Professional Documents

Culture Documents

06 Oil Injected Screw GAR 11-37

06 Oil Injected Screw GAR 11-37

Uploaded by

Bashir MtwaklCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 Oil Injected Screw GAR 11-37

06 Oil Injected Screw GAR 11-37

Uploaded by

Bashir MtwaklCopyright:

Available Formats

ATLAS COPCO

RAILWAY AIR SYSTEMS

Oil-injected Screw Compressor

GAR 11-37

i Compact and tough

The space-saving GAR 11-37 oil-injected screw compressor was designed, built and tested to meet the

toughest ambient conditions, such as extreme climate conditions, high humidity, shocks and vibrations.

Available from 1100 to 4500 l/min free air delivery.

FEATURES AND BENEFITS

Space-saving design Reliability and durability

Air dryer, filters and control integrated in a very compact Minimum amount of moving parts.

compressor package. Use of corrosive resistant materials like stainless steel

Integrated fan concept. and aluminum.

Minimum footprint. Long service intervals.

Gear driven.

Enduring performance

The compressor is designed, built and tested to meet Flexible and easy installation

the toughest conditions in railway applications (extreme Plug and play system.

climatic conditions, high humidity, and shocks and Easy to adapt cooling flow directions.

vibrations). Mainly used inside a railway vehicle.

Built in accordance with international railway standards.

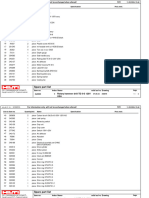

1

6

2 2

7 8

4 5

3

1 The Full Feature version includes 3 High precision gears manufactured 6 Heavy duty air intake filter for

integrated filters and a membrane according to DIN 3961/class 6. Gears efficient operation in dusty

dryer that removes oil and water are oil-lubricated and temperature- environments.

vapor from the compressed air to controlled by the compressor oil.

protect your air piping network and 7 Multi-stage, highly corrosion

braking system from freezing and 4 Integrated cooling fan to optimize resistant oil separator, with a

corrosion. the air flow, which ensures that low (3 ppm) oil carry-over, reduces

the right amount of cooling air is contamination and maintenance

2 Optimally sized, high efficiency delivered efficiently to where it is requirements.

aluminum cooler provides ideal needed with a minimum of noise.

compressor running temperature 8 Atlas Copco’s patented screw

under all conditions. 5 High efficiency, totally enclosed fan- compression element for optimal

cooled (TEFC), IP 55, class F electric energy efficiency and outstanding

railway motor for continuous reliability.

trouble-free operation with greased-

for-life bearings.

OPTIONS

Different drives The compressor can Load/unload valve To be able to control the compressor from running in the

be equipped with different drives, the compressor in different applications. opposite direction due to a phase switch

like an AC motor, DC motor and Control pressure switch To regulate the of the electro motor dP-switch.

hydraulic drive. compressor according to air demand by dP-switch inlet filter For remote warning

Control voltage connector To easily measuring the pressure in the system. in case the inlet filter is clogged.

connect the control voltage lines. Alarm pressure switch To indicate that Heating kit To be able to run the

Motor voltage connector To easily the compressor is still under pressure compressor in ambient temperatures

connect the power voltage lines. and to prevent the compressor from between -40 °C (-40 °F) and -25 °C (-13 °F).

Condensate treatment To treat the restarting too soon against a too high Motor starter Y/D or DOL.

condensate from the filtration line. back-pressure in case of power supply Customized frame To easily integrate

Different approvals CE, ASME, SQL. interruption. the complete package into the available

Anti-rotation switch To signal the space envelope in, under or on top of the

compressor is running and to prevent railway vehicle.

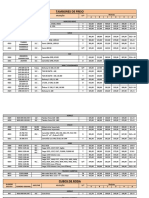

TECHNICAL SPECIFICATIONS

Sound

Capacity* Installed motor power Pressure** pressure Weight

Compressor type level

l/s l/min cfm kW hp bar(e) psig dB(A) kg lbs

50 Hz version

GAR 11 20.0 1200 42 11 15 10 145 70 309 681

GAR 15 29.0 1740 61 15 20 10 145 71 333 734

GAR 18 35.0 2100 74 18.5 25 10 145 72 333 734

GAR 22 45.0 2700 95 22 30 10 145 76 333 734

GAR 30 60.0 3600 127 30 40 10 145 77 381 840

GAR 37 75.0 4500 159 37 50 10 145 78 392 862

60 Hz version

GAR 11 19.0 1140 40 11 15 10 145 72 309 681

GAR 15 27.5 1650 58 15 20 10 145 73 333 734

GAR 18 39.5 2370 84 18.5 25 10 145 74 333 734

GAR 22 45.0 2700 95 22 30 10 145 79 333 734

GAR 30 57.5 3450 122 30 40 10 145 80 381 840

GAR 37 75.5 4530 160 37 50 10 145 81 392 862

Reference conditions:

Absolute inlet pressure: 1 bar (14.5 psi)

Intake air temperature: 20 °C (68 °F)

Effective working pressure: 9.5 bar (138 psi)

Mean noise level measured according to ISO 2151/Pneurop/Cagi PN8NTC2 at 4.6 meter free field

* Unit performance measured at a standard unit (before dryer) according to ISO 1217, Annex C,

latest edition

** Outlet pressures possible between 6 and 13 bar

2935 0949 43 - Subject to alteration without prior notice.

Never use compressed air as breathing air without prior purification in accordance with local legislation and standards. www.atlascopco.com

You might also like

- 38RMDocument26 pages38RMMohamed SaadAllah67% (3)

- Atlas Copco XAS 186 126 106 116 136 156 146Document6 pagesAtlas Copco XAS 186 126 106 116 136 156 146zona amrullohNo ratings yet

- DARI Cat DBS EN 0117 9990014Document28 pagesDARI Cat DBS EN 0117 9990014Moncef RedNo ratings yet

- Specsheet Payne PY3Document28 pagesSpecsheet Payne PY3TheRandoGuyNo ratings yet

- Elgi EG 90 160kW 50Hz D I PDFDocument8 pagesElgi EG 90 160kW 50Hz D I PDFMAZENNo ratings yet

- Traffic Laws, Rules and Regulations: Republic ActsDocument3 pagesTraffic Laws, Rules and Regulations: Republic ActsMarielle Caralipio100% (1)

- 05 Oil Injected Screw GAR 5-14Document2 pages05 Oil Injected Screw GAR 5-14Pavel SokolovNo ratings yet

- Atlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14Document2 pagesAtlas Copco: Railway Air Systems Oil-Injected Screw Compressor GAR 5-14JORGENo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Atlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Railway Air Systems: Oil-Free Scroll Compressor SFR 2-12erfan ahmedNo ratings yet

- 03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRDocument2 pages03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRSerban Aurel CosminNo ratings yet

- Atlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Document2 pagesAtlas Copco Mobility Air Systems: Oil-Free Scroll Compressor SFR 2-12Serban Aurel CosminNo ratings yet

- Commercial Split Systems Air Conditioning Condensing Units: Product DataDocument52 pagesCommercial Split Systems Air Conditioning Condensing Units: Product Datahipolito padronNo ratings yet

- Isotherm TurbocompressorsDocument6 pagesIsotherm TurbocompressorsStefanStanisavljavic100% (1)

- 38au 7 25 03PDDocument60 pages38au 7 25 03PDhccingeniriasasNo ratings yet

- Kaitec - Bro ISO 50HzDocument10 pagesKaitec - Bro ISO 50Hzwijaya adidarmaNo ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- CSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorDocument6 pagesCSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorVolodymуr VorobetsNo ratings yet

- Packaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzDocument8 pagesPackaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzMavista TechnicNo ratings yet

- CompAir D75-275RSDocument8 pagesCompAir D75-275RSIbram GunarsaNo ratings yet

- FFO OR RM MU Ulla A: Rotary Screw CompressorsDocument8 pagesFFO OR RM MU Ulla A: Rotary Screw CompressorsQco MyNo ratings yet

- Ducted Split Systems: Technical DataDocument20 pagesDucted Split Systems: Technical DataFilipNo ratings yet

- 201511ERACS.C Air-Cooled ChillerDocument16 pages201511ERACS.C Air-Cooled ChillerZaw Moe KhineNo ratings yet

- 2021 Catalog CGAP R22 R407C 50HzDocument5 pages2021 Catalog CGAP R22 R407C 50HzhemantNo ratings yet

- 06D, e 3PDDocument24 pages06D, e 3PDAlberto Saul Rivero PlazaNo ratings yet

- Opa 116-201 TD 0521Document12 pagesOpa 116-201 TD 05217tddprzxbbNo ratings yet

- 11 2020 Deitech EngDocument8 pages11 2020 Deitech EngJesus BouzonNo ratings yet

- Pascal: Modular Belt-Driven Rotary Screw CompressorsDocument8 pagesPascal: Modular Belt-Driven Rotary Screw Compressorsluisbmwm6No ratings yet

- AtlasCopco Oil Injected Rotary Screw Compressors Catalogue ALLDocument104 pagesAtlasCopco Oil Injected Rotary Screw Compressors Catalogue ALLacepmuhammadihsan97No ratings yet

- RTUA RTCA Designed To Perform Built To Last PDFDocument20 pagesRTUA RTCA Designed To Perform Built To Last PDFModussar IlyasNo ratings yet

- VE LightDocument12 pagesVE LightMAZENNo ratings yet

- Carrier Rm-psd1 25 To 45.5 TRDocument26 pagesCarrier Rm-psd1 25 To 45.5 TRhany100% (1)

- 27 1 15 L07 L22 RS Brochure GBDocument8 pages27 1 15 L07 L22 RS Brochure GBjennlin.changNo ratings yet

- Static Blower: FDN-H Series FGN-H SeriesDocument7 pagesStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoeNo ratings yet

- Compair l160 l290 SpecDocument12 pagesCompair l160 l290 SpecpfundhNo ratings yet

- Portable Diesel Compressors: People. Passion. PerformanceDocument16 pagesPortable Diesel Compressors: People. Passion. PerformancepowermanagerNo ratings yet

- Tasplgd6346 1 V.KDocument8 pagesTasplgd6346 1 V.KPragnesh PrajapatiNo ratings yet

- RS-D and RSF-D Series With Direct Drive: RENNER - The Expert in Screw CompressorsDocument10 pagesRS-D and RSF-D Series With Direct Drive: RENNER - The Expert in Screw CompressorstitiNo ratings yet

- Plxpmt1725c (Daikin Packaged FD (G) n80-600hv (Y) 14 - R410a)Document8 pagesPlxpmt1725c (Daikin Packaged FD (G) n80-600hv (Y) 14 - R410a)Saeful Malik GintingNo ratings yet

- Portable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMDocument4 pagesPortable Air Compressor: EXPORT-Air-Compressors-C185-T2.indd 1 4/25/2013 2:19:34 PMalex limachiNo ratings yet

- Koolman Air-CooldedWater Chiller With Heat Pump OptionDocument16 pagesKoolman Air-CooldedWater Chiller With Heat Pump OptionLuis PinoNo ratings yet

- Oil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Document8 pagesOil-Injected Rotary Screw Compressors: GA 355-500 (355-500 KW / 450-700 HP)Siva SubramaniyanNo ratings yet

- Hydrogen Dryer LectrodryerDocument4 pagesHydrogen Dryer LectrodryerarisNo ratings yet

- DRE - English enDocument8 pagesDRE - English envijaykmjNo ratings yet

- Compresores Ga 100 PDFDocument16 pagesCompresores Ga 100 PDFFranklin Esteban CárdenasNo ratings yet

- Opa 465-960 Uc8 Eco TD 0322Document24 pagesOpa 465-960 Uc8 Eco TD 03227tddprzxbbNo ratings yet

- RIKT Isothermal Turbocompressors PDFDocument6 pagesRIKT Isothermal Turbocompressors PDFJaswindersingh BhatiaNo ratings yet

- Ecolife 2 - 20 HP: Oil-Free Rotary Scroll CompressorDocument6 pagesEcolife 2 - 20 HP: Oil-Free Rotary Scroll CompressorVolodymуr VorobetsNo ratings yet

- RS (F) - PRO 3,0 Â 18,5 - Brochure - ENDocument16 pagesRS (F) - PRO 3,0 Â 18,5 - Brochure - ENRUN GONo ratings yet

- S3378 1217Document12 pagesS3378 1217eliot martinezNo ratings yet

- SM Series Kaeser CompressorrenDocument16 pagesSM Series Kaeser CompressorrenarieprachmanNo ratings yet

- Mobilair M 100: Portable CompressorsDocument8 pagesMobilair M 100: Portable CompressorsJosue Neftali VargasNo ratings yet

- Turbair Blower (Type RT)Document2 pagesTurbair Blower (Type RT)Amir AbbaszadehNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument8 pagesEG Series Screw Air Compressors: Life Source of Industriespadhu_pNo ratings yet

- Ammonia Absorption Refrigeration TechnologyDocument24 pagesAmmonia Absorption Refrigeration TechnologyPUSHKARKHANNANo ratings yet

- 50VT 16PD CPDocument40 pages50VT 16PD CPJesmar VonNo ratings yet

- Rheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyDocument60 pagesRheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyIshfaqAhmedMayoNo ratings yet

- Kaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesDocument10 pagesKaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesSwapnil PatadeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- A Converted To 3D WEB AMM 11/19/19 TASDocument1 pageA Converted To 3D WEB AMM 11/19/19 TASRUN GONo ratings yet

- En USA Aftermarket Price Book Replacement Parts Products REV 00.PDF - Coredownload.inlineDocument76 pagesEn USA Aftermarket Price Book Replacement Parts Products REV 00.PDF - Coredownload.inlineRUN GONo ratings yet

- A Updated To 3D 17824 NAD 11/26/19 TASDocument1 pageA Updated To 3D 17824 NAD 11/26/19 TASRUN GONo ratings yet

- 800 Series Elements Datasheet US0621Document2 pages800 Series Elements Datasheet US0621RUN GONo ratings yet

- 活塞机英文样本Document6 pages活塞机英文样本RUN GONo ratings yet

- CSL 842 126HCB - 2DDocument1 pageCSL 842 126HCB - 2DRUN GONo ratings yet

- Sheet: Model #: Material: Finish:: 1 OF 1 CT-SML445-301C CT-SML445-301C, BLACKDocument1 pageSheet: Model #: Material: Finish:: 1 OF 1 CT-SML445-301C CT-SML445-301C, BLACKRUN GONo ratings yet

- 11.00 (279 MM) 18.50 (470 MM) : A Added Nameplate DDH 09/09/19 JEBDocument1 page11.00 (279 MM) 18.50 (470 MM) : A Added Nameplate DDH 09/09/19 JEBRUN GONo ratings yet

- Timerdrains Catalogus 2020 BV 1 4 2020Document21 pagesTimerdrains Catalogus 2020 BV 1 4 2020RUN GONo ratings yet

- Dimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedDocument1 pageDimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedRUN GONo ratings yet

- A Updated Bucket & Clip Holders 19180 CRW 10/12/10 M.C. B Converted To 3D - EZR 04/26/16 NAD C Updated Casting - JEB 02/28/19 DDHDocument1 pageA Updated Bucket & Clip Holders 19180 CRW 10/12/10 M.C. B Converted To 3D - EZR 04/26/16 NAD C Updated Casting - JEB 02/28/19 DDHRUN GONo ratings yet

- CSL 234P 401 - 2DDocument1 pageCSL 234P 401 - 2DRUN GONo ratings yet

- 103 1966 PRESS-OPEN enDocument1 page103 1966 PRESS-OPEN enRUN GONo ratings yet

- 1 Manual Rietschle VC202 VC303Document32 pages1 Manual Rietschle VC202 VC303RUN GONo ratings yet

- 12.00 (305 MM) 18.50 (470 MM) : Sheet: Model #: Material: FinishDocument1 page12.00 (305 MM) 18.50 (470 MM) : Sheet: Model #: Material: FinishRUN GONo ratings yet

- CSL 850 251HCB - 2DDocument1 pageCSL 850 251HCB - 2DRUN GONo ratings yet

- G4-7.5 TMDD Dimension Drawing EN Pan-Asia 9829239289Document2 pagesG4-7.5 TMDD Dimension Drawing EN Pan-Asia 9829239289RUN GONo ratings yet

- Parker Legris Master Catalog 3500LEGNYCDocument464 pagesParker Legris Master Catalog 3500LEGNYCRUN GONo ratings yet

- Economy Panel Mounted Gauge: Description & FeaturesDocument2 pagesEconomy Panel Mounted Gauge: Description & FeaturesRUN GONo ratings yet

- CSL 238 301HCB - 2DDocument1 pageCSL 238 301HCB - 2DRUN GONo ratings yet

- BMED Quadruplex SPC 10-15HP Scroll NFPA Flow Diagram en 4107851204 01Document1 pageBMED Quadruplex SPC 10-15HP Scroll NFPA Flow Diagram en 4107851204 01RUN GONo ratings yet

- 550FZL-C6NP35LS4D50B1Q346Document1 page550FZL-C6NP35LS4D50B1Q346RUN GONo ratings yet

- Helioscroll Oil Free CompressorDocument7 pagesHelioscroll Oil Free CompressorRUN GONo ratings yet

- Parker 3-Way Solenoid Valve 7131-7133Document3 pagesParker 3-Way Solenoid Valve 7131-7133RUN GONo ratings yet

- SS5 Parts Book 2002Document24 pagesSS5 Parts Book 2002RUN GONo ratings yet

- Two-Stage Fixed Speed Screw Air Compressor - UCSDocument6 pagesTwo-Stage Fixed Speed Screw Air Compressor - UCSRUN GONo ratings yet

- 2991 7115 60Document100 pages2991 7115 60RUN GONo ratings yet

- Single-Stage VPM (VFD+PM) Screw Air Compressor - UCSDocument9 pagesSingle-Stage VPM (VFD+PM) Screw Air Compressor - UCSRUN GONo ratings yet

- Center of Gravity: Confidentiality Class Acc. To 1102 KDocument1 pageCenter of Gravity: Confidentiality Class Acc. To 1102 KRUN GONo ratings yet

- Hitachi Rotary Screw Compressor: Instruction ManualDocument63 pagesHitachi Rotary Screw Compressor: Instruction ManualRUN GONo ratings yet

- Aph 13 Crankshaft Cylinder Block BNDocument64 pagesAph 13 Crankshaft Cylinder Block BNGica HagiNo ratings yet

- Powertrain Control HardwareDocument11 pagesPowertrain Control Hardwarerodrigo alexis aravena ponceNo ratings yet

- Form Backlog Pt. Inspectindo Mediatama: NO Unit MDL Unit Code S/N E/G MDL / EsnDocument10 pagesForm Backlog Pt. Inspectindo Mediatama: NO Unit MDL Unit Code S/N E/G MDL / EsnReza Abdul Aziz Nur RohmanNo ratings yet

- Interlocking Soil Cement Blockmaking Machines & Accessories: 2019 Dollar PricelistDocument8 pagesInterlocking Soil Cement Blockmaking Machines & Accessories: 2019 Dollar PricelistGift SimauNo ratings yet

- ตารางแปลโค้ด Komatsu Pc130-8Document298 pagesตารางแปลโค้ด Komatsu Pc130-8เสฏฐวุฒิ บุญเข็มNo ratings yet

- Tax Invoice Trucks and BuyersDocument2 pagesTax Invoice Trucks and BuyersSyam JamiNo ratings yet

- Yanmar Ym2210Document155 pagesYanmar Ym2210tcjp4v7d94No ratings yet

- Opw 10 Series Emergency Shut Off ValvesDocument4 pagesOpw 10 Series Emergency Shut Off ValvesHugo Andrés MejíaNo ratings yet

- Cirrus SR22 Systems DescriptionsDocument13 pagesCirrus SR22 Systems DescriptionsGourav DasNo ratings yet

- Liebherr d934 122 MM Diesel EngineDocument28 pagesLiebherr d934 122 MM Diesel EngineSaasiNo ratings yet

- Skid Steer Loaders: Page: 1 / 3Document3 pagesSkid Steer Loaders: Page: 1 / 3fodil laoudjaneNo ratings yet

- Ud Quester First GenDocument17 pagesUd Quester First GenSitichoke SemamonNo ratings yet

- THE SMART POINT CLOUD Digital PDFDocument268 pagesTHE SMART POINT CLOUD Digital PDFMatías FernándezNo ratings yet

- UNICO Sucker-Rod Pump Drive - SensorlesspdfDocument4 pagesUNICO Sucker-Rod Pump Drive - SensorlesspdfjairoNo ratings yet

- Maestro Drill BrochureDocument2 pagesMaestro Drill BrochureDouglas DinizNo ratings yet

- Soal UAS Brake Roller Chain FINAL 9 Dec 2021Document3 pagesSoal UAS Brake Roller Chain FINAL 9 Dec 2021ari rahadyanNo ratings yet

- Gunson Gas Tester Mk2Document16 pagesGunson Gas Tester Mk2Rohan Simon100% (1)

- About: Esteem Star EngineeringDocument2 pagesAbout: Esteem Star EngineeringmuruganandamdesinghNo ratings yet

- Hilti Te6-SDocument5 pagesHilti Te6-SpedjakgNo ratings yet

- Owner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06Document31 pagesOwner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06miguel taipeNo ratings yet

- ScaffoldingDocument41 pagesScaffoldingkhanbabaa914No ratings yet

- The Colonnade, October 13, 2006Document12 pagesThe Colonnade, October 13, 2006Bobcat NewsNo ratings yet

- Ford Kuga Wiring Diagrams2Document1 pageFord Kuga Wiring Diagrams2porter1980No ratings yet

- Fuse Box Diagrams AmarokDocument9 pagesFuse Box Diagrams AmarokDan BaducuNo ratings yet

- AGRIFARM STOU MC SAE 10W-40 enDocument3 pagesAGRIFARM STOU MC SAE 10W-40 enPabloNo ratings yet

- Aircraft Maintenance Manual: Hard Landing Inspection/CheckDocument26 pagesAircraft Maintenance Manual: Hard Landing Inspection/Checkom prakash patelNo ratings yet

- XT660Z - Horcamoto ModificationsDocument6 pagesXT660Z - Horcamoto ModificationsDamian BuczekNo ratings yet

- Service Manual: Tumble Dryer Air Vent AWG 263Document6 pagesService Manual: Tumble Dryer Air Vent AWG 263Oscar CamposNo ratings yet

- BATISTA Produtos NovosDocument3 pagesBATISTA Produtos NovosTruck Center ModeloNo ratings yet