Professional Documents

Culture Documents

Calc. by Date

Uploaded by

Arfel Bartiana0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

10.0 T1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesCalc. by Date

Uploaded by

Arfel BartianaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CALC.

BY DATE:

TRUSS DESIGN CHECK BY: DATE:

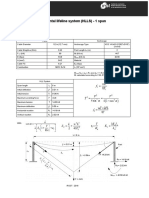

CONTENT: FOR ALL BUILT UP BEAM MARK: ALL

Parameters

Wdl = 10.4 kN/m Dead Load

Wll = 12.31 kN/m Live Load

Peq = 16 kN Seismic Axial Load

Veq = 16 kN Seismic shear force

Meq = 20.18 kN.m Seismic bending force

Design Calculations

For top chord & bottom chord

Design Force For vertical chord & diagonal chord

Cu = 99.6 kN (C) top & bot chor max reaction(cu) Design Force

Other pertinent data Tu = 40.6 kN ( t ) web member Max. Tension (Tu)

φs = 0.9 Strength reduction factor Cu = 51.7 kN (c ) web member Compression (Cu )

Lu = 0.3 m Unbraced Length Other pertinent data

k = 1 effective length factor φs = 0.9 Strength reduction factor

2L 50 mmx 50 mm x 6 mm angle bar Lu = 0.45 m Unbraced Length

Section Properties k = 1 effective length factor

t = 6 mm Thickness ; t 1L 63 mmx 63 mm x 6 mm angle bar

Ash = 1220 sq.m cross sectional area Section Properties

Ix = 288000 mm^4 moment of inertia about x-axis t = 6 mm Thickness ; t

Iy = 558000 mm^4 moment of inertia about y-axis Ash = 1220 sq.m cross sectional area

rx = 15.4 radius of gyration about x-axis Ix = 288000 mm^4 moment of inertia about x-axis

ry = 21.4 radius of gyration about y-axis Iy = 558000 mm^4 moment of inertia about y-axis

Material Properties rx = 19.4 radius of gyration about x-axis

fy = 248 Mpa yield strength ry = 19.4 radius of gyration about y-axis

fu = 400 Mpa Ultimate strength Material Properties

Es = 200000 Mpa modulus of elasticity fy = 248 Mpa yield strength

Checking Adequacy fu = 400 Mpa Ultimate strength

Es = 200000 Mpa modulus of elasticity

kLu/r = 19.5

= 133.8 4.71 √(E/fy) Checking Adequacy

kLu/r < 4.71 √(E/fy) Tension

Fcr = 243.10 mpa ( 0.658^( fy/ Fe)) fy Pn = 302.56 kN Ash*fy

Fe = 5201.5 mpa π^2* E/(klu/r)^2 φPn = 272.30 kN

Pn = 296.58 Fcr(Ag) φPn > Tu, OK !

φPn = 266.92 kN

φPn > cu, OK ! Compression

kLu/r = 23.2

= 133.8 4.71 √(E/fy)

kLu/r < 4.71 √(E/fy)

Fcr = 241.08 kN ( 0.658^( fy/ Fe)) fy

Fe = 3668.67 kN π^2* E/(klu/r)^2

Pn = 294.12 kN Fcr(Ag)

φPn = 132.35 kN

φPn > Cu-- OK !

TRUSS DESIGN Page 1 of 2

CALC. BY DATE:

TRUSS DESIGN CHECK BY: DATE:

CONTENT: FOR ALL BUILT UP BEAM MARK: ALL

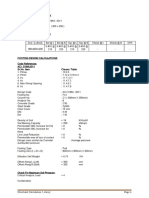

DESIGN FORCES OTHER PARAMETERS

Mux = 20.8 kN.m Bending Force Fy = 250 mpa

Es = 200000 mpa

Vu = 27.56 kN Shear Force ϕf = 0.9

Pu = 16 kN Concentrated load ϕs = 0.9

BASE PLATE ANCHOR BOLT DESIGN

Base plate size

C = 200 mm No. of Anchor bolt each side, n = 4 Pcs

B = 500 mm Diameter of Anchor Bolts = 16 mm

t = 16 mm

Concrete Contact area Ft allow. =0.60Fy = 150 Mpa

x = 300 mm Fv allow. =0.4Fu = 160 Mpa

y = 500 mm

F'c = 20.7 Mpa Bolt shear checks

x - axis

Size Adequacy Fvx= Vux/Abolts = 34.268 Mpa

P/A ± Mc/I ≤ Fp Fv allow. > Fvx act. , Ok !

Fp = 0.35 f'c sqrt.(Acon./Ab) ≤ 0.70 f' c

Bolt Tension checks

Fp = 0.35 f'c sqrt.(Acon./Ab) = 8.87328 Mpa

Fp=0.70f'c = 14.49 Mpa Tx = 1/2*(P/A-Mxc/Ix)(x)*C

Governs Fp = 8.87328 Mpa x = 0, no tension

Compression Tx = 116800 N

Required Area of Bolts

Thickness Adequacy A= (T/n)/Ft = 194.667 sq.mm

Allowable thickness Req'd diameter = sqrt(4*A/π) = 15.7435 mm

t = sqrt.( 3fpn^2/Fb) provided dia. > req'd dia. , Ok !

n1= (C-0.8w)/2 = 210 mm

n2= (B -0.95d)/2 = -42.5 mm

fp = P/Ab = 0.16 Mpa

Fb = 0.75*f'c = 187.5 Mpa

t = sqrt.( 3fpn^2/Fb) = 10.6253 mm

t allw. < t provided, Ok !

WELDING DESIGN

use welding type E-60 xx

Fu= 414 Mpa

Fv = 0.3Fu Fv = 124.2 Mpa

Vu = 27.6 kN

fillet weld size = 6 mm

Provided Lw = 600 mm (2x depth)

Fw = 0.707*tw*Fv Fw = 526.856 Mpa

Required Length of weld

Lw = Vu/Fw Lw = 52.3103 mm

Req'd Lw < actual Lw,Ok !

TRUSS DESIGN Page 2 of 2

You might also like

- 8.0 TrussDocument1 page8.0 TrussArfel BartianaNo ratings yet

- Post Tension Slab Design EtabsDocument2 pagesPost Tension Slab Design Etabs121528No ratings yet

- 5.0. Beam Design-Steel PlateDocument19 pages5.0. Beam Design-Steel PlateFarly VergelNo ratings yet

- AiscDocument13 pagesAiscsteven bianesNo ratings yet

- Design of Concrete PadDocument3 pagesDesign of Concrete PadBeveh G SupSupNo ratings yet

- Aisc360 Box Steel DesignDocument3 pagesAisc360 Box Steel DesignHattori HanzoNo ratings yet

- Direct Analysis Method: Project: DescriptionDocument15 pagesDirect Analysis Method: Project: DescriptionMarkNo ratings yet

- AISC360 Round Filled Composite MemberDocument2 pagesAISC360 Round Filled Composite MemberHattori HanzoNo ratings yet

- Thrust BlockDocument2 pagesThrust BlocksaiengineeringfoundationNo ratings yet

- Steel Beam NSCP2015Document307 pagesSteel Beam NSCP2015Sherwin CairoNo ratings yet

- Structural Analysis SampleDocument14 pagesStructural Analysis SampleJaephee Murphy Oducayen RamosNo ratings yet

- XXXXX Grid Slab - Admin BuildingDocument3 pagesXXXXX Grid Slab - Admin Buildingmrprabhu16No ratings yet

- Culvert Design Using Staad As Per IrsDocument171 pagesCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudNo ratings yet

- Purlin DesignDocument3 pagesPurlin DesignNaveen Kumar PadmanabuniNo ratings yet

- Revised Pedestal CalculationsDocument2 pagesRevised Pedestal Calculationsvikash kumarNo ratings yet

- Column DesignDocument1 pageColumn Designanonymousupldr666No ratings yet

- Design ComputationsDocument17 pagesDesign Computations무제untitledNo ratings yet

- Foundation Engineering - ExcelDocument12 pagesFoundation Engineering - ExcelYath DreNo ratings yet

- Pile Foundation DesignDocument6 pagesPile Foundation DesignscistNo ratings yet

- End Plate Column Splice Connection by IS CodeDocument15 pagesEnd Plate Column Splice Connection by IS CodeStructural SpreadsheetsNo ratings yet

- AISC2005-Anchor BoltDocument9 pagesAISC2005-Anchor Boltnmtam.sdh20No ratings yet

- PSAD Module3 4 PDFDocument44 pagesPSAD Module3 4 PDFmyytchannelroadto1ksubNo ratings yet

- Microsoft Word - Pile Cap AnalysisDocument4 pagesMicrosoft Word - Pile Cap AnalysisDương TrầnNo ratings yet

- Pile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)Document5 pagesPile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)mayoo1986No ratings yet

- Footing Design CalculationsDocument5 pagesFooting Design CalculationsArnold VercelesNo ratings yet

- Combined Footing Type4Document3 pagesCombined Footing Type4vaibhav dahiwalkarNo ratings yet

- Design Calculation Of: Base Plate and Anchor BoltDocument4 pagesDesign Calculation Of: Base Plate and Anchor Bolthanuman sharma0% (1)

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDocument10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiNo ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- Description Default Load Width Load: Minimum Design LoadsDocument13 pagesDescription Default Load Width Load: Minimum Design LoadsRayross Jamilano YacabaNo ratings yet

- Description Default Load Width Load: Minimum Design LoadsDocument13 pagesDescription Default Load Width Load: Minimum Design LoadsRayross Jamilano YacabaNo ratings yet

- Horizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxDocument1 pageHorizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxRajNo ratings yet

- Results PDFDocument1 pageResults PDFRajNo ratings yet

- Long ColumnDocument12 pagesLong Columnsrinivasa raoNo ratings yet

- 1mx1m Conrete BoxDocument2 pages1mx1m Conrete BoxrasikamalNo ratings yet

- Box Culvert 1x1mDocument2 pagesBox Culvert 1x1mrasikamalNo ratings yet

- Design of Box CulvertDocument34 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- Seismic Analysis and DesignDocument11 pagesSeismic Analysis and DesignYra Mae ViluanNo ratings yet

- Structural Calculation.2-StoreyDocument6 pagesStructural Calculation.2-StoreyMiguel LigutanNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Sample - Column DesignDocument2 pagesSample - Column DesignConie CatapanNo ratings yet

- Tyipical Foundation DesignDocument5 pagesTyipical Foundation DesignManoj SinhaNo ratings yet

- Pile Cap DesignDocument104 pagesPile Cap DesignMARIO AGUILARDNo ratings yet

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- DL PDocument5 pagesDL PNiraj ShindeNo ratings yet

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pages1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- 3a. MonorailDocument15 pages3a. MonorailLagnajit DasNo ratings yet

- Stair DesignDocument2 pagesStair DesignAngelika Caguioa BiayNo ratings yet

- Moment Edplate DesignDocument8 pagesMoment Edplate DesignRenato AndradeNo ratings yet

- Isolated Footing - 09mar2021Document12 pagesIsolated Footing - 09mar2021Troy ValeriaNo ratings yet

- Slab DesignDocument11 pagesSlab DesignCarmel Buniel Sabado100% (22)

- Conc Fill CHS To EC4 ExampleDocument2 pagesConc Fill CHS To EC4 ExampleLee CwNo ratings yet

- Reactions Non PRLL - Connection CheckDocument4 pagesReactions Non PRLL - Connection CheckBMU CMACNo ratings yet

- Design of Mullion For C W Wall System: Project NameDocument3 pagesDesign of Mullion For C W Wall System: Project NameSales AlufacadesNo ratings yet

- Counterfort Retaining Wall DesignDocument24 pagesCounterfort Retaining Wall DesignsohaNo ratings yet

- Bearing Capacity of SoilDocument7 pagesBearing Capacity of SoilAsad Hayat WarraichNo ratings yet

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Base ShearDocument1 pageBase ShearArfel BartianaNo ratings yet

- Cantilver Slab: 100 Length of OverhangDocument1 pageCantilver Slab: 100 Length of OverhangArfel BartianaNo ratings yet

- A C C'' C' A' B A C C'' C' A' B: Foundation Plan Second Floor Framing PlanDocument1 pageA C C'' C' A' B A C C'' C' A' B: Foundation Plan Second Floor Framing PlanArfel BartianaNo ratings yet

- Steel Notes: Typical Detail of Stiffener Column & Beam For MasonryDocument1 pageSteel Notes: Typical Detail of Stiffener Column & Beam For MasonryArfel BartianaNo ratings yet

- 9.0 PurlinsDocument1 page9.0 PurlinsArfel BartianaNo ratings yet

- Activity2 MidtermDocument3 pagesActivity2 MidtermArfel BartianaNo ratings yet

- Self and Team Member Evaluation of A Group Project/Presentation Your NameDocument4 pagesSelf and Team Member Evaluation of A Group Project/Presentation Your NameArfel BartianaNo ratings yet

- Geol 212.prelim NotesDocument7 pagesGeol 212.prelim NotesArfel BartianaNo ratings yet

- IncludeDocument1 pageIncludeArfel BartianaNo ratings yet

- Activity2 MidtermDocument3 pagesActivity2 MidtermArfel BartianaNo ratings yet

- Square Footing With Axial and Bending On Both AxisDocument2 pagesSquare Footing With Axial and Bending On Both AxisMaria Rose Giltendez - BartianaNo ratings yet

- Engineering EconomyDocument266 pagesEngineering EconomyGlaiza Lacson0% (1)

- IncludeDocument1 pageIncludeArfel BartianaNo ratings yet

- 318-Example-1 RF r1Document11 pages318-Example-1 RF r1Vatova JarrandNo ratings yet

- Strap Footing Eqns PDFDocument6 pagesStrap Footing Eqns PDFaldert_path100% (2)

- Ce6505 Dore Civil VST Au Unit VDocument34 pagesCe6505 Dore Civil VST Au Unit VArfel BartianaNo ratings yet

- Strap Footing PDFDocument7 pagesStrap Footing PDFMohammed Sumer100% (1)

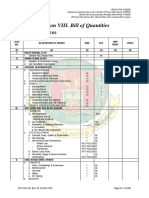

- Rebid 2016.06.29 08-UPRHS BOQREV PDFDocument10 pagesRebid 2016.06.29 08-UPRHS BOQREV PDFJude TicseNo ratings yet

- Revised IRR of National Building Code - Why Is An Injunction Necessary?Document56 pagesRevised IRR of National Building Code - Why Is An Injunction Necessary?clsNo ratings yet

- Ce6505 Dore Civil VST Au Unit VDocument34 pagesCe6505 Dore Civil VST Au Unit VArfel BartianaNo ratings yet

- Rebid 2016.06.29 08-UPRHS BOQREV PDFDocument10 pagesRebid 2016.06.29 08-UPRHS BOQREV PDFJude TicseNo ratings yet

- EARTHQUAKE RfeeDocument39 pagesEARTHQUAKE RfeeArfel BartianaNo ratings yet

- Foundations: Chapter IntroductionDocument2 pagesFoundations: Chapter IntroductionArfel BartianaNo ratings yet

- Revised IRR of National Building Code - Why Is An Injunction Necessary?Document56 pagesRevised IRR of National Building Code - Why Is An Injunction Necessary?clsNo ratings yet

- Slab Shear CoefficientDocument1 pageSlab Shear CoefficientIsbel0% (1)

- Rebid 2016.06.29 08-UPRHS BOQREV PDFDocument10 pagesRebid 2016.06.29 08-UPRHS BOQREV PDFJude TicseNo ratings yet

- Vi. Roofing: Total Roof Area Effective WidthDocument3 pagesVi. Roofing: Total Roof Area Effective WidthMaria Rose Giltendez - BartianaNo ratings yet

- Muttoni 08 BDocument6 pagesMuttoni 08 B2011kumarNo ratings yet

- Case Study - Floating HousesDocument6 pagesCase Study - Floating HousesAkari MeiNo ratings yet

- A History of Wood and Craft in Japanese PDFDocument4 pagesA History of Wood and Craft in Japanese PDFibrahimNo ratings yet

- Rcug-Ahyz1 TC1Document38 pagesRcug-Ahyz1 TC1Site EngineeringtiaNo ratings yet

- Charles Correa The New LandscapeDocument116 pagesCharles Correa The New LandscapeAshish RajadhyakshaNo ratings yet

- AcronisBackupPC Datasheet en-USDocument2 pagesAcronisBackupPC Datasheet en-USe_gerlaNo ratings yet

- Scad A Substation AutomationDocument53 pagesScad A Substation Automationmaheashalwr0% (1)

- Total Control STG Data SheetDocument2 pagesTotal Control STG Data Sheetrebin1988No ratings yet

- Using C# To Send A HL7 MessageDocument2 pagesUsing C# To Send A HL7 Messagered_zackNo ratings yet

- EGK Road To SeethampetaDocument41 pagesEGK Road To SeethampetaD.V.Srinivasa RaoNo ratings yet

- CTMS Admin GuideDocument490 pagesCTMS Admin GuideArshiya BathoolNo ratings yet

- Sika Decap PDFDocument2 pagesSika Decap PDFthe pilotNo ratings yet

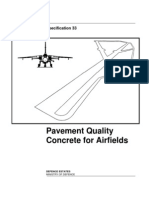

- PQCDocument77 pagesPQCAnkit MittalNo ratings yet

- Bugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumberDocument18 pagesBugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumbersdewssNo ratings yet

- Red Hat Enterprise Linux-7-SELinux Users and Administrators Guide-En-USDocument172 pagesRed Hat Enterprise Linux-7-SELinux Users and Administrators Guide-En-USNawfel GzamNo ratings yet

- Safety: Important Safety Instructions What Ships in The BoxDocument4 pagesSafety: Important Safety Instructions What Ships in The BoxMarraNo ratings yet

- PROFIBUS UFP11A Fieldbus InterfaceDocument44 pagesPROFIBUS UFP11A Fieldbus InterfacethordalsNo ratings yet

- Resume - Developer Marcelo CustódioDocument2 pagesResume - Developer Marcelo CustódioMarceloNo ratings yet

- AR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3Document1 pageAR-1 Lay-Out Plan: Master'S Bedroom Home Theater Bedrm. 3dante mortelNo ratings yet

- Signalling Manager User GuideDocument78 pagesSignalling Manager User GuideJayanta BanerjeeNo ratings yet

- Ernacular Rchitecture: L, B, G, IDocument10 pagesErnacular Rchitecture: L, B, G, IGeetika Agarwal100% (1)

- BRC Mesh Suppliers Malaysia)Document12 pagesBRC Mesh Suppliers Malaysia)Setsuna F. SeieiNo ratings yet

- Gift Shop: Management SystemDocument8 pagesGift Shop: Management SystemRyan MarasiganNo ratings yet

- CBP Wall - DWGDocument1 pageCBP Wall - DWGsambasivammeNo ratings yet

- Cebu CityDocument1 pageCebu CityRgne DiezNo ratings yet

- American Galvanizing Association PDFDocument81 pagesAmerican Galvanizing Association PDFআসিফহাসানখানNo ratings yet

- Concept Plan 2011 REviewDocument24 pagesConcept Plan 2011 REviewLina NgNo ratings yet

- MPLS Over IP TunnelDocument36 pagesMPLS Over IP TunnelAkhmad Badaruddin SaktiNo ratings yet

- Prisma-Plus Switchboard BrochureDocument16 pagesPrisma-Plus Switchboard Brochurem.abdelsalam772570No ratings yet

- 8255ADocument3 pages8255Ababa212No ratings yet

- C++ Q2Document85 pagesC++ Q2MohanNo ratings yet