Professional Documents

Culture Documents

Melin Speed and Feed MTi4,5,7

Uploaded by

Alex L. CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Melin Speed and Feed MTi4,5,7

Uploaded by

Alex L. CruzCopyright:

Available Formats

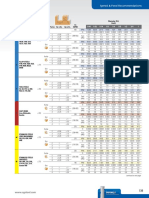

Melin Tool Speed & Feed Information

USA

Series:MTi4, MTi5, MTi7

Carbide MULTI

FLUTES CC

Center

Cutting

MATERIAL CONDITION SFM CUTTING DIAMETER

1/8” 3/16” 1/4” 3/8” 1/2” 5/8” 3/4” 1” 1-1/4”

STAINLESS STEELS ISO-M CHIP PER TOOTH

Precipitation Slotting Up to 1 x Dia. 80-175 .0008 .0013 .0015 .0018 .0024 .0028 .0034 .0050 .0068

13-8, 15-5, 17-4PH HEM Profiling @ 1-1/2 to 2 x D

175-225 .0024 .0031 .0033 .0045 .0055 .0068 .0081 .0102 .0133

Axial / 4 to 5 % D Radial

Austenitic Slotting Up to 1 x Dia. 150-250 .0008 .0013 .0015 .0018 .0024 .0028 .0034 .0050 .0070

302, 303, 304L, 316L HEM Profiling @ 1-1/2 to 2 x D

175-225 .0024 .0031 .0033 .0045 .0055 .0068 .0081 .0102 .0140

Axial / 4 to 5 % D Radial

Martensitic Slotting Up to 1 x Dia. 200-350 .0008 .0013 .0015 .0018 .0024 .0028 .0034 .0050 .0080

403, 410, 416 HEM Profiling @ 1-1/2 to 2 x D

250-425 .0024 .0031 .0033 .0045 .0055 .0068 .0081 .0102 .0142

Axial / 4 to 5 % D Radial

STEELS ISO-P

High Strength Steels Slotting Up to 1 x Dia. 285-325 .0008 .0013 .0015 .0018 .0024 .0028 .0034 .0050 .0075

High Strength Steels HEM Profiling @ 1-1/2 to 2 x D

375-425 .0024 .0031 .0033 .0045 .0055 .0068 .0081 .0102 .0135

4140, 4340 Axial / 4 to 5 % D Radial

Mold and Die Slotting Up to 1 x Dia. 275-300 .0007 .0009 .0011 .0015 .0018 .0022 .0028 .0035 .0060

A2, P-20, D2, H13 HEM Profiling @ 1-1/2 to 2 x D

275-350 .0021 .0023 .0025 .0045 .0047 .0066 .0080 .0085 .0100

Axial / 4 to 5 % D Radial

Low and Medium Alloy Steels Slotting Up to 1 x Dia. 325-400 .0010 .0013 .0013 .0018 .0022 .0030 .0035 .0050 .0080

1018, 11XX, 13XX,200, 250, 300 HEM Profiling @ 1-1/2 to 2 x D

350-525 .0025 .0031 .0038 .0045 .0063 .0072 .0086 .0105 .0145

Axial / 4 to 5 % D Radial

TITANIUMS ISO-S

Titanium Alloys Slotting up to 1 x Dia. 175-225 .0010 .0013 .0013 .0018 .0022 .0030 .0035 .0050 .0070

6AL-4V, ASTM 1, 2, 3, 6AL-2S HEM Profiling @ 1-1/2 to 2 x D

250-325 .0025 .0031 .0038 .0045 .0063 .0072 .0086 .0105 .0135

Axial / 4 to 5 % D Radial

For 5553, decrease SFM and IPM by 25%

Note: All listed technical data provided are suggested starting points. They may be increased or decreased

depending on machine condition, depth of cut, finish required, coolant, etc.

Additional Info: Our Technical Service Team is available to answer any questions. You can contact one of our

expert application specialists at 216-362-4200 or techsupport@melintool.com

Speeds & Feeds Warning: Tools may shatter. Appropriate safeguards required.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- BLTPX 010123Document6 pagesBLTPX 010123cesar cobosNo ratings yet

- Speeds and Feeds 1053 1054Document1 pageSpeeds and Feeds 1053 1054P CHNo ratings yet

- 24 Pilot Mill 1Document2 pages24 Pilot Mill 1jorge vargas zapataNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Pole Sheets: Cold-Rolled Steel StripDocument2 pagesPole Sheets: Cold-Rolled Steel StripL Mahender ReddyNo ratings yet

- M525 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocument1 pageM525 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNo ratings yet

- Page 1 of 2 CADDY® Reversible Beam Clamps - Models 300 & 310Document2 pagesPage 1 of 2 CADDY® Reversible Beam Clamps - Models 300 & 310Jorge InostrozaNo ratings yet

- 450 MCWDocument5 pages450 MCWSantiago Mejia GonzalezNo ratings yet

- 450 MCWDocument5 pages450 MCWSantiago Mejia GonzalezNo ratings yet

- Equipo Hot Tap de 42 inDocument5 pagesEquipo Hot Tap de 42 inSerch Villa100% (1)

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- 1221 Standard Pipe NipplesDocument1 page1221 Standard Pipe NipplesmvinuNo ratings yet

- Bleed Ring ReportDocument1 pageBleed Ring ReportRatna Giridhar KavaliNo ratings yet

- Slurryflex SA Hard Wall Mining Hose DatasheetDocument2 pagesSlurryflex SA Hard Wall Mining Hose DatasheetBeaver Process EquipmentNo ratings yet

- 2017 General Price List: and Valve Automation Equipment Industrial Process High Performance Ball ValvesDocument8 pages2017 General Price List: and Valve Automation Equipment Industrial Process High Performance Ball ValvesjsmarksNo ratings yet

- M924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocument1 pageM924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNo ratings yet

- Pole RssDocument2 pagesPole Rssgenial72No ratings yet

- Twelve Point Flange Screws: Earnest Technical BulletinDocument1 pageTwelve Point Flange Screws: Earnest Technical Bulletinflasher_for_nokiaNo ratings yet

- Pearl Abrasives Depressed Center Grinding WheelsDocument3 pagesPearl Abrasives Depressed Center Grinding WheelsalexzandrousNo ratings yet

- Model BKR Premium Cement Retainer - Mechanical SetDocument1 pageModel BKR Premium Cement Retainer - Mechanical SetCarlos HolguinNo ratings yet

- Model BKR Premium Cement Retainer - Mechanical SetDocument1 pageModel BKR Premium Cement Retainer - Mechanical SetChandra FadhillahNo ratings yet

- Fairlane Rollers PDFDocument62 pagesFairlane Rollers PDFvcockscribdNo ratings yet

- Astm F-594Document1 pageAstm F-594Oswaldo Leyva RNo ratings yet

- 24 Pilot Mill 2Document2 pages24 Pilot Mill 2jorge vargas zapataNo ratings yet

- Reaming Head: Pilot Hole Stem Head Part No. SaddlesDocument1 pageReaming Head: Pilot Hole Stem Head Part No. SaddlesYuriPasenkoNo ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- March Pump Manual 7 Plastic 0155 0046 1000 Rev32Document2 pagesMarch Pump Manual 7 Plastic 0155 0046 1000 Rev32Asima Jaya TamaNo ratings yet

- BT1100 Teltru 16 17Document2 pagesBT1100 Teltru 16 17Prihartono Danan WingusNo ratings yet

- Blueshield LA 7018: Low-Hydrogen ElectrodeDocument2 pagesBlueshield LA 7018: Low-Hydrogen ElectrodeOPAZOSCNo ratings yet

- 08 Casing CutterDocument2 pages08 Casing Cutterjorge vargas zapataNo ratings yet

- Böhler Fox Dcms KB: Classifi CationsDocument1 pageBöhler Fox Dcms KB: Classifi CationsBranko FerenčakNo ratings yet

- Catalog For Pahala BahariDocument4 pagesCatalog For Pahala BahariMuhammad Reza GadranNo ratings yet

- Tuberia HFD.Document16 pagesTuberia HFD.Gerardo Noé Cruz RodríguezNo ratings yet

- Er70S-2 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-2 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Hand ToolsDocument273 pagesHand ToolsTone Ratanalert100% (1)

- Bolting Information Pertaining To ASTM A193Document25 pagesBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Selectalloy 307cDocument1 pageSelectalloy 307cJuan Carlos RodriguezNo ratings yet

- M527 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocument1 pageM527 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNo ratings yet

- 23 Taper MillDocument2 pages23 Taper Milljorge vargas zapataNo ratings yet

- CPS - Bridge PlugDocument8 pagesCPS - Bridge PlugJOGENDRA SINGHNo ratings yet

- Heat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierDocument16 pagesHeat Shrinkable Closures System, Jointing Kits and Cable Repair Sleeves From China Manufacturer and SupplierAlanNo ratings yet

- 9802/9750 B3-3-1 Arms, Loader Shovel LinkageDocument2 pages9802/9750 B3-3-1 Arms, Loader Shovel LinkageMexanik212No ratings yet

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

- Basic Comparison Extruder Slipformer enDocument7 pagesBasic Comparison Extruder Slipformer enOmar MahmoudNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- 8 t2 SC SeriesDocument16 pages8 t2 SC SeriesAntony VeNo ratings yet

- Kohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetDocument4 pagesKohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetJoanne CordesNo ratings yet

- Vad Series: Adjustable Blades Axial Flow FansDocument3 pagesVad Series: Adjustable Blades Axial Flow FansTedi A MaulanaNo ratings yet

- Feeds and Speeds Titan Micro End MillsDocument1 pageFeeds and Speeds Titan Micro End MillsAngel Adan Llamas YañezNo ratings yet

- Self Drilling Screws Fasteners Product Data 1673386Document8 pagesSelf Drilling Screws Fasteners Product Data 1673386Fabio Saraiva BoxNo ratings yet

- EI Bimetal Thermometer: Data SheetDocument5 pagesEI Bimetal Thermometer: Data SheetAntonella EspinozaNo ratings yet

- GelportDocument2 pagesGelportNom YusNo ratings yet

- Dresser Couplings For Steel Pipe Sizes Style 38Document2 pagesDresser Couplings For Steel Pipe Sizes Style 38Shag ShaggyNo ratings yet

- TECHNICALDocument51 pagesTECHNICALAlex L. CruzNo ratings yet

- 3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous MaterialsDocument2 pages3835 Series Alumamill End Mill Is Designed For Aggressive Material Removal Rates in Non-Ferrous MaterialsAlex L. CruzNo ratings yet

- Endmill Solid Carb.: SERIES A-454Document14 pagesEndmill Solid Carb.: SERIES A-454Alex L. CruzNo ratings yet

- SGS Speeds Feeds GP PDFDocument2 pagesSGS Speeds Feeds GP PDFandres179No ratings yet

- Equivalent MaterialDocument1 pageEquivalent MaterialCinthya YasudaNo ratings yet

- SAMPLE-X3 Mill Level 1 Training TutorialDocument77 pagesSAMPLE-X3 Mill Level 1 Training TutorialAdriano CardosoNo ratings yet

- Specification For General Requirements For Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled BarDocument16 pagesSpecification For General Requirements For Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled BarJolettitoNo ratings yet

- ABC 200 Heat ExchangerDocument200 pagesABC 200 Heat Exchanger전상문100% (2)

- Chemistry Form 4 PDF UPLOADDocument18 pagesChemistry Form 4 PDF UPLOADRahmat Syafiq MuhammadNo ratings yet

- Tin Is A Chemical Element With The Symbol SNDocument1 pageTin Is A Chemical Element With The Symbol SNemieZNo ratings yet

- Position Switches FR Series: Selection DiagramDocument12 pagesPosition Switches FR Series: Selection DiagramMehmetLeventÖzsinanNo ratings yet

- Ch34 Surface TreatmentDocument13 pagesCh34 Surface TreatmenthasbyNo ratings yet

- Alloy DensitiesDocument4 pagesAlloy DensitiesjphigbyNo ratings yet

- Master Catalog New 2002 Edition Penn-UnionDocument204 pagesMaster Catalog New 2002 Edition Penn-UnionAnonymous t4eTGwA100% (1)

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingMohammad RizwanNo ratings yet

- Materials - Metals and Non-Metals Worksheet 2Document2 pagesMaterials - Metals and Non-Metals Worksheet 2zakir soomroNo ratings yet

- Sa 612Document5 pagesSa 612Luis MuñozNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-05Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-05wahyuNo ratings yet

- Eglin SteelDocument3 pagesEglin SteelShaun LeeNo ratings yet

- Attachment 2 ConsumableDocument8 pagesAttachment 2 ConsumableabbigtsNo ratings yet

- Welding Defect - WikipediaDocument7 pagesWelding Defect - WikipediaKiky IchanafiNo ratings yet

- Fiat52605 02Document6 pagesFiat52605 02LucaNo ratings yet

- Astm A706 PDFDocument5 pagesAstm A706 PDFRigel IncursioNo ratings yet

- Bega 2231Document1 pageBega 2231jmcfeNo ratings yet

- MST-Structural Steel RepairDocument11 pagesMST-Structural Steel RepairDelta akathehuskyNo ratings yet

- Process Equipment Design (Pinoy Edition)Document40 pagesProcess Equipment Design (Pinoy Edition)Rachel HechanovaNo ratings yet

- The Current State of Worldwide Standards of Ductile IronDocument8 pagesThe Current State of Worldwide Standards of Ductile IronN.PalaniappanNo ratings yet

- Electrical Tools and MaterialsDocument36 pagesElectrical Tools and MaterialsRonaldo Paloma100% (2)

- Adore Electrode BookletDocument207 pagesAdore Electrode BookletKrisna SinghNo ratings yet

- EZYBUILD - PEBliteDocument12 pagesEZYBUILD - PEBliteMatthew JacobsNo ratings yet

- Mig WeldingDocument8 pagesMig WeldingSiddharth PradhanNo ratings yet

- BSI 709 DT Fusion WeldedDocument24 pagesBSI 709 DT Fusion WeldedbonnicoNo ratings yet

- (Handbook) High Performance Stainless Steels (11021)Document95 pages(Handbook) High Performance Stainless Steels (11021)pekawwNo ratings yet

- Series FD Fire Dampers: Product Data SheetDocument4 pagesSeries FD Fire Dampers: Product Data SheetEstevan huertasNo ratings yet

- A 220 - A 220M - 99 (2014) PDFDocument5 pagesA 220 - A 220M - 99 (2014) PDFأسامة وحيد الدين رمضانNo ratings yet

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet