analysis (JHA) Hot Water Geyser installationDocument2 pagesNew Job Hazard Analysis (JHA) Hot Water Geyser installationwaqar naeemNo ratings yet

- I. Categories of Fall Protection Fall Arrest SystemDocument5 pagesI. Categories of Fall Protection Fall Arrest SystemMikaella ManzanoNo ratings yet

- Hazard Identification PlanDocument11 pagesHazard Identification PlanjavithNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- Loading VehiclesDocument5 pagesLoading VehiclesgrahamkazieNo ratings yet

- Hazard & Risk Assessment - HIAB VLCDocument6 pagesHazard & Risk Assessment - HIAB VLCDilzar AliNo ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- FPP & SWP For Water Tank CleaningDocument5 pagesFPP & SWP For Water Tank Cleaning774226abNo ratings yet

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- Carefour RA-For Tile & Granite WorksDocument10 pagesCarefour RA-For Tile & Granite Worksfaizan khan100% (3)

- Hip & Jsa For Abqq-472Document13 pagesHip & Jsa For Abqq-472javithNo ratings yet

- 01 Job Hazard Analysis For Piling Works (JHA)Document3 pages01 Job Hazard Analysis For Piling Works (JHA)AmanNo ratings yet

- Working-at-Height RADocument10 pagesWorking-at-Height RADan NixonNo ratings yet

- Guide Loading Transporting Unloading LogsDocument10 pagesGuide Loading Transporting Unloading LogsPepe Benegas PesegoNo ratings yet

- Hazard & Control Drilling OprDocument108 pagesHazard & Control Drilling OprAlton MangiwaNo ratings yet

- Job Safety Analysis for Cable Laying and PullingDocument4 pagesJob Safety Analysis for Cable Laying and PullingNaukhez A. KashifNo ratings yet

- SWP/JSA Material Lifting SafetyDocument4 pagesSWP/JSA Material Lifting SafetySantosh Singh50% (2)

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- Landscaping Victoria SWMSDocument9 pagesLandscaping Victoria SWMScjNo ratings yet

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Risk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- CN Montreal Yard Rules en PDFDocument1 pageCN Montreal Yard Rules en PDFsargunam santhanamNo ratings yet

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- Boom Lift SWPDocument2 pagesBoom Lift SWPSayed AbbasNo ratings yet

- Capstan (OSRV) SOPDocument7 pagesCapstan (OSRV) SOPakbar muslimNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Material Handling by CraneDocument16 pagesMaterial Handling by Cranenitin369100% (1)

- JOB SAFETY ANALYSIS DikonversiDocument4 pagesJOB SAFETY ANALYSIS DikonversiAgung Tri SugihartoNo ratings yet

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- Unsafe Working Practices While Working Aloft and Over The SideDocument2 pagesUnsafe Working Practices While Working Aloft and Over The SideDaniel Edd BaccolNo ratings yet

- Crane SafetyDocument8 pagesCrane SafetyRaghu Dev Hosur100% (1)

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Guidelines Working Aloft ShipsDocument5 pagesGuidelines Working Aloft ShipsDank100% (1)

- Plant and Traffic MovementDocument5 pagesPlant and Traffic MovementALTHAF HUSSAINNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JSA Cable Tray Erection On Pipe RackDocument7 pagesJSA Cable Tray Erection On Pipe RacknishanthNo ratings yet

- JOB SAFETY ANALYSIS FOR CONE ERECTIONDocument6 pagesJOB SAFETY ANALYSIS FOR CONE ERECTIONEslam lotfy- Eslam elsadatNo ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- JOB SAFETY ANALYSIS FOR CHIMNEY REPAIRDocument2 pagesJOB SAFETY ANALYSIS FOR CHIMNEY REPAIRBrenden PalanithangamNo ratings yet

- Drain Line Work JSA HSE ProfessionalsDocument2 pagesDrain Line Work JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assesment - RT-PTDocument6 pagesRisk Assesment - RT-PTJohn Eric OliverNo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

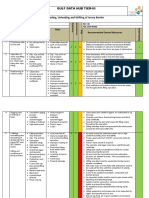

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- SAFE SHIPBOARD WORK PRACTICESDocument16 pagesSAFE SHIPBOARD WORK PRACTICESBenjo gaming100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger22No ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- JSA 48-Man basket lifting and movingDocument3 pagesJSA 48-Man basket lifting and movinggolusinghdataNo ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile Scaffoldmani narayananNo ratings yet

- Asistencia Médica A Bordo de Los BuquesDocument5 pagesAsistencia Médica A Bordo de Los BuquesJulio Martinez RodriguezNo ratings yet

- Extension: Answer KeyDocument6 pagesExtension: Answer Keybenilde bastidaNo ratings yet

- Automatic Identification System (AIS) - Ship Navigation System-ETO - Electro Technical OfficerDocument6 pagesAutomatic Identification System (AIS) - Ship Navigation System-ETO - Electro Technical OfficerNabin Kumar ChaudharyNo ratings yet

- VS0008 CIRRUS FLT PLAN LAX-LHRDocument25 pagesVS0008 CIRRUS FLT PLAN LAX-LHRBenoit VoisinNo ratings yet

- Parts and Function of Tractors by Greatle Mae BasbanoDocument12 pagesParts and Function of Tractors by Greatle Mae BasbanoGreatle Mae D. BasbañoNo ratings yet

- CatalogoDocument69 pagesCatalogoFrancoNo ratings yet

- International Motor Insurance CardDocument2 pagesInternational Motor Insurance CardMirelaNo ratings yet

- Service Manual: 5RW1-AE1Document204 pagesService Manual: 5RW1-AE1Allan DuarteNo ratings yet

- Prebeginner 1 - Diana Lozano - PPT Semana 8Document20 pagesPrebeginner 1 - Diana Lozano - PPT Semana 8REINITA HERMOSANo ratings yet

- Manual of Aircraft Accident and Incident Investigation: Doc 9756 AN/965Document40 pagesManual of Aircraft Accident and Incident Investigation: Doc 9756 AN/965james_bembrick100% (1)

- Safe operation of forkliftsDocument16 pagesSafe operation of forkliftsibrahimNo ratings yet

- 1 Immobilizer 2 Ignition Switch: Engine General Information and Diagnosis: 1A-5Document1 page1 Immobilizer 2 Ignition Switch: Engine General Information and Diagnosis: 1A-5lombardiacmNo ratings yet

- ZX138MF 5G Southeast Asia Lo 100619Document5 pagesZX138MF 5G Southeast Asia Lo 100619Aldi NasohaNo ratings yet

- Project - RawDocument8 pagesProject - Rawomkar ghodkeNo ratings yet

- Baders Assignment 2Document8 pagesBaders Assignment 2Møtshĕgĕtsi GwĕrĕNo ratings yet

- QRH (Quick Reference Handbook) A320Document160 pagesQRH (Quick Reference Handbook) A320FENWICKNo ratings yet

- SAE - 2007 01 1311ToyotaAA80EDocument10 pagesSAE - 2007 01 1311ToyotaAA80Evipper king2012No ratings yet

- Excercises 1-18 Priit SulusteDocument47 pagesExcercises 1-18 Priit SulustePriit SulusteNo ratings yet

- Speakmon Thickness Handout 12 2020Document15 pagesSpeakmon Thickness Handout 12 2020Fernão DiasNo ratings yet

- Rate of Turn IndicatorDocument2 pagesRate of Turn Indicatorjamal_talukderNo ratings yet

- C2R-CHY4: Introduction and FeaturesDocument2 pagesC2R-CHY4: Introduction and FeaturesmaxNo ratings yet

- Operating Costing Questions (FINAL)Document4 pagesOperating Costing Questions (FINAL)Tejas YeoleNo ratings yet

- Fuso Tem - 2022Document100 pagesFuso Tem - 2022abrahambelay92No ratings yet

- Consumer surplus rises with EV market competitionDocument5 pagesConsumer surplus rises with EV market competitionJyotirmaya MohapatraNo ratings yet

- Hyster G118 (R30XM2 R30XMA2 R30XMF2) Forklift Parts ManualDocument8 pagesHyster G118 (R30XM2 R30XMA2 R30XMF2) Forklift Parts ManualManuals CE & AgNo ratings yet

- 3b Midterm Lms Seam 6Document90 pages3b Midterm Lms Seam 6Yhielmar Po SaburnidoNo ratings yet

- Signs and Symbols in Urban DesignDocument42 pagesSigns and Symbols in Urban DesignRodelito GaroboNo ratings yet

- GPS Spoofing CountermeasuresDocument8 pagesGPS Spoofing CountermeasuresRavindra MogheNo ratings yet

- ATR-72 - 80 - List - of - New - CardsDocument98 pagesATR-72 - 80 - List - of - New - CardsGino AcevedoNo ratings yet

- High Speed Craft: Lex Keuning and Do LigtelijnDocument12 pagesHigh Speed Craft: Lex Keuning and Do LigtelijnEmreNo ratings yet