Professional Documents

Culture Documents

Please Replace The Following Pages in The Notes

Uploaded by

asdas0 ratings0% found this document useful (0 votes)

5 views3 pagesThis document discusses dynamic replacement (DR) for treating soft silty clay soils by pounding sand columns into the ground to provide support. It provides calculations to determine the required drop height, energy per blow, and spacing of sand columns for a case study with a required settlement of 0.6m. Design parameters such as pounder size, drop height, and applied energy are compared to guidelines and a past case study at Changi Airport.

Original Description:

Original Title

DC Notes -error (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses dynamic replacement (DR) for treating soft silty clay soils by pounding sand columns into the ground to provide support. It provides calculations to determine the required drop height, energy per blow, and spacing of sand columns for a case study with a required settlement of 0.6m. Design parameters such as pounder size, drop height, and applied energy are compared to guidelines and a past case study at Changi Airport.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesPlease Replace The Following Pages in The Notes

Uploaded by

asdasThis document discusses dynamic replacement (DR) for treating soft silty clay soils by pounding sand columns into the ground to provide support. It provides calculations to determine the required drop height, energy per blow, and spacing of sand columns for a case study with a required settlement of 0.6m. Design parameters such as pounder size, drop height, and applied energy are compared to guidelines and a past case study at Changi Airport.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Please replace the following pages in the notes:

Page 2: to replace page 9 - Question 3 in

Tutorials & Solutions: High Energy Impact

Page 3: to replace page 3 in

Design Guidelines for Dynamic Compaction for Case Study

Dynamic Compaction (DC) is only suitable for densifying loose granular soil.

Dynamic Replacement (DR) which involves the pounding of sand column into

the soft ground to replace the soft silty clay is deemed to be a suitable high

energy impact scheme. The DR sand columns will provide support to the

columns and floor areas.

DR for the treatment of the general floor areas to enforce settlement SE= 0.6 m

Lo et al. (1990) method

For SE = 0.6m, Fig. 1.1 of lecture notes, Is = 400 tm/m2

For Is = 400 tm/m2, Fig 1.2 gives EB/PL = 14 m3

Energy per blow, EB = 14 x PL = 14 x 20 = 280 tm

Use say W = 20 t pounder (size = 1.83m x 1.83m)

1.83 m x 1.83 m pounder will effectively give a sand column with diameter of

about √(2 x 1.832) = 2.59 m (equivalent to diagonal of square pounder). Use

print spacing of 5 m x 5 m.

EB= WH Drop height H =EB/ W = 280/20 = 14 m.

Use 20 m drop height to pound sand columns deeper into soft silty clay. This

give EB = WH = 20 x 20 = 400

Case Study: Compaction of sand fill at Changi Airport (Choa et al. 1979)

Thickness of hydraulic fill = 6.5 m. Required to achieve relative density of 75%.

Gradation of sand fill between 0m to 6m suitable for dynamic compaction (see

Fig. 2)

In Changi field trial, W = 20t, H = 11m; WH = 220 tm (assumed also applied to

main works). Using D = α √(WH) = 0.5 x √(20x11) = 7.4 m (> 6.5m)

(Correction: Changi field trial: W = 11t, H = 20m)

Step 1: Depth of improvement, D = α √(WH) = 6.5m

With α = 0.5, WH = (D/α)2 = 169 tm (W = 17t, H = 10m) < 220 tm

α = 0.5 is based on “average” value (see Figure from Mitchel)

For design assume 85% of average α, α = 0.425

Revised WH = (D/α)2 = 233 tm > 220 tm; (use W = 20t, H = 11.7m)

(Alternative is to keep α = 0.5 and increase depth of improvement by say 15%,

i.e. 1.15 x 6.5 = 7.48 m, which would give WH = 223 tm, similar to Changi)

Pounder size: 1.83m x 1.83m; W/A = 200/1.832 = 59.7 kN/m2 (within range)

(Changi: W/A = 110/1.832 = 32.8 kN/m2 (less than 40 kN/m2 in guidelines)

Step 2: Table 9, Applied energy normally used = 20 – 25 tm/m3

Multiply by deposit thickness,

Range of average energy, I : 20 x 6.5 = 130 tm/m2 to 25 x 6.5 = 162.5 tm/m2

Changi: After field trials, I of 160 tm/m2 reduced to 125 tm/m2 (total for 2 passes)

You might also like

- Design Example Deep CompactionDocument9 pagesDesign Example Deep CompactionCut Meutia RatagNo ratings yet

- Other Methods of Bearing CapacityDocument9 pagesOther Methods of Bearing CapacityDanyal AhmedNo ratings yet

- Asaoka Method PDFDocument67 pagesAsaoka Method PDFAdriel Elezar100% (1)

- Assignment 2 - SolutionDocument25 pagesAssignment 2 - Solutionblasticinc100% (1)

- Fluid Mechanics: University of LeedsDocument16 pagesFluid Mechanics: University of LeedsHasitha MadusankaNo ratings yet

- Sand DrainsDocument7 pagesSand DrainsMelissa SammyNo ratings yet

- Geotecnical Depth Set 2Document40 pagesGeotecnical Depth Set 2rocky21st100% (2)

- Retainning WallDocument14 pagesRetainning Wallahamedtouhid899No ratings yet

- Accelerated Pre-Consolidation Accelerated Pre-Consolidation Using GeosyntheticsDocument64 pagesAccelerated Pre-Consolidation Accelerated Pre-Consolidation Using GeosyntheticsRaghavNo ratings yet

- Exit 300 of 300Document6 pagesExit 300 of 300Omen Jett100% (1)

- Calculation Report For Box Culvert RebarDocument3 pagesCalculation Report For Box Culvert Rebarariefrizki100% (1)

- Chapter 12Document8 pagesChapter 12이희인No ratings yet

- Settlement Prediction of Spread FoundationDocument31 pagesSettlement Prediction of Spread Foundation류태하No ratings yet

- Chapter (1) General Principles of Foundation Design Example 7.2Document47 pagesChapter (1) General Principles of Foundation Design Example 7.2Kyaw Zin HeinNo ratings yet

- Sub Assign2 GeoDocument8 pagesSub Assign2 GeoKwok Cheong ChengNo ratings yet

- Pipe Thickness CalculationDocument7 pagesPipe Thickness CalculationLokman HakimNo ratings yet

- Drilling Mud CalculationsDocument5 pagesDrilling Mud CalculationsSinga Pase89% (9)

- HW10 SolutionDocument9 pagesHW10 SolutionMuath AlShehriNo ratings yet

- CanalesDocument18 pagesCanalesJInez Harrison Alvites AscueNo ratings yet

- Low Rise Luxurious House On A2 IslandDocument2 pagesLow Rise Luxurious House On A2 IslandMelinda GordonNo ratings yet

- Abe Quiz Season XviiDocument7 pagesAbe Quiz Season XviiMeljun GementizaNo ratings yet

- RCD Chapter 8Document4 pagesRCD Chapter 8jereck loquisoNo ratings yet

- Stabilization of River Bank - 23feb-2Document15 pagesStabilization of River Bank - 23feb-2Abhishek VermaNo ratings yet

- LWCE ProblemSolutionDocument7 pagesLWCE ProblemSolutionGorg EousNo ratings yet

- FEN4702 REPORT Rev01Document17 pagesFEN4702 REPORT Rev01Hannes GelderblomNo ratings yet

- CE 71 DRB Internal-2-Answer Key (Student Copy)Document22 pagesCE 71 DRB Internal-2-Answer Key (Student Copy)PaulNo ratings yet

- Structural Design of Combined FootingsDocument6 pagesStructural Design of Combined Footingsselina100% (1)

- 2 - Design and Analysis of One-Way SlabsDocument32 pages2 - Design and Analysis of One-Way SlabsShiyar ArgoshiNo ratings yet

- Astm E1300 - 140414 - OfficeDocument285 pagesAstm E1300 - 140414 - OfficeklynchelleNo ratings yet

- Soil Mech Ques1 NWDocument22 pagesSoil Mech Ques1 NWsenthilkumarm50No ratings yet

- Summative AssessmentDocument6 pagesSummative AssessmentChe BongoNo ratings yet

- Cive1400 200203Document7 pagesCive1400 200203naefmubarakNo ratings yet

- PSC AE QuestionsDocument9 pagesPSC AE QuestionsDipayan MisraNo ratings yet

- Group 8 Geotech Assignment 1Document19 pagesGroup 8 Geotech Assignment 1ephragekaroNo ratings yet

- Chapter 3Document8 pagesChapter 3RameshNo ratings yet

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocument23 pagesDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNo ratings yet

- Shallow Foundation NotesDocument52 pagesShallow Foundation NotesBAMSNo ratings yet

- TCW32052014 Geotechnical Engineering 1.Document6 pagesTCW32052014 Geotechnical Engineering 1.Nyashah FelixNo ratings yet

- Chapter 6Document17 pagesChapter 6Jairo RocgaNo ratings yet

- Problem No1Document1 pageProblem No1FiazNo ratings yet

- Master CalculationDocument9 pagesMaster CalculationRANA1575100% (2)

- Applications of Geosynthetics in Unpaved RoadsDocument34 pagesApplications of Geosynthetics in Unpaved RoadsAlelign AsfawNo ratings yet

- Rock-Engineering Tutorials Solutions BBDDocument7 pagesRock-Engineering Tutorials Solutions BBDSandip PaudelNo ratings yet

- Fluid MechanicsDocument64 pagesFluid MechanicsCiutac Ionut CristianNo ratings yet

- Minimum Cost Aggregate Mix ModelDocument5 pagesMinimum Cost Aggregate Mix ModelSutrisno DrsNo ratings yet

- Free PDF For Class 9Document6 pagesFree PDF For Class 9Movies At HomeNo ratings yet

- Contoh Soal Metode Perbaikan Tanah (Deep Dynamic Compaction)Document5 pagesContoh Soal Metode Perbaikan Tanah (Deep Dynamic Compaction)Medline ParuntuNo ratings yet

- NPTEL Course: Ground ImprovementDocument67 pagesNPTEL Course: Ground ImprovementNurullah Akbulut100% (1)

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Steel Structure AssignmentDocument11 pagesSteel Structure AssignmentGetaneh HailuNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- CE202L2 Axially Loaded Members (Compatibility Mode)Document23 pagesCE202L2 Axially Loaded Members (Compatibility Mode)asdasNo ratings yet

- Hydraulics Slides Without AnimationsDocument4 pagesHydraulics Slides Without AnimationsasdasNo ratings yet

- CE202L1 LocalBucklingDocument16 pagesCE202L1 LocalBucklingasdasNo ratings yet

- CE202L3 RestrainedBeam (Compatibility Mode)Document7 pagesCE202L3 RestrainedBeam (Compatibility Mode)asdasNo ratings yet

- CE202L4 UnrestrainedBeam (Compatibility Mode)Document18 pagesCE202L4 UnrestrainedBeam (Compatibility Mode)asdasNo ratings yet

- CE201 Reinforced & Prestressed Concrete Structures (2010)Document88 pagesCE201 Reinforced & Prestressed Concrete Structures (2010)asdasNo ratings yet

- CE202L6 PlateGirder (Compatibility Mode)Document21 pagesCE202L6 PlateGirder (Compatibility Mode)asdasNo ratings yet

- CE 103 Structural AnalysisDocument80 pagesCE 103 Structural AnalysisasdasNo ratings yet

- Plaxis Le Consolidation: Verification ManualDocument65 pagesPlaxis Le Consolidation: Verification ManualasdasNo ratings yet

- SOLUTIONS FOR Problem Sheet 1Document5 pagesSOLUTIONS FOR Problem Sheet 1asdasNo ratings yet

- Doi 8jul20Document1 pageDoi 8jul20asdasNo ratings yet

- Structural Calculations Fully FramelessDocument13 pagesStructural Calculations Fully FramelessasdasNo ratings yet

- ELI TE: Exposed Gri D System Li GHT DutyDocument4 pagesELI TE: Exposed Gri D System Li GHT DutyasdasNo ratings yet

- Potongan CDocument1 pagePotongan CasdasNo ratings yet

- Drafts - Concrete - Nov 29, 2021Document14 pagesDrafts - Concrete - Nov 29, 2021asdasNo ratings yet

- Blank SheetDocument1 pageBlank SheetasdasNo ratings yet

- AnalysisDocument12 pagesAnalysisasdasNo ratings yet

- CV7001 RefencelistDocument1 pageCV7001 RefencelistasdasNo ratings yet

- 2 The (Galerkin) Finite Element Method: 2.1 Approximate Solution and Nodal ValuesDocument50 pages2 The (Galerkin) Finite Element Method: 2.1 Approximate Solution and Nodal ValuesSayan KumarNo ratings yet

- CBC A 080314Document9 pagesCBC A 080314asdasNo ratings yet

- AnalysisDocument12 pagesAnalysisasdasNo ratings yet

- Course Materials Course MaterialsDocument2 pagesCourse Materials Course MaterialsasdasNo ratings yet

- DasffgDocument1 pageDasffgasdasNo ratings yet

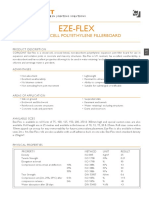

- Eze-Flex: Closed Cell Polyethylene FillerboardDocument2 pagesEze-Flex: Closed Cell Polyethylene FillerboardasdasNo ratings yet

- Jacquiline Dinglasan: To (Addressee)Document1 pageJacquiline Dinglasan: To (Addressee)asdasNo ratings yet

- How To Derive Shape Function Serendipity ElementDocument6 pagesHow To Derive Shape Function Serendipity ElementasdasNo ratings yet

- 2020 CE4257 Exam FormulaDocument6 pages2020 CE4257 Exam FormulaasdasNo ratings yet

- Jointflex: Closed Cell Polyethylene FillerboardDocument2 pagesJointflex: Closed Cell Polyethylene Fillerboardkz shimantoNo ratings yet