Professional Documents

Culture Documents

Sae Ma 1636-2015

Uploaded by

wodonit136Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sae Ma 1636-2015

Uploaded by

wodonit136Copyright:

Available Formats

FEDERAL SUPPLY CLASS

RATIONALE

MA1 636 MA1 636 HAS BEEN REAFFIRMED TO COMPLY WITH THE SAE FIVE-YEAR REVIEW POLICY.

SAE reviews each technical report at least every five years at which time it may be revised, reaffirmed, stabilized, or cancelled. SAE invites your written comments and suggestions.

SAE Technical Standards Board Rules provide that: “This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.”

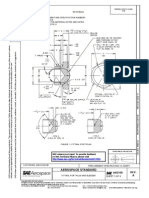

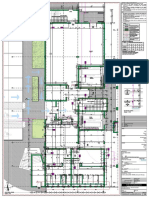

FIGURE 1 - HOSE ASSEMBLY

REAFFIRMED 201 5-04

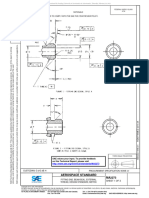

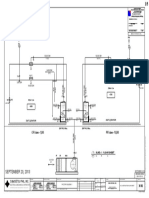

FIGURE 2 - SPIRAL ABRASION COVER /8/

ISSUED 1 998-03

THIRD ANGLE PROJECTION

SAE values your input. To provide feedback

on this Technical Report, please visit

http://www.sae.org/technical/standards/MA1 636

CUSTODIAN: G-3/G-3D PROCUREMENT SPECIFICATION: MA620 /3/

AEROSPACE STANDARD

HOSE ASSEMBLY, CONVOLUTED, MA1 636

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 1 OF 6

CONDUCTIVE, FLARELESS, 45⁰ TO 45 ⁰

Copyright 201 5 SAE International

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of SAE.

TO PLACE A DOCUMENT ORDER: Tel: 877-606-7323 (inside USA and Canada) Tel: +1 724-776-4970 (outside USA)

Fax: 724-776-0790 Email: CustomerService@sae.org SAE WEB ADDRESS: http://www.sae.org

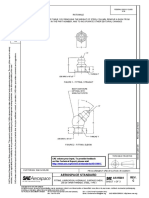

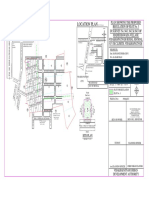

FIGURE 3 - FITTING ANGULAR ORIENTATION /1 8/

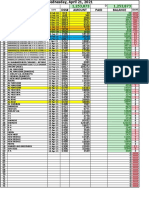

TABLE 1 - ASSEMBLY DIMENSIONS

HOSE HOSE

ASSY NO. ASSEMBLY THREAD T B E /1 1 / MAX F

AND SIZE SIZE PER MA1 370 A GAGE C /1 0/ D D WITHOUT HEX

CODE DN 4g - 6g MAX BASIC MIN MIN MAX SLEEVING (REF)

MA1 636E 06 MJ1 2 x 1 .25 38.6 7.5 3.4 9.8 1 1 .5 1 4.0 14

MA1 636G 10 MJ1 4 x 1 .5 49.0 9.5 6.5 1 2.9 1 4.7 1 7.3 17

MA1 636H 12 MJ1 8 x 1 .5 54.9 1 3.5 8.8 1 4.4 1 6.2 21 .8 22

MA1 636J 16 MJ22 x 1 .5 64.5 1 7.5 1 0.9 1 7.8 1 9.6 24.1 27

MA1 636K 20 MJ27 x 1 .5 72.9 21 .5 1 6.1 1 7.8 1 9.6 32.5 32

MA1 636M 25 MJ33 x 1 .5 81 .0 26.6 21 .2 22.9 24.7 37.3 41

MA1 636N 32 MJ42 x 2 1 02.1 33.7 27.5 25.7 27.5 43.2 46

MA1 636P 40 MJ50 x 2 1 1 6.1 41 .7 33.3 31 .5 33.3 50.8 60

TABLE 2 - ASSEMBLY LENGTH TOLERANCE

HOSE ASSEMBLY LENGTH TOLERANCE

UNDER 457 mm ±3 mm

457 TO 91 4 mm EXCLUSIVE ±7 mm

91 4 TO 1 270 mm EXCLUSIVE ±1 3 mm

1 270 mm AND OVER ±1 %

AEROSPACE STANDARD MA1 636

HOSE ASSEMBLY, CONVOLUTED,

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 2 OF 6

CONDUCTIVE, FLARELESS, 45 ⁰ TO 45⁰

TABLE 3 - HOSE OR COVER OUTSIDE DIAMETER

HOSE UPPER

OR HOSE HOSE HOSE HOSE HOSE HOSE HOSE HOSE TEMP.

COVER HOSE OR TYPE OF SIZE SIZE SIZE SIZE SIZE SIZE SIZE SIZE LIMIT

CODE PROTECTIVE COVER 06 10 12 16 20 25 32 40 °C

NONE HOSE ONLY PER MA620

B REF SPIRAL ABRASION /8/ 1 2.8 1 5.6 21 .0 23.7 29.0 34.5 41 .4 48.0 1 30

H ± .8 mm INTEGRAL FIRESLEEVE /1 2/ – 21 .1 25.7 29.7 34.5 38.3 44.4 50.8 200

N REF FIRESLEEVE SIL/FG (AS1 072) 1 9.3 22.1 26.2 28.7 34.8 41 .4 47.5 54.1 200

/1 2/ /1 3/ /1 4/

K ± .8 mm INTEGRAL ABRASION /9/ 1 2.7 1 6.0 21 .3 23.4 28.8 34.9 40.6 47.5 1 45

(BRAIDED) POLYESTER

J ± .8 mm INTEGRAL FIRESLEEVE /1 5/ 1 7.4 20.2 25.3 27.7 33.0 38.9 – – 200

TABLE 4 - HOSE ASSEMBLY PHYSICAL CHARACTERISTICS

BURST BURST

OPERATING PROOF PRESSURE PRESSURE BEND RADIUS

HOSE PRESSURE PRESSURE ROOM TEMP HIGH TEMP AT INSIDE

SIZE MAX MIN MIN MIN OF BEND

DN kPa kPa kPa kPa (HOSE ONLY)

06 6900 1 3 800 27 600 1 9 300 32

10 6900 1 3 800 27 600 1 9 300 57

12 6900 1 3 800 27 600 1 9 300 73

16 6900 1 2 41 0 24 820 1 7 240 76

20 6900 1 2 41 0 24 820 1 7 240 95

25 6900 1 2 41 0 24 820 1 7 240 1 27

32 6900 1 2 41 0 24 820 1 7 240 1 59

40 51 70 1 0 340 20 680 1 4 480 1 91

TABLE 5 - WEIGHTS (NOM)

HOSE WITH HOSE WITH HOSE WITH HOSE WITH

SPIRAL INTEGRAL TUBULAR POLYESTER

ABRASION FIRESLEEVE FIRESLEEVE ABRASION HOSE LENGTH

HOSE HOSE COVER COVER COVER COVER 45° END CORRECTION

SIZE ONLY CODE B CODE H & J CODE N CODE K FITTING FACTOR - MM /1 7/

DN kg/m kg/m kg/m kg/m kg/m kg EACH 45°

06 0.1 43 0.1 97 – 0.322 0.1 61 0.034 24.7

10 0.1 78 0.250 0.500 0.375 0.21 4 0.041 30.0

12 0.268 0.357 0.572 0.536 0.321 0.090 36.7

16 0.357 0.446 0.750 0.625 0.393 0.1 25 41 .7

20 0.483 0.572 0.893 0.786 0.500 0.221 46.5

25 0.590 0.697 0.982 1 .020 0.680 0.332 54.6

32 0.893 1 .072 1 .250 1 .375 0.804 0.403 59.3

40 1 .072 1 .268 1 .464 1 .91 1 1 .036 0.684 61 .6

AEROSPACE STANDARD MA1 636

HOSE ASSEMBLY, CONVOLUTED,

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 3 OF 6

CONDUCTIVE, FLARELESS, 45 ⁰ TO 45⁰

TABLE 6 - SLEEVE LENGTH

HOSE

SIZE LENGTH

DN (MILLIMETERS)

06

50 ± 6

10

12

65 ± 6

16

20

75 ± 6

25

32

90 ± 6

40

TABLE 7 - MINIMUM INSPECTION BALL SIZE

FOR VERIFYING HOSE ASSEMBLY ID /1 0/

HOSE

SIZE

DN DIA MM

06 2.85

10 5.53

12 7.45

16 9.28

20 1 3.70

25 1 8.03

32 23.43

40 28.28

TABLE 8 - LENGTH CORRECTION FACTORS

HOSE 45°

SIZE END

DN FITTING

06 2.8

10 2.8

12 2.8

16 2.8

20 2.8

25 2.8

32 3.2

40 3.2

AEROSPACE STANDARD MA1 636

HOSE ASSEMBLY, CONVOLUTED,

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 4 OF 6

CONDUCTIVE, FLARELESS, 45 ⁰ TO 45⁰

NOTES:

1 . DN = NOMINAL TUBE OUTSIDE DIAMETER.

2. MATERIALS: HOSE AND FITTINGS PER MA620, TYPE II, CLASS 1 OR 2, AS SPECIFIED BY PART NUMBER.

CODE B, SPIRAL ABRASION COVER, BLACK NYLON COIL PER AS1 294

CODE H AND J, INTEGRAL FIRESLEEVE, RED OR BROWN SILICONE

CODE N, TUBULAR FIRESLEEVE, FIBERGLASS SILICONE PER AS1 072

CODE K, INTEGRAL ABRASION SLEEVE, BRAIDED POLYESTER

/3/ THIS HOSE ASSEMBLY STANDARD SHALL BE QUALIFIED IN ACCORDANCE WITH PROCUREMENT SPECIFICATION

MA620. USERS OF THIS STANDARD ARE ADVISED TO CONTROL SOURCE APPROVAL(S) BY STANDARD PAGE

SUPPLEMENT SHEET OR SIMILAR MEANS.

4. MARKING SHALL BE PER MA620 ON A STAINLESS STEEL BAND NOT OVER 25.0 mm WIDE OR ON THE END

FITTING COLLAR. THE CHARACTERS SHALL BE A MINIMUM OF 1 .5 mm HIGH. THE BAND SHALL BE SO

DESIGNED AS TO REMAIN TIGHT ON THE HOSE TO PREVENT RELATIVE MOTION AND CHAFING. IT SHALL BE OF

SUFFICIENT STRENGTH TO PREVENT REMOVAL BY HAND.

5. CONSTRUCTION AND PERFORMANCE PER MA620. FITTINGS SHALL BE PERMANENTLY ATTACHED TO HOSE.

/6/ LENGTH “L” IS A FOUR DIGIT NUMBER IN “MM”. LENGTH “L” IS MEASURED FROM “GAGE POINT” TO “GAGE

POINT”. SEE TABLE 2 FOR LENGTH TOLERANCES.

/7/ TO CONVERT “GAGE POINT” TO “GAGE POINT” TO “END” TO “END” MEASUREMENT, ADD TO “L” THE APPROPRIATE

TABLE 8 CORRECTION FACTOR FOR EACH END FITTING.

/8/ SPIRAL ABRASION COVER WHEN ASSEMBLED IN THE STRAIGHT CONDITION ON THE HOSE SHALL HAVE AN

AVERAGE GAP BETWEEN SPIRALS NOT EXCEEDING 1 .3 mm. DISPLACEMENT OF THE SPIRAL COVER, CAUSING

A GREATER GAP, SHALL NOT BE CAUSE FOR REJECTION IF THE SPIRALS CAN BE REPOSITIONED TO MEET THE

GAP REQUIREMENT. ENDS OF THE SPIRAL COVER SHALL BE TERMINATED WITH A LENGTH OF

MIL-I-23053/5 BLACK POLYOLEFIN TUBING PER TABLE 6 AND FIGURE 2.

/9/ BRAIDED POLYESTER ABRASION COVER SHALL FORM AN INTEGRAL, PERMANENT PART OF THE HOSE AND

SHALL TERMINATE A MAXIMUM OF 1 6.0 mm FROM THE END OF THE END FITTING COLLAR.

/1 0/ HOSE ASSEMBLY INSIDE DIAMETER SHALL BE VERIFIED BY PASSING THE DESIGNATED, OR LARGER,

SPHERICAL BALL PER TABLE 7 THROUGH THE HOSE ASSEMBLY.

/1 1 / DISTANCE ACROSS CORNERS OF COUPLING NUT MAY EXCEED THIS DIMENSION.

/1 2/ ADD “AS1 055 TYPE IIb CLASS B-S/P” OR “AS1 50 TYPE IIIbB” TO IDENTIFICATION MARKING TO SHOW LEVEL OF

COMPLIANCE, “FIRE-PROOF” (1 5 min), WITH AS1 055 OR AS1 50.

/1 3/ THE CUT ENDS OF THE FIRESLEEVE SHALL BE COATED WITH RTV SILICONE RUBBER, OR EQUIVALENT, PRIOR

TO INSTALLATION TO PREVENT WICKING OF FLUID. THE FIRESLEEVE ENDS SHALL BE SECURED TO THE HOSE

ASSEMBLY END FITTINGS WITH CORROSION RESISTANT STEEL BANDS. AFTER INSTALLATION, CRACKS OR

VOIDS IN THE FIRESLEEVE, WHICH EXPOSE THE FIBERGLASS, SHALL BE COATED WITH RTV SILICONE.

/1 4/ THE TABLE 3 SLEEVE DIAMETERS FOR AS1 072 SLEEVE APPLY WHEN THE SLEEVE IS COMPRESSED, OR

CLAMPED, TO CONTACT THE HOSE. IN THIS CASE A WRINKLE MAY OCCUR OVER APPROXIMATELY 1 0% OF THE

SLEEVE CIRCUMFERENCE.

/1 5/ ADD “AS1 055 TYPE IIa CLASS A-S/P” OR “AS1 50 TYPE IIIaA” TO IDENTIFICATION MARKING TO SHOW LEVEL OF

COMPLIANCE “FIRE RESISTANT” (5 min) WITH AS1 055 OR AS1 50.

1 6. STANDARD COUPLING NUTS SHALL BE IN ACCORDANCE WITH MA2072 OR MA2047. NONSTANDARD COUPLING

NUTS MAY BE USED BUT SHALL COMPLY WITH THE REQUIREMENT (b) OF MA201 4 FOR NONSTANDARD NUTS

AND SHALL BE RETAINED BY THE END FITTING.

/1 7/ FOR EACH END FITTING, DEDUCT APPROPRIATE LENGTH FACTOR FROM HOSE LENGTH TO DETERMINE

ASSEMBLY WEIGHT.

AEROSPACE STANDARD MA1 636

HOSE ASSEMBLY, CONVOLUTED,

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 5 OF 6

CONDUCTIVE, FLARELESS, 45 ⁰ TO 45⁰

NOTES (CONTINUED):

/1 8/ THE FITTING ORIENTATION DASH NUMBER IS A THREE DIGIT NUMBER DEFINING THE RELATIVE POSITION OF

THE END FITTING IN 1 ° INCREMENTS (EXAMPLE 090 = 90°). FITTING ORIENTATION SHALL BE MEASURED

COUNTERCLOCKWISE FROM THE NEAREST END FITTING, WHICH SHALL BE IN THE RELATIVE 000° POSITION

(SEE FIGURE 3). WHEN END FITTINGS ARE POINTED IN THE SAME DIRECTION, THE DASH NUMBER SHALL

BE 000.

1 9. DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

20.

AEROSPACE STANDARD MA1 636

HOSE ASSEMBLY, CONVOLUTED,

POLYTETRAFLUOROETHYLENE, METALLIC REINFORCED SHEET 6 OF 6

CONDUCTIVE, FLARELESS, 45 ⁰ TO 45⁰

You might also like

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- Elect SchematicDocument4 pagesElect SchematicDenis HernandezNo ratings yet

- Idoc - Pub Sae As5202 Port DimensionsDocument3 pagesIdoc - Pub Sae As5202 Port DimensionsrjsnelsonjrNo ratings yet

- Aerospace Standard AS4330: Custodian: Sae G-3/G-3BDocument2 pagesAerospace Standard AS4330: Custodian: Sae G-3/G-3BHenry100% (2)

- HVAC - Standard Detail - ADocument1 pageHVAC - Standard Detail - ARommel Dela Serna100% (1)

- Master Plan - 2031 FOR Satellite Town Ring Road Planning Authority (Strrpa)Document16 pagesMaster Plan - 2031 FOR Satellite Town Ring Road Planning Authority (Strrpa)peednass80% (5)

- Ib History Command Term PostersDocument6 pagesIb History Command Term Postersapi-263601302100% (4)

- Architectural Plans - For BT4 Final RequirementDocument11 pagesArchitectural Plans - For BT4 Final RequirementAngela MaeNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Pivot TableDocument19 pagesPivot TablePrince AroraNo ratings yet

- Pt3 English Module 2018Document63 pagesPt3 English Module 2018Annie Abdul Rahman50% (4)

- Mcdonald 2016Document10 pagesMcdonald 2016Andrika SaputraNo ratings yet

- As 5169Document5 pagesAs 5169Wuod JipangaNo ratings yet

- Iso TS 6521-2-2021Document16 pagesIso TS 6521-2-2021wodonit136No ratings yet

- Ready to Go Guided Reading: Synthesize, Grades 5 - 6From EverandReady to Go Guided Reading: Synthesize, Grades 5 - 6No ratings yet

- Role of Personal Finance Towards Managing of Money - DraftaDocument35 pagesRole of Personal Finance Towards Managing of Money - DraftaAndrea Denise Lion100% (1)

- Sindi and Wahab in 18th CenturyDocument9 pagesSindi and Wahab in 18th CenturyMujahid Asaadullah AbdullahNo ratings yet

- Rationale This Document Has Been Reaffirmed To Comply With The Sae 5-Year Review PolicyDocument3 pagesRationale This Document Has Been Reaffirmed To Comply With The Sae 5-Year Review Policyvinoth67% (3)

- Sae Geia-Std-0008-2011Document21 pagesSae Geia-Std-0008-2011wodonit136No ratings yet

- Excon2019 ShowPreview02122019 PDFDocument492 pagesExcon2019 ShowPreview02122019 PDFSanjay KherNo ratings yet

- Ground Floor Plan: Pedro Runolf DiongzonDocument1 pageGround Floor Plan: Pedro Runolf DiongzonzaccNo ratings yet

- 966M and 972M Wheel Loader 966mDocument2 pages966M and 972M Wheel Loader 966mF Labio AlexNo ratings yet

- Hydraulic Schematic IT38G Series II Wheel LoaderDocument2 pagesHydraulic Schematic IT38G Series II Wheel LoaderDennis OlayaNo ratings yet

- Hima OPC Server ManualDocument36 pagesHima OPC Server ManualAshkan Khajouie100% (3)

- 232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerDocument2 pages232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerPablo Porras100% (1)

- MA2273Document3 pagesMA2273gagalunar789No ratings yet

- AS33514Document4 pagesAS33514gagalunar789No ratings yet

- Roof Top and Deck PlanDocument1 pageRoof Top and Deck PlanWilbert ReuyanNo ratings yet

- AS15001CDocument3 pagesAS15001Cjeniful jenifulNo ratings yet

- Aa 036629 001Document1 pageAa 036629 001hai sunNo ratings yet

- Rationale As1099C Has Been Reaffirmed To Comply With The Sae Five-Year Review PolicyDocument3 pagesRationale As1099C Has Been Reaffirmed To Comply With The Sae Five-Year Review PolicyLarry HareNo ratings yet

- Sae As 5202a 2005-05-25Document3 pagesSae As 5202a 2005-05-25Andr EkmeNo ratings yet

- Plan 4Document9 pagesPlan 4rnz mrnNo ratings yet

- Inglés IDocument4 pagesInglés Iamalia MejiaNo ratings yet

- ST02 - FOUNDATION-Layout1Document1 pageST02 - FOUNDATION-Layout1Fazil RizhafNo ratings yet

- Appendix 5B. Preliminary Electrical Design Drawings Part4Document1 pageAppendix 5B. Preliminary Electrical Design Drawings Part4TaskNo ratings yet

- As85052 - 2b-Clamp, Loop Tube 17-7PH, Cres, 275 °f, Phosphate Ester Fluid ResistantDocument3 pagesAs85052 - 2b-Clamp, Loop Tube 17-7PH, Cres, 275 °f, Phosphate Ester Fluid ResistantJicheng PiaoNo ratings yet

- Notice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049Document3 pagesNotice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049daNo ratings yet

- Issued For Construction: Continuation See Above Right Matchline Sta. 5+000 ForDocument1 pageIssued For Construction: Continuation See Above Right Matchline Sta. 5+000 ForMohamed HaleemNo ratings yet

- Scraper Launcher at South Berri Wip For Details, See Plot PlanDocument1 pageScraper Launcher at South Berri Wip For Details, See Plot PlanMohamed HaleemNo ratings yet

- Legend:: S E W A G E Treatment Plant (P H A S E 2 & 3)Document1 pageLegend:: S E W A G E Treatment Plant (P H A S E 2 & 3)Ian Benedict congresoNo ratings yet

- Water Tank: LegendDocument1 pageWater Tank: LegendIan Benedict congresoNo ratings yet

- Legend:: Ulysses T. Arienza, UapDocument1 pageLegend:: Ulysses T. Arienza, UapIan Benedict congresoNo ratings yet

- LOS1-A-2202-OPS-PH1A - Rev 10 - Plan - Builders Work - Ground LevelDocument1 pageLOS1-A-2202-OPS-PH1A - Rev 10 - Plan - Builders Work - Ground LevelTosin FamuyiwaNo ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- Sae As 33514a 2007-05-01Document3 pagesSae As 33514a 2007-05-01Andr EkmeNo ratings yet

- Internet: F.O - 50 Microns F.O - 50 MicronsDocument3 pagesInternet: F.O - 50 Microns F.O - 50 MicronsJavier CareagaNo ratings yet

- BLDG.# 1 MAUDocument1 pageBLDG.# 1 MAUjeffrey andrinoNo ratings yet

- Location & Lay Out PlanDocument1 pageLocation & Lay Out PlansaiNo ratings yet

- Utilities Substation Ss-053: Saudi Arabian Oil CompanyDocument1 pageUtilities Substation Ss-053: Saudi Arabian Oil CompanyLino AbetoNo ratings yet

- Internal Finishes Schedule External Finishes Schedule: O & M Building General Warehouse Guard HouseDocument1 pageInternal Finishes Schedule External Finishes Schedule: O & M Building General Warehouse Guard HousemarwanfakihNo ratings yet

- SCR 005075Document1 pageSCR 005075jeplgpbmcNo ratings yet

- 42 Sawantmaitreyee DD&ARDDocument5 pages42 Sawantmaitreyee DD&ARDArchana ChavanNo ratings yet

- 1 Key Notes: MECH (F-Viii)Document1 page1 Key Notes: MECH (F-Viii)Cristo BglezNo ratings yet

- PRTAPUDocument1 pagePRTAPUShivam VermaNo ratings yet

- Sae As 33649a 2005-08Document4 pagesSae As 33649a 2005-08Andr EkmeNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- 2ha AnafsDocument1 page2ha AnafsSteffen BrookerNo ratings yet

- Post-Tensioning Slab Shuttering Details For First Slab: PT Slab Area - 66.31 SQM 713.49 SFTDocument9 pagesPost-Tensioning Slab Shuttering Details For First Slab: PT Slab Area - 66.31 SQM 713.49 SFTamit_saxena_10No ratings yet

- RAHEEM CHANNA (0333-3112542) : C-Karachi (Qayoom Solangi 1000/ )Document1 pageRAHEEM CHANNA (0333-3112542) : C-Karachi (Qayoom Solangi 1000/ )Vishal RawlaniNo ratings yet

- Structural Drawing (Sleeves in Raft)Document3 pagesStructural Drawing (Sleeves in Raft)Omer HayatNo ratings yet

- General Notes:-: C68 C72 C69 C71Document1 pageGeneral Notes:-: C68 C72 C69 C71jalaluddin bmNo ratings yet

- Door Schedule Window Schedule Accessibility Details: Sheet NotesDocument1 pageDoor Schedule Window Schedule Accessibility Details: Sheet NotesNeil ArmstrongNo ratings yet

- Workshop 5Document1 pageWorkshop 5Thamarai kannan SrinivasanNo ratings yet

- PLANT - Page 1Document1 pagePLANT - Page 1AlphaMae DitanNo ratings yet

- Ad-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGDocument1 pageAd-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGmcaslamNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNo ratings yet

- FM - 3 - PC - 05002 - 0 DCG12900 KEBAYORAN B (RW05) To ContractorDocument1 pageFM - 3 - PC - 05002 - 0 DCG12900 KEBAYORAN B (RW05) To ContractorIksan GnwnNo ratings yet

- Sae Geia-Geb-0002-2014Document23 pagesSae Geia-Geb-0002-2014wodonit136No ratings yet

- Sae Geia-Std-0010a-2018Document104 pagesSae Geia-Std-0010a-2018wodonit136100% (1)

- Iso TS 23818-1-2020Document54 pagesIso TS 23818-1-2020wodonit136No ratings yet

- Sae Geia-Std-0006a-2016Document18 pagesSae Geia-Std-0006a-2016wodonit136No ratings yet

- BS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)Document26 pagesBS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)wodonit136No ratings yet

- 5c3f1a8b262ec7a Ek PDFDocument5 pages5c3f1a8b262ec7a Ek PDFIsmet HizyoluNo ratings yet

- DPSD ProjectDocument30 pagesDPSD ProjectSri NidhiNo ratings yet

- Chemistry: Crash Course For JEE Main 2020Document18 pagesChemistry: Crash Course For JEE Main 2020Sanjeeb KumarNo ratings yet

- Deal Report Feb 14 - Apr 14Document26 pagesDeal Report Feb 14 - Apr 14BonviNo ratings yet

- PM CH 14Document24 pagesPM CH 14phani chowdaryNo ratings yet

- Ob NotesDocument8 pagesOb NotesRahul RajputNo ratings yet

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormNo ratings yet

- Monkey Says, Monkey Does Security andDocument11 pagesMonkey Says, Monkey Does Security andNudeNo ratings yet

- Report Card Grade 1 2Document3 pagesReport Card Grade 1 2Mely DelacruzNo ratings yet

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowDocument2 pagesLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- Appendix - Pcmc2Document8 pagesAppendix - Pcmc2Siva PNo ratings yet

- Existential ThreatsDocument6 pagesExistential Threatslolab_4No ratings yet

- Ito Na Talaga Yung FinalDocument22 pagesIto Na Talaga Yung FinalJonas Gian Miguel MadarangNo ratings yet

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuNo ratings yet

- Pe 03 - Course ModuleDocument42 pagesPe 03 - Course ModuleMARIEL ASINo ratings yet

- AnticyclonesDocument5 pagesAnticyclonescicileanaNo ratings yet

- Decision Making and The Role of Manageme PDFDocument20 pagesDecision Making and The Role of Manageme PDFRaadmaan RadNo ratings yet

- Guidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17Document5 pagesGuidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17zqhnazNo ratings yet

- MGMT Audit Report WritingDocument28 pagesMGMT Audit Report WritingAndrei IulianNo ratings yet

- Electro Fashion Sewable LED Kits WebDocument10 pagesElectro Fashion Sewable LED Kits WebAndrei VasileNo ratings yet

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNo ratings yet

- Emea 119948060Document31 pagesEmea 119948060ASHUTOSH MISHRANo ratings yet