Professional Documents

Culture Documents

Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building Structures

Uploaded by

kapsarcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building Structures

Uploaded by

kapsarcCopyright:

Available Formats

CHAPTER 5 DESIGN GUIDELINES

SECTION 5.2 STRUCTURAL

SUBSECTION 5.2.3 NON-BUILDING STRUCTURES

3. Pre-Engineered Canopy Structures Including Shades

a. General: Pre-Engineered Canopy Structures are those that are pre-manufactured for

assembly on any site. While some purchase contracts provide for supply only,

others provide for supply and installation, in the appropriate situation, off-the-shelf

structures may provide a readily available, cost-effective method of shade provision.

b. References and Standards:

1) Saudi Building Code SBC-301-18 – Loads and Force Requirements

2) Saudi Building Code SBC-304-18 – Concrete Structures Requirements

3) Saudi Building Code SBC-305-18 – Masonry Structures Requirements

4) Saudi Building Code SBC-306-18 – Steel Structures Requirements

5) American Society of Civil Engineers – ASCE-7-10 – Minimum Design Loads for

Buildings and Other Structures

6) Guidelines for Shade Planning and Design Grounded

c. Purpose:

1) The purpose of Canopy Structures is to provide maximum protection of the

public from UV rays and weather. Pre-Engineered Canopy Structures (PECS)

provide a cost and effective means to installing schedule, shade, and weather

protection.

d. The following preliminary steps are recommended in developing a Pre-Engineered

Canopy structure design.

1) Shade Audit

2) Opinion of Cost

3) Geotechnical Report

4) Approval of the RC

5) Architectural/Landscape Architecture Layout of Canopy

e. Materials: Canopy materials are to be determined and shown on architectural layout

drawings.

f. Components of Canopy Structures: All superstructure components of the canopy

shall be designed, shipped, and installed by the Pre-Engineered Canopy supplier

including:

1) All member sizes and materials

2) Connections

3) Decking and Waterproofing

4) Engineering

5) Certificates and Warranties

g. Design and Construction:

1) The A/E and/or EPC Contractor is responsible for supplying the following

information:

Guiding Engineering Manual

Rev. 1 5.2 - 56

CHAPTER 5 DESIGN GUIDELINES

SECTION 5.2 STRUCTURAL

SUBSECTION 5.2.3 NON-BUILDING STRUCTURES

(a) Design Loads per the SBC-301 including with initial tensile forces for

tensile structures and possible ponding over canopies.

(b) Size, location and materials of proposed canopy structure

(c) Foundation and anchor bolts design of proposed canopy structure

2) The A/E and/or EPC Contractor is responsible to review and approve shop

drawings prior to construction, verify materials and certifications meet required

parameters.

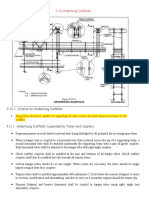

4. Shade Structures

Shade structures shall be designed based on the requirements of the proprietary shade

structure manufacturer, the soil parameters recommended in the GDR, and the wind

speed included in this manual.

5. Water and Wastewater Structures

a. General:

Water and Wastewater structures are required to have the following characteristics:

1) Serviceability.

2) Durability.

3) Limited deflection and cracking in concrete structures

b. References:

1) ACI 350M, Metric Code Requirements for Environmental Engineering Concrete

Structures & Commentary.

2) Rectangular Concrete Tanks, Portland Cement Association (1994).

3) Circular tanks without Pre-stressing, Portland Cement Association (1993).

4) Moments and Reactions for Rectangular Plates, US Bureau of Reclamation.

c. Steel Reinforcement:

1) ASTM A775 Epoxy Coated reinforcing bars

2) Minimum Concrete Cover:

(a) Concrete Base = 75 mm.

(b) Concrete Wall = 50 mm.

(c) Stilling Basin = 150 mm.

d. Flotation Criteria (Flotation Stability Criteria for Concrete Hydraulic Structures, US

Army COE).

1) Loading Conditions FS

2) Construction 1.3

3) Normal Operation 1.5

4) Extreme (max. pool) 1.1

e. Crack Reduction:

1) Reinforcement Distribution - use smaller diameter reinforcement and reduce

bar spacing not to exceed 300 mm.

Guiding Engineering Manual

Rev. 1 5.2 - 57

You might also like

- PVC SpecificationDocument17 pagesPVC SpecificationDavid Ruelas50% (2)

- PFEIFER Structures Section 133100 PVC SpecificationDocument17 pagesPFEIFER Structures Section 133100 PVC Specificationtidipa8386No ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument2 pagesChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- 2010-Tindall Specification FinalDocument12 pages2010-Tindall Specification Finalshahhassa9No ratings yet

- Structural Precast Concrete Cell ModulesDocument12 pagesStructural Precast Concrete Cell ModulesAnonymous YN4aNlNo ratings yet

- Precast Concrete Segment ProductionDocument8 pagesPrecast Concrete Segment Productionsatan007No ratings yet

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- SpecificationDocument5 pagesSpecificationwalidNo ratings yet

- 09 22 00 Acoustical Ceilings Index and SpecificationDocument9 pages09 22 00 Acoustical Ceilings Index and SpecificationKiran D AnvekarNo ratings yet

- Structural Design Report for LV RoomDocument36 pagesStructural Design Report for LV RoomreganNo ratings yet

- Nrqs-Mos-008 Concrete WorksDocument10 pagesNrqs-Mos-008 Concrete Workscivil.godfatherNo ratings yet

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 pagesSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarNo ratings yet

- Specifications - Tensioned Fabric StructuresDocument12 pagesSpecifications - Tensioned Fabric StructuresAristeo V. CabantingNo ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument1 pageChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- SECT051223 Structural SteelDocument19 pagesSECT051223 Structural SteelTewodros TeferaNo ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument2 pagesChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- Arch 2.4 Carbon Steel FinishesDocument2 pagesArch 2.4 Carbon Steel FinishesSherazNo ratings yet

- Spec 1936wDocument30 pagesSpec 1936wThinh LuongNo ratings yet

- Technical Notes 11C - Guide Specifications For Brick Masonry, Part 4 Rev. (July 1972) (Reissued May 1998)Document6 pagesTechnical Notes 11C - Guide Specifications For Brick Masonry, Part 4 Rev. (July 1972) (Reissued May 1998)sabirfurqanNo ratings yet

- Precast Hollow Core Slab Specification GuideDocument19 pagesPrecast Hollow Core Slab Specification GuideShivanan SinghNo ratings yet

- GP 04.01.01Document13 pagesGP 04.01.01Jose VasquezNo ratings yet

- Method Statement FOR Artificial Rock WorkDocument9 pagesMethod Statement FOR Artificial Rock Workbhupsjangir100% (2)

- Section 13 4200 - Pre-Fabricated Precast Concrete Structures Part 1 - GeneralDocument13 pagesSection 13 4200 - Pre-Fabricated Precast Concrete Structures Part 1 - GeneralRavindra MRNo ratings yet

- PS steel space frame specsDocument7 pagesPS steel space frame specsAndriNo ratings yet

- Sec 05720 - Space FrameDocument6 pagesSec 05720 - Space Frametiju2005hereNo ratings yet

- 05 30 00 Decorative MetalsDocument16 pages05 30 00 Decorative MetalsKiran D AnvekarNo ratings yet

- Metal Stairs: 1.0 GeneralDocument7 pagesMetal Stairs: 1.0 GeneralDipu GeorgeNo ratings yet

- Concrete Box Girder BrigdeDocument139 pagesConcrete Box Girder Brigdesujups100% (1)

- Gypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecDocument8 pagesGypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecKiran D AnvekarNo ratings yet

- 09 20 00 Gypsum Board Etc CeilingDocument12 pages09 20 00 Gypsum Board Etc CeilingKiran D AnvekarNo ratings yet

- 03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFDocument12 pages03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFMithun UdayanarayanaNo ratings yet

- Adel Mohamed Dubai Municipality 2Document43 pagesAdel Mohamed Dubai Municipality 2ALPHYL BALASABAS100% (2)

- Connecting Details DWG 001Document9 pagesConnecting Details DWG 001Yadhu .msa17No ratings yet

- SEC 1-Civil Rev.1.Document13 pagesSEC 1-Civil Rev.1.Waseem SaleemNo ratings yet

- Chapter 1 : Limit State Design of Reinforced Concrete StructuresDocument39 pagesChapter 1 : Limit State Design of Reinforced Concrete Structurespeter wongNo ratings yet

- CHAPTER 9b - BearingsDocument6 pagesCHAPTER 9b - Bearings李明环No ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument1 pageChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- Guide Specifications for Engineered Brick Masonry Quality ControlDocument8 pagesGuide Specifications for Engineered Brick Masonry Quality ControlsabirfurqanNo ratings yet

- 03 4110 Precast Double Tees1Document11 pages03 4110 Precast Double Tees1M OdebrechtNo ratings yet

- Precastreinforcedconcreteplanks Andjoistsforroofingandfloortng - SpecificationDocument12 pagesPrecastreinforcedconcreteplanks Andjoistsforroofingandfloortng - SpecificationKencho ChodenNo ratings yet

- Division 05 - Metals: Structural SpecificationDocument19 pagesDivision 05 - Metals: Structural SpecificationFranklyn GenoveNo ratings yet

- AC208 - Steel FibersDocument4 pagesAC208 - Steel FibersAlvaro ArroyoNo ratings yet

- Residential Apartment Structural Design BriefDocument5 pagesResidential Apartment Structural Design Brieftaz_taz3No ratings yet

- R.C NotesDocument326 pagesR.C Notes秦瑋駿No ratings yet

- Criterios de Diseño EstructuralDocument16 pagesCriterios de Diseño Estructuralangelus95No ratings yet

- Is 13920 1993Document24 pagesIs 13920 1993structuralengineersNo ratings yet

- Structural Precast ConcreteDocument20 pagesStructural Precast ConcreteTaher AmmarNo ratings yet

- Precastreinforcedconcreteplanks Andjoistsforroofingandfloortng - SpecificationDocument12 pagesPrecastreinforcedconcreteplanks Andjoistsforroofingandfloortng - SpecificationGrv SrmNo ratings yet

- Applying Precast Concrete Construction TechniquesDocument10 pagesApplying Precast Concrete Construction TechniquesrameshkaaNo ratings yet

- ACI303Document44 pagesACI303Anonymous JSrmKXNo ratings yet

- AC01Document13 pagesAC01Kazuto NakazatoNo ratings yet

- Study of Precast ConstructionDocument3 pagesStudy of Precast Constructiongeorge honNo ratings yet

- DBR PDFDocument7 pagesDBR PDFrajeev shahNo ratings yet

- J&J PEB Technical RequirementsDocument4 pagesJ&J PEB Technical RequirementsHARSHADNo ratings yet

- Design LoadDocument18 pagesDesign LoadBenjie AlmorotoNo ratings yet

- Draft 13920-2014Document35 pagesDraft 13920-2014Shakil AkhterNo ratings yet

- Pre-Cast Concrete Elements for Commercial & Residential BuildingsDocument10 pagesPre-Cast Concrete Elements for Commercial & Residential BuildingsMithun UdayanarayanaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Specification For PumpsDocument29 pagesSpecification For PumpsEmad Rakat100% (1)

- Inch to mm Conversion Chart: Fractional and Decimal InchesDocument1 pageInch to mm Conversion Chart: Fractional and Decimal InchesIvan SimeonNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Pump SealDocument1 pagePump SealkapsarcNo ratings yet

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Summary of Changes To ASME Section IX, 2021 Edition As Published in The Welding Journal, July, 2021Document6 pagesSummary of Changes To ASME Section IX, 2021 Edition As Published in The Welding Journal, July, 2021Menad SalahNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Icp-Pd-102 - CPD - 202203Document22 pagesIcp-Pd-102 - CPD - 202203HalimNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Typical ARC Valve Bypass For PumpDocument1 pageTypical ARC Valve Bypass For PumpkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- ACT 200906 Form 67CDocument67 pagesACT 200906 Form 67Ctd2012No ratings yet

- A 5 Defects of Flat RoofsDocument18 pagesA 5 Defects of Flat RoofsCass LimNo ratings yet

- Sika PDS - E - Sika Hydrotite CJ-TypeDocument4 pagesSika PDS - E - Sika Hydrotite CJ-Typelwin_oo2435No ratings yet

- Precast Concrete Culvert StructuresDocument12 pagesPrecast Concrete Culvert StructuresHenry GutierrezNo ratings yet

- Chapter-5.3 Wall SystemDocument66 pagesChapter-5.3 Wall Systemgetachew asefaNo ratings yet

- Shell Roof-RevDocument45 pagesShell Roof-RevJashin BansalNo ratings yet

- Plaster Assemblies Chapter 02 Plaster Substrates LathDocument26 pagesPlaster Assemblies Chapter 02 Plaster Substrates LathFare NienteNo ratings yet

- Timber report on cement building materialsDocument31 pagesTimber report on cement building materialsLakshya SharmaNo ratings yet

- Design of Concrete Ring Beam For Storage TankDocument5 pagesDesign of Concrete Ring Beam For Storage TanknsutharNo ratings yet

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDocument2 pagesSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanNo ratings yet

- Datasheet Codeline Ecoline 40L30NDocument2 pagesDatasheet Codeline Ecoline 40L30NArmando Corral BlancoNo ratings yet

- 9.15 Underhung Scaffold.Document3 pages9.15 Underhung Scaffold.AfshadNo ratings yet

- Reejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. MasonryDocument1 pageReejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. Masonryreejoy1994No ratings yet

- Schedule of Rates Amravati-Nagpur Region YEAR 2018-2019: MaterialDocument17 pagesSchedule of Rates Amravati-Nagpur Region YEAR 2018-2019: MaterialSathish KumarNo ratings yet

- E-Booklet Tacompact Board 2021Document6 pagesE-Booklet Tacompact Board 2021embenNo ratings yet

- Item Description Unit Quantity 1. Site Clearance and DismantlingDocument7 pagesItem Description Unit Quantity 1. Site Clearance and Dismantlinghemant gaikwadNo ratings yet

- WallFenceBillOfQuantities (BOQ) - 1Document35 pagesWallFenceBillOfQuantities (BOQ) - 1Myless MukendiNo ratings yet

- Earthquake Resistant StructuresDocument11 pagesEarthquake Resistant StructuressolairajaNo ratings yet

- Types of StairsDocument12 pagesTypes of Stairsfaris danial100% (1)

- Nfpa - 286Document19 pagesNfpa - 286Yakdhan YaseenNo ratings yet

- 18th-19th Century Family Houses Architectural FeaturesDocument3 pages18th-19th Century Family Houses Architectural FeaturesHustiuc RomeoNo ratings yet

- 2003 EWS X440 Product Guide-GlulamDocument32 pages2003 EWS X440 Product Guide-GlulamVinícius Da Cunha FerreiraNo ratings yet

- Bison Beam Block BrochureDocument7 pagesBison Beam Block Brochurealberto5791No ratings yet

- Case Study: Multistoried Apartment Rams Maris, CantonmentDocument17 pagesCase Study: Multistoried Apartment Rams Maris, CantonmentpadmajaNo ratings yet

- Chemical Resistance and Types of PaintsDocument29 pagesChemical Resistance and Types of PaintsAldrin FaraonNo ratings yet

- Explore Resort-Style Living at Panarama ResortDocument18 pagesExplore Resort-Style Living at Panarama ResortlibertiNo ratings yet

- Megastructures HistoryDocument18 pagesMegastructures HistoryUrja ShresthaNo ratings yet

- Method of Statement For Concrete WorksDocument15 pagesMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- Restoration Works at Velliyamkallu Heritage ParkDocument20 pagesRestoration Works at Velliyamkallu Heritage Parklifelinegroups nilNo ratings yet

- BS 5906-1980Document20 pagesBS 5906-1980snookersyNo ratings yet