Professional Documents

Culture Documents

Chapter 5 Design Guidelines Section 5.8 Coastal Marine Subsection 5.8.5 Dredging

Uploaded by

kapsarc0 ratings0% found this document useful (0 votes)

5 views1 pageThe document provides guidelines for dredging projects including coastal and marine environments. It states that a constructability report should be prepared for dredging projects that assesses sediment characteristics, excavation volumes, proposed placement and dewatering of dredged material, recommended equipment and transport methods, and a production schedule. It also stresses the importance of characterizing sediments to determine potential environmental impacts and proper management of dredged material. The document recommends referring to technical guidelines from the USACE for evaluating site conditions, applicable standards, equipment selection, production and transportation methods, monitoring, and modeling and characterizing dredged sediments, and suggests best management practices like turbidity curtains to control sediment dispersion during dredging operations.

Original Description:

Dredging specification

Original Title

Dredging

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides guidelines for dredging projects including coastal and marine environments. It states that a constructability report should be prepared for dredging projects that assesses sediment characteristics, excavation volumes, proposed placement and dewatering of dredged material, recommended equipment and transport methods, and a production schedule. It also stresses the importance of characterizing sediments to determine potential environmental impacts and proper management of dredged material. The document recommends referring to technical guidelines from the USACE for evaluating site conditions, applicable standards, equipment selection, production and transportation methods, monitoring, and modeling and characterizing dredged sediments, and suggests best management practices like turbidity curtains to control sediment dispersion during dredging operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageChapter 5 Design Guidelines Section 5.8 Coastal Marine Subsection 5.8.5 Dredging

Uploaded by

kapsarcThe document provides guidelines for dredging projects including coastal and marine environments. It states that a constructability report should be prepared for dredging projects that assesses sediment characteristics, excavation volumes, proposed placement and dewatering of dredged material, recommended equipment and transport methods, and a production schedule. It also stresses the importance of characterizing sediments to determine potential environmental impacts and proper management of dredged material. The document recommends referring to technical guidelines from the USACE for evaluating site conditions, applicable standards, equipment selection, production and transportation methods, monitoring, and modeling and characterizing dredged sediments, and suggests best management practices like turbidity curtains to control sediment dispersion during dredging operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CHAPTER 5 DESIGN GUIDELINES

SECTION 5.8 COASTAL MARINE

SUBSECTION 5.8.5 DREDGING

3) A constructability report shall be prepared for dredging projects. The report

shall include an assessment of sediment characteristics, volumes of

excavation, proposed location and methods for placement and dewatering of

the dredged material, recommended equipment and transport methods and

estimated production schedule.

3. Environmental Impacts

a. Prior to initiating a dredging operation, characterization of the sediment for potential

contamination shall include, but is not limited to, surveys, sediment sampling and

sediment testing. This characterization can determine potential environmental

impacts from the dredging operations as well as proper methods of transportation,

placement, disposal, and management of the dredged sediment. Until it is confirmed

that the dredged sediment is not contaminated with pollutants such as petroleum or

volatile organic compounds, the sediment shall be treated as contaminated material.

1) Refer to the USACE Engineer Research and Development Center’s Technical

Guidelines for Environmental Dredging of Contaminated Sediments (2008,

ERDC/EL TR-08-29) for the following:

(a) Evaluating site conditions and sediment characteristics

(b) Applicable environmental dredging performance standards

(c) Equipment selection and capacities

(d) Sediment production and transportation

(e) Estimation methods for re-suspension, residuals, and release

(f) Dredging measures of control

(g) Methods of operation

(h) Monitoring.

b. If the sediments that are being dredged are confirmed to be not contaminated, and

approval from RCJ is acquired, refer to the USACE’s Geotechnical Properties and

Sediment Characterization for Dredged Material Models (2001, ERDC TN-DOER-

N13) for details on modeling and characterizing dredged sediments.

c. Surveys, sediment sampling and testing and subsequent equipment type selection

shall take into consideration environmental impacts from the dredging operations,

transport of the sediment as well as the placement of the sediment.

d. Dredging operations require best management practices (BMP’s) for sediment and

other environmental impacts. The following are suggested structural and dredging

management BMP’s to control turbidity around the dredging operation and reduce

turbidity of water returning from the disposal area into sea to the specified limits:

1) Turbidity Curtain – Also known as a silt barrier or floating turbidity barrier, a

turbidity curtain allows suspended sediment to settle out of the water column

in a controlled area minimizing the sediment transport from the area of

disturbance. Turbidity curtains are floating impermeable barriers that are

constructed of flexible reinforced thermoplastic material with an upper hem

containing floatation material and a lower hem that is weighted. Turbidity

screens are similar in construction but are constructed of permeable

geosynthetic fabric and allow for water to flow through. The upper limit of

effectiveness for turbidity barrier use is a current velocity of approximately 0.8

m/s. Turbidity barriers shall not be installed across channel flows, as they are

RCJ Guiding Engineering Manual

Rev. 1 5.8 - 54

You might also like

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Seneca Seismic Design Handbook - First Edition PDFDocument94 pagesSeneca Seismic Design Handbook - First Edition PDFBeenayShahi100% (1)

- USACE Technical Guidelines For Environmental Dredging of Contaminated SedimentsDocument11 pagesUSACE Technical Guidelines For Environmental Dredging of Contaminated Sedimentsmurali.5482100% (1)

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelDocument1 pageRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanNo ratings yet

- 95 NW 29Th Street: 29N WynwoodDocument55 pages95 NW 29Th Street: 29N Wynwoodthe next miamiNo ratings yet

- Attachment J (Draft Offshore Pipelines Decommissioning Guideline)Document6 pagesAttachment J (Draft Offshore Pipelines Decommissioning Guideline)smithworkNo ratings yet

- Dredging TechniquesDocument34 pagesDredging Techniquesgeraldo gil100% (1)

- Millard HouseDocument20 pagesMillard HouseMadiha Rehmath100% (1)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- 111111Document1 page111111Je Espenida100% (1)

- R13-12 Investigaciones GeotecnicasDocument14 pagesR13-12 Investigaciones GeotecnicasDannyChaconNo ratings yet

- Anchor Bolt Design, IS Code LSDDocument33 pagesAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyNo ratings yet

- Environmental CriteriaDocument22 pagesEnvironmental CriteriaAji A7xNo ratings yet

- Chapter 7 Storm Water and Drainage 20140401Document59 pagesChapter 7 Storm Water and Drainage 20140401omarizaidNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- New Build Snagging List TemplateDocument13 pagesNew Build Snagging List TemplatekekerodeNo ratings yet

- DredgingDocument22 pagesDredgingMade Twinta WidayanaNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- (This Part Is PTSOM's Code of Practice, Volume 2 - Train System (CP2) "Drainage" CP-TS-958)Document16 pages(This Part Is PTSOM's Code of Practice, Volume 2 - Train System (CP2) "Drainage" CP-TS-958)AlbanNo ratings yet

- Work Method StatementDocument38 pagesWork Method StatementTahir MubeenNo ratings yet

- PlumbingDocument14 pagesPlumbingRajanRanjan100% (2)

- Klohn Crippen Berger (KCB) - 2017 - Study of Tailings Management TechnologiesDocument164 pagesKlohn Crippen Berger (KCB) - 2017 - Study of Tailings Management TechnologiesEvandro_JNo ratings yet

- SPE-65140-MS Open Hole Sand CompletionDocument19 pagesSPE-65140-MS Open Hole Sand CompletionLawNo ratings yet

- 4.0 Construction and Decommissioning: Soil ErosionDocument7 pages4.0 Construction and Decommissioning: Soil ErosionGUGUHPRAKOSONo ratings yet

- Improvements in Small-Scale Standardized Testing of Geotextiles Used in Siltfence ApplicationsDocument12 pagesImprovements in Small-Scale Standardized Testing of Geotextiles Used in Siltfence ApplicationsRajeshwaranNo ratings yet

- Agdex 096-51Document8 pagesAgdex 096-51dejewsonNo ratings yet

- Use of CFD For Development of Sand Erosion Control TechnologyDocument22 pagesUse of CFD For Development of Sand Erosion Control TechnologyMahfoud AMMOURNo ratings yet

- Geosynthetic Lining System For Modern Waste Facilities - Experiences in Developing AsiaDocument8 pagesGeosynthetic Lining System For Modern Waste Facilities - Experiences in Developing AsiaSweetyy KumariNo ratings yet

- Section 013543 Sustainability and Environmental Construction Procedures - Rev0Document3 pagesSection 013543 Sustainability and Environmental Construction Procedures - Rev0Al LopezNo ratings yet

- 9.klohn 2017Document164 pages9.klohn 2017agatha ribeiro hauckNo ratings yet

- Chapter 10 Tailings and Waste Rock ManagementDocument46 pagesChapter 10 Tailings and Waste Rock ManagementJOSE MILDER HUAMAN LEIVANo ratings yet

- Sedimentos Marinos Con Cal y CementoDocument9 pagesSedimentos Marinos Con Cal y CementoGloria MolinaNo ratings yet

- Pezzaniti 2009Document10 pagesPezzaniti 20091703191015No ratings yet

- Section 02370 Geotextiles Sedimentation and ErosionDocument7 pagesSection 02370 Geotextiles Sedimentation and ErosionMØhãmmed ØwięsNo ratings yet

- DMP Water GuidelinesDocument11 pagesDMP Water GuidelinesBOOBOONo ratings yet

- Chapter 4. Additional Studies (Risk Assessment and Management Plan)Document43 pagesChapter 4. Additional Studies (Risk Assessment and Management Plan)Ronit KumarNo ratings yet

- Solidification/stabilization of Dredged Marine Sediments For Road ConstructionDocument9 pagesSolidification/stabilization of Dredged Marine Sediments For Road Constructionwaleed shahidNo ratings yet

- 6 Influence of The Physical and Mechanical Characteristics of Sands On The HydraulicDocument10 pages6 Influence of The Physical and Mechanical Characteristics of Sands On The HydraulicHasan Abdel-FattahNo ratings yet

- 1.3 Filtrexx Check DamsDocument9 pages1.3 Filtrexx Check DamsAbdul Malik AmiriNo ratings yet

- Chemical 18 Sep 14Document4 pagesChemical 18 Sep 14danielsu87No ratings yet

- 21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsDocument13 pages21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsbelavelosoNo ratings yet

- 31 25 13 Erosion and Sedimentation CNTRLDocument11 pages31 25 13 Erosion and Sedimentation CNTRLsbunNo ratings yet

- Pollution Characteristics and Vertical Cutoff Wall o - 2022 - Ecotoxicology andDocument7 pagesPollution Characteristics and Vertical Cutoff Wall o - 2022 - Ecotoxicology andSANDRA K CHANDYNo ratings yet

- Dredging Process and Its Effect: Presented by Indranil Banerjee ROLL NUMBER-001930301008Document32 pagesDredging Process and Its Effect: Presented by Indranil Banerjee ROLL NUMBER-001930301008Indranil BanerjeeNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument7 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringEric ChanNo ratings yet

- CT Tutorial3Document6 pagesCT Tutorial3Jon KokNo ratings yet

- Jurnal 1 GeotekDocument7 pagesJurnal 1 Geotekputrielsari26No ratings yet

- Drainage For DamsDocument10 pagesDrainage For Damschutton681No ratings yet

- Geotextile Filter DesignDocument12 pagesGeotextile Filter DesignMahmoudNo ratings yet

- A Robotic System For Underwater Eco-Sustainable Wire-CuttingDocument11 pagesA Robotic System For Underwater Eco-Sustainable Wire-Cutting31Hanif ArdhioNo ratings yet

- Astm D 5783Document7 pagesAstm D 5783Jorge JiménezNo ratings yet

- Estimating Leakage Rates Through Barrier Systems - PresentationDocument69 pagesEstimating Leakage Rates Through Barrier Systems - Presentationreshan champikaNo ratings yet

- Project Execution For DredgingDocument1 pageProject Execution For DredgingkapsarcNo ratings yet

- Tencate GeotextileDocument12 pagesTencate GeotextileTamilchelvam MurogayahNo ratings yet

- Solid Control System SelectionDocument5 pagesSolid Control System SelectionYuga Agung PratamaNo ratings yet

- Dewatering SpecificationsDocument10 pagesDewatering Specificationsمحمود سعيدNo ratings yet

- Base Metal and Iron Ore Mining: Industry Description and PracticesDocument5 pagesBase Metal and Iron Ore Mining: Industry Description and PracticesminingnovaNo ratings yet

- Geo SyntheticsDocument20 pagesGeo SyntheticsPradeepBansalNo ratings yet

- Archetti Oil SpillDocument4 pagesArchetti Oil SpillResniOktaviaNo ratings yet

- Shoulder ConstructionDocument6 pagesShoulder ConstructionChemicro HoldingsNo ratings yet

- 1 s2.0 S0043135409000694 MainDocument8 pages1 s2.0 S0043135409000694 Mainsugar ffrreeNo ratings yet

- International Journal of Transportation Science and TechnologyDocument15 pagesInternational Journal of Transportation Science and TechnologyAnonymous hCGxuAC0ArNo ratings yet

- ABC OverlayDocument5 pagesABC OverlayChemicro HoldingsNo ratings yet

- 2 - Mastin, Lebster - Use of Geotube Dewatering Containers in Environmental DredgingDocument20 pages2 - Mastin, Lebster - Use of Geotube Dewatering Containers in Environmental DredgingJavier DiazNo ratings yet

- 4.0 Construction and Decommissioning: Soil ErosionDocument7 pages4.0 Construction and Decommissioning: Soil ErosionopaolisNo ratings yet

- Mining GeologyDocument10 pagesMining GeologyRMRE UETNo ratings yet

- Geosynthetic ProtectorsDocument73 pagesGeosynthetic Protectorsgonvic7411No ratings yet

- Sample Rocks Tests and Slope S PDFDocument18 pagesSample Rocks Tests and Slope S PDFRenzo Antúnez de MayoloNo ratings yet

- Collection and Handling of Soils Obtained in Core Barrel Samplers For Environmental InvestigationsDocument6 pagesCollection and Handling of Soils Obtained in Core Barrel Samplers For Environmental Investigationsmohammed karasnehNo ratings yet

- Hamid2018 Article AssessingTheEffectOfDensityAndDocument10 pagesHamid2018 Article AssessingTheEffectOfDensityAndFrimini Mng'anyaNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Drum Screen _DesignDetailsDocument2 pagesDrum Screen _DesignDetailskapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

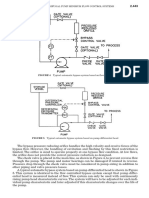

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- NB 95 - 7) N2 Instrument ListDocument8 pagesNB 95 - 7) N2 Instrument Listionut nicolaeNo ratings yet

- Republic of The Philippines: Exam 2Document4 pagesRepublic of The Philippines: Exam 2Jan Jan AnoNo ratings yet

- Ductile Errors in StaadDocument2 pagesDuctile Errors in Staadsitaram gvNo ratings yet

- Water Tank With 2 ColumnDocument21 pagesWater Tank With 2 ColumnlahirujayasiriNo ratings yet

- Buloane PeikkoDocument16 pagesBuloane Peikkovladimir8_addressNo ratings yet

- Seismic Manual Opa 2123 10 - 2 132Document66 pagesSeismic Manual Opa 2123 10 - 2 132abhishek yadavNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IIOğuzhan OğuzNo ratings yet

- Koilwar-Bhojpur Toll Plaza TOOL BOOTH DETAILDocument1 pageKoilwar-Bhojpur Toll Plaza TOOL BOOTH DETAILManinder ChaudharyNo ratings yet

- Numerical Simulations On Wind-Induced Aerodynamics For Tall Buildings With Refuge FloorsDocument9 pagesNumerical Simulations On Wind-Induced Aerodynamics For Tall Buildings With Refuge FloorsErnest OdhiamboNo ratings yet

- TD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietDocument13 pagesTD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietJustin ReyesNo ratings yet

- Typical Cross SectionDocument8 pagesTypical Cross SectionAmit PhadatareNo ratings yet

- ECG553-Chapter1-Subsurface ExplorationDocument66 pagesECG553-Chapter1-Subsurface ExplorationWajihah LazriNo ratings yet

- PRC Quiz1Document1 pagePRC Quiz1Umair AshrafNo ratings yet

- End BlockDocument9 pagesEnd BlockChrisYapNo ratings yet

- Mohammad's ResumeDocument1 pageMohammad's ResumeFarazNo ratings yet

- Ufc 3 260 02 2001Document538 pagesUfc 3 260 02 2001mohammed mustafaNo ratings yet

- York Water Cooled Pacakged YBW SeriesDocument5 pagesYork Water Cooled Pacakged YBW Seriespalitha1902100% (1)

- Acc - AhuDocument3 pagesAcc - AhuAamir ShaikhNo ratings yet

- DSR 2017-18-1Document218 pagesDSR 2017-18-1Ved ChithoreNo ratings yet

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pHarumNo ratings yet

- Long Welded Rails-7Document17 pagesLong Welded Rails-7vpmohammedNo ratings yet