Professional Documents

Culture Documents

Feeds and Speeds Titan Micro End Mills

Uploaded by

Angel Adan Llamas YañezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feeds and Speeds Titan Micro End Mills

Uploaded by

Angel Adan Llamas YañezCopyright:

Available Formats

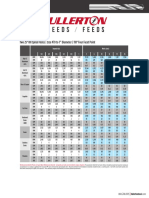

YOUR #1 SOURCE FOR AMERICAN-MADE PREMIUM CUTTING TOOLS

MICRO END MILLS - CARBIDE

THESE VALUES ARE FOR UNCOATED TOOLS. FOR ALTIN COATED TOOLS INCREASE SFM +40%

TECHNICAL INFORMATION

SFM & CHIP LOAD

DIAMETER RANGE - SUGGESTED CHIP LOAD PER TOOTH

MATERIAL / TYPE CONDITIONS STARTING

SFM .005-.015 .015-.030 .030-.045 .045-.060 .06-.075 .075-.090 .090-.105 .105-.12

.105-.125

25

STAINLESS STEELS

PRECIPITATION Slotting @ ≤ 10% of D

Slotting@ 90 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

13-8, 15-5, 17-4PH Profiling @6% of D Axial/≤ 20% of D Radial

Profiling@6% 250 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

AUSTENITIC Slotting

Slotting@@ ≤ 15% of D 100 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

302, 303, 304L, 316L Profiling @6% of D Axial/≤ 30% of D Radial

Profiling@6% 250 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

MARTENSITIC Slotting

Slotting@@ ≤ 15% of D 100 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

302, 303, 304L, 316L Profiling @6% of D Axial/≤ 30% of D Radial

Profiling@6% 250 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005””

HIGH TEMP ALLOYS

COBALT BASE Slotting

Slotting@@ 7% of D 50 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004””

Stellite, Haynes 25, 188, X-40, L-605 Profiling @5% of D Axial/≤ 20% of D Radial

Profiling@5% 80 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004”

NICKEL BASE

Inconel 600, 625, 718, Nickel 200, Slotting

Slotting@@ 7% of D 40 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004”

270, Invar, Monel 400, 405, K-Monel Profiling @5% of D Axial/≤ 20% of D Radial

Profiling@5% 60 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004”

PermaNickel 300, Incoly 600

IRON BASE

Slotting

Slotting@@ 7% of D 80 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004”

Incoly 800-802, Multimet N-155,

Profiling @5% of D Axial/≤ 20% of D Radial

Profiling@5% 100 .0001” .0001” .0002” .0002” .0003” .0003” .0004” .0004”

Timken 16-26-6

STEELS

HIGH STRENGTH STEELS Slotting

Slotting@@ ≤ 15% of D 100 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

4140, 4340, 52100 Profiling @6% of D Axial/≤ 30% of D Radial

Profiling@6% 180 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

HIGH ALLOY STEELS Slotting

Slotting@@ ≤ 10% of D 125 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

MOLD & DIE

Profiling @6% of D Axial/≤ 20% of D Radial

Profiling@6% 250 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

A-2, P20, 01, 02, D2, H-13

MEDIUM ALLOY STEELS Slotting

Slotting@@ ≤ 15% of D 125 .0003” .0003” .0004” .0004” .0005” .0005” .0006” .0006”

200, 250, 300 Profiling @6% of D Axial/≤ 30% of D Radial

Profiling@6% 250 .0003” .0003” .0004” .0004” .0005” .0005” .0006” .0006”

LOW ALLOY STEELS Slotting

Slotting@@ ≤ 15% of D 150 .0004” .0004” .0005” .0005” .0006” .0006” .0007” .0007”

MARAGING

10XX, 11XX, 13XX Profiling @6% of D Axial/≤ 35% of D Radial

Profiling@6% 300 .0004” .0004” .0005” .0005” .0006” .0006” .0007” .0007”

CAST IRONS

DUCTILE IRON Slotting

Slotting@@ ≤ 15% of D 100 .0004” .0004” .0005” .0005” .0006” .0006” .0007” .0007”

Ductile Cast Iron Profiling @10% of D Axial/≤ 25% of D Radial

Profiling@10% 250 .0004” .0004” .0005” .0005” .0006” .0006” .0007” .0007”

CAST IRON Slotting @ ≤ 25% of D

Slotting@ 125 .0004” .0004” .0005” .0005” .0008” .0008” .0010” .0010”

Gray Cast Iron Profiling @10% of D Axial/≤ 35% of D Radial

Profiling@10% 400 .0004” .0004” .0005” .0005” .0008” .0008” .0010” .0010”

TITANIUMS

TITANIUM ALLOYS Slotting @ ≤ 15% of D

Slotting@ 125 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

6AL-4V, ASTM 1, 2, 3, 6AL-2S

@6% of D Axial/≤ 20% of D Radial

Profiling@6%

Profiling 250 .0002” .0002” .0003” .0003” .0004” .0004” .0005” .0005”

For 5553, decrease SFM & IPM 25%

ALUMINUM

ALUMINUM ALLOYS Slotting@

Slotting @ ≤ 15% of D 650 .0004

.0004” .0004”

.00

0004”

4 .0005”

.00 05 .0006” .0008” .0008” .0010” .0010”

6061-T6, 7075 Profiling @10% of D Axial/≤ 35%

Profiling@10% % off D Rad

RRadial

diiall 775 .0004”

0004” .0004”

0004” .0005”

0005” .0006”

.0006

0006” .0008” .0008” .0010” .0010”

SPEED & FEED CALCULATION FORMULAS

RPM

RP M = (3

(3.8

(3.82

.822 x SF

SFM)

M) ÷ Dia.

Dia

ia.. IPR

IPR = IPM

IPM ÷ RPM

RPM SFM

SFM = (RPM

( PM

(R P x Dia.)

Dia

ia.)

.) ÷ 3.82

3.8

.822

IPM = IP

IPT(chip

T((chi

hip load)

d) x No. off Teeth

h x RPM IPT(chip

IPT(chi

( ip load)

load)

d) = IPM ÷ (No.

(No. of teeth x RPM))

888.482.6872 TITAN USA TITANMAN.COM

233

You might also like

- Classic Rotary Switch Range 2020 v1Document19 pagesClassic Rotary Switch Range 2020 v1Dave PotterNo ratings yet

- DRAFTDocument7 pagesDRAFTsNo ratings yet

- Dresser Couplings For Steel Pipe Sizes Style 38Document2 pagesDresser Couplings For Steel Pipe Sizes Style 38Shag ShaggyNo ratings yet

- P6 Limit SwitchDocument3 pagesP6 Limit SwitchABCdude1No ratings yet

- Welding Rod Price N-7018Document7 pagesWelding Rod Price N-7018jremptymakNo ratings yet

- 2012 LMT Onsrud Production Cutting Tools Hard PlasticDocument1 page2012 LMT Onsrud Production Cutting Tools Hard PlasticAnonymous shUWODvoNo ratings yet

- Aerofab NDT Catalog SampleDocument11 pagesAerofab NDT Catalog SampleAlejandro Torrico TamayoNo ratings yet

- TM Arc Triarc 2020h209Document2 pagesTM Arc Triarc 2020h209santyagoNo ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- Oil & Gas Equipment Catalog SectionsDocument31 pagesOil & Gas Equipment Catalog SectionsSergio Alonso Florez BarretoNo ratings yet

- 1499774814+amphenol MIL 26482 62IN SeriesDocument16 pages1499774814+amphenol MIL 26482 62IN SeriesValentin PetracheNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- ERMS Rotary - Switches - Off - On - Rotary - SwitchesDocument10 pagesERMS Rotary - Switches - Off - On - Rotary - SwitchesVivek SavaliyaNo ratings yet

- Paper22 PDFDocument8 pagesPaper22 PDFCristobal Jimenez MuchoNo ratings yet

- Ja Delmas Brochure Large Mining PFBJ0030 enDocument68 pagesJa Delmas Brochure Large Mining PFBJ0030 enmohamed nizmyNo ratings yet

- Accessories & Hardware: ShroudsDocument1 pageAccessories & Hardware: ShroudsDario Gabriel Coz RojasNo ratings yet

- Ficha Técnica Tornos Convencionales CDS CW - Compressed1 PDFDocument1 pageFicha Técnica Tornos Convencionales CDS CW - Compressed1 PDFedisonNo ratings yet

- 4.offshore ProductsDocument32 pages4.offshore ProductsMariano AnselmoNo ratings yet

- Marine FenderDocument56 pagesMarine Fendermadhumster1240No ratings yet

- FenderDocument52 pagesFenderJayapaul ViyagulamNo ratings yet

- C44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingDocument8 pagesC44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingRaphael Santos do NascimentoNo ratings yet

- Fast-Acting, Ceramic Tube FusesDocument2 pagesFast-Acting, Ceramic Tube FusesSHUBHAM PANDEYNo ratings yet

- CEMBRE LUG 90deg Cable Lug - AKBAR TRADING EST - SAUDI ARABIADocument1 pageCEMBRE LUG 90deg Cable Lug - AKBAR TRADING EST - SAUDI ARABIAGIBUNo ratings yet

- H-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - DDocument16 pagesH-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - Dnguyen rinNo ratings yet

- Meiko Brochure 2021Document162 pagesMeiko Brochure 2021Jdk SparepartsNo ratings yet

- 2035 XX SMDocument3 pages2035 XX SMDDAANNIIEELLNo ratings yet

- Water Jacket Motor PDFDocument8 pagesWater Jacket Motor PDFsultaniusNo ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- 9 M6X Ya 00005Document30 pages9 M6X Ya 00005Mohamad ShafeyNo ratings yet

- Acesian Ducting Catalogue (111121)Document20 pagesAcesian Ducting Catalogue (111121)Matthew Ho Choon LimNo ratings yet

- O-Ring Gland DesignsDocument28 pagesO-Ring Gland DesignsGregory Aguilera LopesNo ratings yet

- Fittings or Connection Systems-Pressure - RatingsDocument1 pageFittings or Connection Systems-Pressure - RatingsJim StreitmatterNo ratings yet

- FootprintsDocument254 pagesFootprintsbigblower100% (2)

- ภาพถ่ายหน้าจอ 2566-04-08 เวลา 12.25.23Document40 pagesภาพถ่ายหน้าจอ 2566-04-08 เวลา 12.25.23atinan chotirangseeNo ratings yet

- Amphenol Militar Connectors MS3106Document4 pagesAmphenol Militar Connectors MS3106Stefan OlianoNo ratings yet

- CR4000 Series Service Regulators: Technical BulletinDocument5 pagesCR4000 Series Service Regulators: Technical BulletinFRANKLIN RAMIREZNo ratings yet

- YD 90L 2 4 DatasheetDocument1 pageYD 90L 2 4 DatasheetLance AyoubNo ratings yet

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshNo ratings yet

- Sensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetDocument5 pagesSensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetVictor RamirezNo ratings yet

- Weld Procedure Matrix: Job Number: Prepared By: Customer: Date: Technical Contact: Revision: 0Document3 pagesWeld Procedure Matrix: Job Number: Prepared By: Customer: Date: Technical Contact: Revision: 0RobNo ratings yet

- IMG Scheda ISOLATION-JOINTS Web PDFDocument2 pagesIMG Scheda ISOLATION-JOINTS Web PDFdevpal78No ratings yet

- OEZ - Circuit BreakerDocument296 pagesOEZ - Circuit Breaker600sNo ratings yet

- 65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsDocument9 pages65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsTimothy Joshua GatchalianNo ratings yet

- U Drills and Spade Drills - 2018Document52 pagesU Drills and Spade Drills - 2018ecarrilloNo ratings yet

- Symmetrical Quick Couplers For Excavators June 2011 EditionDocument5 pagesSymmetrical Quick Couplers For Excavators June 2011 EditionpmpintoisqNo ratings yet

- 5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052Document3 pages5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052MahfudNo ratings yet

- 12,0mm Two-Screw Terminal StripDocument2 pages12,0mm Two-Screw Terminal StriptugazonaNo ratings yet

- Wear Ring - WrpagfDocument6 pagesWear Ring - Wrpagfsaurabhbit19No ratings yet

- AsdDocument25 pagesAsdIswell Bert ApongolNo ratings yet

- 98E136 Flexsteel ENG WebDocument2 pages98E136 Flexsteel ENG Webagniva dattaNo ratings yet

- Mousebud The Snap-Lock, Trigger-Release Connector: 860-005R Panel Mounting Receptacles With Solder Cup TerminalsDocument2 pagesMousebud The Snap-Lock, Trigger-Release Connector: 860-005R Panel Mounting Receptacles With Solder Cup TerminalsUday KrishnaNo ratings yet

- #908372001 - 400HA400A (Without Lock) - C000604391Document5 pages#908372001 - 400HA400A (Without Lock) - C000604391Abdelhamid ElballatNo ratings yet

- Design For Axial, Shear Load and Mo En!s" Design For Axial, Shear Load and Mo En!s" Col# N Se$!ion Col# N Se$!ion %&'X%&'X D D$ $ F FDocument8 pagesDesign For Axial, Shear Load and Mo En!s" Design For Axial, Shear Load and Mo En!s" Col# N Se$!ion Col# N Se$!ion %&'X%&'X D D$ $ F FTitus PraveenNo ratings yet

- Footprint LibraryDocument140 pagesFootprint LibraryGiacomo Xerri100% (1)

- ST Capacitor Assemblies: Lead Configuration and Assembly OptionsDocument2 pagesST Capacitor Assemblies: Lead Configuration and Assembly OptionsLeonardoNo ratings yet

- Catalogo ABB PDFDocument28 pagesCatalogo ABB PDFOmarElizondoRamirezNo ratings yet

- Ashraf CadDocument10 pagesAshraf CadAdarsh KrNo ratings yet

- Melin Speed and Feed MTi4,5,7Document1 pageMelin Speed and Feed MTi4,5,7Alex L. CruzNo ratings yet

- Maclean - Isoladores de Suspensão e Line PostDocument23 pagesMaclean - Isoladores de Suspensão e Line PostGuilherme LinharesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- AccuThread CPH 0309Document1 pageAccuThread CPH 0309Angel Adan Llamas YañezNo ratings yet

- CGS Catalog Summer 2020Document45 pagesCGS Catalog Summer 2020Angel Adan Llamas YañezNo ratings yet

- MDM Brochure 2021Document16 pagesMDM Brochure 2021Angel Adan Llamas YañezNo ratings yet

- Fullerton 1510 Speeds FeedsDocument1 pageFullerton 1510 Speeds FeedsAngel Adan Llamas YañezNo ratings yet

- 3200 Series 4-Flute End Mill Is Offered in An Extensive Variety of ConfigurationsDocument2 pages3200 Series 4-Flute End Mill Is Offered in An Extensive Variety of ConfigurationsAngel Adan Llamas YañezNo ratings yet

- Cyclone CS Operator Manual CS-900T-OPT-10Document24 pagesCyclone CS Operator Manual CS-900T-OPT-10Angel Adan Llamas YañezNo ratings yet

- Operating Manual: Ref.1711 Soft: V02.2xDocument160 pagesOperating Manual: Ref.1711 Soft: V02.2xAngel Adan Llamas YañezNo ratings yet

- Guhring Thread Mill CNC ProgramDocument1 pageGuhring Thread Mill CNC ProgramAngel Adan Llamas YañezNo ratings yet

- Jis Beams PDFDocument1 pageJis Beams PDFwisnu_bayusaktiNo ratings yet

- 1 Sunum PDFDocument21 pages1 Sunum PDFHilalAldemirNo ratings yet

- TWI CSWIP 3.2 Handout AnswerDocument5 pagesTWI CSWIP 3.2 Handout AnswerAnna PariniNo ratings yet

- Pipe Support Standard DetailsDocument3 pagesPipe Support Standard DetailsMainuddin AliNo ratings yet

- Properties of structural steel sections appendixDocument43 pagesProperties of structural steel sections appendixvenkatesh1970133% (6)

- T.O. (SH & CH) Division, HDC, Kopt: Traffic ChartDocument2 pagesT.O. (SH & CH) Division, HDC, Kopt: Traffic Chartapi-20018544No ratings yet

- República Democrática de Timor-Leste Ministerio Das Obras PúblicasDocument11 pagesRepública Democrática de Timor-Leste Ministerio Das Obras PúblicasManuel Francisco BarbosaNo ratings yet

- NEW Electroweld Pricelist - APR 25 2022Document7 pagesNEW Electroweld Pricelist - APR 25 2022ernst gencayaNo ratings yet

- Welding Visual ReportDocument6 pagesWelding Visual ReportFerdie OSNo ratings yet

- Stainless Steel Grades DatasheetsDocument7 pagesStainless Steel Grades DatasheetsYeda ZNo ratings yet

- Technical Report: How TGX Filler Rods Can Eliminate Back ShieldingDocument2 pagesTechnical Report: How TGX Filler Rods Can Eliminate Back ShieldingSamuel LatumahinaNo ratings yet

- XVC304Document2 pagesXVC304JESUS MANUEL MARCANO C.No ratings yet

- ESSC Advantages and ProductivityDocument28 pagesESSC Advantages and ProductivityJitendra UmaraliyaNo ratings yet

- Hobart TM Catalog 2020Document26 pagesHobart TM Catalog 2020pawan kumarNo ratings yet

- Aci 364.14T-17Document6 pagesAci 364.14T-17Marisol SanchezNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- MASHOP 3 (New Curriculum) Topic: Electric Arc Welding: Prepared By: Engr. Emiliano P. Heraña JR Faculty, CME. OLFUDocument41 pagesMASHOP 3 (New Curriculum) Topic: Electric Arc Welding: Prepared By: Engr. Emiliano P. Heraña JR Faculty, CME. OLFUBrianss AyangssNo ratings yet

- Plates and SheetsDocument15 pagesPlates and SheetsAntoine AbdoNo ratings yet

- Neco Catlog 4 FoldDocument2 pagesNeco Catlog 4 FoldSanket PhatangareNo ratings yet

- British Steel SectionsDocument32 pagesBritish Steel SectionsIbadurrahman IbadNo ratings yet

- Din 17200 C45Document1 pageDin 17200 C45Afriza NurdiansyahNo ratings yet

- Steelgrades 2Document6 pagesSteelgrades 2dexterisNo ratings yet

- ARTICOMDocument20 pagesARTICOMWajih AnsariNo ratings yet

- DLL Grade 9 Final 1st o 4th QuarterDocument5 pagesDLL Grade 9 Final 1st o 4th QuarterJoy GuevarraNo ratings yet

- Material Standard Comparison TableDocument2 pagesMaterial Standard Comparison TableToniNo ratings yet

- Presentation On: Certified Welding Inspector (CWI)Document36 pagesPresentation On: Certified Welding Inspector (CWI)ssharma9742No ratings yet

- Note & ReportDocument40 pagesNote & Reportvinkumar_hbtiNo ratings yet

- Steel Coding SystemDocument5 pagesSteel Coding SystemWell LojuminNo ratings yet

- Lecture - 05 Welded ConnectionsDocument84 pagesLecture - 05 Welded Connectionssivaenotes100% (2)

- Carbon Steel Equivalents for Shipbuilding & Pressure VesselsDocument10 pagesCarbon Steel Equivalents for Shipbuilding & Pressure Vesselsibson045001256No ratings yet