Professional Documents

Culture Documents

3 - Inspection of Utilities

Uploaded by

Sunil PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

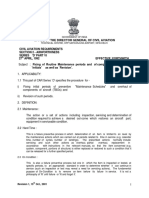

3 - Inspection of Utilities

Uploaded by

Sunil PatilCopyright:

Available Formats

5.

AIDE MEMOIRE

Area of operation/Items

1. HVAC for medicinal Notes Crucial questions Supporting documents

products

1.1 Key design parameters1 Need for separate How do you prevent PIC/S GMP Guide Part I:

systems cross contamination by 3.10, 3.14, 5.10, 5.11,

air? 5.18, 522.

Level of filtration (Filter

specifications) PIC/S GMP Annexes:

Annex 1: 53 -55

Recirculation or make-

up air Annex 2: 7,8, 9, 11, 12,

16, 17

Location of filters

Annex 15: 3.3

Position of inlet and air ISO 14644-4: Clean

return, dust extractors rooms and associated

Temperature controlled environments –

Part 4: Design and

Humidity construction.

Air changes International Organisation

for Standardisation ISO,

Pressure differentials Geneva (April 2001)

EN 1822: High efficiency

Design of ducting

particulate air filters

Easy and effective (HEPA and ULPA):

cleaning Part 1 – Requirements,

testing, marking;

Alarm system Part 2 – Aerosol

Air flow direction- LAF production, measuring

and/or turbulent equipment, particle

counting statistics;

Part 3 – Testing the

planar filter medium;

Part 4 – Testing the filter

element for leaks (scan

method);

Part 5 – Testing the

efficiency of the filter

element.

European Committee for

Standardisation, Brussels

(parts 1-3 were ratified in

March 1998, parts 4-5 in

August 2000).

EN 779: Particle air filters

for general ventilation –

Requirements, testing,

marking.

European Committee for

Standardisation, Brussels

(July 1993).

1.2 Qualification of HVAC DQ, IQ, OQ a PQ How have you PIC/S GMP Guide Part I -

systems1 implemented 4.29, 5.23, 5.24, 5.26,

Average speed and recommendations and 5.42

uniformity of airflow correct deviations

PIC/S GMP Annexes:

Pressure differentials mentioned in

Annex 1:54,

qualification reports?

Air changes Annex 15 :1.1 to 3.14 and

Who is responsible for

evaluating if 4.1 - 4.2

1 Important for the introductory inspection

PI 009-4 Page 3 of 10 1 January 2021

You might also like

- 12 Pi 009 3 Aide Memoire On UtilitiesDocument11 pages12 Pi 009 3 Aide Memoire On UtilitiesAndreea OlaruNo ratings yet

- Pi009-4 Aide-Memoire Inspection of Utilities-2021Document10 pagesPi009-4 Aide-Memoire Inspection of Utilities-2021pipi302No ratings yet

- Federal Register / Vol. 82, No. 10 / Tuesday, January 17, 2017 / Rules and RegulationsDocument54 pagesFederal Register / Vol. 82, No. 10 / Tuesday, January 17, 2017 / Rules and RegulationsRicardo GuerraNo ratings yet

- Pharmaceutical Water System: PI 009-4 Page 7 of 10 1 January 2021Document1 pagePharmaceutical Water System: PI 009-4 Page 7 of 10 1 January 2021Sunil PatilNo ratings yet

- Air Handling Systems: H V A C (HVAC)Document22 pagesAir Handling Systems: H V A C (HVAC)metrologueha1No ratings yet

- Semi-Annual Report Jul-Dec 2009Document6 pagesSemi-Annual Report Jul-Dec 2009Robert Ulatan93% (45)

- A Review of Air Filter TestDocument14 pagesA Review of Air Filter Testhussain mominNo ratings yet

- Sizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled AreasDocument8 pagesSizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled AreasEssam Eldin Metwally AhmedNo ratings yet

- F-Hpje Technical ReportDocument68 pagesF-Hpje Technical ReportrobbertmdNo ratings yet

- Measuring Air Performance Characteristics of Vacuum CleanersDocument17 pagesMeasuring Air Performance Characteristics of Vacuum Cleanersbdr85No ratings yet

- High Efficiency Air Filters (HEPA and Ulpa) Ð: Part 1: Classification, Performance Testing, MarkingDocument16 pagesHigh Efficiency Air Filters (HEPA and Ulpa) Ð: Part 1: Classification, Performance Testing, MarkingDangLuuHaiNo ratings yet

- Jadeela Steel Air Pollution Control InstructionDocument3 pagesJadeela Steel Air Pollution Control Instructionmohamed AbdelazizNo ratings yet

- ProficiecyTestForATCOSDocument44 pagesProficiecyTestForATCOSSalvador CalderonNo ratings yet

- Plastics Piping Systems For Hot and Cold Water Installations Polypropylene (PP) - Part 7: Guidance For The Assessment of ConformityDocument10 pagesPlastics Piping Systems For Hot and Cold Water Installations Polypropylene (PP) - Part 7: Guidance For The Assessment of ConformityMuhammad SyarifNo ratings yet

- FSDM Testing Commissioning Report - Docx 1 - SignedDocument12 pagesFSDM Testing Commissioning Report - Docx 1 - SignedDaniel Joshua AlkuinoNo ratings yet

- Semi Annual Report Jul Dec 2009Document5 pagesSemi Annual Report Jul Dec 2009Mykka ArtillagaNo ratings yet

- AHU Block-V Rev 00 - 2023Document36 pagesAHU Block-V Rev 00 - 2023Chirag S. PatelNo ratings yet

- Flight Operations ManualDocument229 pagesFlight Operations ManualSurya Varma100% (1)

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Guide 15997Document29 pagesGuide 15997djukalNo ratings yet

- AEL ProceduresDocument70 pagesAEL ProceduresGeorge OgbecheNo ratings yet

- 5 - Inspection of UtilitiesDocument1 page5 - Inspection of UtilitiesSunil PatilNo ratings yet

- Monitoring To Provide Evidence of Clean Room Performance Related To Air Cleanliness by Particle Concentration ISO 14622-2Document1 pageMonitoring To Provide Evidence of Clean Room Performance Related To Air Cleanliness by Particle Concentration ISO 14622-2Summiya JaveidNo ratings yet

- ASTMD6830 - 02 - Standard Test MethodDocument8 pagesASTMD6830 - 02 - Standard Test MethodKaffel100% (1)

- Normes InternationalesDocument1 pageNormes InternationalesAKIN ERENNo ratings yet

- Surveillance DocumentsDocument6 pagesSurveillance DocumentsgkkmailzNo ratings yet

- ISO 14664-3 air cleanliness test methodsDocument2 pagesISO 14664-3 air cleanliness test methodsSummiya JaveidNo ratings yet

- Gravimetric Determination of Nonvolatile Residue (NVR) in Environmentally Controlled Areas For SpacecraftDocument14 pagesGravimetric Determination of Nonvolatile Residue (NVR) in Environmentally Controlled Areas For Spacecraftjun floresNo ratings yet

- Handling, Transporting, and Installing Nonvolatile Residue (NVR) Sample Plates Used in Environmentally Controlled Areas For SpacecraftDocument6 pagesHandling, Transporting, and Installing Nonvolatile Residue (NVR) Sample Plates Used in Environmentally Controlled Areas For Spacecraftjun floresNo ratings yet

- Training RequirementsDocument2 pagesTraining Requirementsvin ssNo ratings yet

- HVAC & Plumbing Systems TestingDocument8 pagesHVAC & Plumbing Systems TestingAnonymous NR3qZ30No ratings yet

- Pics Verificaci N de Instalaciones PDFDocument11 pagesPics Verificaci N de Instalaciones PDFMario Vazquez BNo ratings yet

- Air ManualDocument27 pagesAir ManualSuresh Babu V.M.No ratings yet

- USP 797 Compliance Laminar Flow Workstation WhitepaperDocument6 pagesUSP 797 Compliance Laminar Flow Workstation WhitepaperRonald SalasNo ratings yet

- FMEA AirconDocument6 pagesFMEA AirconSUPERB AgentNo ratings yet

- Technical Paper on Airborne Particle CountingDocument5 pagesTechnical Paper on Airborne Particle CountingDenni KurniawanNo ratings yet

- 7711-21B Change 1 PDFDocument20 pages7711-21B Change 1 PDFAkbar BaharuddinNo ratings yet

- AE-4231 Aircraft SystemsDocument4 pagesAE-4231 Aircraft SystemsamaniNo ratings yet

- Testcomm Ac (001 138)Document138 pagesTestcomm Ac (001 138)andro vigersNo ratings yet

- T & C Procedure For HVAC For Goverment Bldg. 2017Document233 pagesT & C Procedure For HVAC For Goverment Bldg. 2017Yongsak YungyuenNo ratings yet

- Test Report From EUROFINS For Model 660x445Document25 pagesTest Report From EUROFINS For Model 660x445BillNo ratings yet

- E 1982 - 98 - Rte5oditotgDocument17 pagesE 1982 - 98 - Rte5oditotgpechugonisNo ratings yet

- Office of The Director General of Civil AviationDocument4 pagesOffice of The Director General of Civil Aviationconfirm@No ratings yet

- ACP WGF28 WP11 - Radio Altimeter InputDocument28 pagesACP WGF28 WP11 - Radio Altimeter InputAchmad Noor FirmanNo ratings yet

- Evaluation of Air Assay Media by The Monodisperse DOP (Dioctyl Phthalate) Smoke TestDocument5 pagesEvaluation of Air Assay Media by The Monodisperse DOP (Dioctyl Phthalate) Smoke TestShaker QaidiNo ratings yet

- Comparison of General Ventilation Air Filter TestDocument9 pagesComparison of General Ventilation Air Filter TestArianaNo ratings yet

- ITU_R_P452Document68 pagesITU_R_P452Madeline CurryNo ratings yet

- AD FlightTestInstrumentationEngineering2Document288 pagesAD FlightTestInstrumentationEngineering2ilter79No ratings yet

- NFPA Inspection Requirements for Fire SystemsDocument28 pagesNFPA Inspection Requirements for Fire SystemssechooNo ratings yet

- FTS Course SyllabusDocument3 pagesFTS Course Syllabusmohammad qaruishNo ratings yet

- Particle Filter Penetration FlyerDocument2 pagesParticle Filter Penetration Flyergr8swapNo ratings yet

- Supplementary Training Modules On GMP: Air Handling Systems H V A C (HVAC)Document20 pagesSupplementary Training Modules On GMP: Air Handling Systems H V A C (HVAC)adityaNo ratings yet

- FAI PravilnikDocument61 pagesFAI PravilnikMarjan IvanovskiNo ratings yet

- Technical Guidance Notes M3 How To Assess Monitoring Arrangements For Emissions To Air in EPR Permit Applications Environment Agency UKDocument18 pagesTechnical Guidance Notes M3 How To Assess Monitoring Arrangements For Emissions To Air in EPR Permit Applications Environment Agency UKheljoalNo ratings yet

- Astm F 2519-05Document20 pagesAstm F 2519-05Maki Salim HussainNo ratings yet

- Astm F3011 - 13Document3 pagesAstm F3011 - 13Sofia YuliNo ratings yet

- Manual On Testing of Radio Navigation AidsDocument188 pagesManual On Testing of Radio Navigation AidshazeypotterNo ratings yet

- ISO Standards for Air Filters and Cleaning DevicesDocument2 pagesISO Standards for Air Filters and Cleaning DevicesvirtechNo ratings yet

- Use of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsFrom EverandUse of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsNo ratings yet

- SonoAce R7 v3.01.00 EDocument544 pagesSonoAce R7 v3.01.00 EEcomedical PlussNo ratings yet

- Halal Policy PDFDocument1 pageHalal Policy PDFSaid SaidiNo ratings yet

- Presentation on Chancroid: Bacterial STI Causes Painful Genital UlcersDocument12 pagesPresentation on Chancroid: Bacterial STI Causes Painful Genital UlcersBikash Sah0% (1)

- 1978 - 90 Day Study or Rhesus Monkey ToxicityDocument4 pages1978 - 90 Day Study or Rhesus Monkey Toxicitygrace poudrierNo ratings yet

- The Dilemma of The Neighborhood BoardDocument2 pagesThe Dilemma of The Neighborhood BoardRosaNo ratings yet

- Comparing Food with Comparative AdjectivesDocument4 pagesComparing Food with Comparative AdjectivesLuisito GonzalezNo ratings yet

- Acp 22 9349 2022Document20 pagesAcp 22 9349 2022merlinakisNo ratings yet

- Salary Exchange... A Tax Efficient Way To Boost Your Plans For The FutureDocument4 pagesSalary Exchange... A Tax Efficient Way To Boost Your Plans For The FutureStandard Life UKNo ratings yet

- Yoga & Diet To Prevent DepressionDocument5 pagesYoga & Diet To Prevent DepressionDietician Mrunmayee DixitNo ratings yet

- Pursuing a Career in CosmetologyDocument3 pagesPursuing a Career in CosmetologyMaria CeciliaNo ratings yet

- Cerberus PRO Product Catalog: Fire Safety Products and AccessoriesDocument253 pagesCerberus PRO Product Catalog: Fire Safety Products and AccessoriesleonardoleitealertaNo ratings yet

- Order - Judgement Query Coram WiseDocument13 pagesOrder - Judgement Query Coram Wisesatish_CJNo ratings yet

- MKT421 New Product Development PDFDocument26 pagesMKT421 New Product Development PDFNass AzwadiNo ratings yet

- Pathology AIIMSDocument26 pagesPathology AIIMSvkNo ratings yet

- Biomechinics PDFDocument8 pagesBiomechinics PDFImran KhanNo ratings yet

- Presley v. Lockwood: Respondent's Trial BriefDocument37 pagesPresley v. Lockwood: Respondent's Trial BriefTony Ortega100% (2)

- M&SDocument39 pagesM&Sgo.pushp70910% (1)

- SWRO-200C Operation Manual AppendicesDocument38 pagesSWRO-200C Operation Manual AppendicestonbaldinNo ratings yet

- Cambridge BiologyDocument78 pagesCambridge BiologyBraweet SapkotaNo ratings yet

- Celecoxib Identification MethodsDocument5 pagesCelecoxib Identification Methodsabc1679No ratings yet

- 2 - FNCPDocument5 pages2 - FNCPIlda Lekka RequizaNo ratings yet

- Providing Shelter and Safety: A Proposed Evacuation and Rehabilitation Center for Masbate CityDocument62 pagesProviding Shelter and Safety: A Proposed Evacuation and Rehabilitation Center for Masbate CityBenjamae MaqueNo ratings yet

- Plumbing-Water-System-Review (3B) PDFDocument22 pagesPlumbing-Water-System-Review (3B) PDFJhyneJazarenoAtutuboNo ratings yet

- Roof Construction Dr. Fixit Newcoat PDFDocument1 pageRoof Construction Dr. Fixit Newcoat PDFRishabh VijayNo ratings yet

- Past PapaersDocument515 pagesPast PapaersShariq ShaNo ratings yet

- SanCoP7 AgendaDocument2 pagesSanCoP7 AgendaNicolaGreeneNo ratings yet

- Separation Processes Lecture 1 IntroductionDocument14 pagesSeparation Processes Lecture 1 Introductionabood assrfndyNo ratings yet

- Sakshijain75.Final ProDocument46 pagesSakshijain75.Final ProOm AherNo ratings yet

- STC Bec Wir Plu D 0209 01 PDFDocument10 pagesSTC Bec Wir Plu D 0209 01 PDFAdel MorsyNo ratings yet

- Mcimt NDT Kids at 1Document12 pagesMcimt NDT Kids at 1api-485106673No ratings yet