Professional Documents

Culture Documents

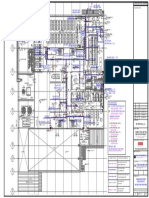

POCVN-MF-SD-CON-M-SEW-03 - Rev03 - Site Plan

POCVN-MF-SD-CON-M-SEW-03 - Rev03 - Site Plan

Uploaded by

Tôn Huỳnh ĐoànOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POCVN-MF-SD-CON-M-SEW-03 - Rev03 - Site Plan

POCVN-MF-SD-CON-M-SEW-03 - Rev03 - Site Plan

Uploaded by

Tôn Huỳnh ĐoànCopyright:

Available Formats

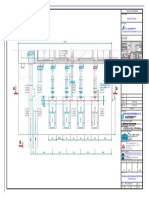

BOP=GL-1150

BOP=FL-1150

A1

A'

CONTROL POINT

97,380

Setback Line

Open Gutter

W=400(inside)

Set Back Line

Setback Line

5000

1000

70400

20005

5000

7500

7000

10800

8800

9000

7700

7800

5900

5900

9000

470

BOTTOM OF PIPE FROM COTE GROUND LEVEL

BOTTOM OF PIPE FROM COTE FINISH FLOOR LEVEL

SLOPE

SLOPE

Line

OPEN DRAIN

SLOPE

Shallow (H20)

107 MACHINE RM

FL-900 (GL+300)

108 CONTROL RM

FL-900 (GL+300)

POC PANEL

4000x1200x2200

MACHINE HATCH

W 0.8xH2.2

50 PACKAGE STORAGE

CH=6000

SLOPE

10 ton

20 ton (W=2.5mx D=3m)

4 ton

4 ton

4 ton

4 ton

4 ton

4 ton

5 ton

3 ton

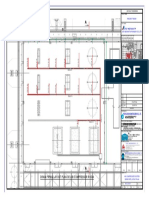

5 ANTIROOM

CH=6000

DOOR WITH VINYL CURTAI,FL+700

Set Back Line

MACHINE HATCH

48 CARTONING RM

CH=3500

W 2.5xH2.5

2-2 SORTING RM 2

CH=3500

7-2 PRODUCT COLD STORAGE

500kg

300kg

300kg

CH=11500

Opening

Air curtain

Air curtain

3-2 PRECOOLING RM 2

CH=6000

1-2 SHIPPING RM

CH=6000

SUBMERSIBLEE PUMP

3m3/h- 12mH20 x2Nos

SLOPE

8-c

Open Gutter

W=300(inside)

Set Back Line

Opening

1,700

HATCH (REMOVABLE PANEL) WITH KEY

46 PACKAGE

CH=3500

45 PACKAGE

CONNECT TO EXTERNAL PIPING

MATERIAL RM2

MATERIAL RM 1

CH=3500

500kg

2,910

(BY CIVIL)

2,460

MACHINE HATCH

W 0.8xH2.2

ABOVE CEILING

SL

OP

SLOPE

WASHING POOL W1.2 x 3.6m

FL-200

8.115

35 DISINFECTING RM 2-2

CH=3500

WASHING POOL W1.2 m

FL-200

H

P

BOP=GL-800

43 PROCESSING RM 2

CH=3500

44 FUTURE PROCESSING RM

CH=3500

DOOR OPENING FULL TIME

42 PREPROCESSING RM 2 ( 170 PERSONS)

CH=3500

33 DISINFECTING RM 1-2

CH=3500

WASHING POOL W1.2 x 3.6m

FL-200

500kg

7-1 MATERIAL COLD STORAGE

HDPE DN65

BOP=GL-500

86,400

UP

UP

CH=11500

500kg

PPR DN80

TO TK09 (WWTP)

GL+500

HANG ON WWTP'S WALLS

SUBMERSIBLE PUMP

20m3/h-10mH20 x2Nos

QC Table

40 SCALE RM 2

MACHINE HATCH

QC Table

Line

W 2.5xH2.5

Air curtain

39 SCALE RM 1

INSPECTION MANHOLE (BY CIVIL)

HDPE DN200, i=0.5%

BOP=GL-1100

MH1

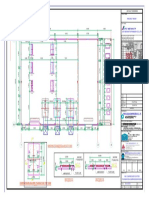

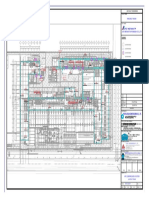

27 TEMPORARY

STORAGE 2

CH=3500

Above

1000kg

Ceiling

23 WASHING RM 2-2

37 CHEMICAL RM 2

26 TEMPORARY

STORAGE 1

CH=3500

21 WASHING RM 1-2

500kg

CH=3500

1000kg

36 CHEMICAL RM 1

CH=3500

BOP=GL-1010

BOP=GL-950

STERILIZE 02

STERILIZE 03

2,500

1,500

BOP=GL-900

ICE MACHINE 1

Air curtain

SUBMERSIBLE PUMP

CONNECT TO IP SEWAGE

101,600

BOP=GL-850

HEADTER TANK 700LIT x2

EXHAUST DUCT 300CMH

MACHINE HATCH

W 0.8xH2.2

ICE MACHINE 2

2,350

2,350

1,100

1,900

15m3/h-15mH20 x2Nos

300kg

MANHOLE

29,900

BELT CUTTING AND SKIN OFF

1,000

1,400

1,000

1,400

1,000

3,914 Sterize shower

UP

UP

17.000

28 ROAST RM

CH=3500

1,200

500kg

2,600

BLANCHING

COOLING

30 PREPROCESSING RM 2 ( 50 PERSONS)

CH=3500

1,400 1,100 1,400

CH=3500

31 FUTURE PREPROCESSING RM

CH=3500

7.5 ton

2,300

1,100

34 DISINFECTING RM 2-1

2,500

2,300

BELT CUTTING AND SKIN OFF

300kg

32 DISINFECTING RM 1-1

CH=3500

3,400

MH3

MH2

1,400

1,500

MH5

SOAKING

1,100

ABOVE CEILING

2,300

3-1 PRECOOLING RM 1

CH=6000

4 COLD

300kg

STORAGE OFFICE

CH=2700

DEFROSTING AND

1,400

MH4

2,500

2,300

1,100

300kg

STEEL STAIR

Air curtain

STERILIZE 01

WASHING POOL W1.2 x 3.6m

FL-200

Air curtain

300kg

300kg CH=3500

WASHING POOL W1.2 m

FL-200

300kg

OUT

(BY CIVIL)

SLOPE 2%

SLOPE 2%

SLOPE 2%

SLOPE

18 SUB MATERIAL RM2

CH=3500

22 WASHING RM 2-1

CH=3500

16 DEFROSTING RM 2

CH=3500

MACHINE HATCH

W 2.5xH2.5

17 CHILLED

STORAGE

CH=3500

20 WASHING RM 1-1

CH=3500

15 DEFROSTING RM 1

CH=3500

6 SUB MATERIAL STORAGE

2-1 SORTING RM 1

CH=6000

HDPE

HDPE DN80

SLOPE 2%

1-1 RECIEVING RM

CH=6000

ELEC.DN65

Air curtain

3,200

STATION (EXISTING)

BOP=GL-1000

i=2%

slope

i=2%

slope

Air curtain

i=2%

slope

6.000

SLOPE

SLOPE

SLOPE

8 UNPACKING RM

CH=3500

300kg

1,080

1.080

SLOPE

1,700

SLOPE

SLOPE

SLOPE

SLOPE

MK01B

TK05B

TK11

TK10A

TK05A

MACHINE HATCH

W 2.5xH2.5

FLATE AREA

1.700 CONCRETE SLOPE

WP02A/B

9 PRE WASTE CHILLED RM

CH=3500

NEED DRAIN PIT INSIDE

WASTE CHILLED RM

10 WASTE CHILLED RM

FL-900 (GL+300)

CH=4400

11 PRE WASTE RM

SLOPE

CH=3500

12 WASTE STORAGE RM

FL-900 (GL+300)

CH=4400

NEED DRAIN PIT INSIDE

WASTE STORAGE RM

NEED DRAIN PIT INSIDE

DEFROSTING RM 2

NEED DRAIN PIT INSIDE

DEFROSTING RM 1

Line

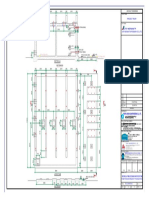

TK09

TK04

TK01

SP02A/B

OPENING

500x500

TK01

MK01A

TK06B

TK06A

WP01A/B

TK10B

TK03B

SD2

-

ND1

-

TK08

TK03A

ND1

-

ND1

-

SD1

-

SD1

-

TK07

TK13

PPR DN65

PPR DN80

TK12

TK10C

BOP=GL-1000

PPR DN65

BOP=GL+1000

SP01A/B

BOP=GL+1000

PPR DN80

OPENING

500x500

TRANSFORM YARD

ELECTRICAL ROOM

(FL0.00)ASL+3000

(Conc. steel trowel w/ grey hardener)

GENERATOR ROOM

(FL0.00)ASL+3000

(Conc. steel trowel w/ grey hardener)

MAINTENANCE ROOM

(FL0.00)ASL+3000

(Conc. steel trowel w/ grey hardener)

Louver

Set Back Line

(BY CIVIL)

-

Louver

-

Louver

-

Louver

-

SP-07/08-GF

BOP=-500

BOP=GL+300

PPR DN80

BOP=GL+500

BOP=GL+700

PPR DN80

(BY CIVIL)

SUBMERSIBLE PUMP

3m3/h- 10mH20 x2Nos

PPR DN65

HDPE DN150, i = 1%

BOP=-400

HDPE DN65

BOP=GL+1000

BOP=GL-550

VP-uPVC-40A

BOP=GL-450

97,600

/ FROM WWTP

HANG ON WWTP'S WALLS

INDUSTRIAL WASTE WATER

TREATMENT PLAN

SEPTIC TANK (BY CIVIL)

101,750

LEGEND DESCRIPTION

WASTE WATER PIPE

SOIL DRAIN PIPE

PROCESS WASTE PIPE

VENT PIPE

KITCHEN PIPE

CONSTRUCTION DRAWING

03

02

01

Rev

17 OCT 2019

27 SEP 2019

10 JULY 2019

CLIENT NAME:

PROJECT NAME:

DATE

FOR CONSTRUCTION

FOR CONSTRUCTION

FOR APPROVE

DESCRIPTION

Lot 16A8-1 & 16A14c, TRA NOC 1 INDUSTRIAL ZONE,

MAIN-CONTRACTOR:

CONTRACTOR:

BINH THUY DIST, CAN THO CITY

2-2-8, KORAKU, BUNKYO-KU TOKYO (112-8576) JAPAN

TEL: +81-338177182 FAX: +81-338177642

PREPARED

DRAWING TITLE:

DWG No:

A3

OFFICE: 17 BUI VAN BA ST., TAN THUAN DONG WARD, DIST.7, HCMC, VIET NAM

REP. OFFICE: 6TH FLOOR, MELODY TOWER, 422-424 UNG VAN KHIEM ST.,

WARD 25, BINH THANH DIST, HCMC, VIET NAM

SCALE: 1/700

CHECKED APPROVED

Rev: 03

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Historical Development Summary of Automatic Cannon Caliber Ammunition 20-30mm by Dale DavisDocument215 pagesHistorical Development Summary of Automatic Cannon Caliber Ammunition 20-30mm by Dale DavisAmmoResearchNo ratings yet

- XMP1 System Description R5.5 PDFDocument374 pagesXMP1 System Description R5.5 PDFIan CutinNo ratings yet

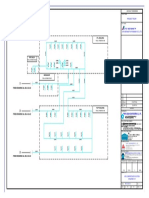

- (For Double Column) (For Double Column) (For Single Column) (For Double Column Inside)Document1 page(For Double Column) (For Double Column) (For Single Column) (For Double Column Inside)Tôn Huỳnh ĐoànNo ratings yet

- M U PW 11Document1 pageM U PW 11Tôn Huỳnh ĐoànNo ratings yet

- From Drawing: No. M-U-PW-01Document1 pageFrom Drawing: No. M-U-PW-01Tôn Huỳnh ĐoànNo ratings yet

- Pump Room: Project RubyDocument1 pagePump Room: Project RubyTôn Huỳnh ĐoànNo ratings yet

- (For Single Column) (For Single Column) (For Single Column) (For Single Column)Document1 page(For Single Column) (For Single Column) (For Single Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- As Built Drawing: This AreaDocument1 pageAs Built Drawing: This AreaTôn Huỳnh ĐoànNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- As Built Drawing: Project RubyDocument1 pageAs Built Drawing: Project RubyTôn Huỳnh ĐoànNo ratings yet

- (For Double Column) (For Double Column) Point of Use - 5 Typical Details (For Double Column) Point of Use - 6 Typical DetailsDocument1 page(For Double Column) (For Double Column) Point of Use - 5 Typical Details (For Double Column) Point of Use - 6 Typical DetailsTôn Huỳnh ĐoànNo ratings yet

- (For Single Column) (For Single Column) (For Double Column) (For Single Column)Document1 page(For Single Column) (For Single Column) (For Double Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- (For Double Column) (For Double Column Inside) (For Double Column Inside) (For Double Column Inside)Document1 page(For Double Column) (For Double Column Inside) (For Double Column Inside) (For Double Column Inside)Tôn Huỳnh ĐoànNo ratings yet

- (For Single Column) (For Single Column) (For Single Column) (For Single Column)Document1 page(For Single Column) (For Single Column) (For Single Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- Drain Piping Layout Plan of Air Compressor RoomDocument1 pageDrain Piping Layout Plan of Air Compressor RoomTôn Huỳnh ĐoànNo ratings yet

- Main Building: Layout PlanDocument1 pageMain Building: Layout PlanTôn Huỳnh ĐoànNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- As Built Drawing: Machine Foundation Layout PlanDocument1 pageAs Built Drawing: Machine Foundation Layout PlanTôn Huỳnh ĐoànNo ratings yet

- (For Double Column) (For Single Column) (For Single Column) (For Single Column)Document1 page(For Double Column) (For Single Column) (For Single Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- From (DRAWING: No. M-U-CA-01) : Project RubyDocument1 pageFrom (DRAWING: No. M-U-CA-01) : Project RubyTôn Huỳnh ĐoànNo ratings yet

- POCVN-MF-SD-CON-M-SEW-05 - Rev03 - 2nd FloorDocument1 pagePOCVN-MF-SD-CON-M-SEW-05 - Rev03 - 2nd FloorTôn Huỳnh ĐoànNo ratings yet

- CPL Building: Project RubyDocument1 pageCPL Building: Project RubyTôn Huỳnh ĐoànNo ratings yet

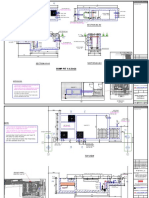

- Top View Section A2-A2: SUMP PIT 1 (1.5m3)Document4 pagesTop View Section A2-A2: SUMP PIT 1 (1.5m3)Tôn Huỳnh ĐoànNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- POCVN-MF-SD-CON-M-SEW-06 07 - Rev03 - Septic TankDocument3 pagesPOCVN-MF-SD-CON-M-SEW-06 07 - Rev03 - Septic TankTôn Huỳnh ĐoànNo ratings yet

- POCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorDocument5 pagesPOCVN-MF-SD-CON-M-SEW-04 - Rev03 - 1st FloorTôn Huỳnh ĐoànNo ratings yet

- Legend Description: Date Description Rev Client NameDocument2 pagesLegend Description: Date Description Rev Client NameTôn Huỳnh ĐoànNo ratings yet

- POCVN-MF-SD-CON-M-SEW-21 - Rev03 - Typical DetailDocument1 pagePOCVN-MF-SD-CON-M-SEW-21 - Rev03 - Typical DetailTôn Huỳnh ĐoànNo ratings yet

- Chemistry FullDocument7 pagesChemistry FullrimshaNo ratings yet

- Geotechnical Engineering 8 Braced Cuts: Sit 1 Sit 3Document2 pagesGeotechnical Engineering 8 Braced Cuts: Sit 1 Sit 3Hassan SabiNo ratings yet

- Human Lymphocyte Culture and Chromosome Analysis: ProtocolDocument8 pagesHuman Lymphocyte Culture and Chromosome Analysis: ProtocoldsadaNo ratings yet

- Ecological Consideration of SiteDocument83 pagesEcological Consideration of SitePJ Sepanton Bierneza67% (30)

- Colonial MentalityDocument2 pagesColonial MentalityInnaNo ratings yet

- Jbase Editor Find and ReplaceDocument1 pageJbase Editor Find and ReplaceFolakunmi OjemuyiwaNo ratings yet

- GEBCO's Global Gridded Bathymetric Data Sets: Seabed 2030 Project Nippon Foundation GebcoDocument13 pagesGEBCO's Global Gridded Bathymetric Data Sets: Seabed 2030 Project Nippon Foundation GebcoJulrialdinNo ratings yet

- Introduction To Mobile RobotsDocument45 pagesIntroduction To Mobile RobotsSELVAKUMAR RNo ratings yet

- Physics Sample Paper 10 - 231221 - 091030Document19 pagesPhysics Sample Paper 10 - 231221 - 091030derexax756No ratings yet

- Drafting Patterns For WomenDocument13 pagesDrafting Patterns For Womenzzz2299100% (2)

- Casio px-130 Ver.4 SMDocument60 pagesCasio px-130 Ver.4 SMPoon Electronic Training CentreNo ratings yet

- Cognitive Engagement StyleDocument19 pagesCognitive Engagement StylesnsclarkNo ratings yet

- Example Design of Steel Roof Truss Filetype PDFDocument2 pagesExample Design of Steel Roof Truss Filetype PDFAmanda40% (10)

- YDS 2016 İlkbahar Deneme - 2Document15 pagesYDS 2016 İlkbahar Deneme - 2Zeynal Abidin ŞabaşNo ratings yet

- DMC 1946Document88 pagesDMC 1946Thangavel MuruganNo ratings yet

- Debug 1214Document3 pagesDebug 1214RedyNo ratings yet

- General Structure of Transportation ProblemDocument9 pagesGeneral Structure of Transportation ProblemRishab Jain 2027203No ratings yet

- Civil Law MTDocument28 pagesCivil Law MTKaira Marie CarlosNo ratings yet

- Effects of Sleep Pattern, Duration, and Quality On Premenstrual Syndrome and Primary Dysmenorrhea in Korean High School GirlsDocument14 pagesEffects of Sleep Pattern, Duration, and Quality On Premenstrual Syndrome and Primary Dysmenorrhea in Korean High School Girlssahariam.palaguyanNo ratings yet

- JAYSON Feasibility 3 PDFDocument68 pagesJAYSON Feasibility 3 PDFReyes Je AnNo ratings yet

- 2SC5200Document6 pages2SC5200Franz RamosNo ratings yet

- Age of IndustrialisationDocument10 pagesAge of IndustrialisationsssssssssssNo ratings yet

- SAP Finance NotesDocument131 pagesSAP Finance NotesMohammed MisbahuddinNo ratings yet

- Digital Image Processing: Lecture # 2 FundamentalsDocument41 pagesDigital Image Processing: Lecture # 2 FundamentalsAhsanNo ratings yet

- Invoice ScissorsDocument1 pageInvoice ScissorsAlex ClunieNo ratings yet

- Cranial Nerves 2016-36782Document51 pagesCranial Nerves 2016-36782Danu Postolache100% (1)

- Amhara Civil Service Bureau DMAUN 2013 Final 2Document46 pagesAmhara Civil Service Bureau DMAUN 2013 Final 2Abebay BishawNo ratings yet

- Open Ended Lab For Soil MechanicsDocument27 pagesOpen Ended Lab For Soil Mechanicsعثمان محيب احمدNo ratings yet