Professional Documents

Culture Documents

Data Sheet - Low Voltage Motor For Package Equipments

Data Sheet - Low Voltage Motor For Package Equipments

Uploaded by

Cassy AbulenciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet - Low Voltage Motor For Package Equipments

Data Sheet - Low Voltage Motor For Package Equipments

Uploaded by

Cassy AbulenciaCopyright:

Available Formats

Data Sheet - Low Voltage Motor for package equipments

Client Bahrain Airport Company Division Oil, Gas & Petrochemicals-Dubai

Project No. 352911 / DP1115 Document No. 352911/DA 3122

Project Title. Fuel Farm Complex and Fuel Hydrant at Bahrain International Airport Page 1 of 1 Rev. 02

1 Equipment No. Note 4 59 No load current * %FLC

2 Quantity (Running / Standby) Note 4 Note 4 60 Locked Rotor Current * %FLC

3 Description Note 4 61 Insulation Class class

*

4 Rating (kW) Note 4 62 Temperature rise * class

5 Supply Parameter 400Vac 3 ph 50Hz 63 Thermal rating constant * sec

6 Space heater voltage / Cable Size Note 8 230 Volts, 50Hz, 1ph / 3C X 4mm² 64 Starting current with 100% V * %FLC

65 Starting Current with 80% V * %FLC

7 Area Classification/Gas Group Note 5 *

66 Starting time with 100% V * sec

8 Type of explosion protection Note 5 * 67 Starting torque with 100% V * %FLT

SPECIFICATION

Class F insulation with Temp rise

9 Class of winding insulation 68 Starting Torque with 80% V %FLT

limited to Class B *

10 Degree of protection IP 55 69 Starting time with 80% V * sec

11 Cooling TEFC 70 Locked Rotor Withstand time

12 Power cable Type / Size Note 4 * 70a Hot * sec

13 Duty S1 - Continuous. 70b Cold * sec

14 Winding Temperature Detectors Note 4 * 71 Safe stalling time cold * sec

15 Bearing Temperature Detectors Note 4 * 72 No of starts Hot * nos

16 Vebration sensors Note 4 * 73 No of starts Cold * nos

17 Applicable standard IEC 60034 74 Locked Rotor Torque * %FLT

18 Direction of Rotation Bi-direction 75 Pull out Torque * %FLT

19 Stator Winding connection Star / Delta 76 Starting shaft torque * %FLT

Refer Site Datasheet -

20 Design Ambient Temperature 77 Break down shaft torque %FLT

352911/DA0001 *

21 Starting Method Note 6 * 78 Pull-up shaft torque %FLT

*

22 Type of load * 79 Rated shaft torque * %FLT

23 Installed Rating * 80 Rated power factor *

24 Absorbed Power Max. * 81 Starting power factor

DATA TO BE FURNISHED BY EQPT.VENDOR

*

25 Motor speed (Syncr.) * 82 Locked Rotor pf *

26 Type of mounting * 83 Efficiency @

VENDOR CONFIRMATION

27 Transmission * 83a 100% FL *

28 Shaft Extension * 83b 50% FL *

2 At absorbed Power

29 Inertia of load GD ( At motor speed) * 83c *

30 Starting Torque required * 84 Method of starting * DOL

31 Starting and running duties required * 85 Acceleration time *

32 Starting time limitation (if any) * 86 a) DOL start * sec

33 No. of starts/hour( start duty ) * 87 b) Assisted start n.a.

34 Motor starting against load * 88 i) Star /delta n.a.

35 unloaded * 89 ii) Auto transformer (tap %) n.a.

36 Type of Enclosure * 90 iii) Soft starter (Ist= %FLC) n.a. sec

37 Dir. Of Rotation of motor (viewed from DE) * 91 stator connection star/delta *

38 Special Requirement * 92 te time (Exe motors) *

Note:Equipment vendor to furnish speed / torque

39 93 GD2 of rotor(kg m2)

curve for driven equipment *

40 Bearing Ref temperature DE * 94 Insulation Class *

41 Bearing Ref temperature NDE * 95 Temperature rise(by res) *

MECH. DIM.& WT. DATA BY

42 Bearing type DE * 96 Duty *

MOTOR VENDOR

43 Bearing type NDE * 97 Type of enclosure *

44 Bearing Lubrication * 98 Degree of protection (enclosure) *

45 Net Weight * 99 Direction of rotation (viewed from DE) *

46 Shipping Weight * 100 Main Tb cable size & no.of entries *

47 Over All Dimension(mm) * 101 Neutral terminal box detail *

48 Out line drawing * 102 Noise(db at 1 meter) *

49 any other information * 103 Space heater Provision/wattage *

50 104 Wdg temperature protection *

46 Manufacturer details * 105 Motor thermal time constant * min

47 Country of Origin * 106 Max. allowable -ve ph seq.current * %FLC

48 Nearest Service station details * 109 Acoustic noise at full load * dB

VENDOR CONFIRMATION

49 Frame Designation * 110 Bearing RTD details n.a.

50 Mounting Type * 111 Winding thermisters details n.a.

51 Type of Rotor * 112 Insulated bearings n.a.

52 Duty * 113 Vibration sensor details n.a.

53 Efficiency class of motor * 114 Anti condensation heater details *

54 Voltage * Volt 115 location of cable terminal box *

55 Rating * Kw 107 Certification Standard *

56 No.of Poles * nos 108 Certification Authorities *

57 Rated Speed * Rpm

58 Full load Current * Amp.

NOTES:

1. Motor vendor to furnish following characteristic curves for motor:

a. Speed v/s Torque , Efficiency v/s Current , Power factor v/s Current.

b. Motor starting curves (Current Time ) with 100% & 80% of rated voltage.

c. Thermal withstand curves (hot as well as cold ) at 100% & 80% of rated voltage.

2. Testing of motors to be in accordance with IEC 60034.

3. Vendor to confirm selection and materials of construction and should return one completed (see * marks) or corrected copy to Engineer.

4. Details to be specified by vendor

5 Motor & associated controlgear selection shall be as per hazardous area classification layout - 352911/71002 & 325911/71003

6. Motor starting method shall be in conformity to EDD Regulations, please refer LV motor specifications - 352911/ TS306

7. Motor shall be compatible with the load characteristics and operational duty of the driven equipment.

8. Interlock shall be provided for the operation of the space heaters if applicable.

9. External Painting-Corrosivity category C5M with Medium Durability as per BSEN ISO 12944-5

10. Motor with VFD/soft starter starting shall be be suitable for starting in DOL mode. Suitable maintenance bypass shall be provided for VFD/soft starter.

11 Motors with VFD drive shall be inverter duty motors.

12 Motor terminal box shall be suitable to rotate in steps of 90 deg.

13 The electrical system shall be in conformity to EDD Regulations.

14 Motor bearing shall not take the axial loads

REV DATE DESCRIPTION ORIGNR CHKD APPD.

00 01/05/16 Preliminary SW VT ADS

01 15/06/16 For Approval SW VT ADS

02 02/08/16 Issued for Tender SW VT ADS

PLEASE NOTE: THIS DATASHEET SHOULD NOT BE USED FOR CONSTRUCTION OR FOR ORDERING MATERIALS UNTIL IT IS APPROVED.

P:\Dubai\ONG\DUO Sub Div\ProjDocs\2015\DP1115- BAC-Fuel Farm-BIA\ENGG\03_Electrical\Documents\Fuel Depot\Datasheets\02.08.2016\352911_DA3122-LVM (01)

You might also like

- AL4 Pressure Regulation Fault 2Document8 pagesAL4 Pressure Regulation Fault 2Ahmed Fotoh100% (12)

- 52124b Catalog Fuel SystemDocument182 pages52124b Catalog Fuel SystemMichael AkhramovichNo ratings yet

- Pt. Semen Kupang Indonesia: Data Sheet & Technical Particular Guarantee For Distibution TransformerDocument15 pagesPt. Semen Kupang Indonesia: Data Sheet & Technical Particular Guarantee For Distibution TransformerharisNo ratings yet

- MP A428 Yale P A418 HysterDocument327 pagesMP A428 Yale P A418 Hystermirko coppini100% (1)

- 2zz-Cylinder Head - InstallationDocument5 pages2zz-Cylinder Head - InstallationGullwing Motor Service100% (1)

- SEBF8106 - Specifications For Cylinder Head Assemblies in 3600 and C280 Engines (1100, 1101, 1102, 1103, 1104, 1105, 1108, 1109)Document10 pagesSEBF8106 - Specifications For Cylinder Head Assemblies in 3600 and C280 Engines (1100, 1101, 1102, 1103, 1104, 1105, 1108, 1109)LUIZ GUSTAVONo ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Screw Compressors: Model: VE22-10BDocument30 pagesScrew Compressors: Model: VE22-10BVoştinar IoanNo ratings yet

- FD ISA Form S20.50 Rev 1 - OriginalDocument1 pageFD ISA Form S20.50 Rev 1 - OriginalRaphael AndradeNo ratings yet

- D50 60 70S-5 (Sb1101e05)Document401 pagesD50 60 70S-5 (Sb1101e05)goxmad100% (1)

- Specifications Eh 500fDocument7 pagesSpecifications Eh 500fElfirman Syafei100% (1)

- Lrs Resistencia Liquid StarterDocument45 pagesLrs Resistencia Liquid StarterQ Llanos HenryNo ratings yet

- DA3113-PRT Recovery Pump MotorDocument1 pageDA3113-PRT Recovery Pump MotorCassy AbulenciaNo ratings yet

- DA3101-hydrant Pump MotorDocument1 pageDA3101-hydrant Pump MotorCassy AbulenciaNo ratings yet

- DA3114-PRT Sump Pump MotorDocument1 pageDA3114-PRT Sump Pump MotorCassy AbulenciaNo ratings yet

- DA3112-Recirculation Pump MotorDocument1 pageDA3112-Recirculation Pump MotorCassy AbulenciaNo ratings yet

- DA3111-BU Pump MotorDocument1 pageDA3111-BU Pump MotorCassy AbulenciaNo ratings yet

- DA3117-APFC UnitDocument1 pageDA3117-APFC UnitCassy AbulenciaNo ratings yet

- GT1044ADocument7 pagesGT1044AMax AyalaNo ratings yet

- TEK20141027023SPECDocument1 pageTEK20141027023SPECHary FadlyNo ratings yet

- Technical Manual EPMDocument53 pagesTechnical Manual EPMJoel TimajoNo ratings yet

- HSD PDFDocument12 pagesHSD PDFDinezJdNo ratings yet

- Pilot Pro 900 ManualDocument12 pagesPilot Pro 900 ManualKiner CalixtoNo ratings yet

- Solenoid Valve JMFH-5-1/8-S: Data SheetDocument2 pagesSolenoid Valve JMFH-5-1/8-S: Data SheetYudi ErmandaniNo ratings yet

- MT28JE5PVEDocument5 pagesMT28JE5PVEJo PastorNo ratings yet

- Ns2 Yt01 P0sha 120002 Ab (Intake Facility) - Motor Data SheetDocument62 pagesNs2 Yt01 P0sha 120002 Ab (Intake Facility) - Motor Data Sheettrong ngoc PhanNo ratings yet

- E90-803-001-001-01 - X 500-2 Brushless - 24v DCDocument20 pagesE90-803-001-001-01 - X 500-2 Brushless - 24v DCAlexNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Siemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDocument3 pagesSiemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDhirender KapoorNo ratings yet

- 2000kva A Sec - AluDocument1 page2000kva A Sec - AluMoncef MAACHINo ratings yet

- DA3102 - LV SwitchgearDocument2 pagesDA3102 - LV SwitchgearCassy AbulenciaNo ratings yet

- 9.-ECP2402T-4 Customer Information PacketDocument9 pages9.-ECP2402T-4 Customer Information PacketmaricruolivarNo ratings yet

- VTSA Valve TerminalDocument2 pagesVTSA Valve TerminalŁukasz OlszewskiNo ratings yet

- SPLN - 18B - 1979-Pedoman Penerapan Pengubah Sadapan BerbebanDocument12 pagesSPLN - 18B - 1979-Pedoman Penerapan Pengubah Sadapan Berbebanreni aprilianaNo ratings yet

- TD 8622Document1 pageTD 8622Abdur RehmanNo ratings yet

- 1084MCDocument11 pages1084MCRicambi fidatiNo ratings yet

- Wiring Diagrams & Elementary Diagrams of Unit Substation TransformerDocument4 pagesWiring Diagrams & Elementary Diagrams of Unit Substation TransformerAgam AditiawarmanNo ratings yet

- EM3714T-5 Customer Information PacketDocument9 pagesEM3714T-5 Customer Information Packetandrade2158No ratings yet

- Baldor Em3558t DatasheetDocument9 pagesBaldor Em3558t DatasheetJerry LoeraNo ratings yet

- SP (PE-DE) 01 SPECIFICATIONS EH Series (EH-1000F)Document6 pagesSP (PE-DE) 01 SPECIFICATIONS EH Series (EH-1000F)rama100% (1)

- ECPM4406T 4 InfoPacketDocument11 pagesECPM4406T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Ar09msfpewqn - SamsungDocument2 pagesAr09msfpewqn - SamsungRafael SequeiraNo ratings yet

- PY600AC Sliding Gate Opener User ManualDocument20 pagesPY600AC Sliding Gate Opener User ManualJose Gregorio Pantaleon Anaya0% (1)

- GT03 7296 3Document2 pagesGT03 7296 3Filippo SettimoNo ratings yet

- Marathon Motors Catalog E965Document7 pagesMarathon Motors Catalog E965Art AlbastroNo ratings yet

- VECP83665T-4 Customer Information PacketDocument10 pagesVECP83665T-4 Customer Information PackettauasiNo ratings yet

- ECPM4407T 4 InfoPacketDocument11 pagesECPM4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Specification & Drawings: EH-500F, 750F, 1000FDocument6 pagesSpecification & Drawings: EH-500F, 750F, 1000FIPSRS TEKNISINo ratings yet

- Nexans FNYAF-1000VDocument3 pagesNexans FNYAF-1000Vmazen zaloudNo ratings yet

- Rotak 320Document10 pagesRotak 320Anuta CosminNo ratings yet

- DVP 04TC S - Instruction PDFDocument2 pagesDVP 04TC S - Instruction PDFDiego Gil100% (1)

- Speed Dome InstaDocument2 pagesSpeed Dome InstaJoy Son100% (1)

- Pub059 021 00 - 0715Document51 pagesPub059 021 00 - 0715cayamajonoriana7No ratings yet

- 0900766b80026e02 PDFDocument11 pages0900766b80026e02 PDFEudis PinedaNo ratings yet

- Data Sheet Level - Independent SW LTX (D 30)Document1 pageData Sheet Level - Independent SW LTX (D 30)Elias EliasNo ratings yet

- 5.5 KW 4p-Ds - EilDocument9 pages5.5 KW 4p-Ds - EilVaibhav PatilNo ratings yet

- Motor Protection Module: ManualDocument5 pagesMotor Protection Module: ManualKaiser IqbalNo ratings yet

- Sumaary Site Visit: Customer Sales DateDocument5 pagesSumaary Site Visit: Customer Sales DateMUHAMAD SAUKINo ratings yet

- "Fuel" Gauge: Curtis Instruments, IncDocument11 pages"Fuel" Gauge: Curtis Instruments, IncGonzalo D'AddarioNo ratings yet

- Service Manual: WWW - Sbskg.co - RsDocument14 pagesService Manual: WWW - Sbskg.co - RsVeljkoNo ratings yet

- Gas 3Document20 pagesGas 3ycrnsfNo ratings yet

- Datasheet Kit Py600ac 4m CremalieraDocument18 pagesDatasheet Kit Py600ac 4m CremalieraalinfromaradNo ratings yet

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalNo ratings yet

- Aesv1s-N 4P 55KW 380KW 50HZ SpecDocument1 pageAesv1s-N 4P 55KW 380KW 50HZ SpecAchmad KNo ratings yet

- Dle4 8CNTDocument12 pagesDle4 8CNTBryant TorresNo ratings yet

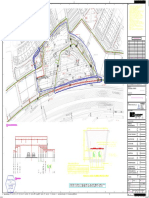

- Tender Design: Chilled Water Pipes NetworkDocument1 pageTender Design: Chilled Water Pipes NetworkCassy AbulenciaNo ratings yet

- Tender Design: Chilled Water Pipes NetworkDocument1 pageTender Design: Chilled Water Pipes NetworkCassy AbulenciaNo ratings yet

- YFC-NATCON-TRANSPO-DXB Bus#2Document1 pageYFC-NATCON-TRANSPO-DXB Bus#2Cassy AbulenciaNo ratings yet

- Pastoral Letter Fiducia Supplicans en 12 21 23Document3 pagesPastoral Letter Fiducia Supplicans en 12 21 23Cassy AbulenciaNo ratings yet

- 0 SignedDocument18 pages0 SignedCassy AbulenciaNo ratings yet

- S 190DCCHWSD 0004 00Document1 pageS 190DCCHWSD 0004 00Cassy AbulenciaNo ratings yet

- 3 - Puddle Flanges DetailsDocument1 page3 - Puddle Flanges DetailsCassy AbulenciaNo ratings yet

- Iiped 16 BN-01 E16161Document8 pagesIiped 16 BN-01 E16161Cassy AbulenciaNo ratings yet

- O & M-GDL-002 - Rev 1Document8 pagesO & M-GDL-002 - Rev 1Cassy AbulenciaNo ratings yet

- INFR-CIVIL SPE-Process (Cover Page)Document3 pagesINFR-CIVIL SPE-Process (Cover Page)Cassy AbulenciaNo ratings yet

- Data Sheet-BackerrodDocument2 pagesData Sheet-BackerrodCassy AbulenciaNo ratings yet

- Backer RodDocument2 pagesBacker RodCassy AbulenciaNo ratings yet

- Iiped BrochureDocument6 pagesIiped BrochureCassy AbulenciaNo ratings yet

- ME-00065-A7110-CN-MCC-P-00-MAR-00001-00 - Pipe Fittings-OkDocument151 pagesME-00065-A7110-CN-MCC-P-00-MAR-00001-00 - Pipe Fittings-OkCassy AbulenciaNo ratings yet

- Iiped PortfolioDocument17 pagesIiped PortfolioCassy AbulenciaNo ratings yet

- Jan HHDocument21 pagesJan HHCassy AbulenciaNo ratings yet

- July Youth Camp 2022Document15 pagesJuly Youth Camp 2022Cassy AbulenciaNo ratings yet

- Sample DrawingDocument1 pageSample DrawingCassy AbulenciaNo ratings yet

- KJ-124-O-EN-SPC-0004 Rev 01 - Fuel System Pipe CoatingDocument14 pagesKJ-124-O-EN-SPC-0004 Rev 01 - Fuel System Pipe CoatingCassy AbulenciaNo ratings yet

- MER2 June2019Document10 pagesMER2 June2019Cassy AbulenciaNo ratings yet

- MER 1 - Day 1 - 18 June 2022Document44 pagesMER 1 - Day 1 - 18 June 2022Cassy AbulenciaNo ratings yet

- MER2 June2019 May29updateDocument17 pagesMER2 June2019 May29updateCassy AbulenciaNo ratings yet

- MER2-June2019Document17 pagesMER2-June2019Cassy AbulenciaNo ratings yet

- Song Sheet - Larger - Than - LifeDocument2 pagesSong Sheet - Larger - Than - LifeCassy AbulenciaNo ratings yet

- MER2 June2019 June10 UpdateDocument18 pagesMER2 June2019 June10 UpdateCassy AbulenciaNo ratings yet

- Chapter3B2 GA Oct2018Document47 pagesChapter3B2 GA Oct2018Cassy AbulenciaNo ratings yet

- Guidelines For MER 2 Participants June21Document3 pagesGuidelines For MER 2 Participants June21Cassy AbulenciaNo ratings yet

- 3C2 Chapter Assembly October 2018Document44 pages3C2 Chapter Assembly October 2018Cassy AbulenciaNo ratings yet

- Chapter3B2 GA Aug2018Document21 pagesChapter3B2 GA Aug2018Cassy AbulenciaNo ratings yet

- Megane RS Trophy-R PDFDocument24 pagesMegane RS Trophy-R PDFTõnis Tranze0% (1)

- Jet 4 125Document178 pagesJet 4 125HonoluluNo ratings yet

- TMBKCG5L6EA700005Document9 pagesTMBKCG5L6EA700005kamran.shahNo ratings yet

- BMW 4 Series Gran Coupe F36 Sales Literature Catalogue Sep 2016 en - Pdf.asset.1558956813417Document27 pagesBMW 4 Series Gran Coupe F36 Sales Literature Catalogue Sep 2016 en - Pdf.asset.1558956813417КурТраселNo ratings yet

- 902900-1183 DespieceDocument448 pages902900-1183 DespieceLIBERTADNo ratings yet

- 1-15 p32 Automated Validation of Canfd Networks Cs-GroupDocument2 pages1-15 p32 Automated Validation of Canfd Networks Cs-GroupRakshithNo ratings yet

- Carestream DV6800 IPL PDFDocument127 pagesCarestream DV6800 IPL PDFSrinivasamoorthi KaliannanNo ratings yet

- Operator'S Manual 81882X: 1" Diaphragm PumpDocument8 pagesOperator'S Manual 81882X: 1" Diaphragm PumptbachelardNo ratings yet

- DESMI Vertical "In-Line" Centrifugal Pump: ESL MonoblocDocument20 pagesDESMI Vertical "In-Line" Centrifugal Pump: ESL MonoblocLeonid KolesnikovNo ratings yet

- Workshop Manual Transporter 2016 4-29Document401 pagesWorkshop Manual Transporter 2016 4-29samueleNo ratings yet

- Diagrama 1 ANTI-LOCK BRAKE MO..Document1 pageDiagrama 1 ANTI-LOCK BRAKE MO..Enrique Arevalo LeyvaNo ratings yet

- Vehicle No. SMK4159M Has Been Successfully Transferred To YouDocument4 pagesVehicle No. SMK4159M Has Been Successfully Transferred To YouKiran KumarNo ratings yet

- 8100 Carrot Harvester Operators ManualDocument31 pages8100 Carrot Harvester Operators ManualDiego EuzarragaNo ratings yet

- CKN Xhe TechnicalDocument72 pagesCKN Xhe TechnicalSolarNo ratings yet

- Aman 4Document1 pageAman 4HamidNo ratings yet

- New Series of Solutions: Product NewsDocument1 pageNew Series of Solutions: Product NewsRktBatamNo ratings yet

- Renewing Crankshaft Sealing Flange - Flywheel EndDocument11 pagesRenewing Crankshaft Sealing Flange - Flywheel EndGasparel MihaiNo ratings yet

- BMW Ewsii&III 3.2systemsDocument6 pagesBMW Ewsii&III 3.2systemsdavidNo ratings yet

- (NISSAN) Manual de Taller Nissan Cube 2014Document123 pages(NISSAN) Manual de Taller Nissan Cube 2014willy_net123No ratings yet

- Refrigeration Research Receivers EasternDocument2 pagesRefrigeration Research Receivers EasternArnulfoNo ratings yet

- Daewoo Lanos SlimDocument2 pagesDaewoo Lanos SlimAbdalla TharwatNo ratings yet

- Desarme Regulador PSG PalenaDocument39 pagesDesarme Regulador PSG PalenaJorge EspinozaNo ratings yet

- TD Systec Englisch PDFDocument52 pagesTD Systec Englisch PDFStefan MilojevicNo ratings yet

- Hyundai Depo CatalogDocument40 pagesHyundai Depo CatalogParts Gallary Auto Spare Parts Trading LLC BR-1No ratings yet