Professional Documents

Culture Documents

Emergency Air Failure

Uploaded by

abhrrajjit SAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emergency Air Failure

Uploaded by

abhrrajjit SACopyright:

Available Formats

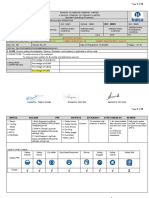

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 1 of 17

(Draft - Only for information purposes)

Management Standard ISO 9001 ISO 14001 OHSAS 18001 EnMS 50001

Element Name Resource management Operational Control Operational Control Operational Control

Element Number 8.1 8.2 4.4.7 4.5.5

1. PURPOSE : Safely operate on air failure

2. SCOPE : It Will Be Applicable For Unit # 1, 2, 3 & 4.

3. REFERENCE : O & M Manual

4. ANNEXURE : NIL

5. DISTRIBUTION : DCS Engineer, Shift in charge, HOD Operation

6. AMENDMENT HISTORY:

S No Amendment Description Page Number(s) Current Ver. No. Current Rev. No Issue Date

1. SI system is change by SAP System. 12 00 01 12.06.2015

2. Change of company name and logo 12 00 02 1.09.2015

3. Periodic review 12 00 03 4.01.2017

4. Change of logo 17 01 04 02.08.2017

5. Periodic review 17 01 05 31.12.2018

6. Periodic review 17 01 06 15.11.2019

7. SOP Reviewed and Updated by Steag 1 01 07 27.11.2020

7. ACTIVITY CHARACTERISTICS:

INPUTS Output Efficiency Effectiveness Review Frequency

All Safety PPE’s In Normal Operation Proper Operation on air Smooth Operation One Year

Place With Normal failure At Permissible on air failure With

Generation Operation Limit Reduce Breakdown

8. RESPOSIBILITY : DCS Engineer, Shift In charge, HOD.

9. DEFINITION : Safe operation On Air failure

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 2 of 17

10. SAFETY TABLE :

Safety Safety

Job description/ PPE Ear Respirator/ PVC Safety Safety

Helmet uniform/ja Safety Shoes

-> muff Dust Mask gloves Goggle Belt

cket

Proper Operation on

Y Y N Y Y Y N/A Y

air failure.

1. EMERGENCY OPERATION OF TOTAL AIR FAILURE

No. Description

In case where all compressors trips in any phase and header pressure is low,

1 open the interconnecting valve between phase 1&2 both service and

instrument air interconnection valve provision available.

In case where all compressors trips in both phase and header pressure is low,

2 open the interconnecting valve between service air and instrument air in that

phase.

Isolate the air supply for the pneumatic valves which are having dual coils and

2 are not affected by air failure.(Refer the list of pneumatic valves) (TPP/ HIR-

BTG/OPE/034/34.3 TO 34.5)

3 Stop the conveying of some passes to avoid service air header pressure loss.

Isolate the pulsing air and instrument air to some headers of fabric filter

4

individual passes. (TPP/ HIR-BTG/OPE/034/34.3 TO 34.5)

Check the status of the Pneumatic Actuators given in list (categorized

5

according to their action on air failure).

Then quickly find the cause of the trip and normalize the issue. (e.g. Normalize

6

the Common 11KV Bus)

7 Line up the service water and maintain header pressure.

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 3 of 17

Start Air Compressors one by one by opening the outlet valve. (Externally

8 arranging the air supply OR not necessary if initially air is isolated). (TPP/ HIR-

BTG/OPE/034/34.2 TO 34.3)

9 Open the inlet and outlet valves of Instrument Air Driers and start the same.

If instrument air header pressure is more than normal operating range, Start

10

the service air drier.

If total air is lost then check the status of the pneumatic valves that are having

11

single coil and operate on air failure.

If condition is out of control and instrument air is not available for a long time

12

then, trip the unit.

Try to isolate the lines by motor operated valves, as per requirement on

13

emergency.

14 Operate the pneumatic valves manually if manual operation provision is there.

ANEXURE-1

SR. VALVE

KKS NO. DISCRIPTION MANUFATURE

NO. TYPE

PNEUMATIC GOVERNING VALVE OF MAIN STEAM NIIGATA AIR TO

1 12LBW10AA101

SUPPLY STATION MESONEILAN CLOSE

PNEUMATIC GOVERNING VALVE OF AUX. STEAM NIIGATA AIR TO

2 12LBW10AA102

SUPPLY STATION MESONEILAN CLOSE

PNEUMATIC GOVERNING VALVE OF OVER FLOW NIIGATA AIR TO

3 12LBW10AA103

STATION MESONEILAN CLOSE

REMOTE AIR TO

4 10LBA10AA402 DRAIN VALVE OF HP MAIN STEAM PIPING

Control CLOSE

DRAIN VALVE OF UPSTREAM #1 MEDIUM REMOTE AIR TO

5 10LBB10AA402

PRESSURE COM-BINED STEAM VALVE Control CLOSE

DRAIN VALVE OF UPSTREAM #2 MEDIUM REMOTE AIR TO

6 10LBB10AA412

PRESSURE COM-BINED STEAM VALVE Control CLOSE

DRAIN VALVE OF DOWNSTRE- AM RH STEAMLP REMOTE AIR TO

7 10LBB10AA422

BYPASS VAL-VE PIPING Control CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 4 of 17

DRAIN VALVE OF DOWNSTRE- AM HP DUMP REMOTE AIR TO

8 10LBC10AA402

STEAM PIPING CHECK VALVE Control CLOSE

DRAIN VALVE OF TURBINE SHAFT SEALING STEAM PISTON AIR TO

9 10LBW10AA425

SUPP-LY PIPING GLOBE VALVE CLOSE

DRAIN VALVE OF TURBINE SHAFT SEALING STEAM PISTON AIR TO

10 10MAM10AA405

LEAK- AGE PIPING GLOBE VALVE CLOSE

DRAIN VALVE OF BFPT SHAFT SEALING STEAM AIR TO

11 10XAW50AA401

SUPPLY PIPING CLOSE

DRAIN VALVE OF UPSTREAM COLD REHEAT CHECK REMOTE AIR TO

12 12LBC10AA402

VALVE Control CLOSE

AIR TO

13 12MAL10AA402 DRAIN VALVE OF #2 HP MSV UPPER VALVE BASE FISHER

CLOSE

AIR TO

14 12MAL10AA404 DRAIN VALVE OF #1 HP MSV UPPER VALVE BASE FISHER

CLOSE

AIR TO

15 12MAL10AA406 DRAIN VALVE OF HP STEAM GUIDE TUBE FISHER

CLOSE

DRAIN VALVE OF #2 MEDIUM PRESSURE AIR TO

16 12MAL10AA412 FISHER

COMBINED STEAM VALVE CLOSE

DRAIN VALVE OF #1 MEDIUM PRESSURE AIR TO

17 12MAL10AA414 FISHER

COMBINED STEAM VALVE CLOSE

DRAIN VALVE OF UPSTREAM #1 HP MAIN STOP AIR TO

18 12MAL10AA408 FISHER

VALVE CLOSE

DRAIN VALVE OF UPSTREAM #2 HP MAIN STOP AIR TO

19 12MAL10AA410 FISHER

VALVE CLOSE

PISTON AIR TO

20 10LBS60AA421 5th EXTRACTION STEAM PIPING DRAIN

GLOBE VALVE CLOSE

PISTON AIR TO

21 10LBS60AA411 5th EXTRACTION STEAM PIPING DRAIN

GLOBE VALVE CLOSE

UPSTREAM 5ST EXTRACTION STEAM PIPING CHECK AIR TO

22 12LBS60AA401 FISHER

VALVE DRAIN CLOSE

PISTON AIR TO

23 10LBS50AA421 5th EXTRACTION STEAM PIPING DRAIN

GLOBE VALVE CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 5 of 17

PISTON AIR TO

24 10LBS50AA411 5th EXTRACTION STEAM PIPING DRAIN

GLOBE VALVE CLOSE

UPSTREAM 5th EXTRACTION STEAM PIPING CHECK AIR TO

25 12LBS50AA401 FISHER

VALVE DRAIN CLOSE

VALVE IN CONDENSATE WATER STORAGE TANK CHINESE AIR TO

26 10LCA25AA101

INLET MAKE OPEN

CHINESE AIR TO

27 10LCA40AA101 DEAERATOR WATER LEVEL VALVE

MAKE OPEN

CHINESE AIR TO

28 10LCA40AA102 DEAERATOR WATER LEVEL SUB CONTROL VALVE

MAKE OPEN

AIR TO

29 10LCA45AA101 VALVE OF CONDENSATE WATER MINIMUM FLOW NOT FOUND

CLOSE

ATTEMPERATING WATER VALVE OF CONDENSER A AIR TO

30 10LCE12AA101 FISHER

THIRD ATTEMPERATOR CLOSE

ATTEMPERATING WATER VALVE OF CONDENSER b AIR TO

31 10LCE13AA101 FISHER

THIRD ATTEMPERATOR CLOSE

ATTEMPERATING WATER VALVE OF FUEL OIL CHINESE AIR TO

32 10LCE21AA101

ATTEMPERATOR OF AUX. STEAM MAKE CLOSE

ATTEMPERATING WATER VALVE OF LP AIR TO

33 10LCA22AA101 MESONEILAN

ATTEMPERATOR OF GLAND SEAL STEAM SYSTEM OPEN

ATTEMPERATING WATER VALVE OF NO.1 PROPER AIR TO

34 10LCE22AA102 FISHER

DRAIN FLASH TANK CLOSE

AIR TO

35 10LCA23AA101 SPRAYING WATER VALVE OF LP CYLINDER FISHER

OPEN

ATTEMPERATING WATER VALVE OF NO.1 PROPER AIR TO

36 10LCE27AA101 FISHER

DRAIN FLASH TANK CLOSE

VALVE OF TURBINE PREHEATING STEAM PRE.

CHINESE AIR TO

37 10LCE28AA101 REDUCING AND DESUPERHEATING DEVICE OF

MAKE CLOSE

AUX.STEAM SYSTEM

VALVE OF GLAND SEAL STEAM ATTEMP ERATOR OF CHINESE AIR TO

38 10LCE29AA101

AUX STEAM SYSTEM MAKE CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 6 of 17

CHINESE AIR TO

39 10LCP40AA101 CONDENSER WATER MAKE-UP VALVE

MAKE OPEN

AIR TO

40 10XAL10AA401 DRAIN VALVE BEFORE LP MSV OF BFPT A FISHER

CLOSE

AIR TO

41 10XAL20AA401 DRAIN VALVE BEFORE LP MSV OF BFPT B FISHER

CLOSE

AB JAPAN AIR TO

42 10LAB55AA101 T-BFP A MINIMUM FLOW VALVE

VALVE CCI K.K CLOSE

AB JAPAN AIR TO

43 10LAB65AA101 T-BFP B MINIMUM FLOW VALVE

VALVE CCI K.K CLOSE

COPES AIR TO

44 10LAH35AA101 M-BFP MINIMUM FLOW VALVE

VULCAN CLOSE

RH DESUPERHEATER A ATTEMPERATING WATER COPES AIR TO

45 11HAM20AA111

VALVE VULCAN CLOSE

RH DESUPERHEATER B ATTEMPERATING WATER COPES AIR TO

46 11HAM20AA121

VALVE VULCAN CLOSE

FIRST CLASS SH DESUPERHEATER A COPES AIR TO

47 11HAM11AA112

ATTEMPERATING WATER VALVE VULCAN CLOSE

FIRST CLASS SH DESUPERHEATER A COPES AIR TO

48 11HAM11AA122

ATTEMPERATING WATER VALVE VULCAN CLOSE

SECOND CLASS SH DESUPERHEATER A COPES AIR TO

49 11HAM12AA112

ATTEMPERATING WATER VALVE VULCAN CLOSE

SECOND CLASS SH DESUPERHEATER B COPES AIR TO

50 11HAM12AA112

ATTEMPERATING WATER VALVE VULCAN CLOSE

PISTON AIR TO

51 10LBS40AA410 4TH EXTRACTION STM PNEUMATIC DRAIN VALVE

GLOBE VALVE CLOSE

PISTON AIR TO

52 10LBS40AA411 4th EXTRACTION STM PNEUMATIC DRAIN VALVE

GLOBE VALVE CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 7 of 17

PISTON AIR TO

53 10LBS40AA421 4th EXTRACTION STM PNEUMATIC DRAIN VALVE

GLOBE VALVE CLOSE

REMOTE AIR TO

54 20LBQ30AA412 3rd EXTRACTION STM PNEUMATIC CHECK VALVE

Control CLOSE

REMOTE AIR TO

55 20LBQ30AA422 3rdEXTRACTION STM PNEUMATIC DRAIN VALVE

Control CLOSE

REMOTE AIR TO

56 20LBQ10AA412 1st EXTRACTION STM PNEUMATIC DRAIN VALVE

Control CLOSE

REMOTE AIR TO

57 20LBQ10AA422 1st EXTRACTION STM PNEUMATIC DRAIN VALVE

Control CLOSE

AIR TO

58 22LBQ20AA402 2nd EXTRACTION STM PNEUMATIC DRAIN VALVE FISHER

CLOSE

AIR TO

59 22LBQ10AA402 1st EXTRACTION STM PNEUMATIC DRAIN VALVE FISHER

CLOSE

AIR TO

60 22LBQ30AA402 3rd EXTRACTION STM PNEUMATIC CHECK VALVE FISHER

OPEN

AIR TO

61 22LBQ40AA401 4TH EXTRACTION STM PNEUMATIC DRAIN VALVE FISHER

CLOSE

BFP-B LOW PRESSURE STEAM AND PISTON AIR TO

62 20LBR12AA401

COMMISSIONING STM. DRAIN VALVE GLOBE VALVE CLOSE

BFP-A LOW PRESSURE STEAM AND PISTON AIR TO

63 20LBR11AA401

COMMISSIONING STM. PNEUMATIC DRAIN VALVE GLOBE VALVE CLOSE

BFPT- B INTERMEDIATE PRESSURE CONTROL DRAIN REMOTE AIR TO

64 20LBR20AA422

VLV Control CLOSE

BFPT-A INTERMEDIATE PR. CONTROL PNEUMATIC REMOTE AIR TO

65 20LBR20AA412

DRAIN VALVE Control CLOSE

ATTEMPERATING WATER VALVE OF FUEL OIL AIR TO

66 10LCE21AA101 CHINESE

ATTEMPERATOR OF AUX. STEAM CLOSE

ATTEMPERATING WATER VALVE OF NO.1 PROPER AIR TO

67 10LCA22AA102 FISHER

DRAIN FLASH TANK CLOSE

ATTEMPERATING WATER VALVE OF NO.1 PROPER AIR TO

68 10LCA27AA101 FISHER

DRAIN FLASH TANK CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 8 of 17

VALVE OF TURBINE PREHEATING STEAM PRE.

AIR TO

69 10LCE28AA101 REDUCING AND DESUPERHEATING DEVICE OF CHINESE

CLOSE

AUX.STEAM SYSTEM

VALVE OF GLAND SEAL STEAM ATTEMP ERATOR OF AIR TO

70 10LCE29AA101 CHINESE

AUX STEAM SYSTEM CLOSE

REMOTE AIR TO

71 10LBA10AA412 Pipe drain valve before MSV1(left)

CONTROL CLOSE

REMOTE AIR TO

72 10LBA10AA422 Pipe drain valve before MSV2(right)

CONTROL CLOSE

AIR TO

73 12LBC10AA001 H.P. cylinder exhaust check valve CHINESE

OPEN

74 12MAQ10AA002 H.P. cylinder ventilation valve

NO.1 steam extraction piping pneumatic operated AIR TO

75 12LBQ10AA001 SEMPELL AG.

NRV OPEN

NO.1 steam extraction piping pneumatic operated AIR TO

76 12LBQ10AA402 FISHER

drain valve 1 CLOSE

NO.1 steam extraction piping pneumatic operated REMOTE AIR TO

77 10LBQ10AA412

drain valve 2 CONTROL CLOSE

NO.1 steam extraction piping pneumatic operated REMOTE AIR TO

78 10LBQ10AA422

drain valve 3 CONTROL CLOSE

NO.2 steam extraction piping pneumatic operated AIR TO

79 12LBQ20AA001 SEMPELL AG.

NRV OPEN

NO.2 steam extraction piping pneumatic operated AIR TO

80 12LBQ20AA402 FISHER

drain valve 1 CLOSE

NO.2 steam extraction piping pneumatic operated REMOTE AIR TO

81 10LBQ20AA412

drain valve 2 CONTROL CLOSE

NO.3 steam extraction piping pneumatic operated AIR TO

82 12LBQ30AA001 SEMPELL AG.

NRV OPEN

NO.3 steam extraction piping pneumatic operated AIR TO

83 12LBQ30AA402 FISHER

drain valve 1 CLOSE

NO.3 steam extraction piping pneumatic operated REMOTE AIR TO

84 10LBQ30AA412

drain valve 2 CONTROL CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 9 of 17

NO.3 steam extraction piping pneumatic operated REMOTE AIR TO

85 10LBQ30AA422

drain valve 3 CONTROL CLOSE

ZHEJIANG

NO.4 steam extraction piping to BFPT A SANFANG AIR TO

86 10LBR11AA401

pneumatic operated drain valve GROUP CO. CLOSE

LTD.

ZHEJIANG

NO.4 steam extraction piping to BFPT B SANFANG AIR TO

87 10LBR12AA401

pneumatic operated drain valve GROUP CO. CLOSE

LTD.

NO.4 steam extraction piping pneumatic operated AIR TO

88 12LBS40AA001 SEMPELL AG.

NRV 1 OPEN

NO.4 steam extraction piping pneumatic operated AIR TO

89 12LBS40AA002 SEMPELL AG.

NRV 2 OPEN

NO.4 steam extraction piping pneumatic operated AIR TO

90 12LBS40AA401 FISHER

drain valve 1 OPEN

NO.4 steam extraction piping to deaerator AIR TO

91 10LBS40AA431

pneumatic operated drain valve OPEN

NO.5 steam extraction piping pneumatic operated AIR TO

92 12LBS50AA001 SEMPELL AG.

NRV OPEN

NO.6 steam extraction piping pneumatic operated AIR TO

93 12LBS60AA001 SEMPELL AG.

NRV OPEN

RH. desuperheater attemperating water mains COPES AIR TO

94 11HAM20AA002

pneumatic valve VULCAN CLOSE

first class SH desuperheater A attemperating COPES AIR TO

95 11HAM11AA011

water pneumatic valve VULCAN CLOSE

first class SH desuperheater B attemperating COPES AIR TO

96 11HAM11AA021

water pneumatic valve VULCAN CLOSE

second class SH desuperheater A attemperating COPES AIR TO

97 11HAM12AA011

water pneumatic valve VULCAN CLOSE

second class SH desuperheater B attemperating COPES AIR TO

98 11HAM12AA021

water pneumatic valve VULCAN CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 10 of 17

NO.1 HP heater normal drain pneumatic operated COPES AIR TO

99 10LCH10AA101

control valve VULCAN CLOSE

NO.1 HP heater emergency drain pneumatic COPES AIR TO

100 10LCH15AA002

operated valve VULCAN CLOSE

NO.2 HP heater normal drain pneumatic operated COPES AIR TO

101 10LCH20AA101

control valve VULCAN CLOSE

NO.2 HP heater emergency drain pneumatic COPES AIR TO

102 10LCH25AA002

operated valve VULCAN CLOSE

NO.3 HP heater normal drain pneumatic operated COPES AIR TO

103 10LCH30AA101

control valve VULCAN CLOSE

NO.3 HP heater emergency drain pneumatic COPES AIR TO

104 10LCH35AA002

operated valve VULCAN CLOSE

NO.5 LP heater normal drain pneumatic operated AIR TO

105 10LCJ50AA101 FISHER

control valve CLOSE

NO.5 LP heater emergency drain pneumatic AIR TO

106 10LCJ55AA101 FISHER

operated valve CLOSE

NO.6 LP heater normal drain pneumatic operated AIR TO

107 10LCJ60AA101 FISHER

control valve A OPEN

NO.6 LP heater normal drain pneumatic operated AIR TO

108 10LCJ60AA102 FISHER

control valve B OPEN

NO.6 LP heater emergency drain pneumatic AIR TO

109 10LCJ65AA101 FISHER

operated valve CLOSE

NO.7A LP heater normal drain pneumatic operated AIR TO

110 10LCJ70AA101 FISHER

control valve CLOSE

NO.7A LP heater emergency drain pneumatic AIR TO

111 10LCJ75AA101 FISHER

operated valve CLOSE

NO.7B LP heater normal drain pneumatic operated AIR TO

112 10LCJ71AA101 FISHER

control valve CLOSE

NO.7B LP heater emergency drain pneumatic AIR TO

113 10LCJ76AA101 FISHER

operated valve CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 11 of 17

NO.8A LP heater normal drain pneumatic operated AIR TO

114 10LCJ80AA101 FISHER

control valve CLOSE

NO.8A LP heater emergency drain pneumatic AIR TO

115 10LCJ85AA101 FISHER

operated valve CLOSE

NO.8B LP heater normal drain pneumatic operated AIR TO

116 10LCJ81AA101 FISHER

control valve CLOSE

NO.8B LP heater emergency drain pneumatic AIR TO

117 10LCJ86AA101 FISHER

operated valve CLOSE

pneumatic control valve from cold reheat steam to AIR TO

118 10LBG15AA101 CHINESE

auxiliary steam CLOSE

pneumatic control valve located steam pipe from AIR TO

119 10LBG51AA101 CHINESE

auxiliary steam to #1 steam air heater CLOSE

pneumatic control valve located steam pipe from AIR TO

120 10LBG52AA101 CHINESE

auxiliary steam to #2 steam air heater CLOSE

Pneumatic drain valve of main steam supply for REMOTE AIR TO

121 10LBW10AA402

gland sealing piping CONTROL CLOSE

Pneumatic drain valve of BFPT shaft sealing steam

122 10XAM50AA401

leakage piping

AIR TO

123 10MAJ15AA002 pneumatic butterfly valve in vacuum pump A inlet TYCO

OPEN

124 10MAJ15AA004 make-up water solenoid valve of vacuum pump A

AIR TO

125 10MAJ16AA002 pneumatic butterfly valve in vacuum pump B inlet TYCO

OPEN

126 10MAJ16AA004 make-up water solenoid valve of vacuum pump B

AIR TO

127 10MAJ17AA002 pneumatic butterfly valve in vacuum pump C inlet TYCO

OPEN

128 10MAJ17AA004 make-up water solenoid valve of vacuum pump C

Solenoid Valve On Cooling Water Pipe of Seal Oil

129 13MKW10AA001

Vacuum Pump

130 13MKW10AA002 Lubricating Oil Solenoid of Seal Oil Vacuum Pump

Generator stator water cooler outlet pneumatic AIR TO

131 10PAK42AA101 CHINESE

valve CLOSE

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 12 of 17

AIR TO

132 10PAK45AA101 Turbine oil cooler outlet pneumatic valve CHINESE

CLOSE

AIR TO

133 10PAK43AA101 hydrogen cooler outlet #1 pneumatic valve CHINESE

CLOSE

AIR TO

134 10PAK43AA102 Hydrogen cooler outlet #2 pneumatic valve CHINESE

CLOSE

Feed water pump A turbine oil cooler outlet AIR TO

135 10PAK49AA101 CHINESE

pneumatic valve CLOSE

Feed water pump B turbine oil cooler outlet AIR TO

136 10PAK49AA102 CHINESE

pneumatic valve CLOSE

Pneumatic control valve of closed cycle cooling AIR TO

137 10PGB41AA101 CHINESE

water expansion tank CLOSE

AIR TO

138 11HJF80AA001 HFO RETURN OIL QUICK CLOSING VALVE SWAGELOK

OPEN

PNEUMATIC CONTROL VALVE OF STEAM AIR AIR TO

139 10LCN10AA101

HEATER DRAIN CLOSE

AIR TO

140 11HJF70AA007 HFO INPUT OIL QUICK CLOSING VALVE

OPEN

AIR TO

141 11HJM70AA101 ATOMISING STEAM PNEUMATIC CONTROL VALVE

OPEN

AIR TO

142 11HJF85AA001 LDO RETURN OIL QUICK CLOSING VALVE

OPEN

LDO PRESSURE PNEUMATIC CONTROL VALVE OF AIR TO

143 11HJF75AA101

INPUT OIL OPEN

AIR TO

144 11HJF75AA007 LDO INPUT OIL QUICK CLOSING VALVE

OPEN

HFO PRESSURE PNEUMATIC CONTROL VALVE OF AIR TO

145 11HJF75AA105

INPUT OIL OPEN

AIR TO

146 11HJF71AA032 PNEUMATIC VALVE OF OIL INLET VALVE

OPEN

AIR TO

147 11HJF71AA033 PNEUMATIC VALVE OF PURGING VALVE

OPEN

AIR TO

148 11HJM71AA032 PNEUMATIC VALVE OF ATOMIZING VALVE

OPEN

coal cut-off pneumatic-operated valve of A mill

149 10HHE10AA001 CYLINDER

A1 pulverized coal feed pipe

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 13 of 17

coal cut-off pneumatic-operated valve of A mill

150 10HHE10AA003 CYLINDER

A3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of A mill

151 10HHE10AA002 CYLINDER

A2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of A mill

152 10HHE10AA004 CYLINDER

A4 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of B mill

153 10HHE20AA001 CYLINDER

B1 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of B mill

154 10HHE20AA003 CYLINDER

B3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of B mill

155 10HHE20AA002 CYLINDER

B2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of B mill

156 10HHE20AA004 CYLINDER

B4 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of C mill

157 10HHE30AA001 CYLINDER

C1 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of C mill

158 10HHE30AA003 CYLINDER

C3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of C mill

159 10HHE30AA002 CYLINDER

C2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of C mill

160 10HHE30AA004 CYLINDER

C4 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of D mill

161 10HHE40AA001 CYLINDER

D1 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of D mill

162 10HHE40AA003 CYLINDER

D3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of D mill

163 10HHE40AA002 CYLINDER

D2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of D mill

164 10HHE40AA004 CYLINDER

D4 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of E mill

165 10HHE50AA001 CYLINDER

E1 pulverized coal feed pipe

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 14 of 17

coal cut-off pneumatic-operated valve of E mill

166 10HHE50AA003 CYLINDER

E3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of E mill

167 10HHE50AA002 CYLINDER

E2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of E mill

168 10HHE50AA004 CYLINDER

E4 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of F mill

169 10HHE60AA001 CYLINDER

F1 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of F mill

170 10HHE60AA003 CYLINDER

F3 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of F mill

171 10HHE60AA002 CYLINDER

F2 pulverized coal feed pipe

coal cut-off pneumatic-operated valve of F mill

172 10HHE60AA004 CYLINDER

F4 pulverized coal feed pipe

173 10HFB10AA001 outlet pneumatic-operated valve A1 coal feeder CYLINDER

174 10HFB10AA002 outlet pneumatic-operated valve A2 coal feeder CYLINDER

175 10HFB20AA001 outlet pneumatic-operated valve B1 coal feeder CYLINDER

176 10HFB20AA002 outlet pneumatic-operated valve B2 coal feeder CYLINDER

outlet pneumatic-operated valve C1 coal

177 10HFB30AA001 CYLINDER

feeder

outlet pneumatic-operated valve C2 coal

178 10HFB30AA002 CYLINDER

feeder

outlet pneumatic-operated valve D1 coal

179 10HFB40AA001 CYLINDER

feeder

outlet pneumatic-operated valve D2 coal

180 10HFB40AA002 CYLINDER

feeder

181 10HFB50AA001 outlet pneumatic-operated valve E1 coal feeder CYLINDER

182 10HFB50AA002 outlet pneumatic-operated valve E2 coal feeder CYLINDER

183 10HFB60AA001 outlet pneumatic-operated valve F1 coal feeder CYLINDER

184 10HFB60AA002 outlet pneumatic-operated valve F2 coal feeder CYLINDER

185 10HFC10AA004 A mill slowing mesh solenoid valve CYLINDER

186 10HFC20AA004 B mill slowing mesh solenoid valve CYLINDER

187 10HFC30AA004 C mill slowing mesh solenoid valve CYLINDER

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 15 of 17

188 10HFC40AA004 D mill slowing mesh solenoid valve CYLINDER

189 10HFC50AA004 E mill slowing mesh solenoid valve CYLINDER

190 10HFC60AA004 F mill slowing mesh solenoid valve CYLINDER

#1 screw air compressor outlet pneumatic INGERSOLL AIR TO

191 A0SCA01AA001

shut-off valve RAND OPEN

#2 screw air compressor outlet pneumatic INGERSOLL AIR TO

192 A0SCA02AA001

shut-off valve RAND OPEN

#3 screw air compressor outlet pneumatic INGERSOLL AIR TO

193 A0SCA03AA001.4011

shut-off valve RAND OPEN

#4 screw air compressor outlet pneumatic INGERSOLL AIR TO

194 A0SCA04AA001.4011

shut-off valve RAND OPEN

#5 screw air compressor outlet pneumatic INGERSOLL AIR TO

195 A0SCA05AA001.4011

shut-off valve RAND OPEN

#6 screw air compressor outlet pneumatic INGERSOLL AIR TO

196 A0SCA06AA001.4011

shut-off valve RAND OPEN

#7 screw air compressor outlet pneumatic INGERSOLL AIR TO

197 A0SCA07AA001.4011

shut-off valve RAND OPEN

#8 screw air compressor outlet pneumatic INGERSOLL AIR TO

198 A0SCA08AA001.4011

shut-off valve RAND OPEN

#9 screw air compressor outlet pneumatic INGERSOLL AIR TO

199 A0SCA09AA001.4011

shut-off valve RAND OPEN

#10 screw air compressor outlet pneumatic INGERSOLL AIR TO

200 A0SCA10AA001.4011

shut-off valve RAND OPEN

#11 screw air compressor outlet pneumatic INGERSOLL AIR TO

201 A0SCA11AA001.4011

shut-off valve RAND OPEN

#12 screw air compressor outlet pneumatic INGERSOLL AIR TO

202 A0SCA12AA001.4011

shut-off valve RAND OPEN

#13 screw air compressor outlet pneumatic INGERSOLL AIR TO

203 A0SCA13AA001.4011

shut-off valve RAND OPEN

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 16 of 17

#14 screw air compressor outlet pneumatic INGERSOLL AIR TO

204 A0SCA14AA001.4011

shut-off valve RAND OPEN

HANGZHOU

1st filter of #1 combined air dryer inlet AIR TO

205 A0SCB10AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #1 combined air dryer inlet AIR TO

206 A0SCB10AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #2 combined air dryer inlet AIR TO

207 A0SCB20AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #2 combined air dryer inlet AIR TO

208 A0SCB20AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #3 combined air dryer inlet AIR TO

209 A0SCB30AA002XG01 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #3 combined air dryer inlet AIR TO

210 A0SCB30AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #4 combined air dryer inlet AIR TO

211 A0SCB40AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #4 combined air dryer inlet AIR TO

212 A0SCB40AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #5 combined air dryer inlet AIR TO

213 A0SCB50AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

VEDANTA LIMITED, 4*600 MW TPP – JHARSUGUDA

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: TPP-TURBINE OPERATION

WORK INSTRUCTION TITLE: STANDARD OPERATION PROCEDURE OF AIR FAILURE

VER.NO: 01 REV.NO : 07 TPP/WI-BTG/OPE/041 DATE:27.11.2020 PAGES 17 of 17

HANGZHOU

2nd filter of #5 combined air dryer inlet AIR TO

214 A0SCB50AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #6 combined air dryer inlet AIR TO

215 A0SCB60AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #6 combined air dryer inlet AIR TO

216 A0SCB60AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

1st filter of #7 combined air dryer inlet AIR TO

217 A0SCB70AA002.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

HANGZHOU

2nd filter of #7 combined air dryer inlet AIR TO

218 A0SCB70AA003.4011 SHANLI, SLD-

pneumatic shut-off valve OPEN

90NW

PREPARED BY REVIEWED BY APPROVED BY

SIGNATURE

NAME KALYAN P.S.KUMAR

You might also like

- ZF P-7300 Manual de PartesDocument3 pagesZF P-7300 Manual de Parteshenotharenas50% (2)

- Automotive Wiring and Circuit DiagramsDocument36 pagesAutomotive Wiring and Circuit Diagramsngelectronic522674% (27)

- Scooty PEPDocument55 pagesScooty PEPAnonymous hPeqAze79% (14)

- TM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 1Document100 pagesTM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 1AdvocateNo ratings yet

- Wiring R15 V3Document2 pagesWiring R15 V3arrahmah 2150% (4)

- Technical Diary ThermalDocument121 pagesTechnical Diary ThermalKush SharmaNo ratings yet

- Beechcraft Baron 58P and Baron 58Tc Maintenance Manual: List of Page EffectivityDocument25 pagesBeechcraft Baron 58P and Baron 58Tc Maintenance Manual: List of Page EffectivityRicardo zafraNo ratings yet

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- 22 SOP of Vaccum PullingDocument18 pages22 SOP of Vaccum PullingSiddhant Satpathy100% (1)

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Power Plant and Calculations - Power Plant Equipments Standard Operating Procedures (SOP)Document7 pagesPower Plant and Calculations - Power Plant Equipments Standard Operating Procedures (SOP)RajeshNo ratings yet

- S06 - Turbine LossesDocument116 pagesS06 - Turbine LossesAmore S100% (1)

- OPERATION REVIEWDocument67 pagesOPERATION REVIEWVishal Kumar LaddhaNo ratings yet

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)SonratNo ratings yet

- DSM Charges SummaryDocument9 pagesDSM Charges Summaryshidupk5 pkNo ratings yet

- Presentation Synopsis: 18 Unit Level Professional Circle ConventionDocument9 pagesPresentation Synopsis: 18 Unit Level Professional Circle ConventionSCE Stage2No ratings yet

- Turbine Protection Class at AnparaDocument41 pagesTurbine Protection Class at Anparabiju singh100% (1)

- Thermal insulation wool mattress quality standardsDocument4 pagesThermal insulation wool mattress quality standardsjagan100% (1)

- 01 Boiler Design General (Compatibility Mode) PDFDocument82 pages01 Boiler Design General (Compatibility Mode) PDFTaraknath MukherjeeNo ratings yet

- JPL 4X600 MW SOP for LDO ChargingDocument4 pagesJPL 4X600 MW SOP for LDO Chargingjp mishraNo ratings yet

- BHAI KrishnapatnamDocument27 pagesBHAI KrishnapatnamRamakrishnan NatarajanNo ratings yet

- A-0. Introduction of Training ProgramDocument22 pagesA-0. Introduction of Training ProgramDangolNo ratings yet

- List of Abbreviations: Training Publication PMC-39-A0126-AF001-00Document10 pagesList of Abbreviations: Training Publication PMC-39-A0126-AF001-00Alexander Goez100% (1)

- DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015Document20 pagesDFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015KamalVirkNo ratings yet

- Bhel Internship ReportDocument32 pagesBhel Internship ReportShubham SinghNo ratings yet

- Seal Oil and Hydrogen SystemDocument34 pagesSeal Oil and Hydrogen Systemashish_ntpcNo ratings yet

- 78-001 Inst List R02 PDFDocument69 pages78-001 Inst List R02 PDFmaneesh_03No ratings yet

- Boiler Interlock and Protection PDFDocument25 pagesBoiler Interlock and Protection PDFShravani Thombre100% (1)

- Vacuum Pump SopDocument4 pagesVacuum Pump SopHarsh KhatriNo ratings yet

- Rotating Equipment & ServiceDocument12 pagesRotating Equipment & Servicenurkasih119No ratings yet

- Coal pulverizer operation and maintenance proceduresDocument7 pagesCoal pulverizer operation and maintenance proceduresPoojit PopliNo ratings yet

- Handling Stage 1 UPS FailureDocument4 pagesHandling Stage 1 UPS FailureNikhilNo ratings yet

- Chapt 2 Power RegulationDocument17 pagesChapt 2 Power RegulationManiraj ShresthaNo ratings yet

- Thermodynamic Correction Curves For Model n600-16 7538538 Steam TurbineDocument27 pagesThermodynamic Correction Curves For Model n600-16 7538538 Steam Turbinearunrajmech09No ratings yet

- Aircraft Equipment List05200729032017 PDFDocument270 pagesAircraft Equipment List05200729032017 PDFJacob Jack YoshaNo ratings yet

- U 3 Turbine Trip ReportDocument1 pageU 3 Turbine Trip ReportKarthi KeyanNo ratings yet

- Circuit Breakers Detailed Gyanendra Sharma Npti DelhiDocument78 pagesCircuit Breakers Detailed Gyanendra Sharma Npti DelhiNPTINo ratings yet

- Indiabulls Power Limited: SOP/OPNS/10 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/10 Operations DepartmentAmit SoniNo ratings yet

- SCED Pilot Study Lowers Generation Costs by Rs. 2.59 Cr DailyDocument11 pagesSCED Pilot Study Lowers Generation Costs by Rs. 2.59 Cr DailyPRAGNo ratings yet

- 3 - Presentation Antisurge Control 2016Document66 pages3 - Presentation Antisurge Control 2016Hayder WasselaNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984No ratings yet

- Standard Checklists for Electrical EquipmentDocument61 pagesStandard Checklists for Electrical EquipmentlrpatraNo ratings yet

- O & M Manual Ut-13000 - Dalmia DSP Unit-1Document62 pagesO & M Manual Ut-13000 - Dalmia DSP Unit-1ranjan shiveshNo ratings yet

- Pakistan Refinery Lube Oil System P&I DiagramDocument2 pagesPakistan Refinery Lube Oil System P&I Diagrammuieed siddiquiNo ratings yet

- Lalitpur Superthermal Power Project - 3 X 660 MWDocument10 pagesLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNo ratings yet

- Turbine EfficiencyDocument41 pagesTurbine EfficiencySouvik Datta100% (1)

- List of BHEL TOP File Handed Over To DocumentationDocument578 pagesList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikNo ratings yet

- Setting and Checking of EhgDocument15 pagesSetting and Checking of EhgShiva KotamrajuNo ratings yet

- G Alstom PDMSDocument177 pagesG Alstom PDMSsayedmhNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- تشغيل محطة بخارية مهم ورائع PDFDocument157 pagesتشغيل محطة بخارية مهم ورائع PDFelsayed100% (1)

- CEP - SavingDocument6 pagesCEP - SavingManoj UpadhyayNo ratings yet

- Technical Specification For Fly Ash Handling System, R0Document7 pagesTechnical Specification For Fly Ash Handling System, R0SumitskbNo ratings yet

- Black Out Is Land OperationDocument41 pagesBlack Out Is Land Operationstubborn002No ratings yet

- Air and Draft System Gyanendra Sharma NPTI DelhiDocument40 pagesAir and Draft System Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Tripping Report of Power PlantDocument3 pagesTripping Report of Power Plantmanohar kumarNo ratings yet

- Case Study - Boiler ExplosionDocument18 pagesCase Study - Boiler ExplosionSatish ChavanNo ratings yet

- STG Training MaterialDocument321 pagesSTG Training MaterialMashudi FikriNo ratings yet

- BHELDocument4 pagesBHELNageswara Reddy GajjalaNo ratings yet

- 033 Filtration Section Operation (Rev.-01 Date-17-01-2019)Document8 pages033 Filtration Section Operation (Rev.-01 Date-17-01-2019)Muhammad Umer RanaNo ratings yet

- SMP PSDocument3 pagesSMP PSSreekanthMylavarapuNo ratings yet

- 31-Planned Shut DownDocument2 pages31-Planned Shut DownSUBHASISH MUKHERJEENo ratings yet

- Jsa SJGT-1 10 10 10Document4 pagesJsa SJGT-1 10 10 10kas2via2No ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeDocument16 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeXmanyeyNo ratings yet

- s3109 FWG FinalDocument191 pagess3109 FWG FinalRaúl Oscar LedesmaNo ratings yet

- Standard Operation Procedure: H2 Storage Tank Draining, Hydrotest & Filling 4X600 MW TPP Val, Jharsuguda, OdishaDocument4 pagesStandard Operation Procedure: H2 Storage Tank Draining, Hydrotest & Filling 4X600 MW TPP Val, Jharsuguda, Odishaabhrrajjit SANo ratings yet

- Department: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJDocument12 pagesDepartment: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJabhrrajjit SANo ratings yet

- F2041s-K0305-01-O Deh & Meh Io ListDocument9 pagesF2041s-K0305-01-O Deh & Meh Io Listabhrrajjit SANo ratings yet

- NTPC Heat Rate PDFDocument395 pagesNTPC Heat Rate PDFcynaidu60% (5)

- Xuv 700 Price List July-2022Document1 pageXuv 700 Price List July-2022RahsbshsNo ratings yet

- BS6 Powerful D-Max Title Gets You AheadDocument16 pagesBS6 Powerful D-Max Title Gets You AheadAnkur MestryNo ratings yet

- Specifications The New BMW X1 Sdrive18d Valid From 07 2015Document2 pagesSpecifications The New BMW X1 Sdrive18d Valid From 07 2015Carlos AcostaNo ratings yet

- Piston and Rings - One-Piece PistonDocument4 pagesPiston and Rings - One-Piece PistonGolbert GolbiNo ratings yet

- RL 5550Document1 pageRL 5550luckybean717No ratings yet

- DYNAPAC F 150 C 769130 - SpecificationDocument254 pagesDYNAPAC F 150 C 769130 - Specificationhoan100% (2)

- Parts Manual: Shibaura Diesel EngineDocument36 pagesParts Manual: Shibaura Diesel Enginecesar100% (1)

- Montagem de Transmissão - 140HDocument32 pagesMontagem de Transmissão - 140Hamsm71No ratings yet

- Model Change of The "NICHIYU PLATTER" Electric Forklift Stand-On Reach TruckDocument5 pagesModel Change of The "NICHIYU PLATTER" Electric Forklift Stand-On Reach TruckLong ThaiNo ratings yet

- 61 Suzuki Esteem Wirin PDFDocument25 pages61 Suzuki Esteem Wirin PDFMiguel Esteban Betancourt CelisNo ratings yet

- Fuel Contamination ControlDocument2 pagesFuel Contamination ControlCarlos MoyaNo ratings yet

- P05 Braking PerformanceDocument58 pagesP05 Braking Performancepepiperepalo3No ratings yet

- Eaton Fuller Heavy Duty Transmissions: Illustrated Parts List AT-1202 March 2003Document20 pagesEaton Fuller Heavy Duty Transmissions: Illustrated Parts List AT-1202 March 2003LEOBARDONo ratings yet

- Grove Gmk6450Document100 pagesGrove Gmk6450cristiano.faddaNo ratings yet

- Tire Circumference Chart ReferenceDocument1 pageTire Circumference Chart ReferenceLazharus HannibalNo ratings yet

- Numax Marine2Document2 pagesNumax Marine2Emily AlexanderNo ratings yet

- DS5 Brochure PDFDocument41 pagesDS5 Brochure PDFIvan RafailovicNo ratings yet

- CO2 Technical Data Sheets - 2020 UL FM VDSDocument20 pagesCO2 Technical Data Sheets - 2020 UL FM VDSWendell de RidderNo ratings yet

- TNR Doors Hdl23Document53 pagesTNR Doors Hdl23Jocelyn SeguinNo ratings yet

- Made in Italy: Adblue® Catalogue - 5.19Document136 pagesMade in Italy: Adblue® Catalogue - 5.19Danijela NovakovicNo ratings yet

- Body Cource OutlineDocument2 pagesBody Cource OutlineAmanuelNo ratings yet

- Membrane Pressure Relief Valves: VHS-CDocument4 pagesMembrane Pressure Relief Valves: VHS-C88jdccNo ratings yet

- Se O Nly: Part CatalogueDocument63 pagesSe O Nly: Part CatalogueTrần Hải PhụngNo ratings yet

- Suzuki Outboard DT30 Owner's ManualDocument52 pagesSuzuki Outboard DT30 Owner's Manualrovad.edzagNo ratings yet