Professional Documents

Culture Documents

Section 3108 F

Uploaded by

Trung Đỗ NguyễnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 3108 F

Uploaded by

Trung Đỗ NguyễnCopyright:

Available Formats

DIVISION 8

SECTION 3108F - FIRE PREVENTION, DETECTION, AND 11. Rescue for terminal and vessel personnel [8.1]

SUPPRESSION

12. Cooling water for pipelines and valves exposed to the

heat

3108F.1 GENERAL. This section provides minimum

13. Contingency planning when supplemental fire support

standards for fire prevention, detection, and suppression at

is not available. Mutual aid agreements can apply to

MOTs. See Subsection 3101F.3 for definitions of “new” (N)

water and land based support

and “existing” (E).

14. Consideration of adverse conditions, such as electrical

3108F.2 Hazard Assessment and Risk Analysis power failure, steam failure, fire pump failure, an

earthquake or other damage to the fire water system.

3108F.2.1 Fire Hazard Assessment and Risk Analysis

(N/E). A fire hazard assessment and risk analysis shall be The audit team shall review and field verify the fire-fighting

performed, considering the loss of commercial power, equipment locations and condition and may check its

earthquake and other relevant events. operability.

3108F.2.2 Fire Plan (N/E). A site-specific Fire Plan shall 3108F.2.3 Cargo Liquid and Fire Hazard Classifications

be prepared by a registered engineer or a competent fire (N/E). The cargo liquid hazard classes are defined in Table

protection professional. The plan shall consider the hazards 31F-8-1, as either High (HC) or Low (LC), depending on the

and risks identified per subsection 3108F.2.1 and shall flash point.

include, but not be limited to, the elements of pre-fire

planning as discussed in Section 9 of [8.1] and Chapter 3 of Fire hazard classifications (Low, Medium or High) are

[8.2]. The Fire Plan shall include goals, resources, defined in Table 31F-8-2, and are based on the cargo liquid

organization, strategy and tactics, including the following: hazard class and the sum of all stored and flowing volumes,

prior to the Emergency Shut Down System (ESD) stopping

the flow of oil.

1. MOT characteristics (e.g. tanker/manifold, product

pipelines, etc.)

The stored volume is the sum of the HC and LC liquid hazard

2. Product types and fire scenarios class piping volumes (VSH and VSL), if the piping is not

3. Possible collateral fire damage to adjacent facilities stripped.

4. Fire-fighting capabilities, including availability of water

(flow rates and pressure), foam type and associated During a pipeline leak, a quantity of oil is assumed to spill at

shelf life, proportioning equipment, and vehicular the maximum cargo flow rate until the ESD is fully effective.

access [8.1, 8.3] The ESD valve closure is required to be completed in 60

seconds if installed prior to November 1, 1980 or in 30

5. The selection of appropriate extinguishing agents [8.1, seconds if installed after that date (2 CCR 2380 (h) (3))[8.3].

8.2] The flowing volume is the sum of the HC and LC liquid

6. Calculation of water and foam capacities, as applicable, hazard class volumes (VFH and VFL), and shall be calculated

consistent with area coverage requirements [8.1] as follows:

7. Coordination of emergency efforts

8. Emergency escape routes [8.2, 8.3] VF = QC x ∆t x (1/3,600) (8-1)

9. Requirements for fire drills, training of wharf personnel,

and the use of non-fixed equipment Where: VF = Flowing Volume (VFH or VFL ) [bbl]

10. Life safety QC = Cargo Transfer Rate [bbl/hr]

∆t = ESD time, 30 or 60 seconds

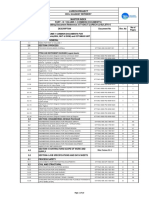

TABLE 31F-8-1

CARGO LIQUID HAZARD CLASS

Class Criterion Reference Examples

Low Flash Point

ISGOTT (Chapter 15, [8.4]) – Non-Volatile #6 Heavy Fuel Oil, residuals, bunker

(LC) 140oF

High Flash Point

ISGOTT (Chapter 15, [8.4]) – Volatile Gasoline, JP4, crude oils

(HC) <140oF

TABLE 31F-8-2

FIRE HAZARD CLASSIFICATIONS

Stored Volume (bbl) Flowing Volume (bbl)

Class Criteria (bbls)*

Stripped VSL VSH VFL VFH

LOW y n n y y VFL VFH , & VT 1200

LOW n y n y n VSL + VFL 1200

MEDIUM n n y n y VSH + VFH 1200

MEDIUM y n N y y VFH > VFL , & VT 1200

HIGH n n y n y VSH + VFH >1200

HIGH y n n y y VT > 1200

HIGH n y y y y VT > 1200

HIGH n y n y n VSL + VFL > 1200

HIGH n n y n y VSH + VFH > 1200

y yes

n no

Stripped product purged from pipeline following product transfer event.

VSL stored volume of low hazard class product

VSH stored volume of high hazard class product

VFL volume of low hazard class product flowing through transfer line during 30 - 60 secs. ESD.

VFH volume of high hazard class product flowing through transfer line during 30 - 60 secs. ESD.

VT VSL + VSH + VFL + VFH = Total Volume (stored and flowing)

* Quantities are based on maximum flow rate, including simultaneous transfers.

3108F.3 Fire Prevention 2. Be clearly identified together with associated

pipeline (N/E).

3108F.3.1 Ignition Source Control 3. Have adequate lighting (N/E).

4. Be provided with communications or control

3108F.3.1.1 Protection from ignition by static circuits to synchronize simultaneous closure of

electricity, lightning or stray currents shall be in the ESD system with the shut down of loading

accordance with API RP 2003 [8.5](N/E). pumps (N).

3108F.3.1.2 Requirements to prevent electrical 5. Have a manual reset to restore the SIV system to

arcing shall be in conformity with 2 CCR 2341 [8.3] an operational state after each shut down event

(N/E). (N).

3108F.3.1.3 Multi-berth terminal piers shall be 6. Be provided with thermal expansion relief to

constructed so as to provide a minimum of 100 ft accommodate expansion of the liquid when

between adjacent manifolds (N). closed. Thermal relief piping shall be properly

sized and routed around the SIV, into the

3108F.3.2 Emergency Shutdown Systems. An downstream segment of the pipeline or into other

essential measure of fire prevention is containment (N/E).

communications in conjunction with the emergency

shutdown. The ESD and isolation system shall

SIVs installed in pipelines carrying hazard class, H C

conform to 2 CCR 2380 (h) [8.3] and 33 CFR 154.550

liquids, or at a MOT with a risk classification “Medium”

[8.6]. An ESD system shall include or provide:

or “High” (see Table 31F-4-1), shall be equipped with

“Local” and “Remote” actuation capabilities. Local

1. An ESD valve, located near the dock manifold control SIVs may be motorized and/or operated

connection or loading arm (N/E). manually (N).

2. ESD valves, with “Local” and “Remote” actuation

capabilities (N).

3. Remote actuation stations strategically located,

so that ESD valve(s) may be shut within required

times (N).

4. Multiple actuation stations installed at strategic

locations, so that one such station is located

more than 100 feet from areas classified as Class

I, Group D, Division 1 or 2 [8.7]. Actuation

stations shall be wired in parallel to achieve

redundancy and arranged so that fire damage to

one station will not disable the ESD system (N).

5. Communications or control circuits to

synchronize simultaneous closure of the Shore

Isolation Valves (SIVs) with the shut down of

loading pumps (N).

6. A manual reset to restore the ESD system to an

operational state after each initiation (N).

7. An alarm to indicate failure of the primary power

source (N).

8. A secondary (emergency) power source (N).

9. Periodic testing of the system (N).

10. Fire proofing of motors and control-cables that

are installed in areas classified as Class I, Group

D, Division 1 or 2 [8.7]. Fire proofing shall, at a

minimum, comply with the recommendations of

API Publication 2218 (see Section 6 of [8.8]) (N).

3108F.3.3 Shore Isolation Valves (SIV). Shore

Isolation Valve(s) shall:

1. Be located onshore for each cargo pipeline. All

SIVs shall be clustered together, for easy access

(N).

1. Marine structures including the pier/wharf and

TABLE 31F-8-3

MINIMUM FIRE SUPPRESSION PROVISIONS (N/E)

Vessel and Cargo

Fire Hazard Classification

Liquid Hazard Class MINIMUM PROVISIONS

(From Table 31F-8-2)

(From Table 31F-8-1)

Barge with LC (including 500 gpm of water

LOW drums) 2 x 20 lb. portable dry chemical and 2 x 110 lb. wheeled dry

chemical extinguishers or the equivalent.

Barge with HC (including 1,500 gpm of water

drums) 2 x 20 lb. portable dry chemical and 2 x 165 lb. wheeled dry

LOW

Tankers < 50 KDWT, chemical extinguishers or the equivalent.

handling LC or HC

Tankers < 50 KDWT 1,500 gpm of water

MEDIUM handling LC 2 x 20 lb. portable dry chemical and 2 x 165 lb. wheeled dry

chemical extinguishers or the equivalent.

2,000 gpm of water

Tankers < 50 KDWT,

MEDIUM 4 x 20 lb. portable dry chemical and 2 x 165 lb. wheeled dry

handling HC

chemical extinguishers or the equivalent.

3,000 gpm of water

Tankers < 50 KDWT,

HIGH 4 x 20 lb. portable dry chemical and 2 x 165 lb. wheeled dry

handling LC or HC

chemical extinguishers or the equivalent. .

3,000 gpm of water

Tankers > 50 KDWT,

LOW, MEDIUM, HIGH 6 x 20 lb. portable dry chemical and 4 x 110 lb. wheeled dry

handling LC or HC

chemical extinguishers or the equivalent.

Notes: LC and HC are defined in Table 31F-8-1.

KDWT = Dead Weight Tons (Thousands)

3108F.4 Fire Detection. An MOT shall have a approach trestle

permanently installed automated fire detection or 2. Terminal cargo manifold

sensing system (N).

3. Cargo transfer system including loading arms,

3108F.5 Fire Alarms. Automatic and manual fire hoses and hose racks

alarms shall be provided at strategic locations. The 4. Vessel manifold

fire alarm system shall be arranged to provide a visual 5. Sumps

and audible alarm that can be readily discerned by all

6. Pipelines

personnel at the MOT. Additionally, visual and

audible alarms shall be displayed at the Facility’s 7. Control Stations

Control Center (N/E).

If the fire alarm system is integrated with the ESD 3108F.6.2 Fire Hydrants. Hydrants shall be located

system, the operation shall be coordinated with the not greater than 300 ft. apart, along the wharf and

closure of SIVs, block valves and pumps to avoid approach trestle [Section 4.2.3 of API 2001 [8.1].

adverse hydraulic conditions (N/E). Additional hose connections shall be provided at the

base of fixed monitors and upstream of the water and

foam isolation valves. Connections shall be

3108F.6 Fire Suppression. Table 31F-8-3 gives the

accessible to fire trucks or mutual aid equipment as

minimum provisions for fire-water flow rates and fire

identified in the Fire Plan (N).

extinguishers. The table includes consideration of the

fire hazard classification (Low, Medium or High), the

Hydrants and hoses shall be capable of applying two

cargo liquid hazard class (Low or High) and the

independent water streams covering the cargo

vessel or barge size. The minimum provisions may

manifold, transfer system, sumps and vessel manifold

have to be augmented for multi-berth terminals or

(N/E).

those conducting simultaneous transfers, in

accordance with the risks identified in the Fire Plan.

3108F.6.3 Fire Water. The source of fire water

should be reliable and provide sufficient capacity as

3108F.6.1 Coverage (N/E). The fire suppression

determined in the fire plan.

system shall provide coverage for:

1. All wet systems shall be kept pressurized (jockey

pump or other means) (N/E).

2. Wet system headers shall be equipped with a may not provide more than one-quarter of the total

low-pressure alarm wired to the control room (N). water requirements specified in the Fire Plan.

3. Fire pumps shall be installed at a distance of at

least 100 ft. from the nearest cargo manifold area Additionally, supplementary systems shall not be

(N). considered in a Fire Plan, unless available within 20

minutes following the initiation of a fire alarm. Mutual

4. Hose connections for fireboats or tugboats shall aid may be considered as part of the supplemental

be provided on the MOT fire water line. system.

Connections shall be installed at a safe access

distance from the high-risk areas such as sump,

manifold and loading arms (N/E). 3108F.7 References.

[8.1] American Petroleum Institute, 1998, API

3108F.6.4 Foam Supply (N/E). Product Recommended Practice 2001 (API RP

flammability, foam type, water flow rates and 2001), “Fire Protection in Refineries,” 7th ed.,

application duration shall be considered in foam Washington, D.C.

supply calculations.

[8.2] Oil Companies International Marine Forum

Fixed foam proportioning equipment shall be located (OCIMF), 1987, “Guide on Marine Terminal

at a distance of at least 100 ft. from the high-risk Fire Protection and Emergency Evacuation,”

areas such as sump, manifold and loading arms, 1st ed., Witherby, London.

except where hydraulic limits of the foam delivery

system require closer proximity. [8.3] 2 CCR 2300-2407 (Title 2, California Code of

Regulations, Sections 2300-2407).

MOTs shall have a program to ensure that foam is

replaced according to the manufacturer’s [8.4] International Chamber of Shipping (ICS), Oil

recommendations. Companies International Marine Forum

(OCIMF), International Association of Ports

3108F.6.5 Fire Monitor Systems. Fire monitors and Harbors (IAPH), 1996, “International

shall be located to provide coverage of MOT cargo Safety Guide for Oil Tankers and Terminals

manifolds, loading arms, hoses, and vessel manifold (ISGOTT),” 4th ed., Witherby, London.

areas. This coverage shall provide at least two

independent streams of water/foam. Monitors shall be [8.5] American Petroleum Institute, 1998, API

located to provide an unobstructed path between the Recommended Practice 2003 (API RP

monitor and the target area (N/E). 2003), “Protection Against Ignitions Arising

If the vessel manifold is more than 30 ft. above the Out of Static, Lightning, and Stray Currents,”

wharf deck, the following factors shall be considered, 6th ed., Washington, D.C.

in order to determine if monitors located on elevated

masts or towers are required (N/E): [8.6] 33 CFR 154.550 (Title 33, Code of Federal

1. Maximum tanker freeboard Regulations, Section 154.550).

2. Tidal variations

[8.7] National Fire Protection Association, 2002,

3. Pier/wharf/loading platform elevation NFPA 70, “National Electric Code,” Quincy,

4. Winds MA.

5. Fire water line pressure

[8.8] American Petroleum Institute, 1999, API

Sprinklers and/or remotely controlled water/foam Publication 2218, “Fireproofing Practices in

monitors shall be installed to protect personnel, Petroleum and Petrochemical Processing

escape routes, shelter locations and the fire water Plants,” 2nd ed., Washington, D.C.

system (N).

Isolation valves shall be installed in the fire water and Authority: Sections 8755 and 8757, Public

the foam lines in order to segregate damaged Resources Code.

sections without disabling the entire system. Readily

accessible isolation valves shall be installed 100 – Reference: Sections 8750, 8751, 8755 and

150 ft from the manifold and the loading arm/hose 8757, Public Resources Code.

area (N).

3108F.6.6 Supplemental Fire Suppression

Systems (E). A supplemental system is an external

waterborne or land-based source providing

suppressant and equipment. Supplemental systems

You might also like

- Sample Calculation For Ammonia Tank - API 620 11th EdDocument43 pagesSample Calculation For Ammonia Tank - API 620 11th EdAde FaruroziNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- TestingTransformerDifferentialRelays PDFDocument64 pagesTestingTransformerDifferentialRelays PDFEdwin Cob Guri100% (2)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- CLPS - 11kV GSUT and GEN Protection CT Sizing Calculation Rev ADocument5 pagesCLPS - 11kV GSUT and GEN Protection CT Sizing Calculation Rev ATosikur Rahman100% (1)

- Inland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Document1,008 pagesInland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Advocate100% (1)

- EPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Document10 pagesEPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Structures ProductionNo ratings yet

- USArmy ICOM Radio MaintenanceDocument444 pagesUSArmy ICOM Radio Maintenancelcnblzr3877100% (1)

- Aircraft Instruments DataDocument61 pagesAircraft Instruments DataGabriel DediuNo ratings yet

- Att. - 04 Vessel Liquid Volume and Wetted Area CalcDocument3 pagesAtt. - 04 Vessel Liquid Volume and Wetted Area Calcgopal krishnanNo ratings yet

- Wind Load Calculation For Touatgaz Project - 01Document5 pagesWind Load Calculation For Touatgaz Project - 01Oscar Paredes GarcíaNo ratings yet

- Inland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Document664 pagesInland and Coastal Large Tug (LT) NSN 1925-01-509-7013 (EIC XAG)Advocate100% (1)

- Fire Water Demand PDFDocument28 pagesFire Water Demand PDFOmar TocmoNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Gas Detector InstallationDocument11 pagesGas Detector InstallationOmar TocmoNo ratings yet

- Bollard Pull CalculationsDocument7 pagesBollard Pull CalculationsᎮᏂᎩᏗᎥ ᏇᏗᎥ ᏗᏬᏁᎶ75% (4)

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Fire Water Demand CalculationDocument16 pagesFire Water Demand CalculationHSEI Jatim - NSU 2020100% (2)

- Dust Extract SystemDocument17 pagesDust Extract Systemmathan_aeNo ratings yet

- Muros Cortafuego IEC 61936-1Document9 pagesMuros Cortafuego IEC 61936-1Nicole Albornoz GonzálezNo ratings yet

- ENG Connecting DEC To MErcedes m102Document3 pagesENG Connecting DEC To MErcedes m102Vincent RenaNo ratings yet

- Doc. Eng. Temp. For CISEMDocument5 pagesDoc. Eng. Temp. For CISEMAgus MarpaungNo ratings yet

- IADC Equipment List - Semisub R0 (2010!04!28)Document27 pagesIADC Equipment List - Semisub R0 (2010!04!28)Rohith KommuNo ratings yet

- Gas Reception Terminal InformationDocument7 pagesGas Reception Terminal InformationkhadijaNo ratings yet

- Mitigation of Voltage Sag Using DVR Under Feedback and Feedforward Control SchemeDocument12 pagesMitigation of Voltage Sag Using DVR Under Feedback and Feedforward Control SchemeabhiNo ratings yet

- Wind InducedDocument62 pagesWind Inducedcen1510353No ratings yet

- ECP 11-0512c Schneider RN2, RN6, RN2c and RN6c With Vip 300 Test FormDocument14 pagesECP 11-0512c Schneider RN2, RN6, RN2c and RN6c With Vip 300 Test FormCata CatalinNo ratings yet

- tpc8040 HDocument7 pagestpc8040 HMoises HernandezNo ratings yet

- Report On The Research Project OWID - OffshoreDocument3 pagesReport On The Research Project OWID - OffshoreaseNo ratings yet

- Ta7280p, Ta7281pDocument15 pagesTa7280p, Ta7281pivirgilNo ratings yet

- Supplemental InstructionsDocument25 pagesSupplemental InstructionsRobin HoodNo ratings yet

- Chapter 9 - Emergency Equipment and Evacuation ProceduresDocument41 pagesChapter 9 - Emergency Equipment and Evacuation ProceduresKelvinNo ratings yet

- FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019Document12 pagesFirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019ananthu.uNo ratings yet

- Comparing The Economic Feasibility of of PDFDocument15 pagesComparing The Economic Feasibility of of PDFNarayanan JayachandranNo ratings yet

- 1.a.3.a Aviation GB2013 FinalDocument51 pages1.a.3.a Aviation GB2013 FinalSenad BajrićNo ratings yet

- Choosing Surge Arresters - Merlin GerinDocument13 pagesChoosing Surge Arresters - Merlin Gerinjobpei2No ratings yet

- ABS 2010 SVR RCN1 Jul2010Document10 pagesABS 2010 SVR RCN1 Jul2010Marc FazioliNo ratings yet

- Copeland CR22K6E PFV 875 Submittal SheetDocument3 pagesCopeland CR22K6E PFV 875 Submittal SheetDraganNo ratings yet

- Rumaila Project: P102551-PC-HAC-001Document12 pagesRumaila Project: P102551-PC-HAC-001Jalal AlbadriNo ratings yet

- Product Bulletin Fisher VBL Volume Booster en 125388Document6 pagesProduct Bulletin Fisher VBL Volume Booster en 125388Omar Al SousliNo ratings yet

- Draft: HoltecDocument6 pagesDraft: HoltecYerania SalinasNo ratings yet

- TLP2301 Datasheet en 20160113Document11 pagesTLP2301 Datasheet en 20160113teomondoNo ratings yet

- pp03 Asep NSCP 2015 Update On ch2 Minimum Design LoadspdfDocument71 pagespp03 Asep NSCP 2015 Update On ch2 Minimum Design LoadspdfMira RuthNo ratings yet

- YWP111 - Application - Commissioning - Manual (2) .2012Document12 pagesYWP111 - Application - Commissioning - Manual (2) .2012maherNo ratings yet

- TPC8050-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter ApplicationsDocument7 pagesTPC8050-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter Applicationsjesus barriosNo ratings yet

- Dopler Speed Log Model DS-80 PDFDocument35 pagesDopler Speed Log Model DS-80 PDFKerri FosterNo ratings yet

- DCD 708Document18 pagesDCD 708ezbinNo ratings yet

- Gmdss Radio InsatallationDocument8 pagesGmdss Radio InsatallationHoàng VũNo ratings yet

- An TozziDocument38 pagesAn TozziHellen MartinssonNo ratings yet

- TPC8053-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter ApplicationsDocument7 pagesTPC8053-H: Switching Regulator Applications Motor Drive Applications DC-DC Converter ApplicationsGabriel EscamillaNo ratings yet

- F, N U N N N NN: T T T T T T T T TRDocument1 pageF, N U N N N NN: T T T T T T T T TRAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Transient Phenomena in Francis Turbine Power Plants: Interaction With The Power NetworkDocument11 pagesTransient Phenomena in Francis Turbine Power Plants: Interaction With The Power NetworkFabio FolpiniNo ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- VRVSelectionReport NMBC AHU VRV - Wiring DiagramDocument104 pagesVRVSelectionReport NMBC AHU VRV - Wiring DiagramlalwinNo ratings yet

- MP Avt 157 08Document14 pagesMP Avt 157 08Saeed ZamaniNo ratings yet

- Aircraft General DataDocument20 pagesAircraft General DataclebersjcNo ratings yet

- TQ KRT2 Manual Englisch Remote Control 2018Document20 pagesTQ KRT2 Manual Englisch Remote Control 2018hbalu007No ratings yet

- On-Load Tap-Changer OILTAP® G: Technical Data TD 48Document34 pagesOn-Load Tap-Changer OILTAP® G: Technical Data TD 48Ravindra AngalNo ratings yet

- Wave and Tidal EnergyFrom EverandWave and Tidal EnergyDeborah GreavesNo ratings yet

- Pump Hydro Storage PlantsDocument14 pagesPump Hydro Storage PlantsRisa RianiNo ratings yet

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- File 1620307458Document36 pagesFile 1620307458Paulo SergioNo ratings yet

- Equipmentname Serial Identifier Id Function Event Description Event State Associated Measure Date/TimeDocument3 pagesEquipmentname Serial Identifier Id Function Event Description Event State Associated Measure Date/TimeEngr Fahimuddin QureshiNo ratings yet

- Impact of Energy Structure On Carbon Emission and Economy of China inDocument11 pagesImpact of Energy Structure On Carbon Emission and Economy of China inKai GötzNo ratings yet

- Factori de Conversie PT LemnDocument4 pagesFactori de Conversie PT LemnnickybudauNo ratings yet

- Current Reference Generation Based On Next-Generation Grid Code Requirements of Grid-Tied Converters During Asymmetrical FaultsDocument14 pagesCurrent Reference Generation Based On Next-Generation Grid Code Requirements of Grid-Tied Converters During Asymmetrical FaultsXiaoxiao LiuNo ratings yet

- CE 3107-Hydraulics and Hydraulic StructuresDocument2 pagesCE 3107-Hydraulics and Hydraulic StructuresPranto KhanNo ratings yet

- Canadian - Solar Datasheet BiHiKu5 - CS3Y MB AG - ENDocument2 pagesCanadian - Solar Datasheet BiHiKu5 - CS3Y MB AG - ENQuang TuanNo ratings yet

- The Positive Effect of The Pyramid Phenomenon: Mircea GOLOȘIE Marinel COJOCARDocument7 pagesThe Positive Effect of The Pyramid Phenomenon: Mircea GOLOȘIE Marinel COJOCARAbhimanyu BhatiaNo ratings yet

- Effective ApertureDocument10 pagesEffective ApertureLeo HambirepiNo ratings yet

- מפרט רכש טורבינות - - BoBo - UTEXDocument8 pagesמפרט רכש טורבינות - - BoBo - UTEXYoninNo ratings yet

- Assignment-N0 2Document3 pagesAssignment-N0 2Anthonette DimayugaNo ratings yet

- 01 Natural Venting Smoke Management NFPA 204Document28 pages01 Natural Venting Smoke Management NFPA 204youssryNo ratings yet

- 6ztaa13-G3 Datasheet - enDocument8 pages6ztaa13-G3 Datasheet - enHERS14No ratings yet

- Charging System Troubleshooting: Identify The System To Be TestedDocument1 pageCharging System Troubleshooting: Identify The System To Be TestedEBNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson PhinniNo ratings yet

- Product Service Update 2011Document104 pagesProduct Service Update 2011fabbromauricioyahoo.com.arNo ratings yet

- THD-IZ - Dimension SheetDocument1 pageTHD-IZ - Dimension Sheetrachman hardianNo ratings yet

- Transformer Oil TestDocument3 pagesTransformer Oil TestROYAL GAMINGNo ratings yet

- Decarbonisation of Steam CrackersDocument7 pagesDecarbonisation of Steam CrackersAtharva OfficeNo ratings yet

- Sustainable Food Drying Technologies Based On Renewable Energy SourcesDocument16 pagesSustainable Food Drying Technologies Based On Renewable Energy SourcesMarina HardiyantiNo ratings yet

- House Extension Design Guide: South Dublin County Council Planning DepartmentDocument38 pagesHouse Extension Design Guide: South Dublin County Council Planning DepartmentAdrian TurcuNo ratings yet

- AAN - 006-06 - Informações de Segurança Intrínseca para AprovaçõesDocument2 pagesAAN - 006-06 - Informações de Segurança Intrínseca para AprovaçõesMario Ricardo CambraiaNo ratings yet

- Price List RetailsDocument16 pagesPrice List RetailsKishan AhirNo ratings yet

- FC 50 CalibracionDocument5 pagesFC 50 CalibracionSamuel CastilloNo ratings yet

- Asbuilt Drawing Km2-ModelDocument2 pagesAsbuilt Drawing Km2-ModelHanif HalimNo ratings yet