Professional Documents

Culture Documents

Appendix O1 - Allawuna Landfill Construction Health and Safety Risk Assessment

Uploaded by

Andisiwe SongoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix O1 - Allawuna Landfill Construction Health and Safety Risk Assessment

Uploaded by

Andisiwe SongoCopyright:

Available Formats

RISK ASSESSMENT –

CONSTRUCTION ACTIVITIES FOR

ALLAWUNA FARM LANDFILL

This document describes the Occupational Safety and Health risks associated with the Construction

of the Site Infrastructure and Landfill Cell 1 and Landfill Infrastructure for Allawuna Farm Landfill, as

identified during the design and approvals process.

March 2015

Prepared By

Environmental Engineering Consultants

Waste Management Specialists

www.bowmanassociates.com.au

Risk Assessment – Construction Activities for Allawuna Farm Landfill

DISCLAIMER

The content contained herewith has been compiled in good faith using normal industry practices

employed by Civil and Environmental Engineers and Environmental Scientists. Bowman & Associates

Pty Ltd accepts no liability for loss or damages incurred by any individual or organisation due to

reliance on the included content. This document and its contents cannot be used for any other

purpose or reasons other than those agreed between the Client and Bowman & Associates Pty Ltd

without first obtaining written consent from Bowman & Associates Pty Ltd.

DOCUMENT CONTROL

VERSION DATE ISSUED PREPARED BY APPROVED BY APPROVED

SIGNATURE

A 17.03.15 A O’Malley B Bowman

B 25.03.15 A O’Malley B Bowman

C 31.03.15 A O’Malley B Bowman

DOCUMENT DISTRIBUTION

VERSION TYPE FORMAT ISSUED TO ORGANISATION

A Draft - for comment pdf David Rushton Golder Associates

B Draft pdf David Rushton Golder Associates

C Final pdf David Rushton Golder Associates

FILE NAME

150331 AO Allawuna Construction Contractor Risk Assessment - Rev C Final.docx

Prepared by Bowman & Associates Pty Ltd Page 2 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

CONSTRUCTION RISK ASSESSMENT AND REVIEW

Bowman & Associates has considered the construction practicalities and likely risks to be faced by

the contractor(s) executing the construction of the Site Infrastructure, Landfill Cell 1 and associated

infrastructure for Allawuna Farm Landfill.

The assessment of the specific environmental aspects for the operation of the site infrastructure and

Landfill Cell 1 has been addressed in separate risk assessment reports provided by Bowman and

Associates and Golder Associates.

The risk management approach outlined in this document is based on the framework in the

Australian Standard Risk Management (AS/NZS ISO 31000:2009) on which the Victorian EPA Licence

Assessment Guidelines (2010) have been based. We have also considered the Western Australian

Occupational Safety and Health Regulations (1996).

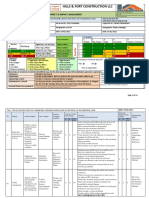

The below tables describe the risk ranking system used when assessing a particular activity for both

personnel and environmental risk using the Victorian EPA Assessments Guidelines structure.

Prepared by Bowman & Associates Pty Ltd Page 3 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Table 1 Qualitative measures of likelihood

Rating Indicator Description Frequency

Is expected to occur almost all of

5 Almost certain Multiple incidents have been recorded

the time

Is expected to occur most of the

4 Likely Several incidents have been recorded

time

3 Probable Some incidents have been recorded Might occur

2 Not likely Few recorded or known incidents Might occur but not expected to

Only expected to occur under

1 Rare No recorded or known incidents

atypical conditions

Table 2 Qualitative measures of consequence/impact

Rating Indicator Description

Human deaths, operations cause catastrophic off-site impacts, immense

5 Severe

financial loss

Extensive human injuries or illness, operations cause substantial off-site

4 Significant

impacts, major financial loss

Some health impacts to humans, operations cause some external impacts,

3 Medium

large financial loss

First aid treatment, operations cause minimal off-site impacts, small financial

2 Minor

loss

Operations cause no injuries, negligible off-site impacts, and negligible

1 Negligible

financial loss

Table 3 Qualitative risk analysis matrix – Level of risk

Likelihood

Consequence Almost

Likely Probable Not likely Rare

certain

Severe V V V V H

Significant V V V H H

Medium V H H M M

Minor H H M L L

Negligible H M L L L

V = Very high risk; immediate action required

H = High risk; management required from senior staff

M = Medium risk; specify required management

L = Low risk; manage with standard operating procedure

Prepared by Bowman & Associates Pty Ltd Page 4 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Table 4 below describes some of the typical risks that have been identified during the design phase,

their impacts, assessed levels of risk and control measures that have been taken to mitigate them to

acceptable levels

The risk assessment generally covers the following site construction and infrastructure works:-

Earthworks (Excavation and Filling),

Construction of intersection to Great Southern Highway and Landfill entrance,

Construction of Entrance Road from GSH to Infrastructure area,

Construction of internal access road and Infrastructure area (car parking, truck parking),

Construction of perimeter access road and turning bays (to Landfill cells and ponds),

Construction of swale drains and installation of stormwater culverts,

Installation of conducts, cabling and electronic systems including pumps,

Installation of security fencing and gates,

Installation of potable and fire fighting water tanks,

Installation of 4 bay carport,

Installation of site office and ablution,

Construction and installation of weighbridge,

Construction of power generator (genset) pad including concrete and pipework, and

Installation of mud shaker and sump pit.

The risk assessment generally covers the following Landfill Cell 1 construction and associated

infrastructure works:-

Earthworks (Excavation and Filling),

Excavation and Construction of Cell 1,

Construction of Leachate Pond pad including concrete and pipework,

Construction of subsurface drainage well and associated pipework,

Construction of Cell leachate sump including concrete and pipework,

Construction of Stormwater Dam and associated spillway,

Installation of geosynthetic lining system in Cell 1, Leachate Pond and Retention Pond,

Placement of leachate drainage aggregate,

Installation of ballast for pond liners, and

Installation of conducts, cabling and electronic systems including pumps.

This list is by no means exhaustive, as many risks are a function of the construction methods and

techniques employed by the construction contractor(s), and cannot be clearly defined during the

design phase.

Prepared by Bowman & Associates Pty Ltd Page 5 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Table 4 Risk Assessment - Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

General

General Travel of personnel to Extensive human 2 4 High Co-ordination between

and from the site. injuries. construction and landfill

operations contractors.

Awareness of all site users,

standard operation procedures

and use of appropriate visibility

gear.

General Contamination of site Polluted water 2 2 Low The storage and handling of

with hydrocarbons or source. chemicals and fuels will be in

polluted water. accordance with the Dangerous

Goods Safety (Storage and

Handling of Non-explosives)

Regulations 2007 and Australian

Standard AS 1940 The storage and

handling of flammable and

combustible liquids.

Spill response established in

Landfill Management Plan.

Water discharge procedure

described in Landfill Management

Plan.

Prepared by Bowman & Associates Pty Ltd Page 6 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

General Stormwater event - Erosion of partially 3 2 Medium Design has considered storm

excessive rainfall completed events and has allowed adequate

construction works, drainage along roads, hardstand

wash out of road, areas, along creek lines, near low

or temporary lying areas.

works.

Stormwater culverts have been

designed for stormwater events.

Contractor(s) to employ temporary

stormwater control during works

as per the specification.

Clearing and Stripping

Clearing and Trees falling on Serious injury to 2 4 High Plant operators to be proficient in

Stripping bystanders during human. the use of their machinery.

clearing. Bystanders to be clear of

machinery when it is operating.

Contractor to operate safely when

felling trees.

High visibility clothing for persons

on site.

Prepared by Bowman & Associates Pty Ltd Page 7 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Earthworks

Earthworks Injury due to buried Unintentional 2 4 High Contractor required to ‘dial before

services such as gas and piercing of gas or you dig’ and locate services prior

power. power lines may to commencement of works.

result in severe Initial works will be on

injury. Unlikely if undeveloped land, underground

correct procedures services will be recorded as

are followed. installed.

Earthworks Rollover of plant Injury or death of 2 4 High Design batter slopes at maximum

equipment. Plant operator or 1:3 grade.

bystander.

Design calls for no deep excavation

or steep grades.

Contractors are responsible for

safe operation of vehicles.

Earthworks Personnel falling into Injury from a fall or 2 3 Medium No deep excavations or high

excavated holes or ledge collapse. ledges in the designed landform.

trenches. Contractor(s) expected to using

bunting or flagging for temporary

hazards in line with their own

Occupational Health and Safety

procedures.

Prepared by Bowman & Associates Pty Ltd Page 8 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Earthworks Machinery falling into Machinery or 2 3 Medium No deep excavations or high

excavated holes, personnel injury ledges in the designed landform.

trenches or large from fall.

Contractor(s) expected to using

excavations.

bunting or flagging for temporary

hazards in line with their own

Occupational Health and Safety

procedures.

Earthworks Personnel struck by Serious injury to 3 4 Very High Effective communication between

machinery bystander. onsite personnel and machine

operators as per site procedures.

UHF radios to be carried by site

personnel and in every machine

onsite.

Onsite toolboxes to inform site

personnel of current works onsite.

Earthworks Radiation exposure from Low powered 1 1 Low Contractor will employ an

Nuclear Density Soil instrument, single appropriately NATA accredited soil

Gauge. dose no impact. laboratory.

Prepared by Bowman & Associates Pty Ltd Page 9 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Site Infrastructure

Cranes Use of machinery to lift Head trauma from 4 4 Very High Materials to be lifted using correct

Truck Lifters and place site facilities falling objects. lifting points and with suitability

(for example office sized crane or lifting equipment.

Manitou

blocks, water tanks, No personnel to be positioned

Generator, HDPE pipes, under lifting area or in front of

concrete wells, concrete moving lifting machinery.

culverts etc)

Manual Personnel injury when Injury/strains from 4 2 High Current manual handling

handling handling or lifting incorrect lifting techniques.

objects. techniques. Two or more person lifts where

required.

Heavy items to be lifted or carried

by appropriate lifting equipment.

Site traffic Vehicle / machinery Vehicle or 3 3 High Traffic management plan to be in

being struck or machinery place during construction works.

collisions. collisions. Designated parking areas for truck

and light vehicles.

All contractors to be inducted.

Regular toolbox talks.

Entrance road and internal roads

designed to suit construction and

operational traffic, with good lines

of sight and suitable road widths.

Prepared by Bowman & Associates Pty Ltd Page 10 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Landfill Construction

(Cell 1, Leachate Pond, Retention Pond, Stormwater Dam)

Lifting Use of Manitou to lift Head trauma from 3 4 Very High Materials/rolls to be lifted using

Geosynthetic and place geosynthetic falling objects, Hit correct lifting points and with

rolls rolls and pipework. by moving suitability sized lifting equipment.

machinery. No personnel to be positioned

under lifting area or in front of

moving lifting machinery.

Liner Personnel injury when Slips, trips and falls, 3 2 Medium Installer must comply with

Installation - deploying the rolls of or injury due to manufacturers guidelines.

GCL geosynthetic clay liner incorrect lifting

Installer must develop a work

technique.

(GCL) material. method statement for safe roll

deployment.

Smooth subgrade limits

opportunity to fall over rocks or

loose stones.

Design liner orientation (long seam

down slope) reduces work

required on sloping ground.

Prepared by Bowman & Associates Pty Ltd Page 11 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Liner Personnel injury when Slips, trips and falls, 3 2 Medium Installer must comply with

Installation - deploying HDPE or injury due to manufacturers guidelines.

HDPE geomembrane liner. incorrect lifting

Installer must develop a work

technique.

method statement for safe roll

deployment.

Liner is not to be deployed in

windy conditions.

Liner Personnel injury when Minor sprains. 4 2 High HDPE liner is designed to be

Installation - traversing HDPE liner on double textured.

HDPE batters and in sump. Rope ladders to be used on

batters.

Access to the sump to be in the

corners where gradient is least.

Liner Personnel injury when Minor burns from 4 2 High Amount of welding required

Installation - welding HDPE liner. extrusion minimised by panel layout.

HDPE equipment or cuts

Main joins performed with

from knife use.

automatic wedge welder, limiting

extrusion welding requirement.

Test welds required to ensure

operator proficiency.

Prepared by Bowman & Associates Pty Ltd Page 12 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Liner Personnel injury when Slips, trips and falls, 4 2 High Design liner orientation (long seam

Installation - deploying the rolls of or injury due to down slope) reduces work

Cushion cushion geotextile incorrect lifting required on sloping ground.

technique. Minor

Geotextile material. Preceding liners are maintained

burns from heat

bonding panels free of debris which may cause

together. injury.

Leachate Personnel injury when Manual handling 2 2 High Pipes to be handled in accordance

Collection installing HDPE pipes. injuries. with Australian Standard AS2033 -

System - Burns from welding Installation of polyethylene pipe

HDPE pipes HDPE. systems.

Appropriately qualified pipe

welding technician to perform

welding activities.

Leachate Use of hand tools or Manual handling 3 3 High Contractor will employ

collection power equipment for injuries and power appropriately trained personnel to

system - HDPE pipe drilling and tool injuries. undertake these tasks.

HDPE pipes holes in concrete pipe Drilling equipment to be checked

prior to use.

Leachate Personnel injury when Hand or arm 3 2 Medium Leachate riser pipes to be secured

Collection installing leachate trauma. with concrete anchor block.

System - pumps Correct manual handling

Pumps techniques to be employed.

Prepared by Bowman & Associates Pty Ltd Page 13 of 14

Risk Assessment – Construction Activities for Allawuna Farm Landfill

Construction Potential Impacts Likelihood / Consequence

Description of Risk Level of risk Design Control Measures

Element Frequency Severity Rating

Leachate Personnel injury when Trip, slip and falls 3 2 Medium Contractor will employ

Collection placing leachate or Being struck by appropriately trained personnel to

System - drainage aggregate machinery. undertake these tasks.

Aggregate Effective communication between

onsite machinery placing

aggregate and site contractors

working within cell footprint.

Separation Personnel injury when Slips, trips and falls, 4 3 High Design liner orientation (long seam

Geotextile deploying the rolls of or injury due to down slope) reduces work

Installation separation material. incorrect lifting required on sloping ground.

technique.

The aggregate material is placed as

Minor burns from

a smooth working surface.

heat bonding

panels together.

Subsurface Personnel injury when Being struck by 3 3 High Correct machinery used for lifting.

Drainage placing 1200 mm concrete sump Suitable clear area around lifting

System diameter concrete area, no personnel within clear

sump. area.

Bunding of flagging around

perimeter of lifting area.

Prepared by Bowman & Associates Pty Ltd Page 14 of 14

You might also like

- Ins200 Assignment Hazardous PlaceDocument10 pagesIns200 Assignment Hazardous PlaceNur Syafatin Natasya86% (7)

- RA For Sump PumpsDocument9 pagesRA For Sump PumpsAnonymous ubta67y6eNo ratings yet

- Risk Assessment For Cleaning ServicesDocument11 pagesRisk Assessment For Cleaning ServicesThandabantu MagengeleleNo ratings yet

- Waste Treatment Plant HiraDocument5 pagesWaste Treatment Plant HiraBharath KumarNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- Drainage Design Manual Final DraftDocument27 pagesDrainage Design Manual Final Draftjimhtolbert434No ratings yet

- Land Fill OperationDocument15 pagesLand Fill OperationSyed Haider Abbas KazmiNo ratings yet

- Sample Risk Management PlanDocument12 pagesSample Risk Management PlanEdwin Okoampa BoaduNo ratings yet

- PTW Risk Assessment: CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022Document1 pagePTW Risk Assessment: CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022First ChoiceNo ratings yet

- Sample Risk Management Plan: (Insert Name of Event and Date)Document12 pagesSample Risk Management Plan: (Insert Name of Event and Date)ge120120No ratings yet

- Risk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectDocument5 pagesRisk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectSalman LodhiNo ratings yet

- CONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormDocument6 pagesCONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormPerwez21No ratings yet

- Hira - IbsplDocument7 pagesHira - IbsplAbdul Raheem100% (1)

- Appendix A Risk Assessment & Mode of ContractDocument5 pagesAppendix A Risk Assessment & Mode of ContractSherif MahmoudNo ratings yet

- Method Statement & Risk AssessmentDocument20 pagesMethod Statement & Risk AssessmentHafis Aikal AmranNo ratings yet

- Qinghan Gao-Risk Analysis Report 2Document7 pagesQinghan Gao-Risk Analysis Report 2api-708505329No ratings yet

- Anatomy of HazardDocument14 pagesAnatomy of HazardAndria Rose BrionesNo ratings yet

- Training On HIRADocument26 pagesTraining On HIRAparvezblogNo ratings yet

- Environmental Risk Assessment: Allawuna Farm LandfillDocument20 pagesEnvironmental Risk Assessment: Allawuna Farm LandfillOQC PetroleumNo ratings yet

- Risk CompilationDocument50 pagesRisk CompilationCheryl Diane Mae LumantasNo ratings yet

- Risk Register Aligned ASNZS4360Document22 pagesRisk Register Aligned ASNZS4360Emmanuel TsabolaNo ratings yet

- Confined Space Risk Assessment WHSFOR-009BDocument3 pagesConfined Space Risk Assessment WHSFOR-009BvictorNo ratings yet

- HSE FRM-38 Environmental Risk Assessment and Control FormDocument2 pagesHSE FRM-38 Environmental Risk Assessment and Control FormAtesNo ratings yet

- Risk Analysis ReportDocument8 pagesRisk Analysis Reportapi-704474683No ratings yet

- Fiddil Risk AssessmentDocument7 pagesFiddil Risk Assessmentsunday austineNo ratings yet

- Hazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety CommitteeDocument14 pagesHazard and Risk Register Template: The South Australian Mining and Quarrying Occupational Health and Safety Committeearunshan1984100% (1)

- Criteria For Assessing An Environmental Aspect: Easibind Quality and Environmental Management System Manual QEP51-6/1Document5 pagesCriteria For Assessing An Environmental Aspect: Easibind Quality and Environmental Management System Manual QEP51-6/1BhargavNo ratings yet

- Item 14.1.1 - Attachment A - Stormwater Infrastructure Risk Management Plan - November 2016Document41 pagesItem 14.1.1 - Attachment A - Stormwater Infrastructure Risk Management Plan - November 2016Mark Joseph BajaNo ratings yet

- 009.1c Risk Scoring Matrix 250713Document2 pages009.1c Risk Scoring Matrix 250713idrisngrNo ratings yet

- Identifikasi Bahaya Dan Resiko New PDFDocument54 pagesIdentifikasi Bahaya Dan Resiko New PDFcindyNo ratings yet

- Hazard Identification & Risk AssessmentDocument9 pagesHazard Identification & Risk AssessmentLathakula RajashekharNo ratings yet

- GS - RA Gulfstar - Environmental Aspect and ImpactDocument6 pagesGS - RA Gulfstar - Environmental Aspect and Impactsajin100% (1)

- Excavation Permmit To WorkDocument3 pagesExcavation Permmit To WorkWilson Wambua0% (1)

- Section 17 Health and Safety RiskDocument10 pagesSection 17 Health and Safety Riskdysgla0828No ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

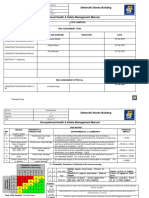

- Stefanutti Stocks Building: Site: Date CompiledDocument5 pagesStefanutti Stocks Building: Site: Date CompiledPinto MendesNo ratings yet

- LSPfor Risk AssessmentDocument7 pagesLSPfor Risk AssessmentadhavanannathuraiNo ratings yet

- Hazard Identification & Risk Assessment (HIRA)Document25 pagesHazard Identification & Risk Assessment (HIRA)Suraj PantNo ratings yet

- Mobile CranesDocument5 pagesMobile CranesSAYED100% (1)

- P4-Procedure For Hazard Identification, Risk Assessment, and Determining ControlsDocument5 pagesP4-Procedure For Hazard Identification, Risk Assessment, and Determining ControlsSamsu SamsNo ratings yet

- 9.0 HSSE Risk ManagementDocument10 pages9.0 HSSE Risk Managementsinghal.ns4497No ratings yet

- 4risk ManagementDocument8 pages4risk ManagementSomar SafatlyNo ratings yet

- Islamic P&I Club: Loss Prevention Surveys - A Guide For SurveyorsDocument22 pagesIslamic P&I Club: Loss Prevention Surveys - A Guide For SurveyorsreiNo ratings yet

- IA - Incident Management Plan - 2021Document12 pagesIA - Incident Management Plan - 2021Charly MNNo ratings yet

- Jin 2012Document6 pagesJin 2012Anita MarquinaNo ratings yet

- 121212baseline Risk Assessment - Matla 2 School Rev00Document34 pages121212baseline Risk Assessment - Matla 2 School Rev00Vepxvia NadiradzeNo ratings yet

- Hazard Risk IdentificationDocument52 pagesHazard Risk IdentificationPanchdev KumarNo ratings yet

- 01 - ACCIDENT - INCIDENT INVESTIGATION AND REPORTING - Engr. DimzonDocument26 pages01 - ACCIDENT - INCIDENT INVESTIGATION AND REPORTING - Engr. DimzonJude-lo AranaydoNo ratings yet

- Standard Procedure For Risk AssessmentDocument14 pagesStandard Procedure For Risk AssessmentSachin Vaidya100% (1)

- (GFB) Risk Assessment Tool - Make ADocument100 pages(GFB) Risk Assessment Tool - Make Aeya dridiNo ratings yet

- ASPECT HIRAC-GuidelinesDocument8 pagesASPECT HIRAC-GuidelinesPablo EstebanNo ratings yet

- Procedure For Emergency Prepareness PDFDocument4 pagesProcedure For Emergency Prepareness PDFAnggoro AntonoNo ratings yet

- Basic Offshore Safety Induction and Emergency Training: CtsiDocument72 pagesBasic Offshore Safety Induction and Emergency Training: Ctsiangel coazoNo ratings yet

- (OHS) Procedure For Hazard IdentificationDocument6 pages(OHS) Procedure For Hazard IdentificationTuan AnhNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- 4.1.2 Covid-19 Risk AssessmentDocument41 pages4.1.2 Covid-19 Risk AssessmentaceNo ratings yet

- COVID 19 RA v8 Sept 2020Document1 pageCOVID 19 RA v8 Sept 2020Djole GeorgeNo ratings yet

- Turn Down the Heat: Climate Extremes, Regional Impacts, and the Case for ResilienceFrom EverandTurn Down the Heat: Climate Extremes, Regional Impacts, and the Case for ResilienceNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- CBRN and Hazmat Incidents at Major Public Events: Planning and ResponseFrom EverandCBRN and Hazmat Incidents at Major Public Events: Planning and ResponseNo ratings yet

- IT Auditing and Application Controls for Small and Mid-Sized Enterprises: Revenue, Expenditure, Inventory, Payroll, and MoreFrom EverandIT Auditing and Application Controls for Small and Mid-Sized Enterprises: Revenue, Expenditure, Inventory, Payroll, and MoreNo ratings yet

- Highway 61 Stormwater Natural Drainage and Retrofit Identification Project (306-10-07)Document58 pagesHighway 61 Stormwater Natural Drainage and Retrofit Identification Project (306-10-07)Minnesota's Lake Superior Coastal ProgramNo ratings yet

- Stormwater Drainage Report: Site Work PermitDocument30 pagesStormwater Drainage Report: Site Work PermitBilal SubzwariNo ratings yet

- Greenery and Landscaping 2019 PDFDocument174 pagesGreenery and Landscaping 2019 PDFNeeraj VashistNo ratings yet

- DFR Main1Document221 pagesDFR Main1Timothy MudomeNo ratings yet

- URS 2009 Westside RecommendationsDocument6 pagesURS 2009 Westside Recommendationsjimhtolbert434No ratings yet

- ART 1999 NiemczynowiczDocument14 pagesART 1999 NiemczynowiczAnita MarquezNo ratings yet

- Kobuleti Water Supply Rehabilitation Project Environmental Impact AssesmentDocument151 pagesKobuleti Water Supply Rehabilitation Project Environmental Impact AssesmentopentapsNo ratings yet

- Sustainable Guide ch3 PDFDocument14 pagesSustainable Guide ch3 PDFrimjhim swamiNo ratings yet

- June 15, 2010Document12 pagesJune 15, 2010The Delphos HeraldNo ratings yet

- Environmental Permitting Guide For Ethanol Facilities in OhioDocument29 pagesEnvironmental Permitting Guide For Ethanol Facilities in OhioMEGAN ASBROCKNo ratings yet

- Guide Dewatering PDFDocument15 pagesGuide Dewatering PDFMarlou GonzalboNo ratings yet

- Task 1 - Facility Background and Site Visit Observations: General InformationDocument37 pagesTask 1 - Facility Background and Site Visit Observations: General InformationNeilNo ratings yet

- Design of STPDocument53 pagesDesign of STPChanel100% (1)

- DEIR Appendix BDocument21 pagesDEIR Appendix BL. A. PatersonNo ratings yet

- Design Guidelines For "Greening" Surface Parking LotsDocument29 pagesDesign Guidelines For "Greening" Surface Parking LotsXtian AnesNo ratings yet

- BBWMP 2012 Appendices PDFDocument51 pagesBBWMP 2012 Appendices PDFMuhammad Rehan AnisNo ratings yet

- Team Sponge - Sponge Handbook ChennaiDocument83 pagesTeam Sponge - Sponge Handbook Chennairam kumarNo ratings yet

- Community Planning Renewal Along CoastlineDocument18 pagesCommunity Planning Renewal Along CoastlineUniqueQuiverNo ratings yet

- Rainwater Infiltration: by Norma Khoury-NoldeDocument8 pagesRainwater Infiltration: by Norma Khoury-NoldeNiong DavidNo ratings yet

- Benefits of Modular Green Roof Technology in Urban EcosystemDocument27 pagesBenefits of Modular Green Roof Technology in Urban EcosystemAnas Khalid TahirNo ratings yet

- Lee Dap Exam Practice QuestionsDocument35 pagesLee Dap Exam Practice QuestionsCarolina Genevieve VerdialNo ratings yet

- City of Edmonton Residential Lot Grading GuidelinesDocument26 pagesCity of Edmonton Residential Lot Grading GuidelinessjchilwalNo ratings yet

- Spa Cwa - 1811 SD 000 Standard Drawing Index PDFDocument62 pagesSpa Cwa - 1811 SD 000 Standard Drawing Index PDFDantex IncaNo ratings yet

- Storm Water Harvesting GuidelineDocument16 pagesStorm Water Harvesting GuidelineJulio CabezasNo ratings yet

- CNMI and Guam Stormwater Management Manual: Final - October 2006Document205 pagesCNMI and Guam Stormwater Management Manual: Final - October 2006Mike RackNo ratings yet

- Letter From Mercyhealth President CEO Javon BeaDocument1 pageLetter From Mercyhealth President CEO Javon BeaKevin HaasNo ratings yet

- Geneva Rock Mining PermitDocument361 pagesGeneva Rock Mining PermitThe Salt Lake Tribune100% (1)

- Water Sensitive Design-ShashiDocument9 pagesWater Sensitive Design-ShashiShashikant Nishant SharmaNo ratings yet

- USDCM Volume 3 PDFDocument589 pagesUSDCM Volume 3 PDFSaga CastañedaNo ratings yet