Professional Documents

Culture Documents

Affiliated To Anna University Chennai, Approved by Aicte-Newdelhi

Uploaded by

Ram0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

DTS QP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageAffiliated To Anna University Chennai, Approved by Aicte-Newdelhi

Uploaded by

RamCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

density of a belt is 0.

0015 kg/cm3and maximum

Register No: stress is limited to 400×104 N/ m2 . If µ = 0.15,

find the power that can be transmitted, if the wheel

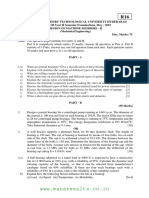

St. MICHAEL COLLEGE OF ENGG. & TECH., has a mean diameter of 300 mm and runs at 1000

Affiliated to Anna University Chennai, Approved by AICTE-NewDelhi

rpm.

St. Santhiyagappar Nagar, Kalayarkoil – 630551

(OR)

A Stone crushing machine receives power from

DEPARTMENT OF MECHANICAL ENGINEERING motor rated at 50 kw at 1800 rpm by means of a

CENTRALIZED INTERNAL ASSESMENT TEST - I flat belt pulley dia are 200 mm and 700 mm

ME8651– DESIGN OF TRANSMISSION SYSTEMS 9. b (12) CO1 K3

distance between pulley is 4 m design the belt

Year & Semester: III& 06 Date: 28.04.2022 drive the direction or rotation of 2 pulley opposite

Time: AN Marks : 50 to each other.

PART – A Answer All questions. (7× 2 = 14 Marks)

Design a straight spur gear drive to transmit 8 kW.

Give the relationship of ratio of tensions in a V- The pinion speed is 720 rpm and the speed ratio is

1. CO1 K1

belt drive. 2. Both the gears are made of the same surface

2. Mention the materials used for making belts. CO1 K1 10. a (12) CO2 K4

hardened carbon steel with 55RC and core

3. Mention the losses in belt drives. CO1 K2 hardness less than 350 BHN. Ultimate strength is

What are the factors upon which the coefficient of 720 N/mm2 and yield strength is 360 N/ mm2.

4. K2

friction between the belt and pulley depends? CO1

(OR)

5. What does the ray-diagram indicate? CO2 K1

Design a pair of spur gear drive to transmit 20 kW.

What are the possible arrangements to achieve 12

6. CO1 K3 The pinion speed is 1400 rpm and the transmission

speeds from a gear box? 10. b (12) CO2 K4

ratio is 4. Assume suitable materials and stresses.

Name any two methods used for changing speeds

7. CO2 K1

in gear boxes. **** All The Best ****

PART - B Answer All Questions (3 × 12 = 36 Marks)

Design a flat belt to transmit 12 kw at 450 rpm for

an engine to a shaft running at 1200 rpm the

8. a (12) CO1 K3

diameter of engine pulley is 600 mm and centre

distance 2 m.

(OR)

In The electric motor drives the exhaust fan using flat

belt design the belt drive as per the following

specification a center distance between the pulley

8. b is 2.5 m. The permissible stress on the belt is 2.5 (12) CO1 K2

n/mm2 the thickness of the belt is 5 mm and its

able to transmit 22.5 kw check the width of the

belt using standard formula.

A V- Belt having a lap of 180°has a cross section

9. a (12) CO1 K2

area of 2.5 cm2 and groove angle as 45°. The

You might also like

- Ford Edge 2019 Electrical Wiring DiagramDocument22 pagesFord Edge 2019 Electrical Wiring Diagramclaudiajohnson200285ctd100% (53)

- Suspension Mansons 2Document45 pagesSuspension Mansons 2Andres Silva67% (3)

- 2006 Johnson 9.9, 15 Tiller 4 StrokeDocument56 pages2006 Johnson 9.9, 15 Tiller 4 StrokeАлександр ПрохоренкоNo ratings yet

- DTS Ciat 2Document1 pageDTS Ciat 2MECHANICAL SMCETNo ratings yet

- St. Michael College of Engg. & Tech.,: Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiDocument1 pageSt. Michael College of Engg. & Tech.,: Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiRamNo ratings yet

- 2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIDocument4 pages2017 AS (Summer) Sem VII Mech Engg Machine Design N Drawing IIMayur DhanokarNo ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- DME Unit Test 4 - 2018Document3 pagesDME Unit Test 4 - 2018hodmech tjsec.inNo ratings yet

- PART-A (10 X 2 20 Marks)Document4 pagesPART-A (10 X 2 20 Marks)Arun R UNo ratings yet

- Ee8002-Doea - Open Book TestDocument4 pagesEe8002-Doea - Open Book Testsaranraj rNo ratings yet

- Dom MP 2Document2 pagesDom MP 2darlingprabhas95709No ratings yet

- Design of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Document2 pagesDesign of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Rohit RangariNo ratings yet

- Question Paper Checklist CT 1Document3 pagesQuestion Paper Checklist CT 1sar_tpgitNo ratings yet

- Dom MP 1Document2 pagesDom MP 1darlingprabhas95709No ratings yet

- Dme Model Set BDocument3 pagesDme Model Set BSAMUEL SANJAY RAJA R MECHNo ratings yet

- DMD PDFDocument14 pagesDMD PDFAstik ThombareNo ratings yet

- Me0405 7 SemDocument2 pagesMe0405 7 SemSurya BalamuruganNo ratings yet

- 3rdi A QP Faculty DME-2Document3 pages3rdi A QP Faculty DME-2vaijanath patilNo ratings yet

- SSD Iat-I Q2Document3 pagesSSD Iat-I Q2MR.A. ANN RUFUSNo ratings yet

- DME Question BankDocument18 pagesDME Question BankAditya PatilNo ratings yet

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- Cia I QP DomDocument2 pagesCia I QP DomThiyagu SundaramNo ratings yet

- Design of Mechanical Drives w17Document4 pagesDesign of Mechanical Drives w17aniket ingle100% (1)

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- DTS - Mid Term Question BankDocument2 pagesDTS - Mid Term Question Bankomchavan9296No ratings yet

- Question Paper Checklist CT 2Document3 pagesQuestion Paper Checklist CT 2sar_tpgitNo ratings yet

- Met401 Design of Machine Elements, December 2022Document4 pagesMet401 Design of Machine Elements, December 2022malluboy1729No ratings yet

- Gujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70Document3 pagesGujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70NILESH SUTHARNo ratings yet

- FME CT I QP (20-21) - Even SemDocument3 pagesFME CT I QP (20-21) - Even SemUjjwal ChauhanNo ratings yet

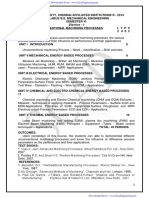

- Design of Transmission Systems - Department of Mechanical EngineeringDocument10 pagesDesign of Transmission Systems - Department of Mechanical EngineeringDesejo SozinandoNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- Unit3 Premodel1Document2 pagesUnit3 Premodel1T.V.B.BabuNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Chp1 3Document47 pagesChp1 3Azhar BaigNo ratings yet

- Stucor Qp-Me8593 PDFDocument22 pagesStucor Qp-Me8593 PDFSalmon JNo ratings yet

- Dts Model Que Type B 2018-19Document2 pagesDts Model Que Type B 2018-19rammit2007No ratings yet

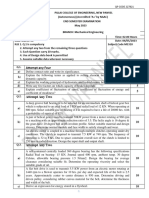

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Me 7 Sem Design of Mechanical Drives Winter 2017Document2 pagesMe 7 Sem Design of Mechanical Drives Winter 2017djniksthehearteditorNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)PradeepNo ratings yet

- B.Tech Mechatronics DOM SupplyDocument4 pagesB.Tech Mechatronics DOM SupplyMakesh KrishnaNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- Assignment No 1 NME 602 MD 2Document2 pagesAssignment No 1 NME 602 MD 2nitin_johri0% (1)

- Me - (6th Sem) - Machine-Design-2-Rme603-2019Document3 pagesMe - (6th Sem) - Machine-Design-2-Rme603-2019Raghawendra SinghNo ratings yet

- Internal 1 Set I - DME1Document12 pagesInternal 1 Set I - DME1A VasanthkumarNo ratings yet

- Machine Design-IIDocument2 pagesMachine Design-IIPrathamesh MhatreNo ratings yet

- Be Winter 2022Document2 pagesBe Winter 2022shivamparmartechNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityNILESH SUTHARNo ratings yet

- Dynamics of MachineryDocument2 pagesDynamics of MachineryGopi TNo ratings yet

- 2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesDocument2 pages2 2440 - GUG-S-16-6620 - Year - B.E. (With Credits) - Regular-Semester 2012-Mechanical Engineering Sem VII Subject - ME - Design of Mechanical DrivesKunal MohurleNo ratings yet

- Model Tom.2Document4 pagesModel Tom.2jamunaa83No ratings yet

- Model Tom.1Document4 pagesModel Tom.1jamunaa83No ratings yet

- Apollo Priyadarshanam Institute of Technology Department of Mechanical Engineering Cycle Test - Ii Subject Code/Name: Me6601/Dts Date: Year/Sem: Iii/Vi Max - Marks: 50 Part-A (5x2 10MARKS)Document3 pagesApollo Priyadarshanam Institute of Technology Department of Mechanical Engineering Cycle Test - Ii Subject Code/Name: Me6601/Dts Date: Year/Sem: Iii/Vi Max - Marks: 50 Part-A (5x2 10MARKS)Ramar Madasamy100% (1)

- LL, LLLLLLRLLLLL: - Machine and DrawingDocument2 pagesLL, LLLLLLRLLLLL: - Machine and DrawingMayur DhanokarNo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- IFS Mechanical Engineering 2015 Part 1Document4 pagesIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajNo ratings yet

- Fabrication and Test Results of A Prototype, NB SN Superconducting Racetrack Dipole MagnetDocument5 pagesFabrication and Test Results of A Prototype, NB SN Superconducting Racetrack Dipole MagnetLei WuNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- AE111 End Sem PDFDocument2 pagesAE111 End Sem PDFLoves MusicNo ratings yet

- Organic Light-Emitting Transistors: Towards the Next Generation Display TechnologyFrom EverandOrganic Light-Emitting Transistors: Towards the Next Generation Display TechnologyNo ratings yet

- High-Temperature Superconducting Materials Science and Engineering: New Concepts and TechnologyFrom EverandHigh-Temperature Superconducting Materials Science and Engineering: New Concepts and TechnologyNo ratings yet

- St. Michael College of Engg. & Tech.Document1 pageSt. Michael College of Engg. & Tech.RamNo ratings yet

- EEDocument2 pagesEERamNo ratings yet

- Production Planning and Control Int 1 Question PaperDocument1 pageProduction Planning and Control Int 1 Question PaperRamNo ratings yet

- Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiDocument1 pageAffiliated To Anna University Chennai, Approved by Aicte-NewdelhiRamNo ratings yet

- St. Michael College of Engg. & Tech.,: Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiDocument1 pageSt. Michael College of Engg. & Tech.,: Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiRamNo ratings yet

- Me8694-Hydrauics and PneumaticsDocument1 pageMe8694-Hydrauics and PneumaticsRamNo ratings yet

- St. Michael College of Engg. & Tech., St. Michael College of Engg. & Tech.Document2 pagesSt. Michael College of Engg. & Tech., St. Michael College of Engg. & Tech.RamNo ratings yet

- Cad Int 1 Question PaperDocument1 pageCad Int 1 Question PaperRamNo ratings yet

- Me6004 UcmpDocument93 pagesMe6004 UcmpRam100% (1)

- Planos Hidraulicos Troidon 66 - jmc-516Document12 pagesPlanos Hidraulicos Troidon 66 - jmc-516Maria Isabel Alzate RamirezNo ratings yet

- Wiring Diagram SectionDocument76 pagesWiring Diagram Sectiondavydenkoanton5No ratings yet

- Código Tipo Año Marca Modelo #Ptas Cilndr. Comb. Transm.: Identificacion de VehículoDocument42 pagesCódigo Tipo Año Marca Modelo #Ptas Cilndr. Comb. Transm.: Identificacion de VehículosambojoviNo ratings yet

- 2011 FORD E-250 5.4L V8 Fuel Pump & Housing Assembly RockAutoDocument1 page2011 FORD E-250 5.4L V8 Fuel Pump & Housing Assembly RockAutoJoe RomeroNo ratings yet

- DHR 6Document74 pagesDHR 6Muhammad ZainudinNo ratings yet

- Group 2 SpecificationDocument15 pagesGroup 2 SpecificationЕвгений СолдатовNo ratings yet

- Volkswagen Golf R Line Spec SheetDocument12 pagesVolkswagen Golf R Line Spec SheetKai Heng ChanNo ratings yet

- Flotech DK631-000 Airless Sprayer (Manual) 1653529297Document12 pagesFlotech DK631-000 Airless Sprayer (Manual) 1653529297jery laksaNo ratings yet

- Internship For Automobile Engneering Students and Freshers 2021-2022Document9 pagesInternship For Automobile Engneering Students and Freshers 2021-2022dhan singhNo ratings yet

- G4A-El / Gf4A-El: FWD 4 Speed (2 Pans)Document6 pagesG4A-El / Gf4A-El: FWD 4 Speed (2 Pans)kuya batokNo ratings yet

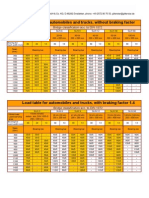

- 9 Gitterstar LoadTable Autom TrucksDocument1 page9 Gitterstar LoadTable Autom TrucksSnaz_nedainNo ratings yet

- Catalog All New Kijang Innova Zenix Hybrid EvDocument12 pagesCatalog All New Kijang Innova Zenix Hybrid EvAbraham AnugrahNo ratings yet

- Type OSPB, OSPC and OSPF PDFDocument32 pagesType OSPB, OSPC and OSPF PDFmusafirNo ratings yet

- Operation & Maintenance Manual T870 Compact Track Loader: S/N B3BZ11001 & AboveDocument230 pagesOperation & Maintenance Manual T870 Compact Track Loader: S/N B3BZ11001 & AboveJhon Mahecha LdsNo ratings yet

- 512 Dental LineDocument6 pages512 Dental LineMehdi MehdiNo ratings yet

- John Deere Xuv 825i s4 Gator Utility Vehicle Operators ManualDocument108 pagesJohn Deere Xuv 825i s4 Gator Utility Vehicle Operators ManualLloyd Harvey100% (1)

- Merkel Chevron Seal Set Ek, Ekv: MaterialDocument1 pageMerkel Chevron Seal Set Ek, Ekv: MaterialStorm RiderNo ratings yet

- Massey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)Document20 pagesMassey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)bvk2980022No ratings yet

- Fitting & Machining N2 Nodrm-1Document481 pagesFitting & Machining N2 Nodrm-1Junior Khanya ApleniNo ratings yet

- !!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsDocument7 pages!!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsAmaury FreireNo ratings yet

- Brake Pad Sensor2Document1 pageBrake Pad Sensor2Ebrahem Ahmed HafezNo ratings yet

- Riduttori Per Rotazione Slewing Gearboxes: RR1800 ÷ RR10000Document4 pagesRiduttori Per Rotazione Slewing Gearboxes: RR1800 ÷ RR10000RenjithSivaNo ratings yet

- Kitsen CatalogueDocument20 pagesKitsen CatalogueAbdul MunirNo ratings yet

- BMW Ix Specification Guide I20.pdf - Asset.1637886382519Document12 pagesBMW Ix Specification Guide I20.pdf - Asset.1637886382519Emanuel Gamboa ChacònNo ratings yet

- Ebook Modern Diesel Technology Heavy Equipment Systems PDF Full Chapter PDFDocument67 pagesEbook Modern Diesel Technology Heavy Equipment Systems PDF Full Chapter PDFelia.green622100% (27)

- 02-04-02 Tilt Cylinder (L.HDocument4 pages02-04-02 Tilt Cylinder (L.HricardoNo ratings yet

- Part 4 Hoisting SystemDocument35 pagesPart 4 Hoisting SystemJood SultanNo ratings yet