Professional Documents

Culture Documents

Tool Test

Uploaded by

BikramMuduliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tool Test

Uploaded by

BikramMuduliCopyright:

Available Formats

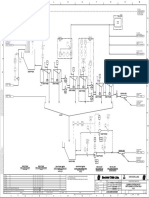

80

409

1,6

1,6

2

220 0,1 100 0,025 *HR* 0,02 X

30

+0,2

20 0,1

B7

0

5

0,

9,6

R 0,8 R

3,2

R0

0,4

3,2

2 ,2 1,6

+0,2

R 0, 0,8

12 9,6 0

,8

R0

1,6

5

0

5,85 -0,1

,2

R3

R0

R

R0

0,

,2 5

8

3,2 4

0,8

0,4

30

,2

R0

R0

2

R3

20

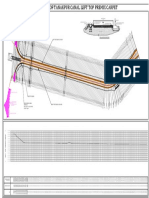

846,4 PAINTING EXTERNAL LIMIT

,2

R

8

1,6

0,

R

R 0,

*HB*

2

8

X

30

1,6

0,02

R

0,

X

0,

R

R1

X

8

8

R

X

0,02

0,02

0,02

850 g6 *HC*

1,6

+0,1

0

1 x45 13

0,1

418,3

1,6

836 f7

+0,2

9,6

+0,1

55

960

0,025 40,4

B1 (C1) 0

0

DETAIL

+0,1

0

2:1

838,3

SCALE

B7 (A5)

920

44,7 DETAIL

5 RAW POSITION DIM.

SCALE 2:1

STARTING DIM. FOR MACHINING

E3 R8 D1

SH.3 0 SH.2

295 FROM

135

E4

B1

R 80

3,2 R

3

3

R3

21

R

R

3

1,6 R

R3 3

R

3 3 R

5

R

1 x45

0,02 X 8

0,02 Y R 0,

3

3 R

R

1 x45

3,2

3,2

3,2

0,

5

+0,1

12 6,5 0

D6 15 3,2 1,6 15 1,6 1,6

8

30 1,6

15

1,6

15

2 2 4

2

R 0,2

R0

3,2

*GA*

,2

1 x45

3,2

X

1,6

30

0,02

3,2

330 H7 *BA*

3,2

210 H7 *EA*

281 H7

283 H7

+0,1

285 H7

287 H7

475 H7

+0,1

270 H7

3,2

340

226 H12

+0,2

330

+0,1

+0,1

12 0,1

289

461

305

1 x45 2 1 x45

0

308

430 g6

6,3 3,2 1,6 0,8 0,4

257

220

378

0,2 x45 DETAIL D6 (D1)

SCALE 2:1

+0,1

10 0 0,2 x45 NOTES:

1-MACHINING AND CHECKING RULES ACC. TO ITEM 3

0,02 Y

Y 2-DIMENSIONS WITHOUT INDICATION OF TOLERANCE

+0,25 ACC. TO ITEM 1.

5 +0,15

3-DIMENSIONS WITHOUT GEOMETRICAL TOLERANCE

ACC. TO ITEM 2.

4-THE VALUES OF THE GEOMETRICAL TOLERANCES

0,6 ARE THE MAX READING ON THE GAUGE (F.I.R.)

0

32 -0,2

1,6

5-UNLESS OTHERWISE SPECIFIED BREAK SHARP EDGES 0,5x45

30

6-UNLESS OTHERWISE SPECIFIED FILLET RADIUS R1.2

39,5 27,5

7-VERIFY THE EFFECTIVE BREAKTHROUGH OF THE

HOLES IN THE RISPECTIVE CHAMBERS.

WHERE THE PASSAGE SECTIONS RESULT REDUCED,

INCREASE AND BLEND WITH THE GRID.

543 PAINTING INTERNAL LIMIT

0

104 -0,2

*JN* 20 5 8-THE INTERFACE HOLES ARE BETWEEN THE

PRINCIPAL AXIS

,8

R0 9-ALL THE DIAMETERS WITH TOLERANCE H7

139 13 MUST BE 0.03 X

10-THE BOLD DIMENSION WITH SUFFIX *XX* ARE C.T.Q.

165 13

0,02 X 30

11-DOCUMENT FOR THE CODIFY OF THE C.T.Q. SEE ITEM 4

0,02 X

12-IF NOT OTHERWISE SPECIFIED ALL THE PLUGS HAVE

DETAIL E4 (C5)

538 js11

200 0,1 22 H7 5

SCALE 10:1 APPLICABLE DOCUMENTS TO BE WELDED

ITEM NP CODE DOCUMENT TITLE

DEVIATION FOR DIMENSIONS 13-WEIGHT 952 Kg.

238 1

WITHOUT INDICATION OF TOLERANCE

0,02 Y

GEOMETRICAL TOLERANCES FOR

2 FEATURES WITHOUT INDIVIDUAL

3,2

258 0,1 TOLERANCE INDICATION

MATERIAL RAW CODE FINISHED CODE

END FLANGES FOR CENTRIFUGAL

3 COMPRESSORS MANUFACTURING ASTM A350 LF6 CL.2

AND TESTING SPECIFICATIONS

274 0,1

REFERENCE REFERENCE DOCUMENTS

ITEM DENOMINATION CODE Q.TY

CODE ITEM NP CODE DOCUMENT TITLE

A PLUG 3/4" 1

INDIVIDUATION AND CODIFICATION

B PLUG 1" 4 4 OF CRITICAL DIMENSIONAL

C PLUG 1 1/2" 1 CHARACTERISTICS OF HEAD FLANGE

18 N 3 HOLES EQ. SP.

1 50,5 TO CORRESPONDENCE OF THE

40 EXISTING LIFTING HOLES

20 N 11 HOLES M 20

48 30 1 G1 E9 DEPTH 25/35

0 18,5 135 REF.

1

G2 -0.5 R 31,5

1 1 50

16

/2"

GAS

35

15

B8

36

33

XVIII C

1 G1

SECTION A5-A5 (C2)

160

N 4 HOLES M 24 XXV

38

DEPTH 36/48 G1-G1

1

G2 SECTION 1

38

0,2

XXV 26

F8

335

VII

B6

XVIII

22

79

0

D7 N 16 HOLES M 12 EQ. SPACED 32 175

DEPTH 20/26

30

30 60

0

38

30

22

32

XXVI

33

30

175 FROM

3,2

30

F1 HOLE 8 H12

D5 DEPTH 10

13

SECTION B8-B8 (A2)

ROTATED FOR CLARITY

1,5

11,25

R3 375 517 50,5

SECTION B6-B6 (A4)

ROTATED FOR CLARITY 135

30

30

70

B9 50 COUNTERBORE

A5

0,8

65 H7

F4 A5 SH.3 44 M 16 N 3 HOLES EQ. SP.

30

F8 0,2 FOR SPANSET EYEBOLTS

9

R 14

16 35

36

31,5

121 0

12

5 x15

12

1,6

1" G 16

AS

2

30

30

27

35

B

26

45

23

XXII

5

68 R 0,8

478

33

35

F5 45

TO

25

XXVI

211

38

330

B5 G2-G2 1

28

SECTION

SH.3 VII

5

28,

20 20

160

XXIV

(DRAIN)

38

XXVII 25

XXIII

3,2

VIEW D1 (B5 SH.1)

17

F6 20 H12 DEPTH 15

150

B4

F2 18,5

20 XXI SH.3 75

,5 250

R 169

B2 XIII 2 3

N 4 HOLES M 20

R4 XXX SECTION D5-D5 (B1) DEPTH 40/50

SH.3 ROTATED FOR CLARITY

13

10

10

12 11 SECTION D7-D7 (B1)

ROTATED FOR CLARITY

F2 44 32 B3

75

30 42

112,5 FROM

SH.3

DETAIL F1 (B3) SECTION F2-F2 (F1) G3

1:1

92

370 FROM

SCALE

SCALE 1:1

E1

40

DETAIL E9 (A3)

5 2 SCALE 1:2

R

90

22

31

25

17

0

R3

XXIV G3

17

E1

440

E7

SECTION E1-E1 (E3) R0

,8

29

200 FROM

180 XXVII

27

40 2

45 10 0

R

92 XXII

A

15

R

90

VIEW E7

20

23

" GAS

3/4

12

28

SECTION F4-F4 (C1) 18

ROTATED FOR CLARITY SECTION F5-F5 (D1) SECTION F6-F6 (D2)

SECTION G3-G3 2 ROTATED FOR CLARITY 50,5 ROTATED FOR CLARITY

75

22

39

0

25

25

I

190

XXI

22 XIII

165

25

25

H

UG

400

10

10

RO

27

TH

340

22

345

22

10

170

XXX XXIII

25

5

39,

23

B

23

26

23

26

26

B

B

1" GAS

AS S

1" G 1" GA

12

35

12

12

35

,5 18,5 35

12

50,5 SECTION B3-B3 (E3 SH.2) 10

ROTATED FOR CLARITY 50,5

50,5

SECTION B2-B2 (D2 SH.2) SECTION B4-B4 (D4 SH.2)

ROTATED FOR CLARITY ROTATED FOR CLARITY

SECTION B5-B5 (C4 SH.2)

ROTATED FOR CLARITY

N 4 HOLES M 20

N 4 HOLES M 20 EQ. SPACED DEPTH 27/36 N 4 HOLES M 14

N 4 HOLES M 14 FLANGE 1" 2500# RJ

EQ. SPACED DEPTH 33/41 EQ. SPACED DEPTH 20/30

FLANGE 3/4" 2500# RJ EQ. SPACED DEPTH 20/30 SECTION

N 4 HOLES M 14 B9-B9 (C5 SH.2) FLANGE 1 1/2" 150# RF

N 8 HOLES M 16 DEPTH 32/36

FLANGE 1" 150# RF ROTATED FOR CLARITY

45 EQ. SPACED DEPTH 20/30

44 FLANGE 3/4" 150# RF

45 ,5 45

45

,95

107

5 7 42

95,

2 79,3 5 98,

69,8

30

30

VIEW C5

VIEW C4 VIEW C6 VIEW C8

,2 FOR CONNECTION: VIEW C7 FOR CONNECTION:

0 FOR CONNECTION: XXVI, XXI, I FOR CONNECTION: FOR CONNECTION:

2 XVIII, XXIV, XXVII, XIII XXII, XXIII XXV

89 XXX

30

8,731 0,2

E6

1,6

1,6

5

0,

23

17

17

23

0,5

3,2

46

9

39

+0,4

0,1

E6

R

4

FR

0

R

0,

9

OM

,7

79

6,35

R0

4

VIEW D4 (F6) 20 50,8 0,13

16

E9-E9

17

SECTION

64

17

0,1 SCALE 2:1

FOR CONNECTION:

FROM

XVIII, XXIV, XXVII, XIII

M8

FROM

45

0,1

0,1

+0,2

21

0

369

426

8,731

19,6

0,2

R1

SECTION E6-E6 (D5)

R1

1,6

1,6

3,2

5

0,

23

3,2

E5

23

0,

5

30

28 28 3,2

90

+0,4

0

6 6

R0

94

6,35

,7

,7

0,5 x45

94

R0

3,2

60,32 0,13

64,5 H7

73 SECTION F9-F9

50 FOR CONNECTION:

XXII, XXIII

E5 D4

SECTION E5-E5 (F3)

ROTATED FOR CLARITY

TYP. 4 POS.

VIEW E3 (C1 SH.1)

You might also like

- 01 - Levantamento TopoDocument1 page01 - Levantamento TopoJuliana LimaNo ratings yet

- NEBB Psych Chart Sea Level 11x17Document1 pageNEBB Psych Chart Sea Level 11x17JojolasNo ratings yet

- Est Act - AYADocument1 pageEst Act - AYAFiorela Anait Vera ParqueNo ratings yet

- E-T2-02-VIGAS SOTANO 2Document1 pageE-T2-02-VIGAS SOTANO 2recepcionNo ratings yet

- 19038-001 Implantations Ind02Document1 page19038-001 Implantations Ind02Virane DantonNo ratings yet

- Planos Area 2 4131Document43 pagesPlanos Area 2 4131Cristian SoublettNo ratings yet

- Dau Site Dev Plan-ModelDocument1 pageDau Site Dev Plan-ModelJhn Cbllr BqngNo ratings yet

- TBD-caarreterta 001-Lbjer44t-Layout2Document1 pageTBD-caarreterta 001-Lbjer44t-Layout2Levi Paulo HenriquezNo ratings yet

- Pfinal IcaDocument1 pagePfinal IcaAndresSantidasNo ratings yet

- Rack para Bike: Tamanho Da Peça Na Posição RealDocument1 pageRack para Bike: Tamanho Da Peça Na Posição RealEverson R AcetiNo ratings yet

- Projeto Rack Pire Bike Versao PloterDocument1 pageProjeto Rack Pire Bike Versao PloterReginaldo SilvaNo ratings yet

- Don't Lose, Aru!Document5 pagesDon't Lose, Aru!miller humire luceroNo ratings yet

- Podloga Radoje Dakić 2Document1 pagePodloga Radoje Dakić 2Mandic SutomoreNo ratings yet

- Hit The Road Jack Ray Charles Piano CoverDocument2 pagesHit The Road Jack Ray Charles Piano CoverLévy BenjaminNo ratings yet

- p01 - c3d San Jose - 2018-Layout1Document1 pagep01 - c3d San Jose - 2018-Layout1Gilmer AHNo ratings yet

- soleares_compas_variations-tabDocument4 pagessoleares_compas_variations-tabharryjones999No ratings yet

- Saneamiento Físico Legal - : Julio Del 2021Document1 pageSaneamiento Físico Legal - : Julio Del 2021NH LestherNo ratings yet

- 飛鳥與蟬Document4 pages飛鳥與蟬蔡秉宏No ratings yet

- Plano Planta de Jardinerias ESC 1/750: Jr. Progreso 96Document1 pagePlano Planta de Jardinerias ESC 1/750: Jr. Progreso 96Johann MendozaNo ratings yet

- Apc Back-Ups Rs-800 Br800i Chassis 640-0189d SCHDocument5 pagesApc Back-Ups Rs-800 Br800i Chassis 640-0189d SCHRadu Paul100% (1)

- Apc 1500 VaDocument7 pagesApc 1500 VacontatofontesbhNo ratings yet

- 07.cau Lac Bo Doanh Nhan Dat Viet Tai Thanh Pho HCM (426 Thanh Vien)Document34 pages07.cau Lac Bo Doanh Nhan Dat Viet Tai Thanh Pho HCM (426 Thanh Vien)TN GINNo ratings yet

- WHOLEDocument1 pageWHOLEPia LagmanNo ratings yet

- Homeostasis: A State of Balance in The BodyDocument9 pagesHomeostasis: A State of Balance in The BodyhanidanorazlanNo ratings yet

- Simulation & ModellingDocument9 pagesSimulation & ModellinghanidanorazlanNo ratings yet

- Luna ZoéDocument10 pagesLuna ZoéTeo MondejarNo ratings yet

- 鋼琴ver1Document3 pages鋼琴ver1chiochiiooNo ratings yet

- Primix Carpet SectionDocument1 pagePrimix Carpet SectionvijjaiksinghNo ratings yet

- Kenr5406 03 00 PubDocument2 pagesKenr5406 03 00 PubAhmed MoustafaNo ratings yet

- PGD-1 1Document1 pagePGD-1 1Srijon BrahmacharyNo ratings yet

- Planta General Desvio Fase 2.0 - eDocument1 pagePlanta General Desvio Fase 2.0 - ePatricio Alejandro Álvarez MendozaNo ratings yet

- Ciné Défile PDFDocument1 pageCiné Défile PDFLaure DNo ratings yet

- Spiderman Far From HomeDocument3 pagesSpiderman Far From HomeAlexander LamónNo ratings yet

- Apc Ups 1500 640-0253F - Rev06schDocument4 pagesApc Ups 1500 640-0253F - Rev06schezmel77733% (3)

- La_bella_y_la_bestia__bella_y_bestia_son__Misc_Soundtrack_La_bella_y_la_bestiaDocument3 pagesLa_bella_y_la_bestia__bella_y_bestia_son__Misc_Soundtrack_La_bella_y_la_bestiaccarrerasmNo ratings yet

- Running Up That Hill Kate BushDocument3 pagesRunning Up That Hill Kate Bushjulioair86No ratings yet

- XC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18Document1 pageXC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18percyctba FilhoNo ratings yet

- LOTIZACION Etapa IDocument1 pageLOTIZACION Etapa IAlexis RafaelNo ratings yet

- Msi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aDocument66 pagesMsi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aВладимир МазурNo ratings yet

- 640-0762 (Inversora) - SURT7500,8000,10000Document7 pages640-0762 (Inversora) - SURT7500,8000,10000Helder RizziNo ratings yet

- E0 01 AligeradosDocument1 pageE0 01 AligeradosJose IlberNo ratings yet

- (Women'S Voices) : Sally DefordDocument4 pages(Women'S Voices) : Sally DefordMargot De RidderNo ratings yet

- 02.plan de Amplasare PDFDocument1 page02.plan de Amplasare PDFPopa SergiuNo ratings yet

- RTA System MapDocument2 pagesRTA System MapMorNo ratings yet

- Altamira Implantacion Sotano-ModelDocument1 pageAltamira Implantacion Sotano-ModelAlfonso UribeNo ratings yet

- The Greatest of These Is Love (Piano Only)Document3 pagesThe Greatest of These Is Love (Piano Only)Hesty F. P.No ratings yet

- The Witcher WhoresonDocument4 pagesThe Witcher WhoresonJimerkarante12No ratings yet

- Cancun Centro Enero 2020Document1 pageCancun Centro Enero 2020saulmarquez120812No ratings yet

- The Shadow of Your Smile: AcordeonDocument2 pagesThe Shadow of Your Smile: AcordeonDaniel LazărNo ratings yet

- Shadow PianDocument2 pagesShadow PianDaniel LazărNo ratings yet

- La Vie en Rose LouiguyDocument2 pagesLa Vie en Rose LouiguyEvelin Julie100% (2)

- Xstrata Bechtel Alliance: A. Gonzalez A. GonzalezDocument1 pageXstrata Bechtel Alliance: A. Gonzalez A. GonzalezjhonNo ratings yet

- MaydayDocument4 pagesMaydaythfv7ksqndNo ratings yet

- M Other: For F M (Mono)Document1 pageM Other: For F M (Mono)Aung HeinNo ratings yet

- Arquitectura Rolando Final 2Document1 pageArquitectura Rolando Final 2Jhordan VizalayaNo ratings yet

- Instructions KepeeDocument18 pagesInstructions Kepeedoog unbeuNo ratings yet

- Plano ReplanteoDocument1 pagePlano ReplanteoMejia Andia SixtoNo ratings yet

- Trabajo RagtimeDocument6 pagesTrabajo Ragtimesebastian alvarezNo ratings yet

- 4 Week Beginner Workout Routine For Women: The Tools You Need To Build The Body You WantDocument1 page4 Week Beginner Workout Routine For Women: The Tools You Need To Build The Body You WantBikramMuduliNo ratings yet

- Properties of SteamDocument24 pagesProperties of SteamBikramMuduliNo ratings yet

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDocument96 pagesDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardNarasimhamurthy AdaviNo ratings yet

- Threads and FastenersDocument21 pagesThreads and FastenersSunil DeoNo ratings yet

- PartnershipDocument8 pagesPartnershipBikramMuduliNo ratings yet

- Rewriting Acts IIDocument8 pagesRewriting Acts IIBikramMuduliNo ratings yet

- Intro To Centrifugal Compressor ComponentsDocument7 pagesIntro To Centrifugal Compressor ComponentsMuhammad Ridhwan100% (2)

- Rewriting - Sale of Goods ActDocument10 pagesRewriting - Sale of Goods ActBikramMuduliNo ratings yet

- GE CC Axial CompressorDocument28 pagesGE CC Axial CompressormishraenggNo ratings yet

- The Evolution of Mighty HorseDocument1 pageThe Evolution of Mighty HorseBikramMuduliNo ratings yet

- Tesla Turbine So FarDocument1 pageTesla Turbine So FarBikramMuduliNo ratings yet

- Fiat PalioDocument1 pageFiat PalioBikramMuduliNo ratings yet

- Suikoden 2 - WalkthroughDocument70 pagesSuikoden 2 - WalkthroughAdrian DjohanNo ratings yet

- Input and Output DevicesDocument5 pagesInput and Output DevicesMouseManXNo ratings yet

- Mobile Legends addiction effects on senior high studentsDocument3 pagesMobile Legends addiction effects on senior high studentsREY MICHEAL JOSEPH LAGURANo ratings yet

- CardFortuneTelling Forgotten BookDocument161 pagesCardFortuneTelling Forgotten Booklia100% (5)

- Maid RPG 120% Steward Character CreationDocument3 pagesMaid RPG 120% Steward Character CreationBattleBrosephNo ratings yet

- Lap 5 Worksheet 8Document10 pagesLap 5 Worksheet 8Mc Kevin Jade MadambaNo ratings yet

- 2005 Finneytown WildDocument51 pages2005 Finneytown WildMichael Schearer100% (2)

- Sega Vs NintendoDocument10 pagesSega Vs Nintendozuly díazNo ratings yet

- I. Multiple Choice. Read and Analyze Each Question and Encircle The Letter of The Correct Physical EducationDocument3 pagesI. Multiple Choice. Read and Analyze Each Question and Encircle The Letter of The Correct Physical EducationMarck Jhon YalungNo ratings yet

- Building Full Court ScrambleDocument35 pagesBuilding Full Court ScramblelexappealNo ratings yet

- EvaluationDocument14 pagesEvaluationEmeline Sarmiento RamosNo ratings yet

- TzeentchDocument4 pagesTzeentchdamienhell100% (1)

- Soft Ball Training PlanDocument9 pagesSoft Ball Training Planegolipardonephi480No ratings yet

- Heroquest Rules - RotatedDocument32 pagesHeroquest Rules - RotatedRegényi MátyásNo ratings yet

- Wyvern RulesDocument8 pagesWyvern RulesszaszhareenNo ratings yet

- Stamp & Coin Mart - October 2015Document142 pagesStamp & Coin Mart - October 2015Narendra Reddy BhumaNo ratings yet

- DDAL00-04 - Winters Flame 1.02Document18 pagesDDAL00-04 - Winters Flame 1.02Dan LabNo ratings yet

- Test 9 - Use of EnglishDocument4 pagesTest 9 - Use of EnglishMadestrusNo ratings yet

- Imran KhanDocument3 pagesImran KhanTariq MuhammadNo ratings yet

- The Football Association Laws For Mini Soccer 7v7Document5 pagesThe Football Association Laws For Mini Soccer 7v7Павле КрстевскиNo ratings yet

- Boeing 777-200ER GE WhiteDocument18 pagesBoeing 777-200ER GE WhitejhoymixxNo ratings yet

- Nature WordsearchDocument3 pagesNature WordsearchDomenickNo ratings yet

- Rittal Technical DetailsDocument2 pagesRittal Technical DetailsDavid Radu100% (1)

- TSR 1044 The Great Khan GameDocument73 pagesTSR 1044 The Great Khan GameIker Antolín MedinaNo ratings yet

- Daggerfall - Reference Card PDFDocument4 pagesDaggerfall - Reference Card PDFМаксим ДьяконенкоNo ratings yet

- Smite Loki Build Guide Stealthed Slayer - SeasDocument1 pageSmite Loki Build Guide Stealthed Slayer - SeasRicardo RoddNo ratings yet

- Activity Sheets For PrintingDocument10 pagesActivity Sheets For PrintingLovely VillasNo ratings yet

- How Life Imitates ChessDocument1 pageHow Life Imitates ChessNamık MehmetbeyliNo ratings yet

- Starblazer Adventures - Character Sheet InteractiveDocument1 pageStarblazer Adventures - Character Sheet InteractiveRobNo ratings yet

- D&D Basic Rules, Version 1.0, Released November 2018Document179 pagesD&D Basic Rules, Version 1.0, Released November 2018eradasdwNo ratings yet