Professional Documents

Culture Documents

DPF Fat Reports

DPF Fat Reports

Uploaded by

Sudhakar Jay0 ratings0% found this document useful (0 votes)

12 views5 pagesOriginal Title

DPF FAT REPORTS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views5 pagesDPF Fat Reports

DPF Fat Reports

Uploaded by

Sudhakar JayCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

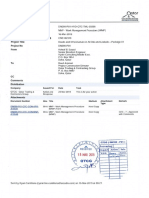

Po.Box.No.S0311,

Doha Precast Factory

Tel: 00974 44903836, Fax: 00974 44903835, Doha, State of Qatar, Email: mail@dohaprecast.com

Ail 3) cull sill Aa gall inca

EPOXY COATING THICKNESS

ecTRns

Revs date 01-442013

Report No. : (Ud - 2000] 2400-00) *

Project : Roads and Infrastructure in Al Ebb & Leabaib - Package 01

Client ‘ASHGHAL,

Consultant : HYDER Consulting Middle East

Contractor : Qatar Trading & Contracting Group

Pipe :_RCP (Jacking Pipe) BS 5911 P1 & BS EN 1916 - Class 120

[Test No 1 2 3 4 5

[Class of Pipe BS 5911 P | & BS EN 1916 Class 120

[Pipe Ref No. 6233

Date of Casting 10-0819

Date of Testing Q0-Obynd

|Age of Concrete-days:| 10

[Internal dia(mm) 2000

[Effective length (mm):| 3000 -

‘Vernier Caliper reading 1

1 Flo

2 430

3

|Ave J 20.

[Required (Minimum) | 400 400

Remarks Equipment : Di Vernier Caliper-Asset: DPF-LAB-CT-19-01 Cal. Due Date: 06-10-2019

Lined with GRP Liner

[Consultant [Remarks Contractor:

|Checked BY Tested By

Verified By

Approved By

Page 01 of OL

Doha Precast Factory

Hila All ll gl Aa gall gine

Po.Box.No.50311, Tel: 00974 44903836, Fax: 00974 44903835, Doha, State of Qatar, Email: mail@dohaprecast.com

PULL OFF TEST FOREENER / EPOXY COATING gece

Revs aa

0343013

Test No.CLo- Qoco/i4.9- 00)

Date of testing Q0-O1 19 Date of Casting = 19 -Oh 19

‘Type of Pipe : RCP (Jacking Pipe) BS 5911 P1 & BS EN 1916 - Class 120

Pipe Ref No. 6233 Age of Concrete: Days 19

Pipe dia + 2000/2400mm, Pipe Effective length: Soca mm

Project Details : Roads and Infrastructure in Al Ebb & Leabaib - Package 01

Client Details : ASHGHAL

Consultant : HYDER Consulting Middle Fast

Contractor : Qatar Trading & Contracting Group

[Description Reading REMARKS

Max. Reading in the Device 92 Mpa Dolly Dia 20mm

Result y& Nim?) /

Required 1.0 N/mm?

Remarks Equipment: Pull Off Tester- Asset:DPF-LAB-ET-01-08 Cal. Due Date: 12-10-2019

Lined with GRP Liner

[Consuttant Remarks Contractor:

IChecked BY [Tested By

Verified By

|Approved By

Doha Precast Factory 2 Agi SD) Gul gall Aa yall ha

0. NaH, Doha, Stato Qatar ee HONG Fa, Ea: ledoprestcom

mal Report of Finished Product Forno GOP -tae

ASTM C76 M (BS 5911 P-1/ ACPA Q Cast Fev. 01 Dated 0.042018

Fipeltdanhole Size 720002400 Report No: Cw Race] 200-0

FipaiManhole Class: RCP Uacking Pipe) BSS911 PI &BSENI916-Cass120 Checking Date? 20: 01, 2014

Project Details Roads and Infrastructure in Al Ebb & Leabaib - Package OL

(Gient Details = _ASHGHAL Date of Casting: 10 “Ol 2019

[Consultant HYDER Consulting Middle East

Contractor (Qatar Trading & Contracting Group

PipeiManhole # ‘Specifcatonmm)

us

or | 00.3

2990.

Lerten 30-3025

Length ae -

& | 90°

180"

SY are

Psp

so

[average Pep

[Average Pso.

30, >

End [90°

Barrel internal Dia | Ex {eon

End [20°

average: 00

o 0:

Internal Dia Socket oF oah aia 006

average: 2085 | 7

30 > oo

End [0° Hol

Barrel Outer Dia End | oor te af mone

End [20 a

lrrerage 544 =

Spigot Outer Dia oe fe

oF oFK 2076-2088

laverags: 10.

es

90 | 0 f

Pe 180° [1g Not Less Than-193

270° 12.00

lrrerage: a4 Z

e

or

[Concrete Cover = ees

210"

Verage

[Remarks : Egbert Wesavtng Tape i hasatOPPURBPTOSD1 Cabos Doe COTODTS

Laser NeasuerePFAS FT-08-01 Ca. Due On 0-10-2019, Steel Rut PF-AT-OGD1 Galbue GalsGa O20

‘ewer CaiperDPF-LAB-C- 10-01 Cal Dus Dat 6-102 Pipe Maasuirg Teo DPF-PT 04-08 CaBun Date0-1210

Nisual inspection: “OK

Lined with GRP Liner

Consutant

[checked BY

[witness by

<—DF— F— __DOWAPRECAST FACTORY - QC Laboratory

Crushing Strength BS EN 1916 Annex C

20-0H 4

2014 oK(0-1- PL

Qolq Olo-1

§ lo-0 Qld

RCP (Jacking Pipe) BS 5911 P1 & BS EN 1916 - Class 120

Crushing Strength BS EN 1916 Annex C

Nil

2000/2400mm

N/A

etl

Reading

Pipe No. 623

Date of Casted \o-o 14

Test Date Lo-Onl4

Age Day fel

length of the Pipe mm Boao

Rate of Loading N/mm 20

Weight of Loading bearer KN qab6

Convertion factor kb Lo

Proof Load F, kN 536 63- HSH

Unit Proof lead (total) N/m 196 -2i« Ibo:8

Width of Crack mm No Cyeclt +

Ultimate Load F, kN

Unit Ultimate Load (total) —_kN/m

Equipements Used: Pipe Crushing Machine DPF-LAB-PT-01-01 valid 02-10-2019

Remarks

Consultant Remarks contractor:

checked BY Tested By

verified By

lapproved By

a?

‘Test Date / Report Date

Test ID / Report No.

Compressive strength of test specimens BS EN 12390 P 3

DOHA PRECAST FACTORY - QC Laboratory

12 Joy fasi 7

ps (7 0G/4~O2-1-€S

oid 3 - or!

Sample ID i

‘Sampled Date 13 /6y/d

Material. “oncrete C 50 ( OPC,GGBS,MS) fo

Test Method Compressive strength of test specimens BS EN 12390 P3

Test ethod Varaton nil

‘Sample Preparation /As Per BS EN 12390-2

‘Ambient Temperature |N/A

Tested By 178

‘Speciment Condition ssD

Speciment No Unit] 2 2 3 4 5 6 | Requirement

fest Date wef l rlyyl & MVE

lage (days) 2

[Top length (Ave) mom | eo-s | su 6 | (60-0

[rep width (Ava) mm | jsu-% | jso- S| /$0 +3

Bottom length (Ave) mm | /50. ro 0] /gu-7

bottom width (avg) mm | jgo.a | 750-3 [7 sv-2

sides measurement (ave)_| mm | yeu | /$0-) | 1Sd-2

|Flatness mm | 20: 0£| 2 6-of| ¢ bos

jPerpenticularity mm ou ou ou

area em [2264] 227 res 7

[volume cc IGEN 33970 | 9256 |

[cube Mass e [essa | cay | €2g¢

Density afc [2.5300] 2890.0] W590

hax. Load kn [7399.0 177-1 | 4b

[compressive Strength nfo 625| 626 50

[Type of Failure ae EF.

Equipements Used: Equipment: Compressive Machine Asset: DPF-LAB-CT-01-02 Cal. Due Date: 27-02-2020

ital Vernier Caliper-Asset: DPFALAG-CT-19-01 Cal, Due Date: 06-10-2019

Electronic Balance Asset: DPF-LAB-AT-14-03 Cal. Due Date: 09-06-2019

Remarks

[consuttant Remarks Contractor:

checked BY rested By

FM

Verified By

approved By

ee

2 Z Br HE TED rev Oi 370A

ie

Qor-

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 06 - Part 5 - Asphalt WorksDocument57 pages06 - Part 5 - Asphalt WorksSudhakar JayNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Land Survey No.81Document1 pageLand Survey No.81Sudhakar JayNo ratings yet

- DN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsDocument2 pagesDN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsSudhakar JayNo ratings yet

- List of Approved Companies or Service Providers Working in Environmental Management and Sustainability in PWA ProjectsDocument5 pagesList of Approved Companies or Service Providers Working in Environmental Management and Sustainability in PWA ProjectsSudhakar JayNo ratings yet

- PP FiberDocument2 pagesPP FiberSudhakar JayNo ratings yet

- Ds 2003 Profs Lipt BRDocument8 pagesDs 2003 Profs Lipt BRSudhakar JayNo ratings yet

- Flow Meter Vendor ListDocument1 pageFlow Meter Vendor ListSudhakar JayNo ratings yet

- Ashghal Approved Asphalt Mixes and Plants-75Document11 pagesAshghal Approved Asphalt Mixes and Plants-75Sudhakar JayNo ratings yet

- Lessons SDocument1 pageLessons SSudhakar JayNo ratings yet

- List 7706022024094802Document11 pagesList 7706022024094802Sudhakar JayNo ratings yet

- Botanical Health CertificateDocument1 pageBotanical Health CertificateSudhakar JayNo ratings yet

- CBM2 - Sieve AnalysisDocument1 pageCBM2 - Sieve AnalysisSudhakar JayNo ratings yet

- PlantingDocument1 pagePlantingSudhakar JayNo ratings yet

- Medstar Presentation - Medical Coverage OptionsDocument11 pagesMedstar Presentation - Medical Coverage OptionsSudhakar JayNo ratings yet

- Outplacement Assistance PackDocument12 pagesOutplacement Assistance PackSudhakar JayNo ratings yet

- Name of State Sr. No. Name & Address of Nursery Nursey Code Rating Leter Issued Rating Star Accredited Nurseries and Its RatingDocument38 pagesName of State Sr. No. Name & Address of Nursery Nursey Code Rating Leter Issued Rating Star Accredited Nurseries and Its RatingSudhakar JayNo ratings yet

- 3-NCR ProcedureDocument16 pages3-NCR ProcedureSudhakar JayNo ratings yet

- Green Gram CultivationDocument7 pagesGreen Gram CultivationSudhakar JayNo ratings yet

- SA009-Audit Notification System AuditDocument1 pageSA009-Audit Notification System AuditSudhakar JayNo ratings yet

- NCR Follow-Up and ClosingFunnel Slides V1 Rev. 2Document1 pageNCR Follow-Up and ClosingFunnel Slides V1 Rev. 2Sudhakar JayNo ratings yet

- (TW-P6-F47) MirDocument2 pages(TW-P6-F47) MirSudhakar JayNo ratings yet

- Quality and Safety Department MAY 2022: Balkhawaja@ashghal - Gov.qaDocument16 pagesQuality and Safety Department MAY 2022: Balkhawaja@ashghal - Gov.qaSudhakar JayNo ratings yet

- AAP 2019-20 Final To DistrictDocument1 pageAAP 2019-20 Final To DistrictSudhakar JayNo ratings yet

- Mix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Document2 pagesMix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Sudhakar JayNo ratings yet

- Plants Price - Horticulture2013Document12 pagesPlants Price - Horticulture2013Sudhakar JayNo ratings yet

- PVC Water-TankDocument4 pagesPVC Water-TankSudhakar JayNo ratings yet