Professional Documents

Culture Documents

DA3113-PRT Recovery Pump Motor

DA3113-PRT Recovery Pump Motor

Uploaded by

Cassy Abulencia0 ratings0% found this document useful (0 votes)

7 views1 pageThis document provides specifications for a low voltage motor used for a product recovery pump at Bahrain International Airport, including:

1) The motor is used for product recovery from two PRT tanks, is 11 kW, and has 400V 3-phase 50Hz power supply.

2) The motor has IP55 protection, TEFC cooling, and F class insulation with temperature rise limited to class B.

3) The document lists several performance characteristics such as no load current, locked rotor current, starting torque, duty cycle, and applicable standards.

Original Description:

Original Title

352911_DA3113-PRT Recovery pump motor (02)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a low voltage motor used for a product recovery pump at Bahrain International Airport, including:

1) The motor is used for product recovery from two PRT tanks, is 11 kW, and has 400V 3-phase 50Hz power supply.

2) The motor has IP55 protection, TEFC cooling, and F class insulation with temperature rise limited to class B.

3) The document lists several performance characteristics such as no load current, locked rotor current, starting torque, duty cycle, and applicable standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageDA3113-PRT Recovery Pump Motor

DA3113-PRT Recovery Pump Motor

Uploaded by

Cassy AbulenciaThis document provides specifications for a low voltage motor used for a product recovery pump at Bahrain International Airport, including:

1) The motor is used for product recovery from two PRT tanks, is 11 kW, and has 400V 3-phase 50Hz power supply.

2) The motor has IP55 protection, TEFC cooling, and F class insulation with temperature rise limited to class B.

3) The document lists several performance characteristics such as no load current, locked rotor current, starting torque, duty cycle, and applicable standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

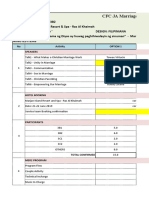

Data Sheet - Low Voltage Motor (PRT Recovery Pump Motor)

Client Bahrain Airport Company Division Oil, Gas & Petrochemicals-Dubai

Project No. 352911 / DP1115 Document No. 352911/DA3113

Project Title. Fuel Farm Complex and Fuel Hydrant at Bahrain International Airport Page 1 of 1 Rev. 02

1 Equipment No. PM17, PM19 59 No load current * %FLC

2 Quantity (Running / Standby) One(1) One (1) 60 Locked Rotor Current * %FLC

Product Recovery from PRT 3 & PRT

3 Description 61 Insulation Class class

4 *

4 Rating (kW) Note 4 11 62 Temperature rise * class

5 Supply Parameter 400V AC 3 ph. 50Hz 63 Thermal rating constant * sec

5a System Fault level & duration 65kA for 1 sec 64 Starting current with 100% V * %FLC

6 Space heater voltage / Cable Size 230 Volts, 50Hz, 1ph / 3C X 4mm² 65 Starting Current with 80% V * %FLC

7 Area Classification/Gas Group Note 9 66 Starting time with 100% V * sec

8 Type of explosion protection Ex (e) / Ex(n) 67 Starting torque with 100% V * %FLT

Class F insulation with Temp rise

68 Starting Torque with 80% V

SPECIFICATION

9 Class of winding insulation %FLT

limited to Class B *

10 Degree of protection IP 55 69 Starting time with 80% V * sec

11 Cooling TEFC 70 Locked Rotor Withstand time

Refer cable schedule-

12 Power cable Type / Size 70a Hot sec

352911/DA3105 *

13 Duty S1 - Continuous. 70b Cold * sec

14 Winding Temperature Detectors Not Required 71 Safe stalling time cold * sec

15 Bearing Temperature Detectors Not Required 72 No of starts Hot * nos

16 Vibration sensors Not Required 73 No of starts Cold * nos

17 Applicable standard IEC 60034 74 Locked Rotor Torque * %FLT

18 Direction of Rotation Bi-direction 75 Pull out Torque * %FLT

19 Stator Winding connection Star / Delta 76 Starting shaft torque * %FLT

Refer Site Datasheet-

20 Design Ambient Temperature 77 Break down shaft torque %FLT

352911/DA0001 *

Soft Starter with bypass provision

21 Starting Method 78 Pull-up shaft torque %FLT

(Refer Note 11) *

22 Type of load * 79 Rated shaft torque * %FLT

23 Installed Rating * 80 Rated power factor *

24 Absorbed Power Max. * 81 Starting power factor *

DATA TO BE FURNISHED BY EQPT.VENDOR

25 Motor speed (Synch.) * 82 Locked Rotor pf *

VENDOR CONFIRMATION

26 Type of mounting * 83 Efficiency @

27 Transmission * 83a 100% FL *

28 Shaft Extension * 83b 50% FL *

29 2 * 83c At absorbed Power

Inertia of load GD ( At motor speed) *

30 Starting Torque required * 84 Method of starting * Soft starter / DOL

31 Starting and running duties required * 85 Acceleration time *

32 Starting time limitation (if any) * 86 a) DOL start * sec

33 No. of starts/hour( start duty ) * 87 b) Assisted start n.a.

34 Motor starting against load * 88 i) Star /delta n.a.

35 unloaded * 89 ii) Auto transformer (tap %) n.a.

36 Type of Enclosure * 90 iii) Soft starter (Ist= %FLC) * sec

37 Dir. Of Rotation of motor (viewed from DE) * 91 stator connection star/delta *

38 Special Requirement * 92 te time (Exe motors) *

Note: Equipment vendor to furnish speed / torque

39 93 GD2 of rotor(kg m2)

curve for driven equipment *

40 Bearing Ref temperature DE * 94 Insulation Class *

41 Bearing Ref temperature NDE * 95 Temperature rise(by res) *

MECH. DIM.& WT. DATA BY

42 Bearing type DE * 96 Duty *

MOTOR VENDOR

43 Bearing type NDE * 97 Type of enclosure *

44 Bearing Lubrication * 98 Degree of protection (enclosure) *

45 Net Weight * 99 Direction of rotation (viewed from DE) *

46 Shipping Weight * 100 Main Tb cable size & no.of entries *

47 Over All Dimension(mm) * 101 Neutral terminal box detail *

48 Out line drawing * 102 Noise(db at 1 meter) *

49 any other information * 103 Space heater Provision/wattage *

50 104 Wdg temperature protection *

46 Manufacturer details * 105 Motor thermal time constant * min

47 Country of Origin * 106 Max. allowable -ve ph. seq.current * %FLC

48 Nearest Service station details * 109 Acoustic noise at full load * dB

VENDOR CONFIRMATION

49 Frame Designation * 110 Bearing RTD details n.a.

50 Mounting Type * 111 Winding thermistors details n.a.

51 Type of Rotor * 112 Insulated bearings n.a.

52 Duty * 113 Vibration sensor details n.a.

53 Efficiency class of motor * 114 Anti condensation heater details *

54 Voltage * Volt 115 location of cable terminal box *

55 Rating * Kw 107 Certification Standard *

56 No.of Poles * nos 108 Certification Authorities *

57 Rated Speed * Rpm

58 Full load Current * Amp.

NOTES:

1. Motor vendor to furnish following characteristic curves for motor:

a. Speed v/s Torque , Efficiency v/s Current , Power factor v/s Current.

b. Motor starting curves (Current Time ) with 100% & 80% of rated voltage.

c. Thermal withstand curves (hot as well as cold ) at 100% & 80% of rated voltage.

2. Testing of motors to be in accordance with IEC 60034.

3. Vendor to confirm selection and materials of construction and should return one completed (see * marks) or corrected copy to Engineer.

4. Motor rating is only indicative and to be confirmed based on the selected pump. Contractor to refer to Mechanical Datasheet for Pump 352911/DA1110

5. Motor shall be compatible with the load characteristics and operational duty of the driven equipment. The motor shall be suitable for intermittent operational requirement.

6. Motor shall be mounted on base frame & coupled to the pump at factory, the alignment between motor and pump shall be using laser or equivalent technique.

7. Interlock shall be provided with the LV switchgear for the operation of the space heaters.

8. This data sheet should be used in conjunction with the technical specification TS306.

9 Shall confirm to Group II , Temperature Class T3.Vendor to submit the type test certificate.

10. External Painting-Corrosivity category C5M with Medium Durability as per BSEN ISO 12944-5

11. Motor shall be suitable for starting & running on Soft starter as well as DOL mode.

12. Motor bearing shall not take the axial loads

13. Motor terminal box shall be suitbale to rotate in steps of 90 deg.

14. Factory and site acceptance test shall be ensured by contractor, In addition to third party inspection during FAT shall be arranged as minimum.

15. One year operating & commissioning spares shall be supplied.

REV DATE DESCRIPTION ORIGNR CHKD APPD.

00 09/02/16 Preliminary SW VT ADS

01 15/06/16 For Approval SW VT ADS

02 02/08/16 Issued for Tender SW VT ADS

PLEASE NOTE: THIS DATASHEET SHOULD NOT BE USED FOR CONSTRUCTION OR FOR ORDERING MATERIALS UNTIL IT IS APPROVED.

P:\Dubai\ONG\DUO Sub Div\ProjDocs\2015\DP1115- BAC-Fuel Farm-BIA\ENGG\03_Electrical\Documents\Fuel Depot\Datasheets\02.08.2016\352911_DA3113-PRT Recovery pump motor (01)

You might also like

- DA3112-Recirculation Pump MotorDocument1 pageDA3112-Recirculation Pump MotorCassy AbulenciaNo ratings yet

- DA3114-PRT Sump Pump MotorDocument1 pageDA3114-PRT Sump Pump MotorCassy AbulenciaNo ratings yet

- DA3101-hydrant Pump MotorDocument1 pageDA3101-hydrant Pump MotorCassy AbulenciaNo ratings yet

- Data Sheet - Low Voltage Motor For Package EquipmentsDocument1 pageData Sheet - Low Voltage Motor For Package EquipmentsCassy AbulenciaNo ratings yet

- DA3111-BU Pump MotorDocument1 pageDA3111-BU Pump MotorCassy AbulenciaNo ratings yet

- Ns2 Yt01 P0sha 120002 Ab (Intake Facility) - Motor Data SheetDocument62 pagesNs2 Yt01 P0sha 120002 Ab (Intake Facility) - Motor Data Sheettrong ngoc PhanNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- 9.-ECP2402T-4 Customer Information PacketDocument9 pages9.-ECP2402T-4 Customer Information PacketmaricruolivarNo ratings yet

- ECP4400T 4 InfoPacketDocument9 pagesECP4400T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- TEK20141027023SPECDocument1 pageTEK20141027023SPECHary FadlyNo ratings yet

- ECPM4406T 4 InfoPacketDocument11 pagesECPM4406T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- GT1044ADocument7 pagesGT1044AMax AyalaNo ratings yet

- Siemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDocument3 pagesSiemens: Motor Type: 1PQ8 356-XXXX-X N-Compact SeriesDhirender KapoorNo ratings yet

- VECP83665T-4 Customer Information PacketDocument10 pagesVECP83665T-4 Customer Information PackettauasiNo ratings yet

- Baldor Em3558t DatasheetDocument9 pagesBaldor Em3558t DatasheetJerry LoeraNo ratings yet

- Aesv1s-N 4P 55KW 380KW 50HZ SpecDocument1 pageAesv1s-N 4P 55KW 380KW 50HZ SpecAchmad KNo ratings yet

- General Technical Particulars Motors Project Name 10/01/2020 Sheet 1 of 2Document2 pagesGeneral Technical Particulars Motors Project Name 10/01/2020 Sheet 1 of 2mishtinilNo ratings yet

- CECP4115T InfoPacket 50HP 1800RPMDocument11 pagesCECP4115T InfoPacket 50HP 1800RPMrrobles011No ratings yet

- EM3714T-5 Customer Information PacketDocument9 pagesEM3714T-5 Customer Information Packetandrade2158No ratings yet

- ECPM4407T 4 InfoPacketDocument11 pagesECPM4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- 10.-ECP84410T-4 Customer Information PacketDocument11 pages10.-ECP84410T-4 Customer Information PacketmaricruolivarNo ratings yet

- DA3117-APFC UnitDocument1 pageDA3117-APFC UnitCassy AbulenciaNo ratings yet

- Pt. Semen Kupang Indonesia: Data Sheet & Technical Particular Guarantee For Distibution TransformerDocument15 pagesPt. Semen Kupang Indonesia: Data Sheet & Technical Particular Guarantee For Distibution TransformerharisNo ratings yet

- 2000kva A Sec - AluDocument1 page2000kva A Sec - AluMoncef MAACHINo ratings yet

- Design Data Sheet (ID Fan Motor 800 KW)Document4 pagesDesign Data Sheet (ID Fan Motor 800 KW)Swarup Nayak100% (1)

- ECPM4115T 4 InfoPacketDocument13 pagesECPM4115T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Ns2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data SheetDocument19 pagesNs2-Yt01-p1qc-120002-Ab (Chemical Dosing System) - Motor Data Sheettrong ngoc PhanNo ratings yet

- Motor DetoxDocument8 pagesMotor DetoxAlvaro Iparraguirre NavarroNo ratings yet

- VEM3546T InfoPacket 4Document10 pagesVEM3546T InfoPacket 4Gerardo ReyesNo ratings yet

- P-02-0098-DCVL-Refractory SpecificationDocument26 pagesP-02-0098-DCVL-Refractory SpecificationYhaneNo ratings yet

- C42-4122-202201-2842 - For Proposal - 20220203Document4 pagesC42-4122-202201-2842 - For Proposal - 20220203Juliyanto STNo ratings yet

- Doc. No.: Ibce-6373-C00-Ele-Dat-000-0012Document6 pagesDoc. No.: Ibce-6373-C00-Ele-Dat-000-0012rahul rNo ratings yet

- Cp11a NK 3275 El MT 004 A4 MtoDocument2 pagesCp11a NK 3275 El MT 004 A4 Mtosugeng wahyudiNo ratings yet

- Pilot Pro 900 ManualDocument12 pagesPilot Pro 900 ManualKiner CalixtoNo ratings yet

- 1.1 Technical Data SheetDocument2 pages1.1 Technical Data SheetRoberto GuevaraNo ratings yet

- Eaton 072738 PKZM0 6,3 en - GBDocument10 pagesEaton 072738 PKZM0 6,3 en - GBGILBERTO ANÍBAL BONILLA COSAMALÓNNo ratings yet

- Service Manual: WWW - Sbskg.co - RsDocument15 pagesService Manual: WWW - Sbskg.co - RsVeljkoNo ratings yet

- Diesel Generator Set Technical Parameters: WWW - Fogo.plDocument2 pagesDiesel Generator Set Technical Parameters: WWW - Fogo.plsolomonNo ratings yet

- ECP4314T 4 InfoPacketDocument8 pagesECP4314T 4 InfoPacketmaricruolivarNo ratings yet

- ECP4407T 4 InfoPacketDocument10 pagesECP4407T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Technical Manual EPMDocument53 pagesTechnical Manual EPMJoel TimajoNo ratings yet

- Pub059 021 00 - 0715Document51 pagesPub059 021 00 - 0715cayamajonoriana7No ratings yet

- Pewwe30 18 286TDocument4 pagesPewwe30 18 286TMinor AchioNo ratings yet

- G 160 - Final-5Document1 pageG 160 - Final-5parth sapariaNo ratings yet

- Jet Fan 300ºc - 4950 CFM - Technical DataDocument4 pagesJet Fan 300ºc - 4950 CFM - Technical DataHidraulica MAB InprosacNo ratings yet

- Wiring Diagrams & Elementary Diagrams of Unit Substation TransformerDocument4 pagesWiring Diagrams & Elementary Diagrams of Unit Substation TransformerAgam AditiawarmanNo ratings yet

- ECP4404T Customer Information BALDORDocument9 pagesECP4404T Customer Information BALDOREduleofNo ratings yet

- 5.5 KW 4p-Ds - EilDocument9 pages5.5 KW 4p-Ds - EilVaibhav PatilNo ratings yet

- Ar09msfpewqn - SamsungDocument2 pagesAr09msfpewqn - SamsungRafael SequeiraNo ratings yet

- Hanbell Ex-ModelDocument4 pagesHanbell Ex-ModelTareq JildehNo ratings yet

- Technical Data Compressor: Model 104G7800 115V/60Hz 1Document6 pagesTechnical Data Compressor: Model 104G7800 115V/60Hz 1bryanzapien33No ratings yet

- Data Sheet of Cummins 500kva by IntranusaDocument9 pagesData Sheet of Cummins 500kva by IntranusaDeni DendenNo ratings yet

- Pak Elektron Limited Technical Data Sheet of Transformer: SpecificationDocument1 pagePak Elektron Limited Technical Data Sheet of Transformer: SpecificationbilalNo ratings yet

- 37kW, 4P, IMB3, Brake Motor DatasheetDocument1 page37kW, 4P, IMB3, Brake Motor DatasheetsyamprasadNo ratings yet

- Tqm-221105-c - 220kw Tech & Drawing (Tradeone)Document2 pagesTqm-221105-c - 220kw Tech & Drawing (Tradeone)Louie FernandezNo ratings yet

- Model WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionDocument8 pagesModel WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionLe DucNo ratings yet

- EL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018Document2 pagesEL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018mafevalle4201No ratings yet

- 1311231-6,3 MVA 110-0,8-0,8 KV (1) MBT PDFDocument1 page1311231-6,3 MVA 110-0,8-0,8 KV (1) MBT PDFh.tamazyan1402No ratings yet

- Heavy Oil Burners: Installation, Use and Maintenance InstructionsDocument16 pagesHeavy Oil Burners: Installation, Use and Maintenance Instructionskosmc123No ratings yet

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- Tender Design: Chilled Water Pipes NetworkDocument1 pageTender Design: Chilled Water Pipes NetworkCassy AbulenciaNo ratings yet

- Tender Design: Chilled Water Pipes NetworkDocument1 pageTender Design: Chilled Water Pipes NetworkCassy AbulenciaNo ratings yet

- YFC-NATCON-TRANSPO-DXB Bus#2Document1 pageYFC-NATCON-TRANSPO-DXB Bus#2Cassy AbulenciaNo ratings yet

- Pastoral Letter Fiducia Supplicans en 12 21 23Document3 pagesPastoral Letter Fiducia Supplicans en 12 21 23Cassy AbulenciaNo ratings yet

- 0 SignedDocument18 pages0 SignedCassy AbulenciaNo ratings yet

- S 190DCCHWSD 0004 00Document1 pageS 190DCCHWSD 0004 00Cassy AbulenciaNo ratings yet

- 3 - Puddle Flanges DetailsDocument1 page3 - Puddle Flanges DetailsCassy AbulenciaNo ratings yet

- Iiped 16 BN-01 E16161Document8 pagesIiped 16 BN-01 E16161Cassy AbulenciaNo ratings yet

- O & M-GDL-002 - Rev 1Document8 pagesO & M-GDL-002 - Rev 1Cassy AbulenciaNo ratings yet

- INFR-CIVIL SPE-Process (Cover Page)Document3 pagesINFR-CIVIL SPE-Process (Cover Page)Cassy AbulenciaNo ratings yet

- Data Sheet-BackerrodDocument2 pagesData Sheet-BackerrodCassy AbulenciaNo ratings yet

- Backer RodDocument2 pagesBacker RodCassy AbulenciaNo ratings yet

- Iiped BrochureDocument6 pagesIiped BrochureCassy AbulenciaNo ratings yet

- ME-00065-A7110-CN-MCC-P-00-MAR-00001-00 - Pipe Fittings-OkDocument151 pagesME-00065-A7110-CN-MCC-P-00-MAR-00001-00 - Pipe Fittings-OkCassy AbulenciaNo ratings yet

- Iiped PortfolioDocument17 pagesIiped PortfolioCassy AbulenciaNo ratings yet

- Jan HHDocument21 pagesJan HHCassy AbulenciaNo ratings yet

- July Youth Camp 2022Document15 pagesJuly Youth Camp 2022Cassy AbulenciaNo ratings yet

- Sample DrawingDocument1 pageSample DrawingCassy AbulenciaNo ratings yet

- KJ-124-O-EN-SPC-0004 Rev 01 - Fuel System Pipe CoatingDocument14 pagesKJ-124-O-EN-SPC-0004 Rev 01 - Fuel System Pipe CoatingCassy AbulenciaNo ratings yet

- MER2 June2019Document10 pagesMER2 June2019Cassy AbulenciaNo ratings yet

- MER 1 - Day 1 - 18 June 2022Document44 pagesMER 1 - Day 1 - 18 June 2022Cassy AbulenciaNo ratings yet

- MER2 June2019 May29updateDocument17 pagesMER2 June2019 May29updateCassy AbulenciaNo ratings yet

- MER2-June2019Document17 pagesMER2-June2019Cassy AbulenciaNo ratings yet

- Song Sheet - Larger - Than - LifeDocument2 pagesSong Sheet - Larger - Than - LifeCassy AbulenciaNo ratings yet

- MER2 June2019 June10 UpdateDocument18 pagesMER2 June2019 June10 UpdateCassy AbulenciaNo ratings yet

- Chapter3B2 GA Oct2018Document47 pagesChapter3B2 GA Oct2018Cassy AbulenciaNo ratings yet

- Guidelines For MER 2 Participants June21Document3 pagesGuidelines For MER 2 Participants June21Cassy AbulenciaNo ratings yet

- 3C2 Chapter Assembly October 2018Document44 pages3C2 Chapter Assembly October 2018Cassy AbulenciaNo ratings yet

- Chapter3B2 GA Aug2018Document21 pagesChapter3B2 GA Aug2018Cassy AbulenciaNo ratings yet

- Data Sheet NPNB HN22PA3Document2 pagesData Sheet NPNB HN22PA3Liliana ZamoraNo ratings yet

- APL 100: Minor 2Document3 pagesAPL 100: Minor 2kamleshNo ratings yet

- Introduction To The Module and The Carnot CycleDocument17 pagesIntroduction To The Module and The Carnot Cycleأحمد صلاح الدينNo ratings yet

- Horizontal Pressure Vessel Designe Project One: AcknowledgementDocument7 pagesHorizontal Pressure Vessel Designe Project One: Acknowledgementshibabw worknehNo ratings yet

- 2 Alternate Stages of FlowDocument7 pages2 Alternate Stages of FlowHalima Sibayan SawanganNo ratings yet

- Week 8 Grade 7 HeatDocument39 pagesWeek 8 Grade 7 HeatmkraemerNo ratings yet

- NSK TrustDocument138 pagesNSK TrustoktovaNo ratings yet

- Quarter 3, Week 2: Mathematics 7 Activity SheetDocument4 pagesQuarter 3, Week 2: Mathematics 7 Activity SheetMariel Pastolero100% (1)

- TraverseDocument13 pagesTraversebawanlavaNo ratings yet

- Chem2003 2011 Inorganic TestDocument7 pagesChem2003 2011 Inorganic Testdladlasphesihle258No ratings yet

- Toefl Exercise Choose The Letter of The Underlined Word or Groups That Is Not CorrectDocument2 pagesToefl Exercise Choose The Letter of The Underlined Word or Groups That Is Not CorrectDadan NoviandriNo ratings yet

- Compound AnglesDocument14 pagesCompound AnglesChainarong TaepanichNo ratings yet

- Atomic Structure v1.0Document47 pagesAtomic Structure v1.0Bilal RashidNo ratings yet

- Gantrex Mk20 Pad Data Sheet MetricDocument2 pagesGantrex Mk20 Pad Data Sheet Metricjhon jairo arangoNo ratings yet

- Physical Science Week 8 Day 1Document2 pagesPhysical Science Week 8 Day 1daniel loberizNo ratings yet

- (Multivariable Calculus) : by Sarah AmjadDocument16 pages(Multivariable Calculus) : by Sarah AmjadDanyal NasirNo ratings yet

- Fuxin Profduct StandardDocument6 pagesFuxin Profduct StandardYin DavonNo ratings yet

- PrePoMax-v1 3 5-ManualDocument4 pagesPrePoMax-v1 3 5-ManualMarcelo ResendeNo ratings yet

- Periodic Table NeetDocument5 pagesPeriodic Table NeetYash ChopadeNo ratings yet

- Workshop Electrical Jointing & Termination Part 1Document74 pagesWorkshop Electrical Jointing & Termination Part 1widiNo ratings yet

- College of Engineering: Department of Mechanical Engineering Phys 1A: Physics For Engineers IDocument9 pagesCollege of Engineering: Department of Mechanical Engineering Phys 1A: Physics For Engineers Ipablo escobarNo ratings yet

- Physics MSC All SemDocument83 pagesPhysics MSC All Sem46Rohit. ChaudhariNo ratings yet

- Comepi Ep1 DatasheetsDocument8 pagesComepi Ep1 DatasheetsYHONATAN JIMENEZNo ratings yet

- Ohm's LawDocument79 pagesOhm's Laweugene rellamaNo ratings yet

- Aastu Data SheetDocument9 pagesAastu Data SheetteshNo ratings yet

- Hilti - Corrosion-Handbook - Tech Manual - 10 - 2015Document48 pagesHilti - Corrosion-Handbook - Tech Manual - 10 - 2015هدوء السماءNo ratings yet

- Imaging in Pediatric Dental Practice: A Guide To Equipment, Techniques and Clinical Considerations Johan ApsDocument139 pagesImaging in Pediatric Dental Practice: A Guide To Equipment, Techniques and Clinical Considerations Johan ApsFarheen MahmoodaNo ratings yet

- Unit 7 Radar: StructureDocument28 pagesUnit 7 Radar: StructureParminder singh parmarNo ratings yet

- 1 SmartgyroDocument52 pages1 SmartgyroPengjing WangNo ratings yet

- Unit II MCQ Electricity, Magnetism and SemiconductorDocument14 pagesUnit II MCQ Electricity, Magnetism and SemiconductorUmesh PatilNo ratings yet